Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

198results about How to "Increase formation rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of stabilizing imiquimod

InactiveUS7902242B2Short lifeImpaired stabilityBiocideOrganic chemistryPharmaceutical formulationOleic Acid Triglyceride

Pharmaceutical formulations and methods including an immune response modifier (IRM) compound and an oleic acid component are provided where stability is improved by using oleic acid have low polar impurities such as peroxides.

Owner:MEDICIS PHARMA CORP

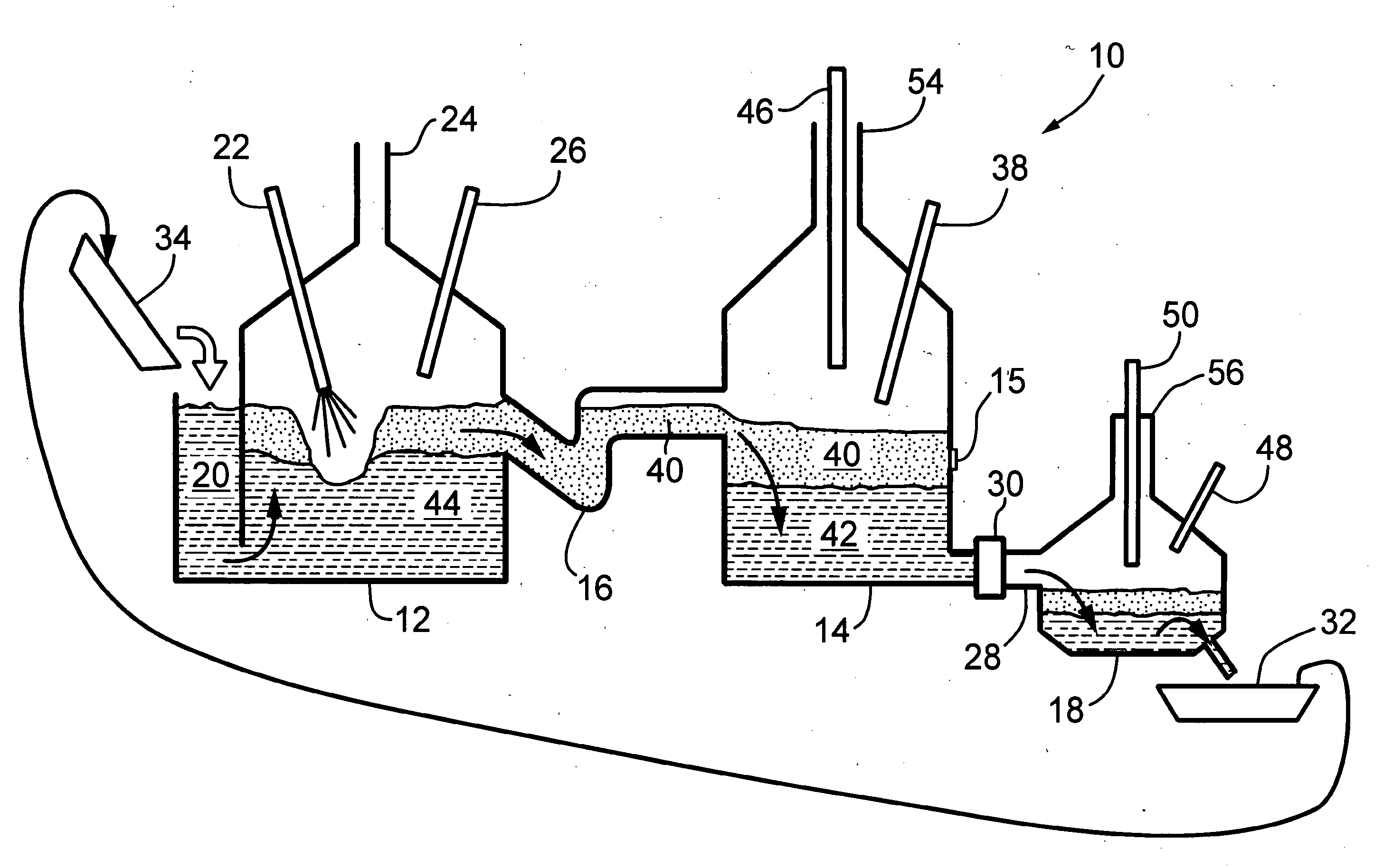

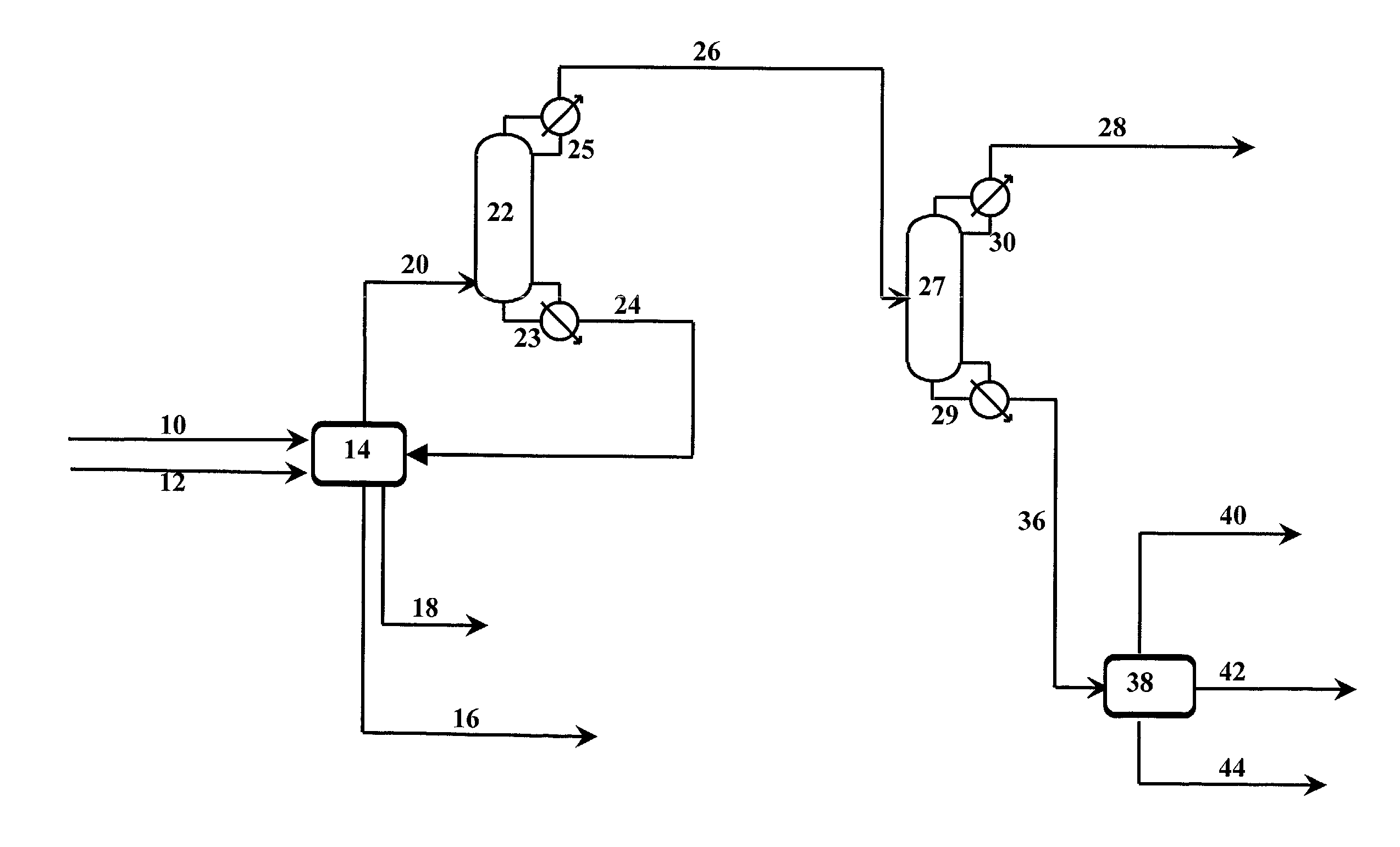

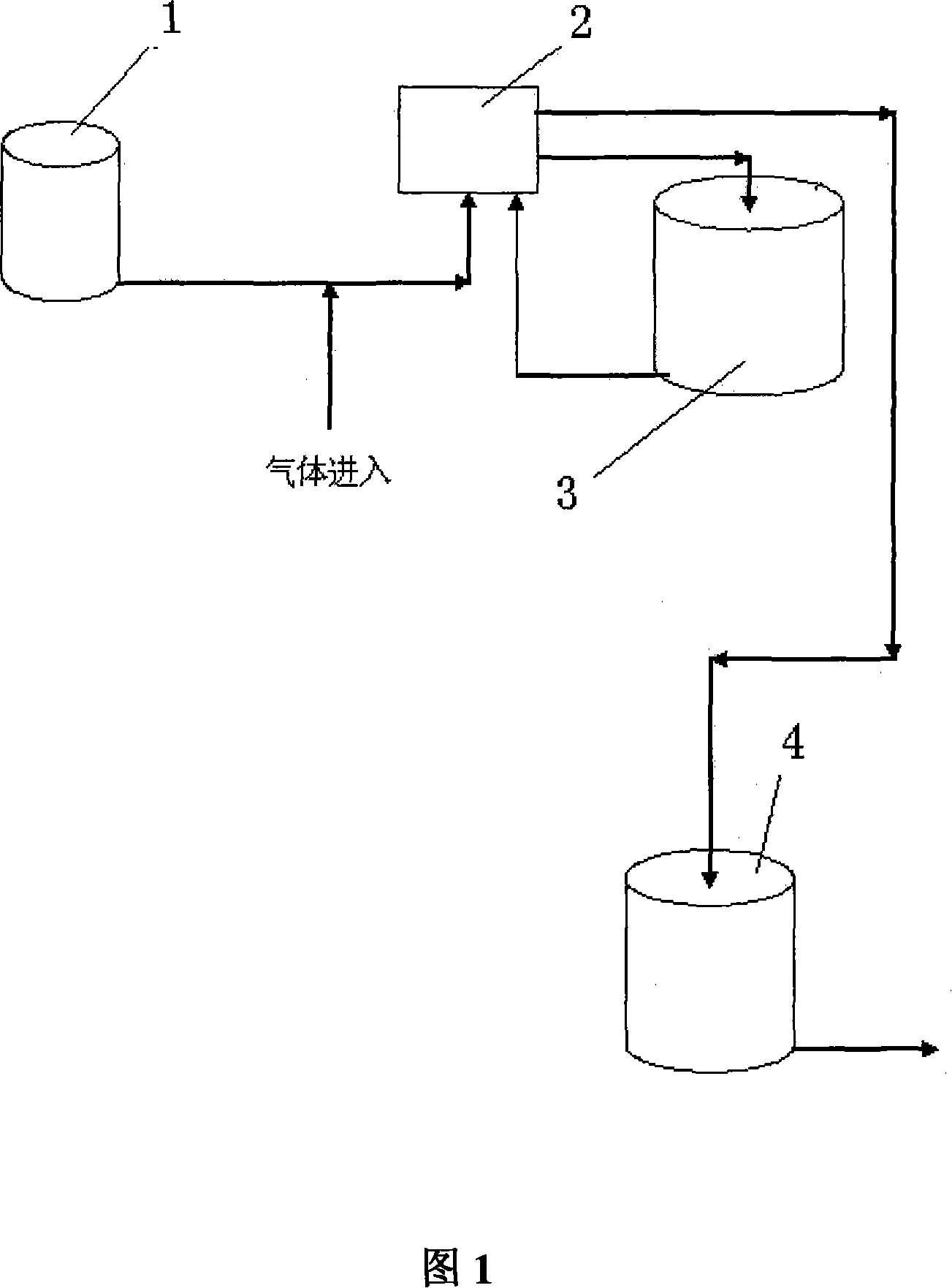

Reactor and process for the continuous production of hydrogen based on steam oxidation of molten iron

InactiveUS7914765B2Reduce contentImprove usabilityHydrogen productionCarbon monoxideCoalOxidation reduction

The present invention provides a reactor and gasification process for the continuous controlled production of hydrogen (H2) and a by-product synthesis gas (mixture of CO+H2+CO2), such a process called a hydrogen priority poly-generation process (HPPP). The reactor uses a circulating molten iron process, which is capable of gasifying a variety of carbonaceous materials including low rank coals and biomass. The process employs an iron steam oxidation-reduction cycle in a multi-chamber reactor including a multi-vessel reactor system, where in one compartment or vessel hydrogen is produced by steam oxidation of molten iron; and in a second compartment or vessel the iron is regenerated by carbon reduction of molten iron oxide thereby producing a by-product synthesis gas (CO+H2+CO2), and excess heat which can be used to produce steam, and in a third step the iron is purified before being returned to the steam oxidation step in the process. An embodiment of this process uses low rank coals having high ash levels in a reactor, which is designed to continuously extract ash from the molten iron bath. A second embodiment uses low ash carbon materials such as highly beneficiated coals in a simpler process that produces pure streams of hydrogen and CO.

Owner:AVAILABLE ENERGY CORP

Downhole percussion tool

ActiveUS20070102196A1Increase ratingsSmooth rotationDrill bitsBorehole drivesTransverse pressureEngineering

A pressure fluid actuated downhole percussion tool includes a reciprocating piston hammer with differential transverse pressure surfaces cooperable with a cylinder housing, a guide sleeve and a bit carried exhaust tube to form opposed pressure fluid chambers to which pressure fluid may be conducted to deliver repeated impact blows to a bit having circumferentially spaced bosses and replaceable cutting inserts. The bit is drivenly connected to the tool by plural drive pins supported in circumferentially spaced grooves in the bit shank and in a removable sub supported by the tool housing. Improved earth penetration performance is realized utilizing a claw bit with a pressure fluid actuated percussion tool providing rotation as well as selective deliverance of impact blows through the bit.

