Ultrasonic contrast medium and its preparing process

An ultrasound contrast agent and said technology, applied in echo/ultrasound imaging agents and other directions, can solve the problems of unclear feasibility of large-scale commercial production, unknown microspheres, etc., to increase the optimized processing technology and reduce the investment in equipment. , improve efficacy and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Example 1 Effect of Maltose on Microsphere Formation Rate, Microsphere Average Particle Size and Microsphere Size Distribution

[0040] In the case of adding maltose and no maltose, the preparation was carried out according to the process method, and the relevant indicators of the microspheres were detected. The average particle size is small, especially in the effective range (3.0 ~ 4.5μm), the percentage of microspheres is significantly increased (see Table 1). When the concentration of maltose increases gradually, the concentration of microspheres increases, and the range of effective microspheres increases, but when the concentration of maltose reaches 75mg / ml and above, the increase of the concentration of microspheres is not obvious, and the range of effective microspheres increases. decreased, so the range of maltose is 40-60mg / ml (see Table 2).

[0041] Table 1 Concentration, average particle size and size distribution of microspheres with or without maltose

...

Embodiment 2

[0045] The influence of the rotational speed of embodiment 2 homogenizer on the relevant parameter of microsphere

[0046] Due to the different rotation speeds of the homogenizer, the formed microsphere concentration, microsphere average particle size and microsphere size distribution are also different (see Table 3). The results in Table 3 show that the premixed rotation speed of the preparation solution is the same, but the rotation speed of the microspheres is different, and the average particle size and concentration of the microspheres are different; the premixed rotation speed of the preparation solution is different, and the rotation speed of the microspheres is different. When consistent, the average particle size and concentration of microspheres are also different.

[0047] Table 3 Effect of homogenizer rotation speed on the concentration, average particle size and size distribution of microspheres

[0048] Premix rotation speed (rpm / min)

Embodiment 3

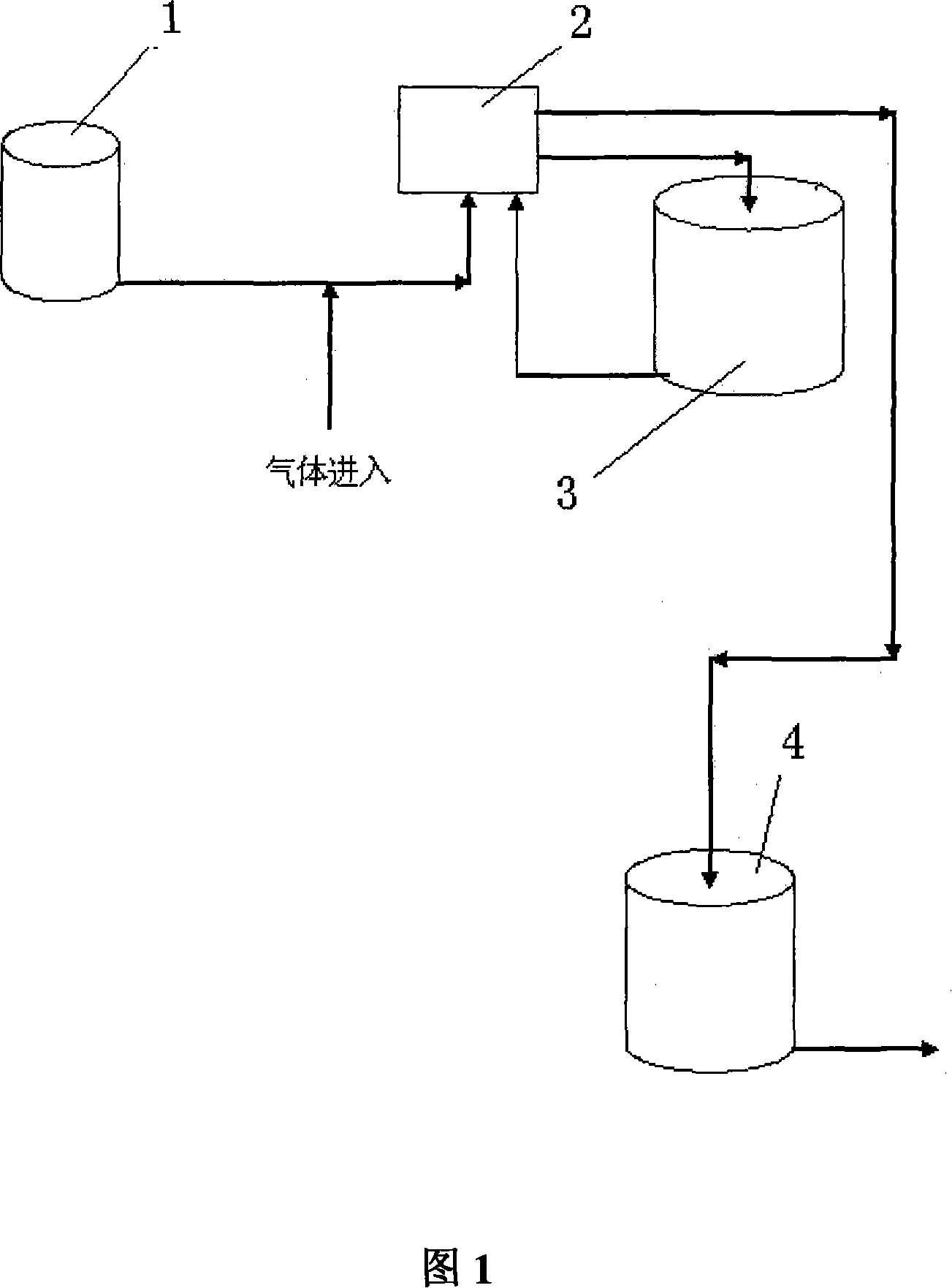

[0049] Example 3 Detailed description of the method for preparing an ultrasound contrast agent:

[0050] (1) Take commercially available human serum albumin, sodium chloride injection, and self-prepared maltose (sterilized by 0.22 μm membrane filtration) as raw materials and mix them according to the ratio required by the components to make 500ml of human blood containing 10mg / ml The preparation solution of albumin, 50mg / ml maltose, and 9mg / ml sodium chloride was packed into a raw material bottle and preheated to 74°C.

[0051] (2) the homogenizer rotating speed is transferred to 5000 rpm, the preheated preparation solution is injected into the grinding chamber of the homogenizer at a speed of 20ml / min, and the fluorocarbon insoluble gas is injected into the liquid at a speed of 15ml / min. Rotary grinding makes the protein wrap the insoluble gas of fluorocarbon to form a microsphere solution with large particle size and inhomogeneity.

[0052] (3) The speed of the homogenizer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com