Steel slag ball production equipment and granulating system thereof

A technology for producing equipment and steel slag balls, applied in the direction of recycling technology, etc., can solve the problems of incomplete granulation of steel slag balls, lowering the quality of steel slag balls, uneven distribution of steel slag flow, etc., achieving low cost, large production capacity, large size uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

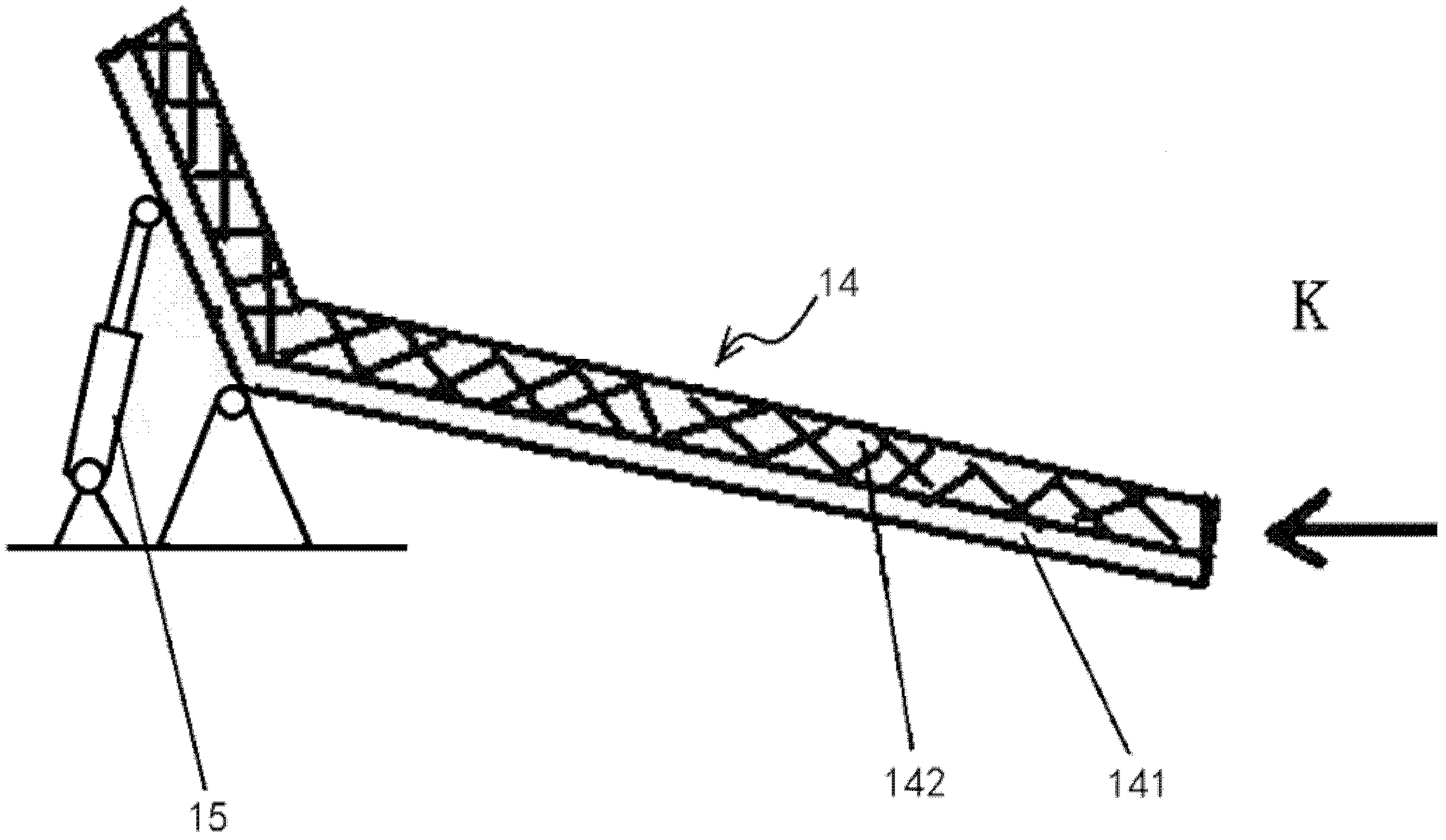

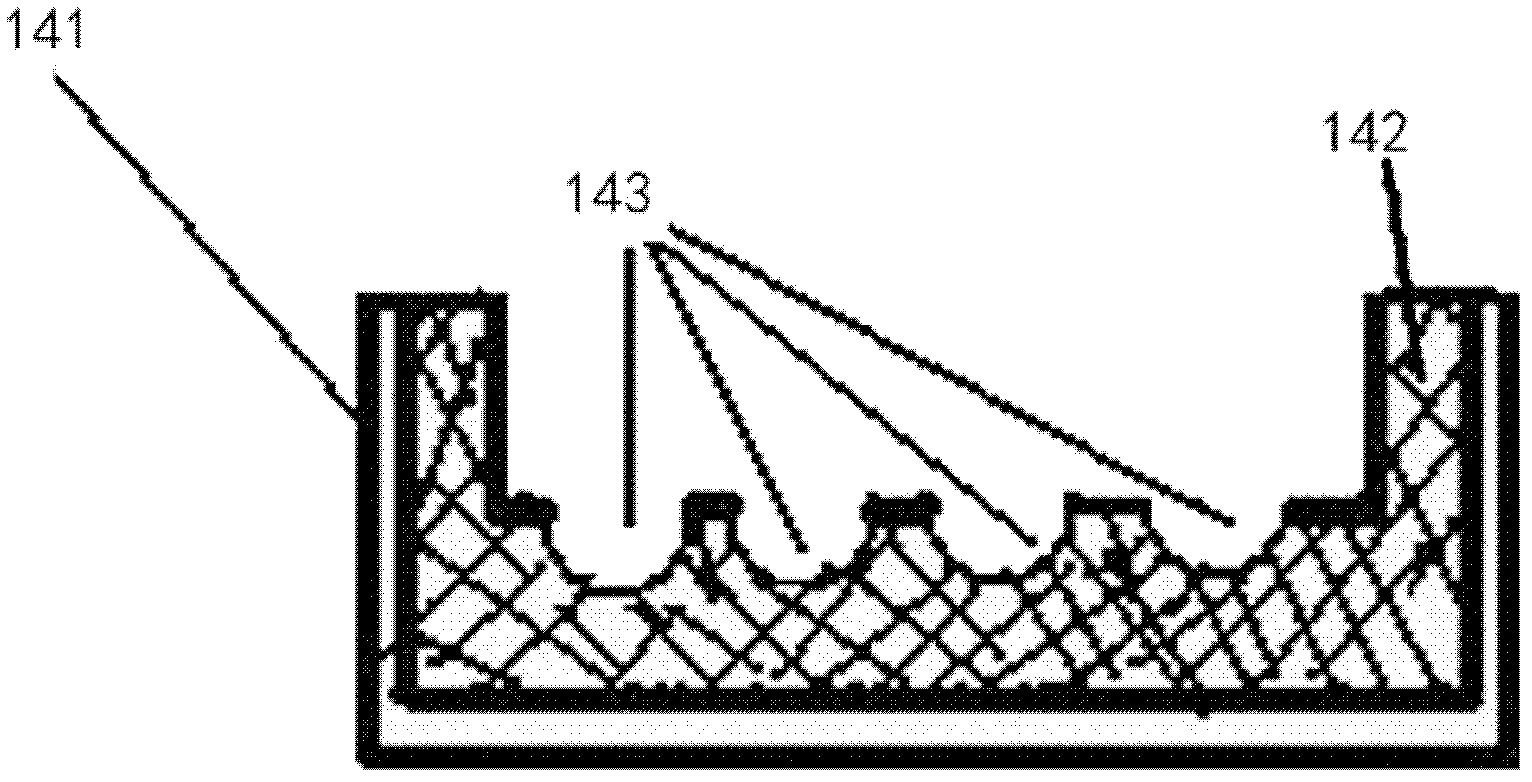

[0025] Such as Figure 1 to Figure 8 As shown, the specific embodiment of the steel slag ball production equipment of the present invention is a kind of steel slag ball production equipment, which mainly includes a slag tank for containing and pouring out molten steel slag, and a device for guiding the steel slag poured out from the slag tank to fall in a direction. The launder device 14, the granulation system for spraying and cooling the steel slag flowing out of the launder with high-pressure air and water flow, the cooling water pool system for cooling and recycling the steel slag, and the steel slag ball screening and collection system for collecting the finished steel slag.

[0026] The slag pot in this embodiment is a slag pot 5 with an open upper end, and the slag pot 5 is transported between the smelting furnace 1 for melting waste steel slag and the pot turning mechanism 9 by the transport vehicle 4. Of course, in other embodiments of the present invention, the smelti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com