Owner:VAREL MINING & IND LLC

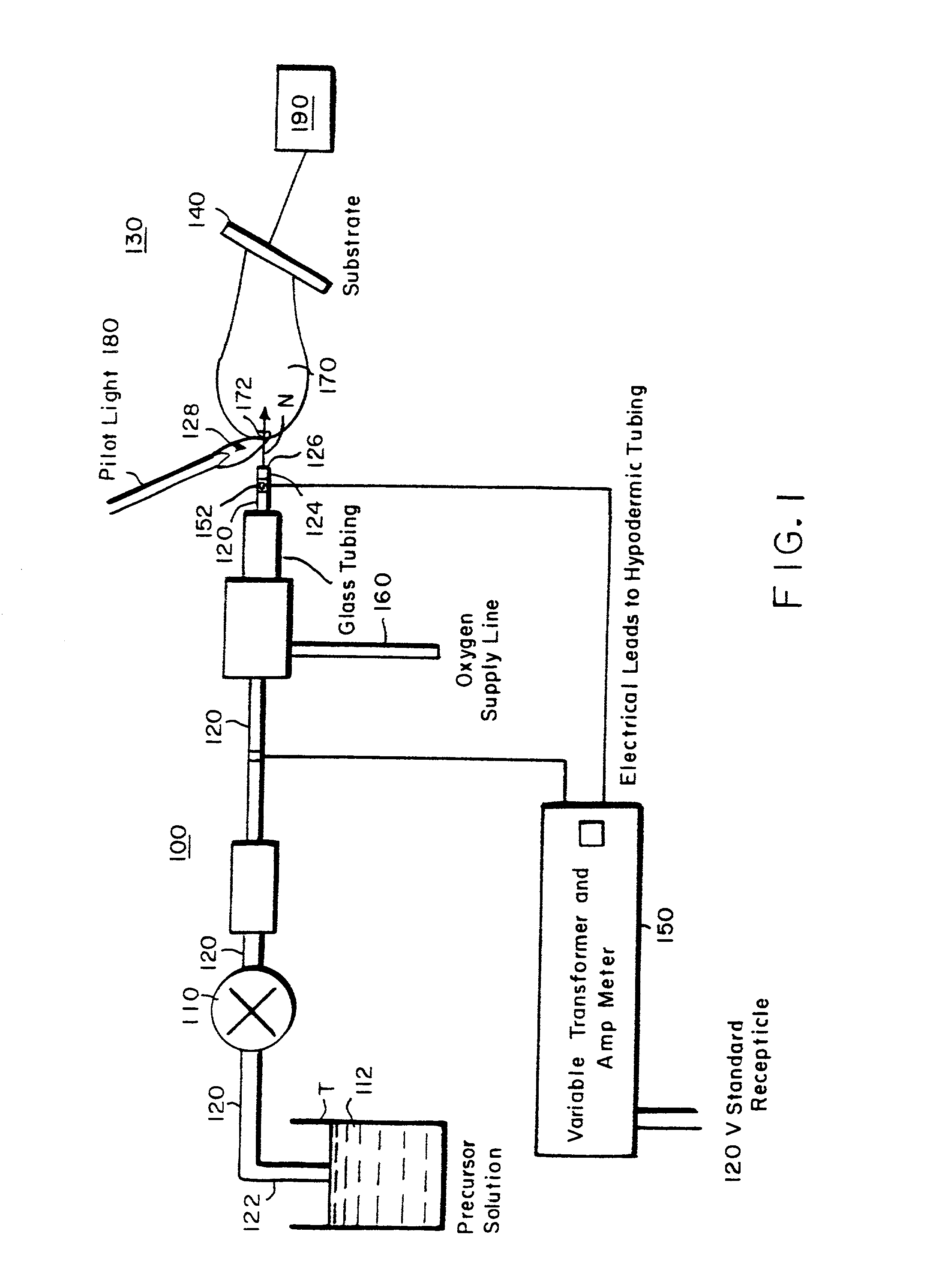

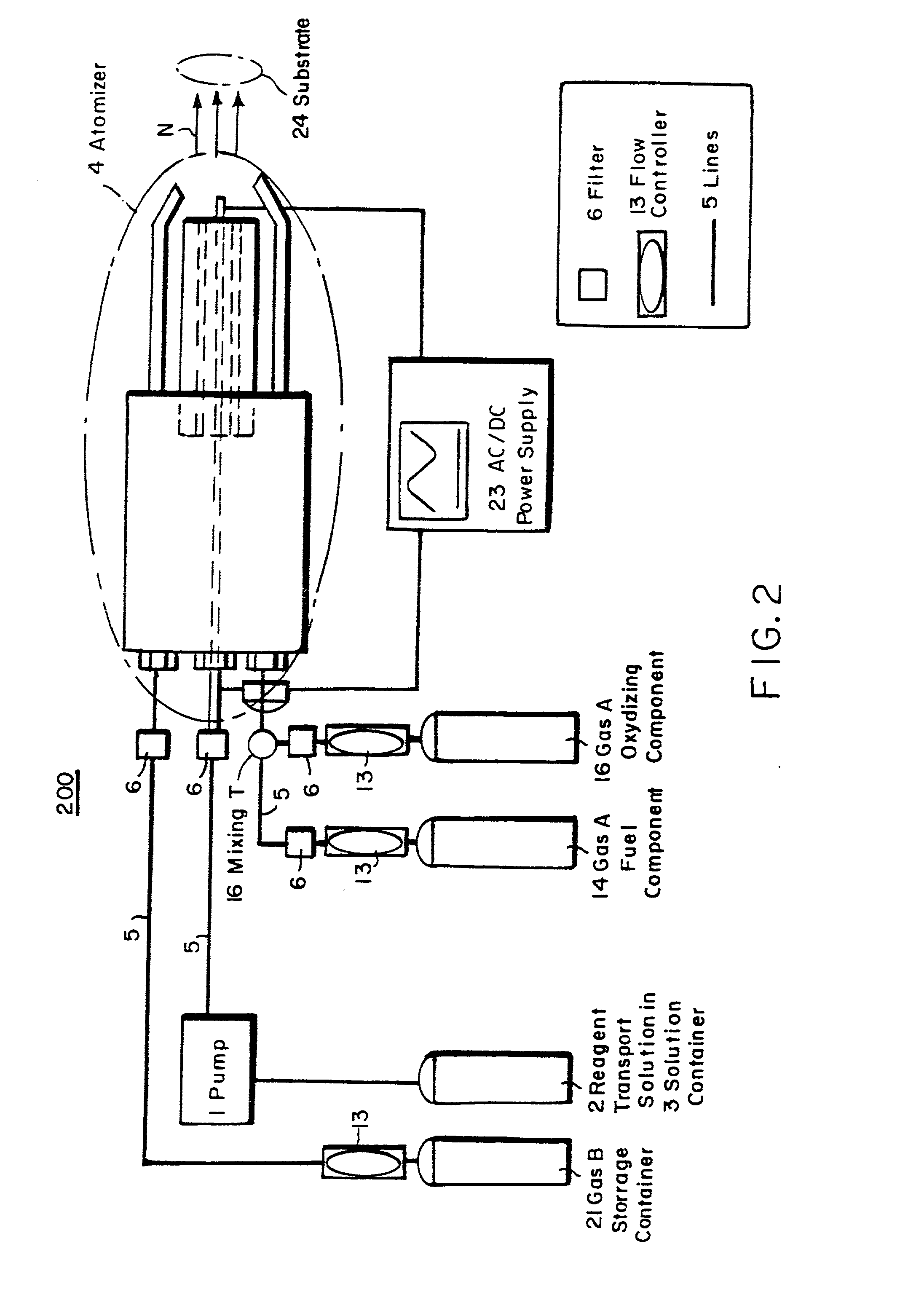

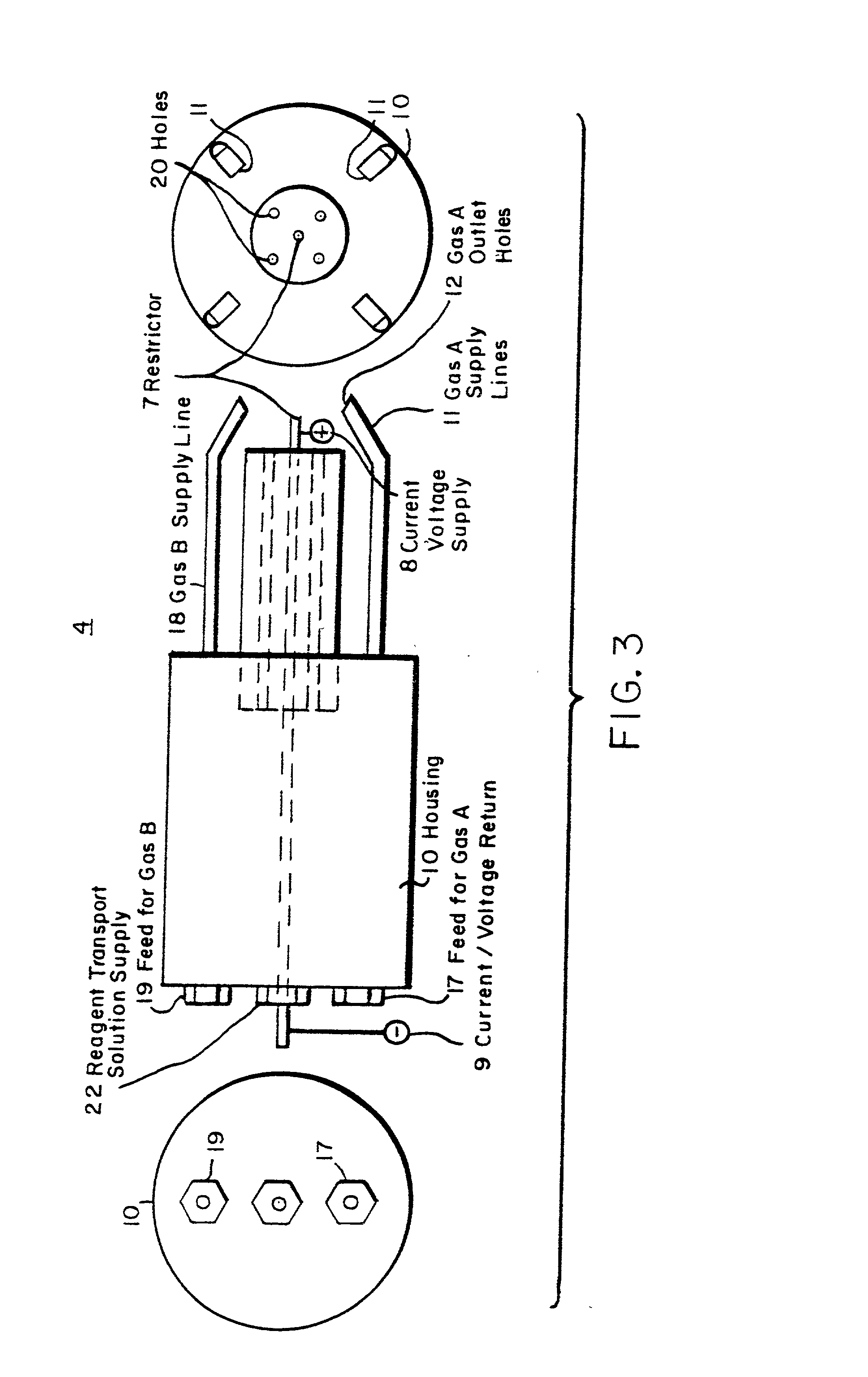

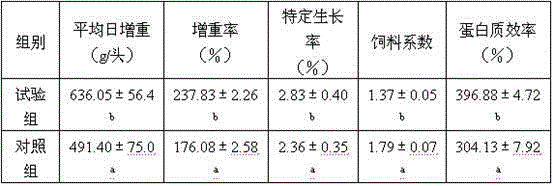

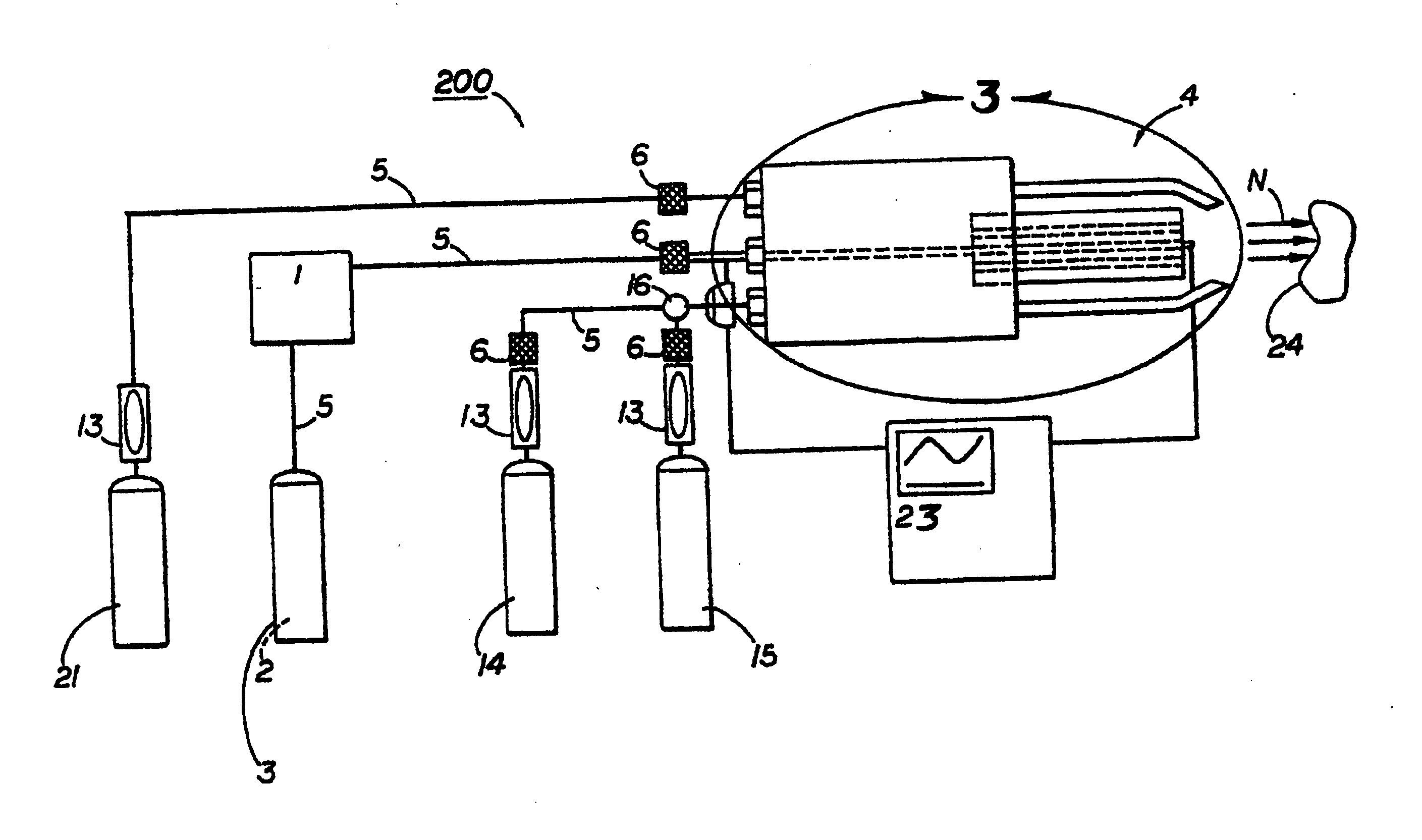

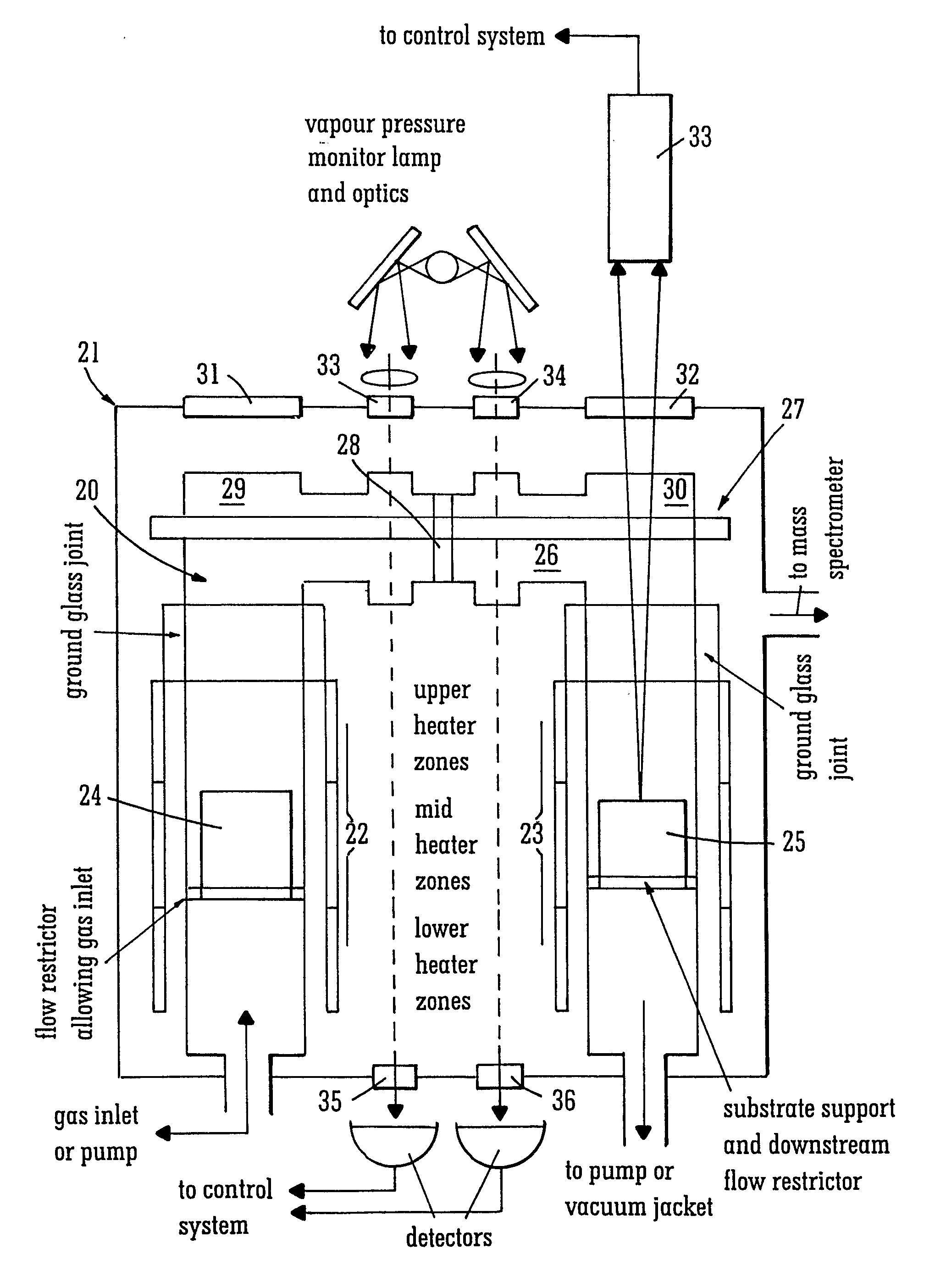

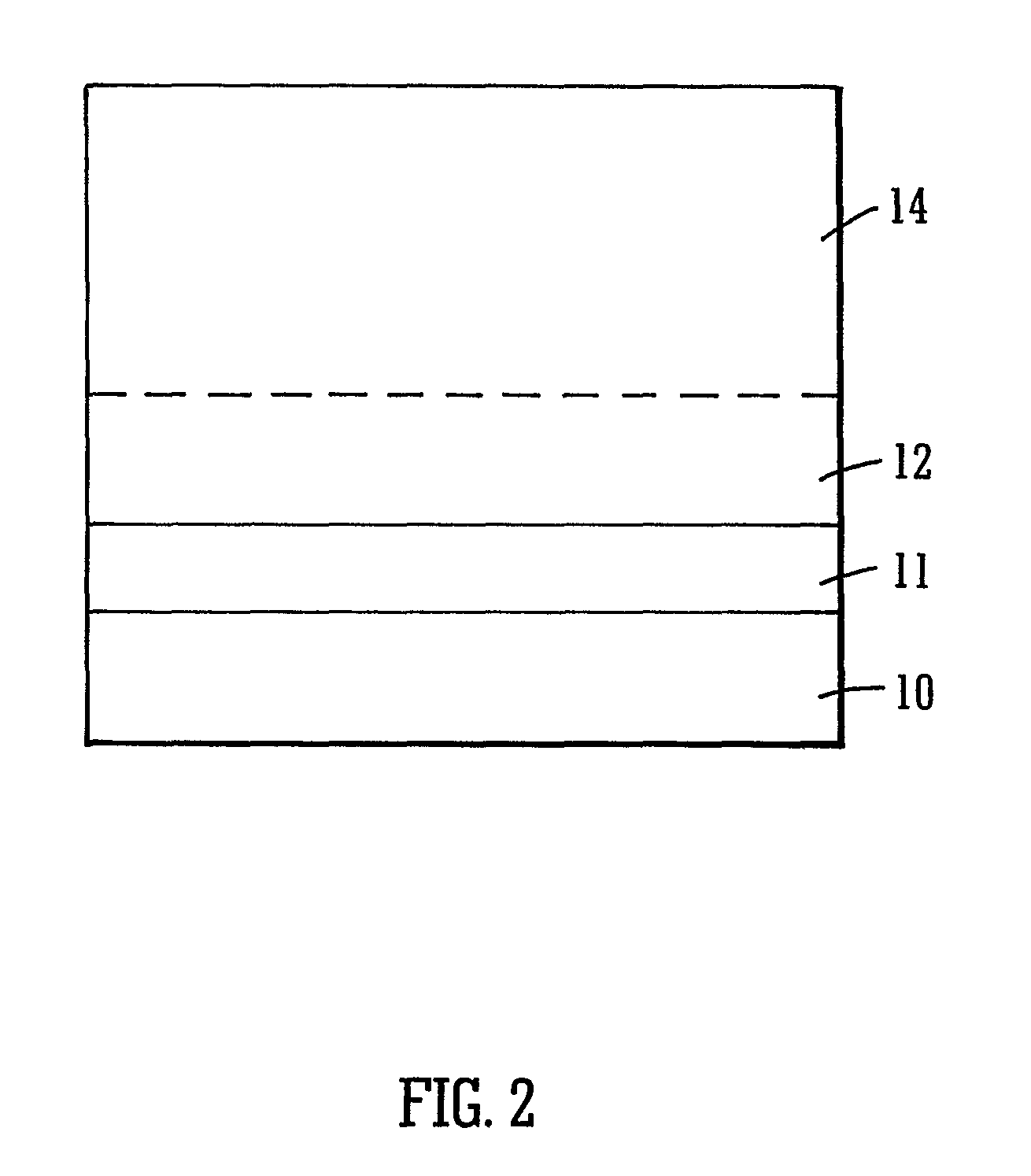

Chemical vapor deposition and powder formation using thermal spray

InactiveUS20010039919A1Promote formationMinimize occurrenceOxygen/ozone/oxide/hydroxideLiquid surface applicatorsThermal sprayingGas phase

A method for chemical vapor deposition using a very fine atomization or vaporization of a reagent containing liquid or liquid-like fluid near its supercritical temperature, where the resulting atomized or vaporized solution is entered into a flame or a plasma torch, and a powder is formed or a coating is deposited onto a substrate. The combustion flame can be stable from 10 torr to multiple atmospheres, and provides the energetic environment in which the reagent contained within the fluid can be reacted to form the desired powder or coating material on a substrate. The plasma torch likewise produces the required energy environment, but, unlike the flame, no oxidizer is needed so materials stable in only very low oxygen partial pressures can be formed. Using either the plasma torch or the combustion plasma, coatings can be deposited and powders formed in the open atmosphere without the necessity of a reaction chamber, but a chamber may be used for various reasons including process separation from the environment and pressure regulation.

Owner:HUNT ANDREW T +1

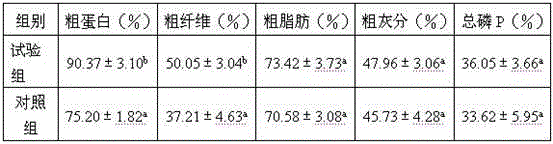

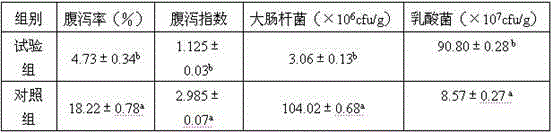

Composite bacillus preparation containing three strains, preparation method of composite bacillus preparation and application of composite bacillus preparation to ecological breeding

InactiveCN104480052APromote Microecological BalancePromote digestion and absorptionBacteriaAnimal feeding stuffEcological environmentBacillus megaterium

The invention provides a composite bacillus preparation containing three strains, a preparation method of the composite bacillus preparation and application of the composite bacillus preparation to ecological breeding, and belongs to the technical field of microorganism and feed additives. Bacillus coagulans, butyric acid clostridia and bacillus megaterium are used as fermentative strains respectively, and large-scale, low-cost and high-density fermentation production of spores is conducted through step-by-step magnification; three live bacterium preparations are prepared by mixing bacterial sludge with the spores and dry starch; the three live bacterium preparations are matched according to the equal weight ratio, the composite bacillus preparation is obtained, and the concentration of the spores reaches more than 1*108-109 cfu / g; the composite bacillus