Preparation method of high bonding strength polytetrafluoroethylene hollow fiber membrane

A polytetrafluoroethylene and fiber membrane technology, which is applied in the field of preparation of high bonding strength polytetrafluoroethylene hollow fiber membrane, can solve the problem that the pore diameter of the polytetrafluoroethylene hollow fiber membrane is unstable, easy to fall off, and the bonding strength is not enough. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

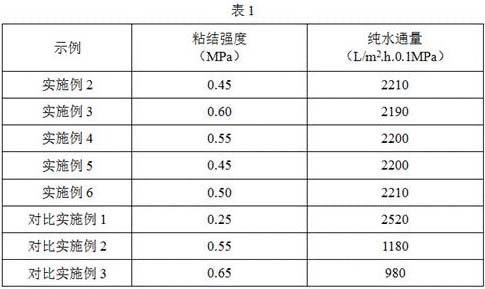

Examples

Embodiment 1

[0021] Example 1: A method for preparing a high bond strength polytetrafluoroethylene hollow fiber membrane, comprising the following steps: (1) cutting, selecting a fully sintered biaxially stretched polytetrafluoroethylene flat membrane with an average pore size range of 0.05 μm-0.5μm, the thickness is 5μm-50 μm, the endothermic peak of PTFE material obtained by differential scanning calorimetry is at 325°C-335°C, and the flat film of biaxially stretched PTFE is completely sintered Slit into polytetrafluoroethylene tape film with a width of 5mm-15mm;

[0022] (2) Impregnation, immersing the polytetrafluoroethylene tape film in the low molecular weight polytetrafluoroethylene organic dispersion; the mass fraction of low molecular weight polytetrafluoroethylene in the low molecular weight polytetrafluoroethylene organic dispersion is 10-60% The number average molecular weight of low molecular weight polytetrafluoroethylene in low molecular weight polytetrafluoroethylene organi...

Embodiment 2

[0024] Embodiment 2: A kind of preparation method of high bonding strength polytetrafluoroethylene hollow fiber membrane, comprises the following steps: (1) cutting, selects biaxially stretched polytetrafluoroethylene fully sintered flat membrane, and its average pore diameter is 0.05 μm, the thickness is 50 μm, and the endothermic peak of the polytetrafluoroethylene material obtained by differential scanning calorimetry is at 325°C. Tetrafluoroethylene tape film;

[0025] (2) Dipping, immersing the polytetrafluoroethylene tape film in the low molecular weight polytetrafluoroethylene organic dispersion; the mass fraction of low molecular weight polytetrafluoroethylene in the low molecular weight polytetrafluoroethylene organic dispersion is 10%; low The number average molecular weight of the low molecular weight polytetrafluoroethylene in the molecular weight polytetrafluoroethylene organic dispersion is 1 million; the average particle size of the low molecular weight polytetr...

Embodiment 3

[0027] Embodiment 3: A kind of preparation method of high bonding strength polytetrafluoroethylene hollow fiber membrane, comprises the following steps: (1) cutting, selects biaxially stretched polytetrafluoroethylene fully sintered flat membrane, and its average pore diameter is 0.5 μm, the thickness is 5μm, and the endothermic peak of the polytetrafluoroethylene material obtained by differential scanning calorimetry is at 335°C. Vinyl fluoride strip film;

[0028] (2) Dipping, dipping the polytetrafluoroethylene tape film in the low molecular weight polytetrafluoroethylene organic dispersion; the mass fraction of low molecular weight polytetrafluoroethylene in the low molecular weight polytetrafluoroethylene organic dispersion is 60%; low The number average molecular weight of the low molecular weight polytetrafluoroethylene in the molecular weight polytetrafluoroethylene organic dispersion is 4 million; the average particle size of the low molecular weight polytetrafluoroet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com