Process for preparing expandable polystyrene/silica airgel core-shell composite particle

A technology of expandable polystyrene and composite particles, which is applied in the field of thermal insulation material preparation, can solve the problems of high thermal conductivity of thermal insulation boards, uneven distribution of cells, large cells, etc., and achieve the effect of accelerating the crystallization speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

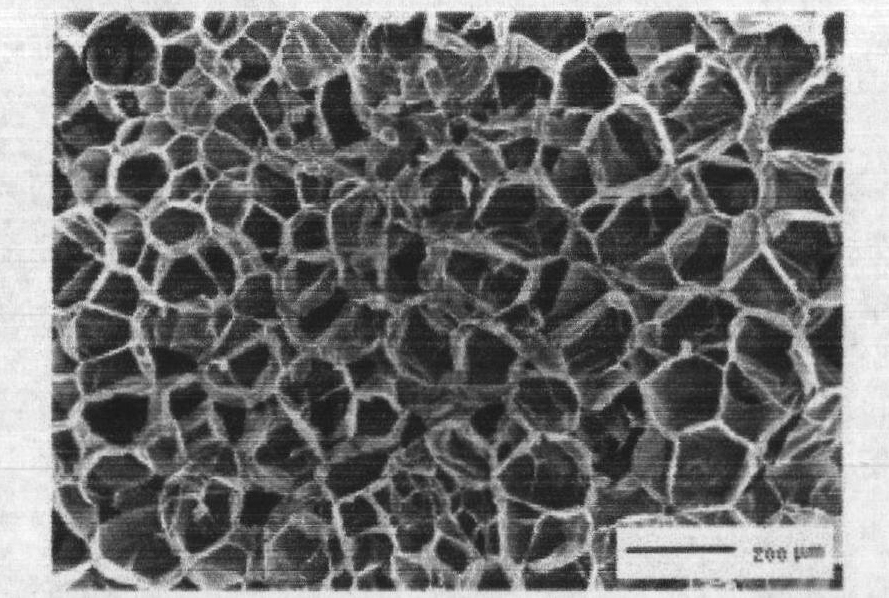

Image

Examples

Embodiment 1

[0023] An expandable polystyrene / SiO 2 The preparation process of airgel core-shell composite particles comprises the following steps:

[0024] 1) Preparation of water phase solution, 400 parts of water, 3 parts of tricalcium phosphate, and 7 parts of polyvinyl alcohol solution are prepared into water phase solution, dispersed in a high-pressure reactor for 20 minutes and heated up, and the temperature is set at 60°C;

[0025] 2) Oil phase solution preparation, in 100 parts of styrene monomer, add benzoyl peroxide, tributyl phosphate and other auxiliary agents to mechanically disperse for 15 minutes, and pass the mixed solution into the outer tube of the core-shell droplet generator; Hydrophobically modified SiO 2 Two parts of the airgel are drawn out from the inner tube of the core-shell droplet generator;

[0026] 3) When the temperature in the reactor reaches 60°C, introduce the oil phase solution into the water phase solution through the core-shell droplet generator, set...

Embodiment 2

[0030] An expandable polystyrene / SiO 2 The preparation process of airgel core-shell composite particles comprises the following steps:

[0031] 1) Preparation of water phase solution, 400 parts of water, 6 parts of tricalcium phosphate, and 5 parts of polyvinyl alcohol solution are prepared into water phase solution, dispersed in a high-pressure reaction kettle for 20 minutes and heated up, and the temperature is set at 60°C;

[0032] 2) Oil phase solution preparation, in 100 parts of styrene monomer, add benzoyl peroxide, tributyl phosphate and other auxiliary agents to mechanically disperse for 15 minutes, and pass the mixed solution into the outer tube of the core-shell droplet generator; 5 parts of hydrophobically modified SiO2 airgel are drawn out from the inner tube of the core-shell droplet generator;

[0033] 3) When the temperature in the reactor reaches 60°C, introduce the oil phase solution into the water phase solution through the core-shell droplet generator, set...

Embodiment 3

[0037]An expandable polystyrene / SiO 2 The preparation process of airgel core-shell composite particles comprises the following steps:

[0038] 1) Preparation of water phase solution, 400 parts of water, 5 parts of tricalcium phosphate, and 6 parts of polyvinyl alcohol solution are prepared into water phase solution, dispersed in a high-pressure reactor for 20 minutes and heated up, and the temperature is set at 60°C; 2) Oil Phase solution preparation, in 100 parts of styrene monomer, add benzoyl peroxide, tributyl phosphate and other additives to mechanically disperse for 15 minutes, and pass the mixed solution into the outer tube of the core-shell droplet generator; at the same time, the hydrophobic modification Three parts of SiO2 airgel are drawn out from the inner tube of the core-shell droplet generator;

[0039] 3) When the temperature in the reactor reaches 60°C, introduce the oil phase solution into the water phase solution through the core-shell droplet generator, se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com