preparation serves as a microorganism and feed additive to be added to farmed animal feed according to the mass ratio ranging from 0.02% to 0.5%. The composite bacillus preparation is simple and stable in process, low in cost, high in spore content and environment tolerance, easy to store and high in survival rate; the purposes of composition and synergism are achieved through the collaborative supplementary effects of different bacilli in the aspect of micro-ecology adjustment, growth of farmed animals is promoted, the feed utilization rate and feed rewards are increased, diarrhea is prevented and reduced, and the breeding ecological environment is improved.

Owner:江苏省苏微微生物研究有限公司 +3

Chemical vapor deposition and powder formation using thermal spray

InactiveUS20050019551A1Promote formationMinimize occurrenceMolten spray coatingLayered productsThermal sprayingGas phase

A method for chemical vapor deposition using a very fine atomization or vaporization of a reagent containing liquid or liquid-like fluid near its supercritical temperature, where the resulting atomized or vaporized solution is entered into a flame or a plasma torch, and a powder is formed or a coating is deposited onto a substrate. The combustion flame can be stable from 10 torr to multiple atmospheres, and provides the energetic environment in which the reagent contained within the fluid can be reacted to form the desired powder or coating material on a substrate. The plasma torch likewise produces the required energy environment, but, unlike the flame, no oxidizer is needed so materials stable in only very low oxygen partial pressures can be formed. Using either the plasma torch or the combustion plasma, coatings can be deposited and powders formed in the open atmosphere without the necessity of a reaction chamber, but a chamber may be used for various reasons including process separation from the environment and pressure regulation.

Owner:HUNT ANDREW T +1

Downhole percussion tool

ActiveUS7377338B2Smooth rotationIncrease formation rateDrill bitsBorehole drivesTransverse pressureEngineering

A pressure fluid actuated downhole percussion tool includes a reciprocating piston hammer with differential transverse pressure surfaces cooperable with a cylinder housing, a guide sleeve and a bit carried exhaust tube to form opposed pressure fluid chambers to which pressure fluid may be conducted to deliver repeated impact blows to a bit having circumferentially spaced bosses and replaceable cutting inserts. The bit is drivenly connected to the tool by plural drive pins supported in circumferentially spaced grooves in the bit shank and in a removable sub supported by the tool housing. Improved earth penetration performance is realized utilizing a claw bit with a pressure fluid actuated percussion tool providing rotation as well as selective deliverance of impact blows through the bit.

Owner:VAREL MINING & IND LLC

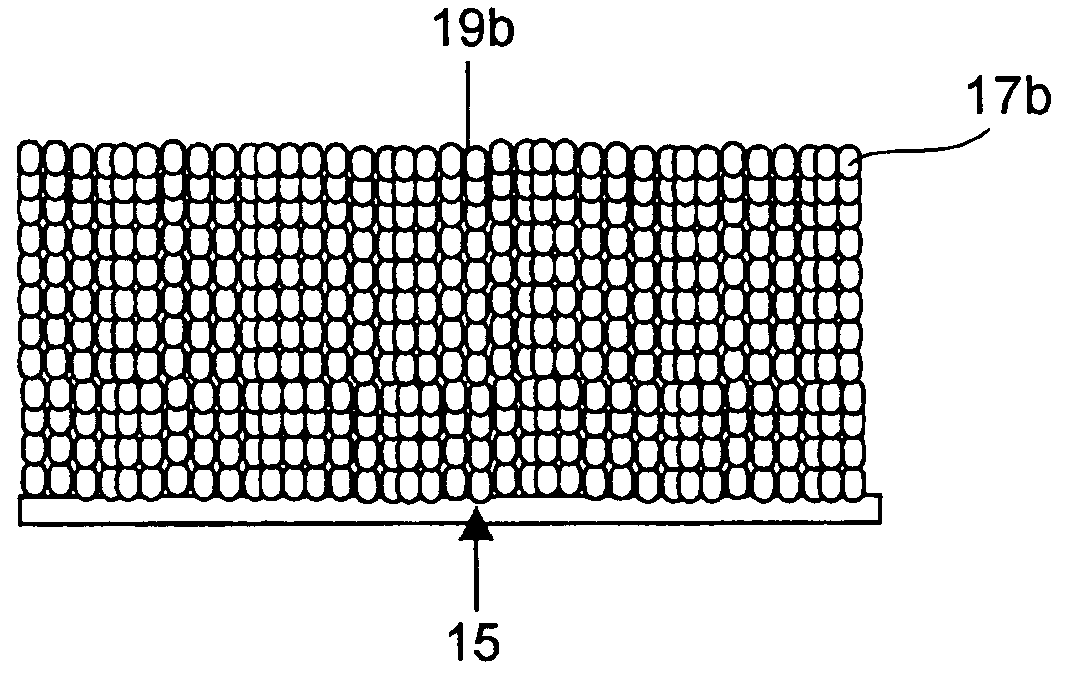

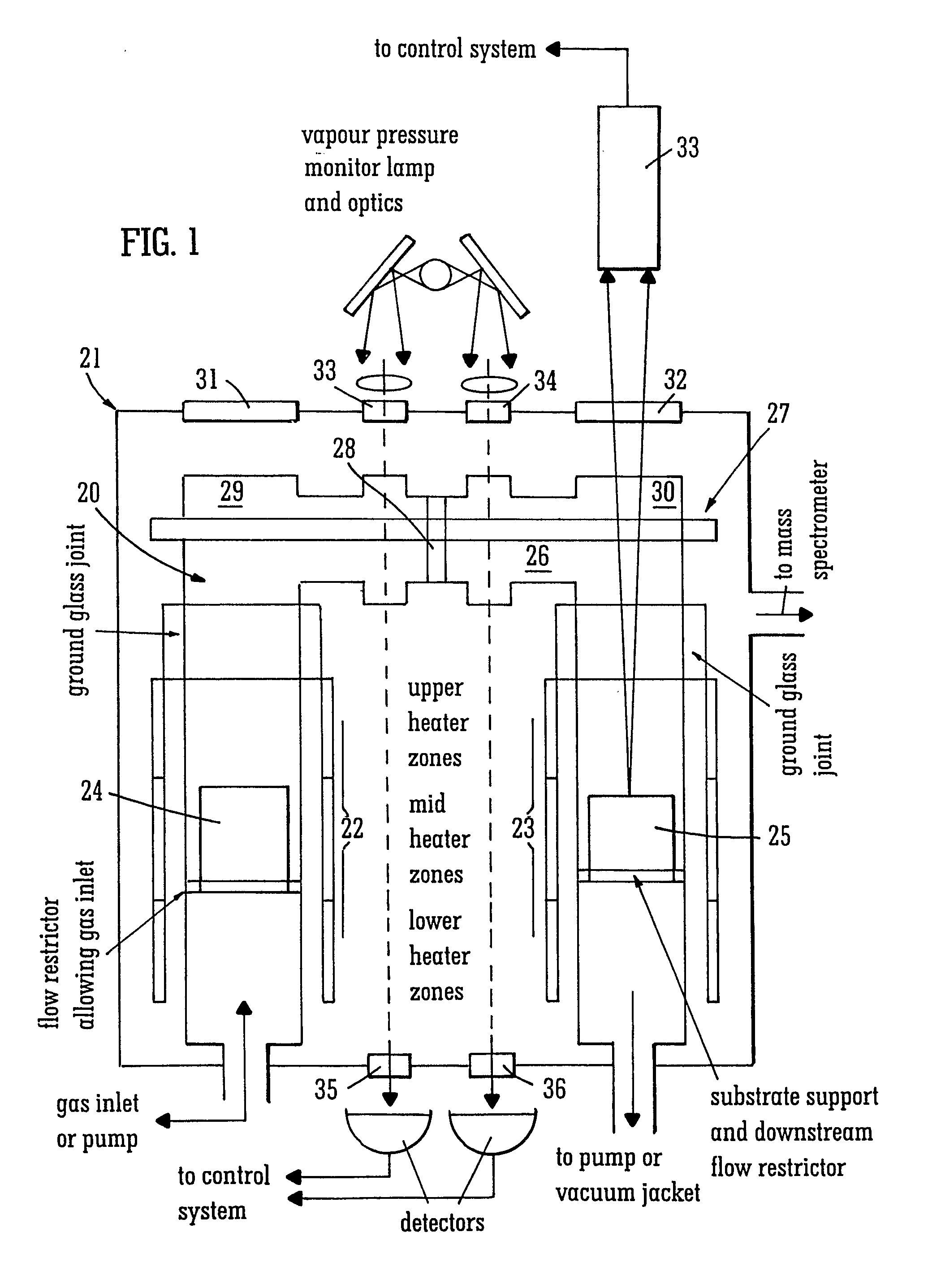

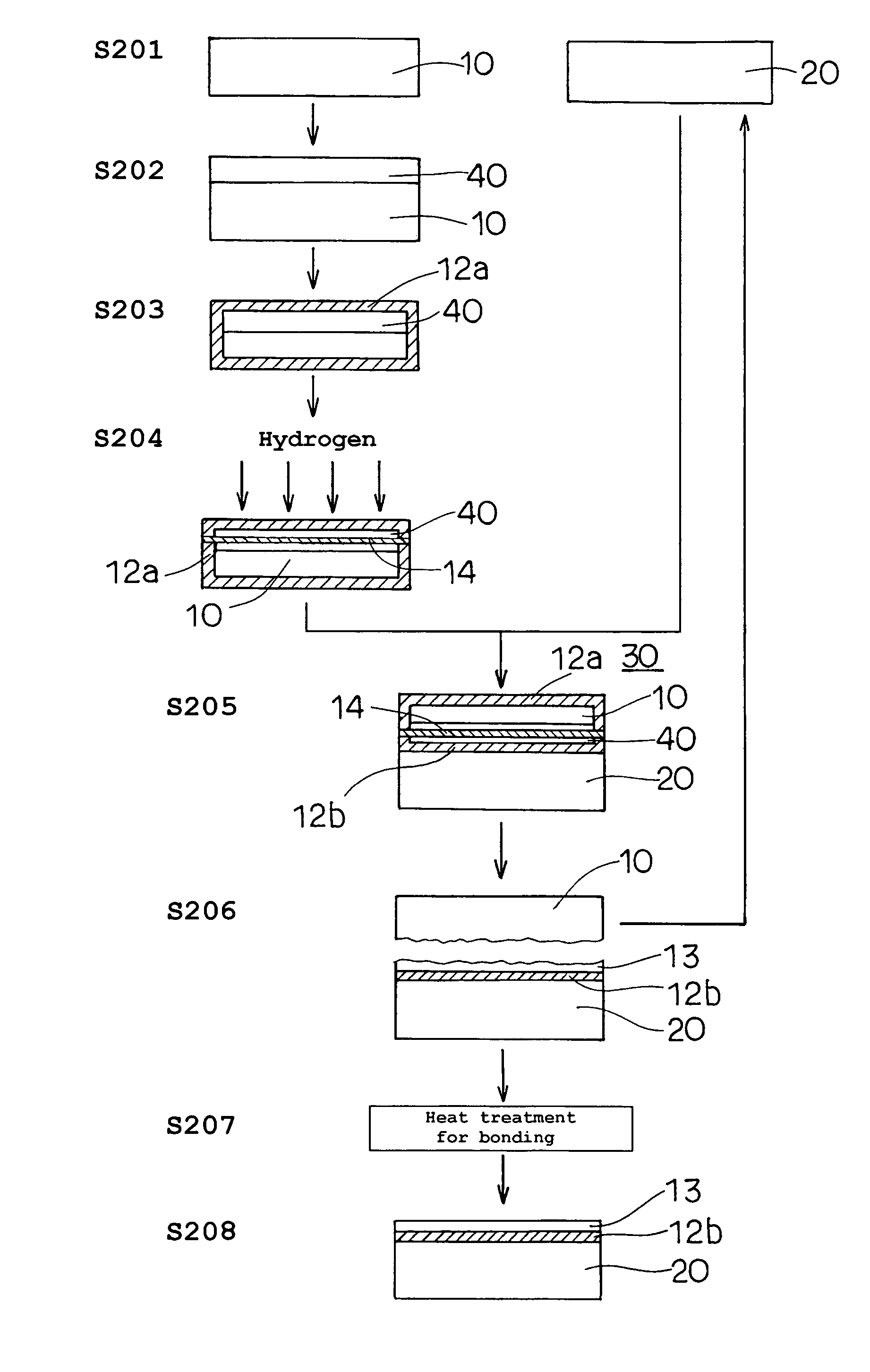

Method for producing bonded wafer

InactiveUS20060281280A1High throughputHigh yieldSemiconductor/solid-state device manufacturingHigh rateOptoelectronics

A bonded SOI substrate having an active layer which is free from crystal defects is obtained by adding more than 9×1018 atoms / cm3 of boron to a wafer for active layer (10). Since the boron concentration in the wafer for active layer is high, a silicon oxide film is formed at a high rate. Consequently, there can be obtained a Smart-Cut wafer with high throughput. Furthermore, damages to the active layer due to the ion implantation can be reduced, thereby improving the quality of the active layer.

Owner:SUMCO CORP

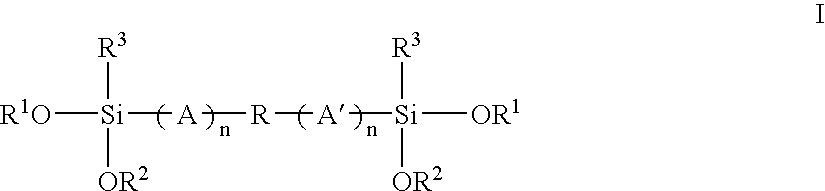

Mixed alkoxysilyl functional polymers

This invention relates to silylated polymers having mixed alkoxy groups on the silyl portion thereof, methods of their preparation, and compositions and reaction products formed therefrom. These alkoxysilylated polymers can be crosslinked when exposed to atmospheric moisture to become useful elastomers, sealants or adhesives. The presence of different alkoxy groups on the silicon atoms can control or otherwise moderate the cure speeds of these silylated polymers.

Owner:HENKEL KGAA

Method for rejuvenating cordyceps militaris strains

The invention relates to rejuvenation of degenerated edible bacterial strains, in particular to a method for rejuvenating cordyceps militaris strains, which mainly comprises steps of cordyceps militaris strain activated culture, cordyceps militaris strain rejuvenation, and cordyceps militaris strain conservation. The method is characterized in that: the rejuvenation culture is that: the activatedcordyceps militaris strain is inoculated to a potato dextrose agar (PDA) plate which is compounded with one or more kinds of antibiotics for first rejuvenation culture, and the strain which is subject to first rejuvenation culture is inoculated to a PDA plating culture medium which is compounded with one or more kinds of antibiotics for second rejuvenation culture. The invention breaks through the traditional strain rejuvenation method, and rejuvenates the strain by an antibiotic method which is easy to operate, simple and practical, and has remarkable effect. The strain which is rejuvenated by the method has robust and compact hypha, and the growing speed of the strain is improved by about 8 times compared with that of the strain which is not rejuvenated.

Owner:FUJIAN NORMAL UNIV

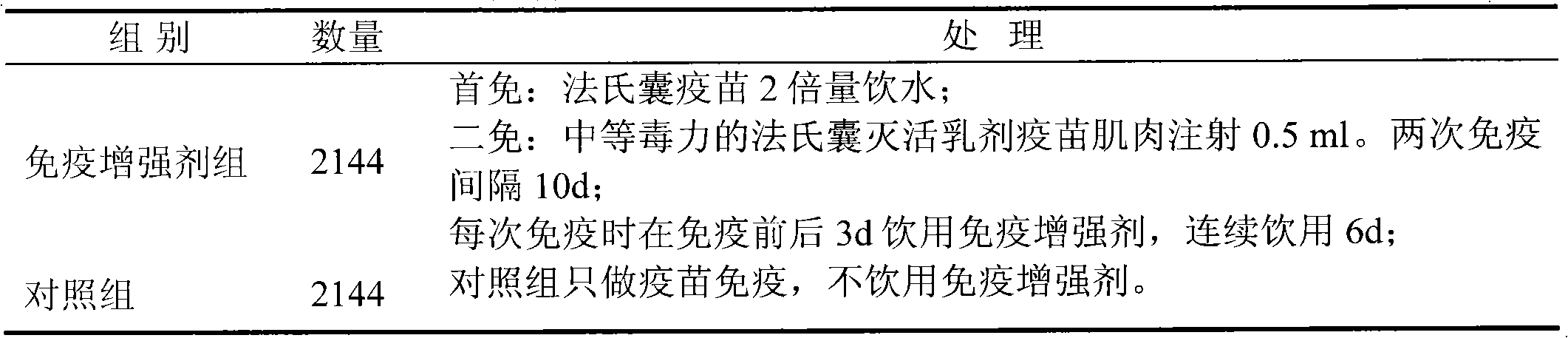

Chinese herbal immunopotentiator for chicken

ActiveCN101856387AEnhance chicken disease resistanceImprove immunityPharmaceutical delivery mechanismImmunological disordersDiseaseAstragalus

The invention relates to a Chinese herbal immunopotentiator for chicken as oral liquid comprising the following raw materials in parts by weight: 4-5 parts of Echinacea purpurea, 2-4 parts of hoantchy root, 0.5-1.5 parts of rhodiola root, 1-3 parts of Dangshen and 0.5-1.5 parts of liquorice. The Chinese herbal immunopotentiator for chicken is prepared by the following steps of: crashing the raw materials, mixing, boiling with water for leaching, concentrating and encapsulating. The Chinese herbal immunopotentiator for chicken has better effects of reinforcing the disease resistance and the disease prevention of chicken and increasing immunizing power.

Owner:石家庄燕科生物科技有限公司

Reactor and process for the continuous production of hydrogen based on steam oxidation of molten iron

InactiveUS20080166291A1Low hydrogen contentOvercome disadvantagesHydrogen productionCarbon monoxideCoalOxidation reduction

The present invention provides a reactor and gasification process for the continuous controlled production of hydrogen (H2) and a by-product synthesis gas (mixture of CO+H2+CO2), such a process called a hydrogen priority poly-generation process (HPPP). The reactor uses a circulating molten iron process, which is capable of gasifying a variety of carbonaceous materials including low rank coals and biomass. The process employs an iron steam oxidation-reduction cycle in a multi-chamber reactor including a multi-vessel reactor system, where in one compartment or vessel hydrogen is produced by steam oxidation of molten iron; and in a second compartment or vessel the iron is regenerated by carbon reduction of molten iron oxide thereby producing a by-product synthesis gas (CO+H2+CO2), and excess heat which can be used to produce steam, and in a third step the iron is purified before being returned to the steam oxidation step in the process. An embodiment of this process uses low rank coals having high ash levels in a reactor, which is designed to continuously extract ash from the molten iron bath. A second embodiment uses low ash carbon materials such as highly beneficiated coals in a simpler process that produces pure streams of hydrogen and CO.

Owner:AVAILABLE ENERGY CORP

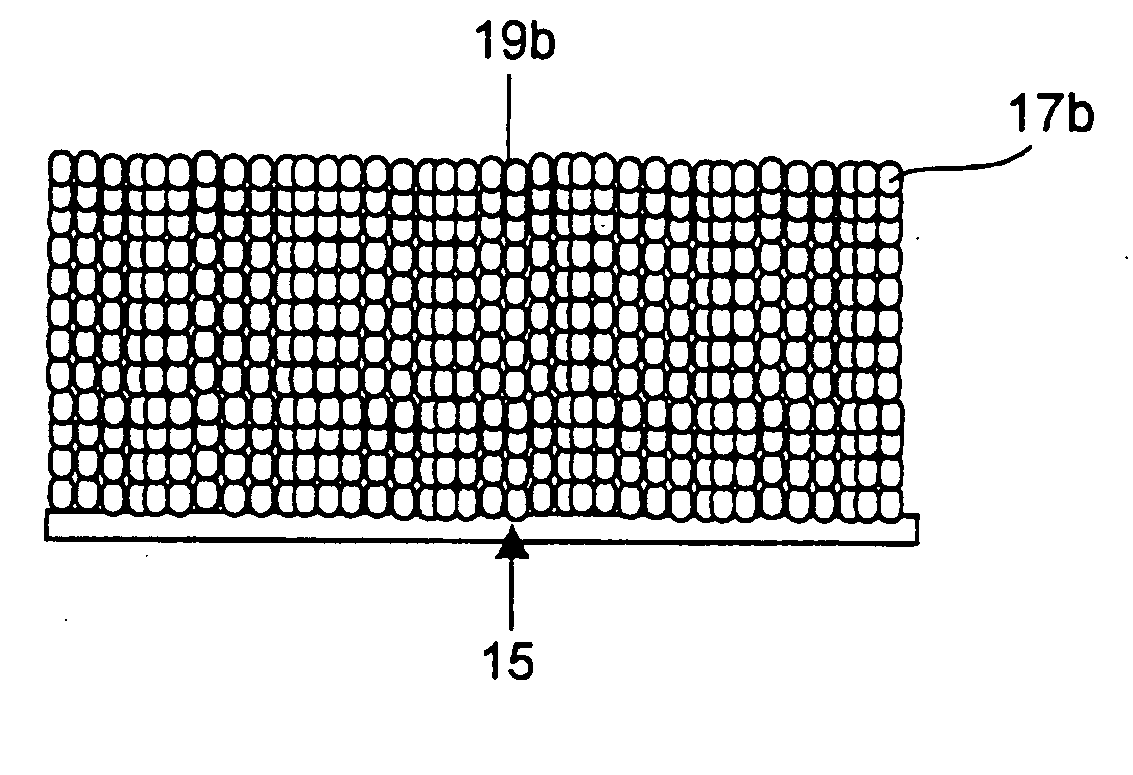

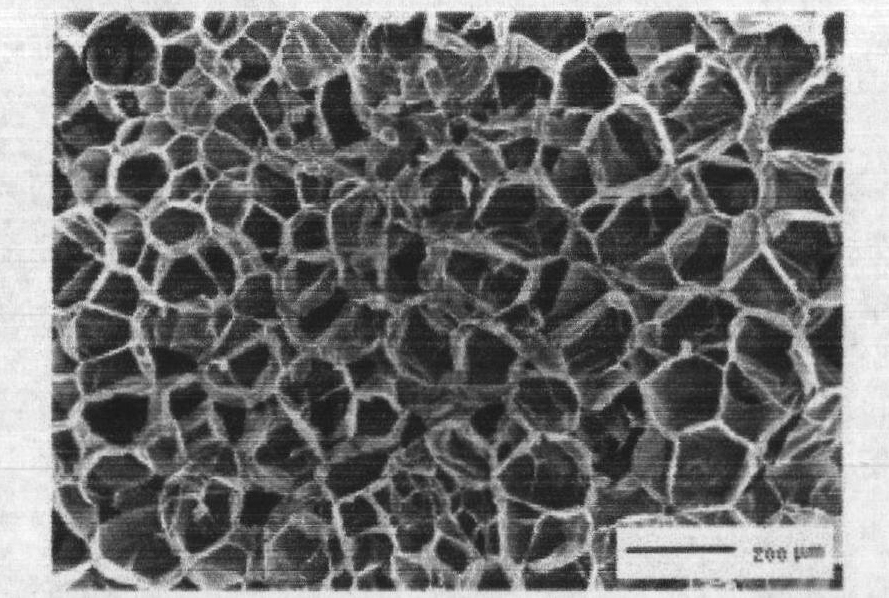

Ferrite thin film, method of manufacturing the same and electromagnetic noise suppressor using the same

ActiveUS7160636B2Formation rate improveIndustrial productivity increaseMagnetic materials for record carriersLiquid applicationMagnetic anisotropyElectromagnetic noise

A ferrite film is formed by regularly arranging constituents such as magnetized grains or one analogous to that. In the ferrite film, the constituents have at least one of the uniaxial anisotropy and the multiaxial anisotropy. The ferrite film has the magnetic anisotropy or the magnetic isotropy. The ferrite film is formed by the use of the plating method in the presence of a magnetic field. Furthermore, an electromagnetic noise suppressor includes the ferrite film.

Owner:TOKIN CORP

Semiconductor device and method of manufacture thereof

InactiveUS20090053453A1Improve consistencyMaterial becomes quickVacuum evaporation coatingSemiconductor/solid-state device manufacturingBulk crystalDevice material

A structure including a substrate, an intermediate layer provided and formed directly onto the substrate, a transition region, and a group II-VI bulk crystal material provided and formed as an extension of the transition region. The transition region acts to change the structure from the underlying substrate to that of the bulk crystal. In a method of manufacture, a similar technique can be used for growing the transition region and the bulk crystal layer.

Owner:KROMEK

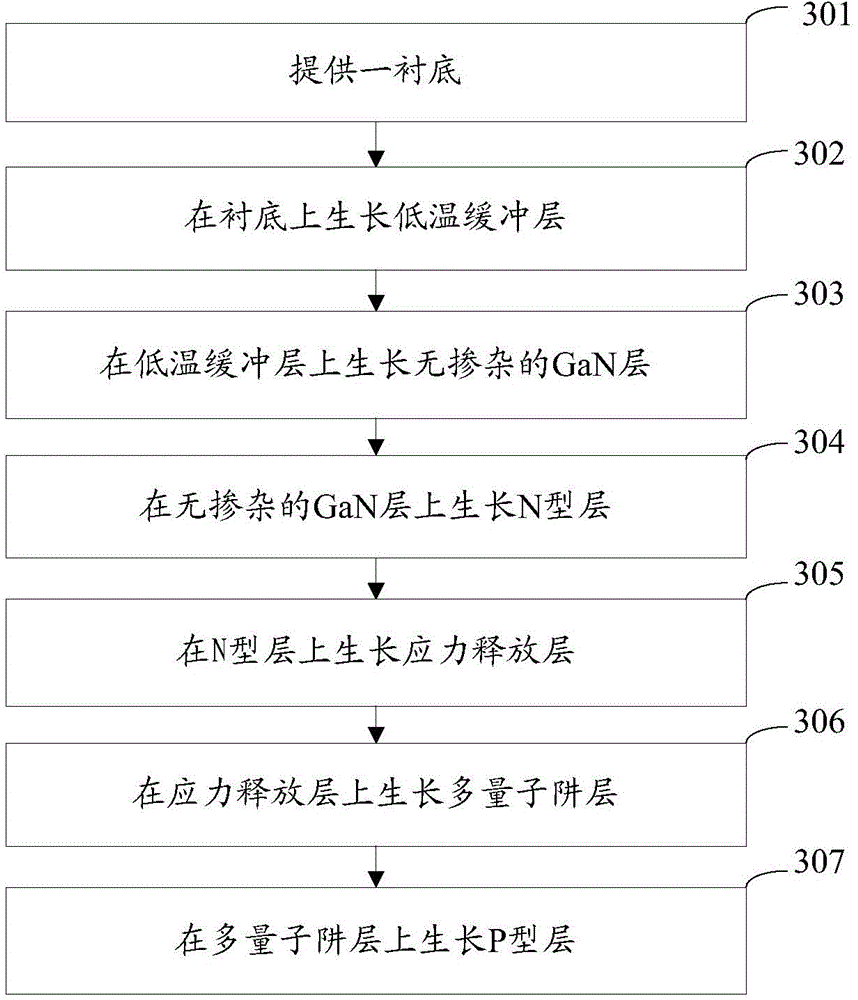

Light-emitting diode epitaxial slice and preparation method thereof

The invention discloses a light-emitting diode epitaxial slice and a preparation method thereof, and belongs to the field of light-emitting diodes. The epitaxial slice comprises a substrate, a buffer layer, an N-type layer, a stress release layer, a multiple quantum well layer and a P-type layer, wherein the buffer layer, the N-type layer, the stress release layer, the multiple quantum well layer and the P-type layer sequentially grow on the substrate, the multiple quantum well layer is of a super-lattice structure, each cycle of the multiple quantum well layer includes an InyGa1-yN layer and a GaN layer, 0<y<1, the stress release layer is of a cycle structure, each cycle of the stress release layer includes a GaN layer, an InN layer and an InxGa1-xN layer growing on the InN layer, and 0<x<y. The InGaN layer grows on the InN layer in each cycle of the stress release layer, the formation probability of an In-N bond in the InGaN layer is high in rich In atmosphere, and In atoms can be more easily doped into a lattice to form the InGaN layer with high In component content.

Owner:HC SEMITEK SUZHOU

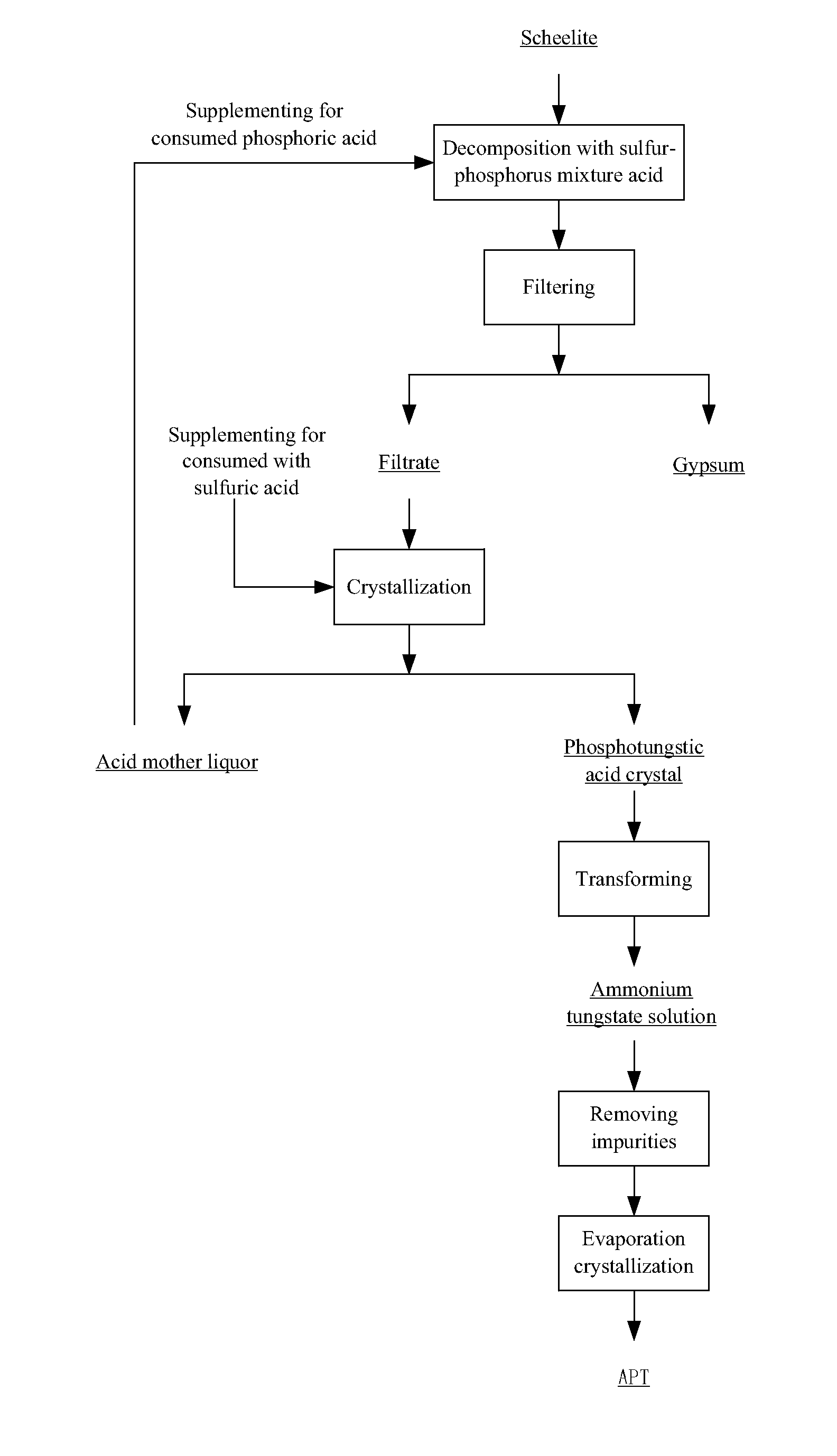

Method for extracting tungsten from scheelite

ActiveUS20130195737A1Increase formation rateAvoid packagingSolvent extractionMolybdeum compoundsDecompositionAmmonium paratungstate

A method for extracting tungsten from scheelite by: 1) adding a mixed acid including H2SO4 and H3PO4 to a decomposition reactor; 2) heating the mixed acid to a temperature of 70-100° C.; adding scheelite while controlling the liquid-solid ratio at about 3:1-8:1 L / kg; allowing the components in the decomposition reactor to react for 1-6 h, and filtering to obtain a filtrate; 3) supplementing the filtrate with sulfuric acid consumed in the reaction; 4) crystallizing the filtrate to obtain phosphotungstic acid crystals and mother liquor; 5) dissolving the phosphotungstic acid crystals in water to obtain phosphotungstic acid solution; 6) transforming the phosphotungstic acid solution into an ammonium tungstate solution for the purpose of preparing ammonium paratungstate; and 7) supplementing the mother liquor with phosphoric acid and water to an initial level and reusing the mother liquor for ore leaching.

Owner:CENT SOUTH UNIV

Ferrite thin film, method of manufacturing the same and electromagnetic noise suppressor using the same

InactiveUS20070077369A1Increase formation rateIncrease productivityMagnetic materials for record carriersLiquid applicationMagnetic anisotropySuppressor

A ferrite film is formed by regularly arranging constituents such as magnetized grains or one analogous to that. In the ferrite film, the constituents have at least one of the uniaxial anisotropy and the multiaxial anisotropy. The ferrite film has the magnetic anisotropy or the magnetic isotropy. The ferrite film is formed by the use of the plating method in the presence of a magnetic field. Furthermore, an electromagnetic noise suppressor includes the ferrite film.

Owner:TOKIN CORP

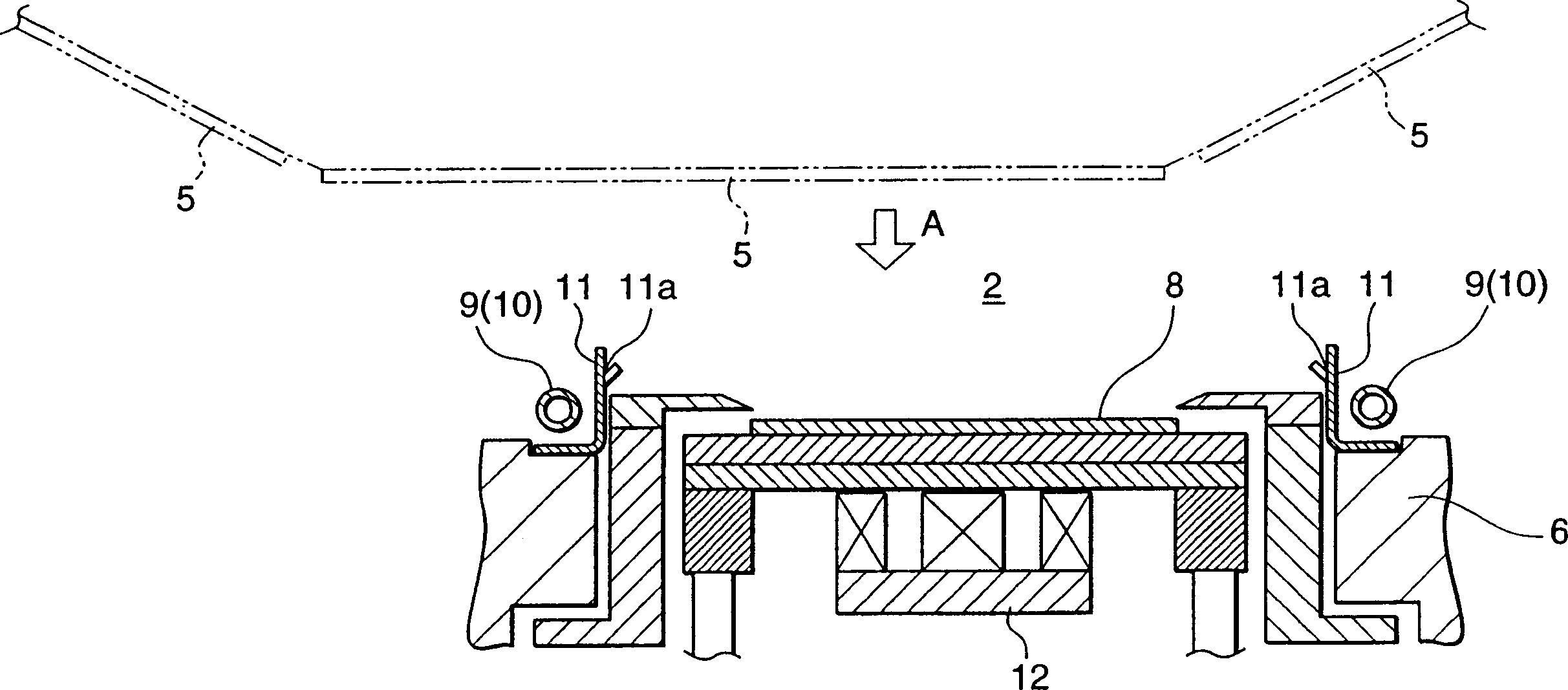

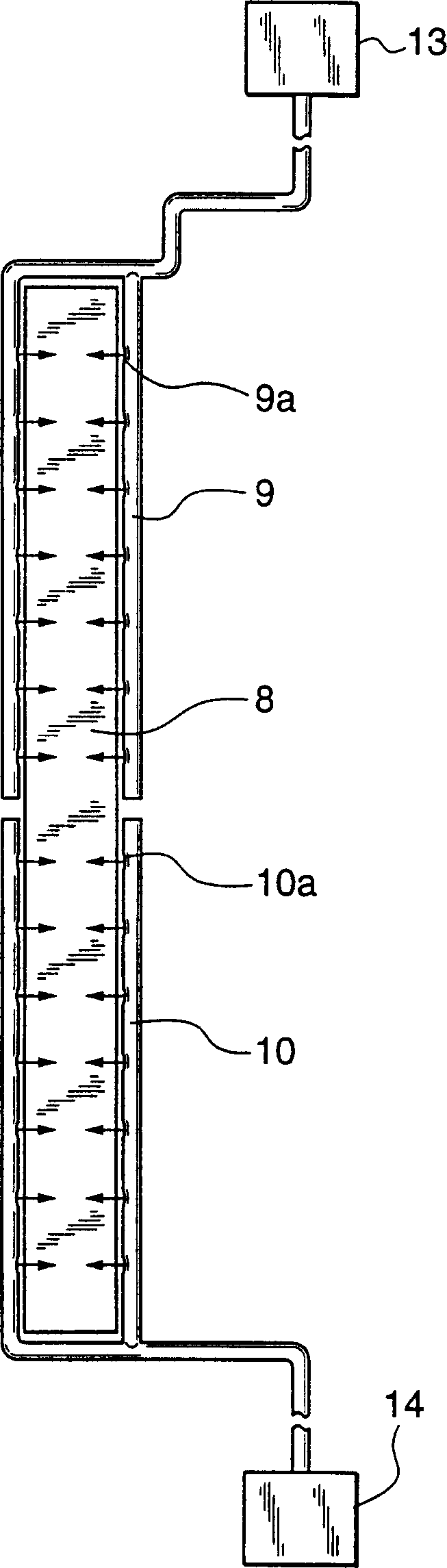

Sputtering device

InactiveCN1455826AIncrease formation rateGlow discharge state is stableVacuum evaporation coatingSputtering coatingSputteringEngineering

A sputtering apparatus 1 sputters a target 8 with ions in a plasma using a magnetron sputtering method, to form an ITO film from the target 8 on glass substrates 5 mounted on a rotating carousel 4. Manifolds 9 and 10, which have a shape that is symmetrical about each of two mutually orthogonal central axes in the plane of the target 8, are disposed so as to surround the whole periphery of the target 8, and process gas discharge ports 9a and 10a for discharging a process gas onto the target 8 are provided in a manner being distributed over the whole of the manifolds 9 and 10.

Owner:NIPPON SHEET GLASS CO LTD

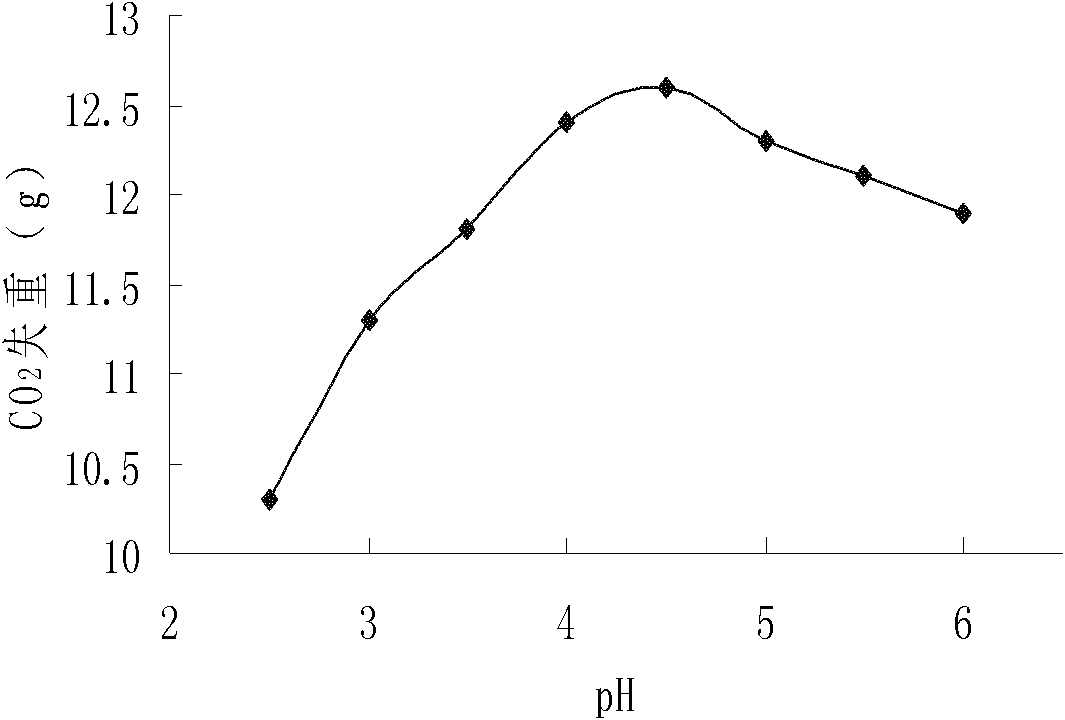

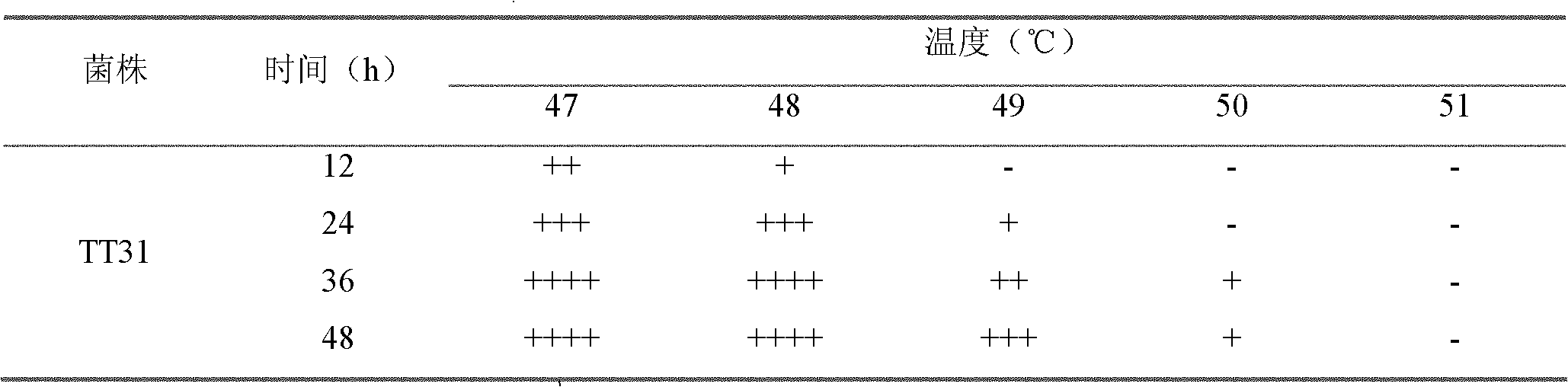

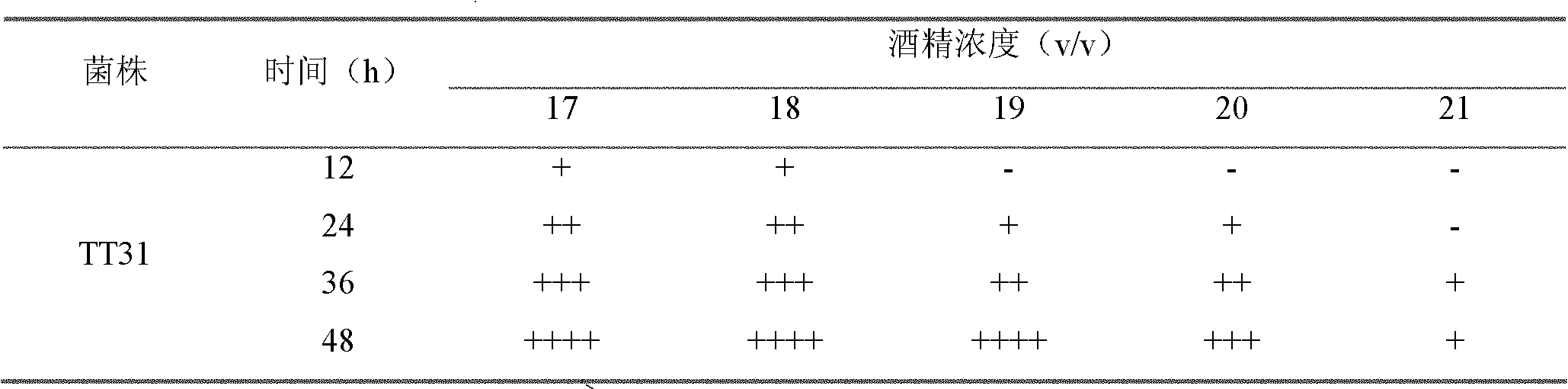

Multi-resistant high-yield alcohol yeast mutant strain TT31 and screening method thereof

InactiveCN102154138AIncrease formation rateHigh regeneration rateFungiHybrid cell preparationTriphenyltetrazolium chlorideSucrose

The invention relates to a multi-resistant high-yield alcohol yeast mutant strain TT31 and a screening method thereof. A genome reorganizing technology is used for screening high temperature-resistant, alcohol-resistant and acidity-resistant high-yield alcohol yeast mutagenic strain. The method comprises the following steps of: mutating a three-strain yeast strain by ultraviolet; selecting a ten yeast mutant strain which have three resistance and are higher in alcohol yield by a triphenyltetrazolium chloride (TTC) method at a first-level screening, a dieulafoy pipe fermentation method at a second-level screening, and a bottle shaking fermentation method at a third-level screening; preparing protoplast of the ten yeast mutant strains; and reorganizing genome at thee turns to finally obtain the yeast mutant strain TT31 which has higher improvemrnt on temperature resistance, alcohol resistance and acidity resistance. Under the condition of 35 DEG C, the mutant strain is fermented for 72h with alcohol by taking sucrose as a carbon source, and the alcohol yield reaches 101.9g / L.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Hard wire steel wire rod

The invention discloses a hard wire steel wire rod. The hard wire steel wire rod is prepared from the following components in percentage by mass: 0.78-0.82% of C, 0.18-0.25% of Si, 0.60-0.65% of Mn, not greater than 0.018% of P, not greater than 0.010% of S, not greater than 0.015% of [Al], not greater than 0.015% of As, not greater than 0.10% of Cr, not greater than 0.10% of Ni, not greater than 0.10% of Cu, not greater than 0.10% of other inevitable impurity elements and the balance of Fe. The average sorbitic level of the hard wire steel wire rod is not smaller than 90%, the section shrinkage rate of the hard wire steel wire rod is not smaller than 31% and the tensile strength of the hard wire steel wire rod is not smaller than 1100Mpa. According to the hard wire steel wire rod disclosed by the invention, the types, the content and the preparation process of each element are regulated, so that the sorbitizing degree of the steel wire rod is high; meanwhile, the hard wire steel wire rod has excellent shaping and strength, and is an ideal raw material for preparing subsequent products.

Owner:CHONGQING IRON & STEEL CO LTD

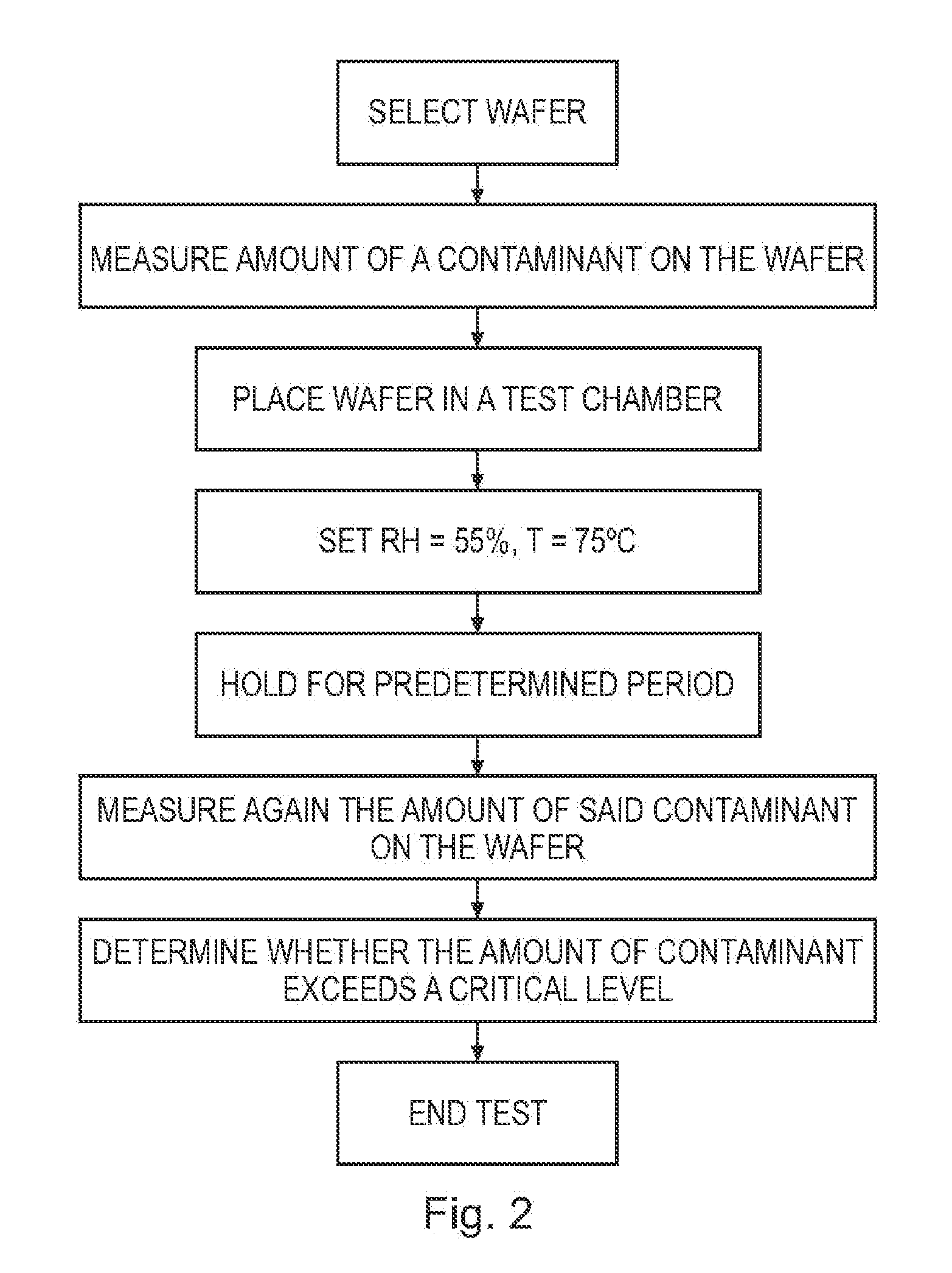

Azeotropic distillation of cyclic esters of hydroxy organic acids

InactiveUS6984293B2Increase formation rateAvoid racemizationOrganic compound preparationVacuum distillation separationOrganic acidOrganic Ester

Cyclic esters of hydroxy organic acids can be produced and recovered via azeotropic distillation. In certain embodiments cyclic esters, such as glycolide and lactide, can be produced from a fermentation broth or other feed stream that contains a hydroxy organic acid, an ammonium salt of a hydroxy organic acid, an amide of a hydroxy organic acid, or an ester of a hydroxy organic acid using azeotropic distillation. The hydroxy organic acid of the feed stream or the hydroxy organic acid derived from the feed stream by decomposition is reacted to produce the cyclic ester. In other embodiments a crude composition of a cyclic ester of an organic ester can be purified using azeotropic distillation.

Owner:TATE & LYLE INGREDIENTS AMERICAS INC

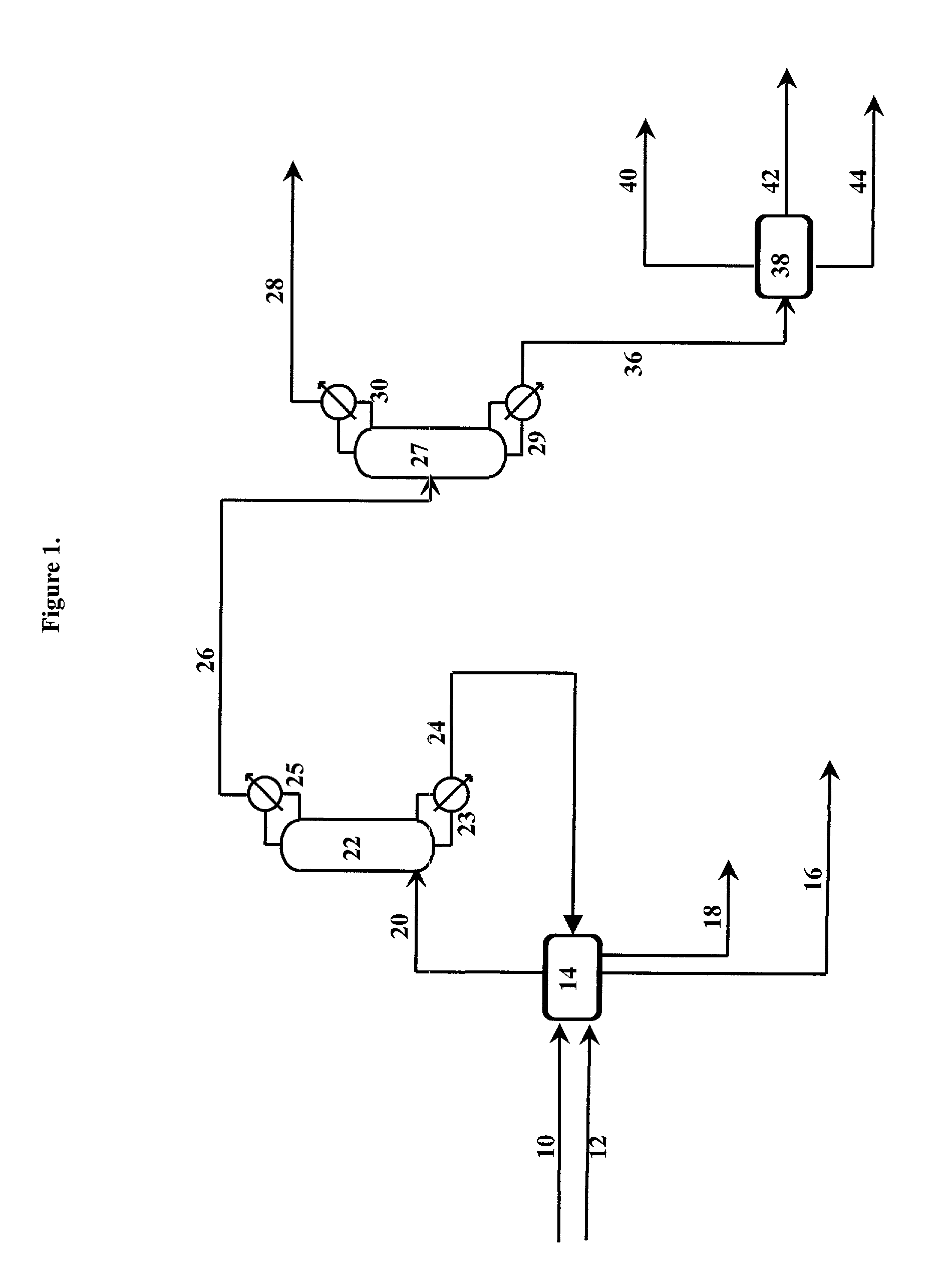

Method for performing a shelf lifetime acceleration test

InactiveUS20090277287A1Avoid introducingPrevent surfaceSemiconductor/solid-state device testing/measurementWeather/light/corrosion resistanceEngineeringContamination

Embodiments of the invention provide a method of determining a storage lifetime of a wafer in a storage environment, the storage environment corresponding to an environment having a first value of temperature and a first value of relative humidity, the wafer having a pre-test value of a first contamination parameter, including the steps of: subjecting the wafer to a test environment for a test period, the test environment includes an environment having a second value of temperature and a second value of relative humidity; subsequently, inspecting the wafer thereby to determine a post-test value of a second contamination parameter, wherein the second value of relative humidity is greater than 30% and the second value of wafer temperature is greater than 30° C.

Owner:CHARTERED SEMICONDUCTOR MANUFACTURING +1

Process for preparing expandable polystyrene/silica airgel core-shell composite particle

The invention relates to a process for preparing an expandable polystyrene / silica airgel core-shell composite particle, which comprises the following steps of preparing an aqueous phase solution; preparing an oil phase solution; and after the temperature inside a reaction kettle reaches 60 DEG C, introducing the oil phase solution into the aqueous phase solution by a core-shell droplet generator, setting the temperature of the reaction kettle to be 90 DEG C, realizing the control of core-shell ratio of the composite particle by controlling the flow rate of a styrene monomer in the core-shell droplet generator, after the temperature of the reaction kettle reaches 90 DEG C, starting to time, adding pentane after 2.5 hours, after the temperature reaches 100 DEG C, keeping the temperature for 3 hours, cooling to 40 DEG C and discharging. The silica airgel / polystyrene composite heat insulation material designed by the invention simultaneously has the characteristics of low density, good mechanical properties, good flame resistance, low thermal conductivity and the like, and the heat insulation of the prepared polystyrene / silica airgel composite heat insulation board is increased by 65.4% compared with the current EPS (expandable polystyrene) board for heat insulation of buildings.

Owner:陕西得波材料科技有限公司

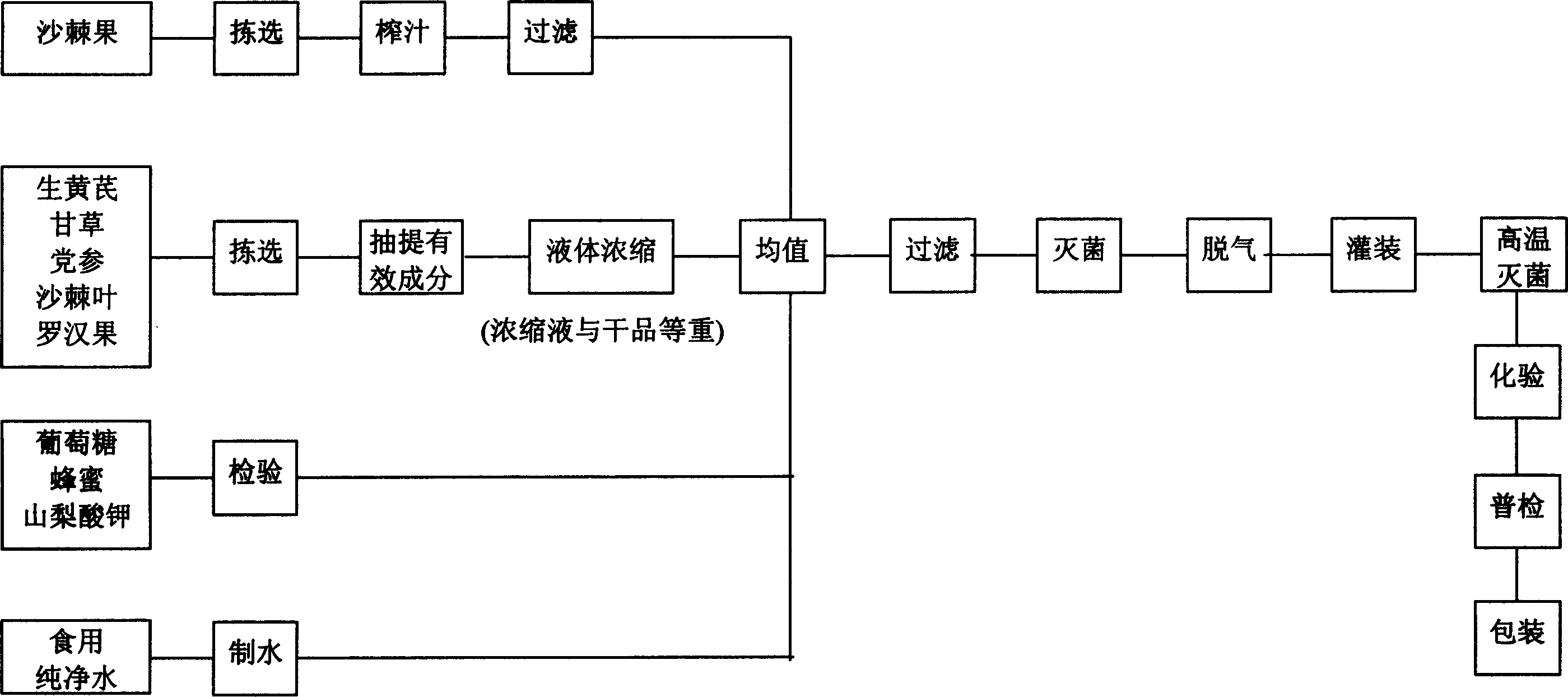

Sea-buckthorn astragalus root beverage

A sea-buckthorn and milk vetch root beverage for preventing SARS, characterized in that the beverage mainly comprises sea-buckthorn fruit juice, raw astragalus root and flavoring agent, wherein the percentage by weight of each constituent are, seabuckthorn fruit juice 0.5-5%, raw astragalus root 0.8-3%, flavoring agent 1-30%, the rest for drinking water. The functional beverage possesses the effect of enhancing human body resistance to diseases, and has good taste.

Owner:任志田

Traditional Chinese medicine feed addictive for controlling degradation of laying rate of chicken

InactiveCN101869180AEnhance phagocytosisLower body temperatureAnimal feeding stuffCyrtomium fortuneiCodonopsis pilosula

The invention relates to a traditional Chinese medicine feed addictive for controlling the degradation of the laying rate of chicken, which is powder prepared from the following raw materials in parts by weight: 4-6 parts of dyer woad leaf, 4-6 parts of cyrtomium fortunei, 7-9 parts of leonurus heterophyllus, 2-4 parts of fructus ligustri lucidi, 2-4 parts of fllase asiabelI root, 2-4 parts of astragalus root and 1-3 parts of liquorice. The traditional Chinese medicine feed addictive is prepared by crushing and mixing the raw materials. The invention is used for controlling the degradation of the laying rate of chicken, has favorable effect, and also has the characteristics of convenient use, safety and no medicine residue.

Owner:HEBEI NORMAL UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for cultivating pearl by inducing triploid hyriopsis cumingii

InactiveCN101940183APromote maturityIncrease formation rateClimate change adaptationPisciculture and aquariaNormal growthAqueous solution

The invention discloses a method for cultivating a pearl by inducing triploid hyriopsis cumingii. The method comprises the following steps of: cultivating the triploid hyriopsis cumingii by induction, namely selecting diploid hyriopsis cumingii with age of 3 to 6, shell length of over 15cm and shell thickness of over 5cm in normal growth as parent clams; isolating the male clams from the female clams of the selected parent clams for cultivation respectively; tracking and observing the development condition of the eggs of the female clams; transferring the female clams into a pond for cultivating the male clams to perform natural insemination on the female clams after the eggs are maturely developed; observing the development condition of the fertilized eggs; putting the female clams into 300 to 450 mu mol / L aqueous solution of 6-dimethyl aminopurine after over 80 percent of the fertilized eggs have first polar bodies; and performing induction processing for 10 to 30 minutes to obtain induced female clams; cultivating the female clams, and hatching and raising the seedlings to obtain the triploid juvenile clams; and performing cultivation to obtain the triploid hyriopsis cumingii. In the method, the normal diploid hyriopsis cumingii is used as the parents, and the natural insemination is adopted, so that the induction success rate is improved to over 70 percent.

Owner:ZHEJIANG SHANXIAHU PEARL GROUP CO LTD +1

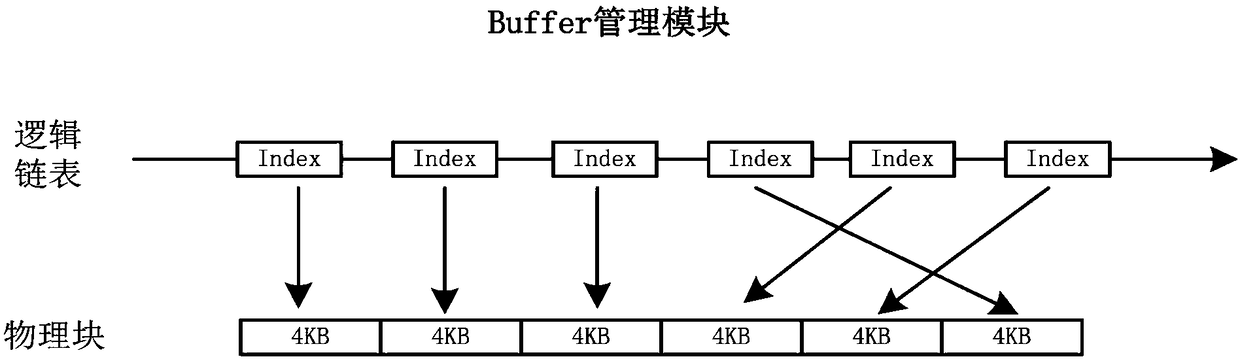

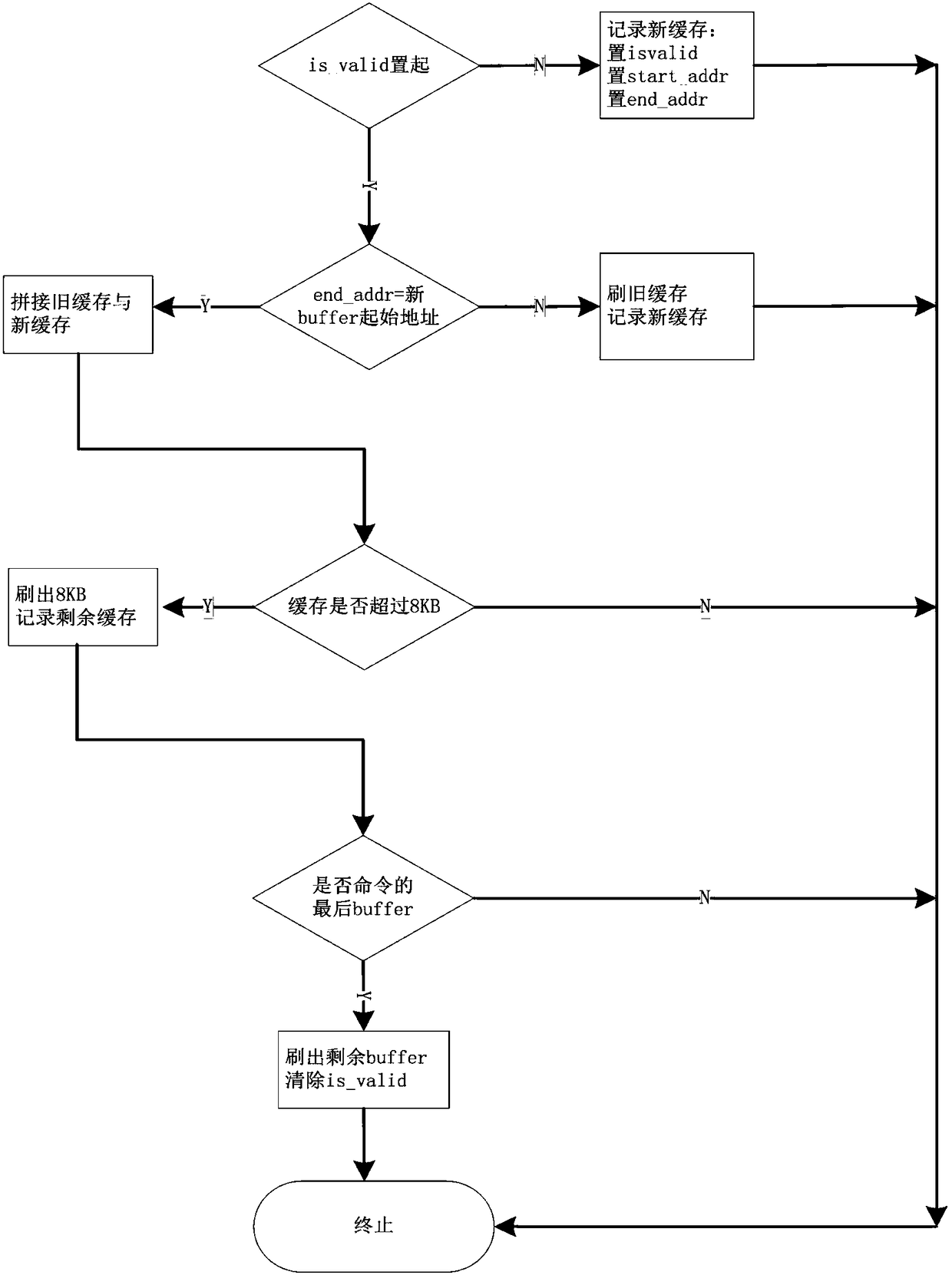

Solid-state-disk cache management method and solid state disk

InactiveCN108255420AIncrease the probability of formationImprove read and write performanceInput/output to record carriersSolid-stateCache management

The invention discloses a solid-state-disk cache management method and a solid state disk. The method is characterized by: dividing a solid-state-disk cache is into multiple management units accordingto 8 KB as a unit, dividing each management unit into two cache management sub-units of 4KB units, and setting an allocation number to record the number of already allocated units of each managementunit; using 4KB as a unit to apply for the cache from a cache management module by an external module, and according to an application order, allocating a new sub-cache-management-unit from a new management unit only when allocation numbers of management units are 2. The new cache management method is introduced, a splicing module is coordinated, forming probability V of 8KB Data FIS (Data Frame Information Structure) is increased, and then an effect of improving reading / writing performance of the solid state disk can be realized.

Owner:SHENZHEN YILIAN INFORMATION SYST CO LTD

Ultrasonic contrast medium and its preparing process

InactiveCN101130094ASimple and fast operationReduce manufacturing costEchographic/ultrasound-imaging preparationsLow speedMicrosphere

The invention discloses a making method of hypersonic contrast medium, which comprises the following steps: dispensing the raw material with 5-50mg / ml protein, 10-100mg / ml sugar, 7-9mg / ml sodium chloride, 0. 20-0. 8ml / ml fluorocarbon gas; preheating the material; rotating at low speed to preblend; rotating at high speed to generate microball; optimizing the grain size of the microball; detecting the semi-product; packing the product. The invention has good uniformity of grain size, which improves the quality effectively for industrialized manufacturing.

Owner:SHANGHAI XINXING MEDICINE

Electrode comprising lithium nickel oxide layer, method for preparing the same, and electrochromic device comprising the same

ActiveUS20100014145A1Easy to contactHigh transparencyVacuum evaporation coatingPretreated surfacesVoltageLithium

Owner:LG CHEM LTD

Method for producing bonded wafer

InactiveUS7446016B2Quality improvementImprove throughputSemiconductor/solid-state device manufacturingHigh rateSmart Cut

A bonded SOI substrate having an active layer which is free from crystal defects is obtained by adding more than 9×1018 atoms / cm3 of boron to a wafer for active layer (10). Since the boron concentration in the wafer for active layer is high, a silicon oxide film is formed at a high rate. Consequently, there can be obtained a Smart-Cut wafer with high throughput. Furthermore, damages to the active layer due to the ion implantation can be reduced, thereby improving the quality of the active layer.

Owner:SUMCO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com