Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

75results about How to "Avoid packaging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

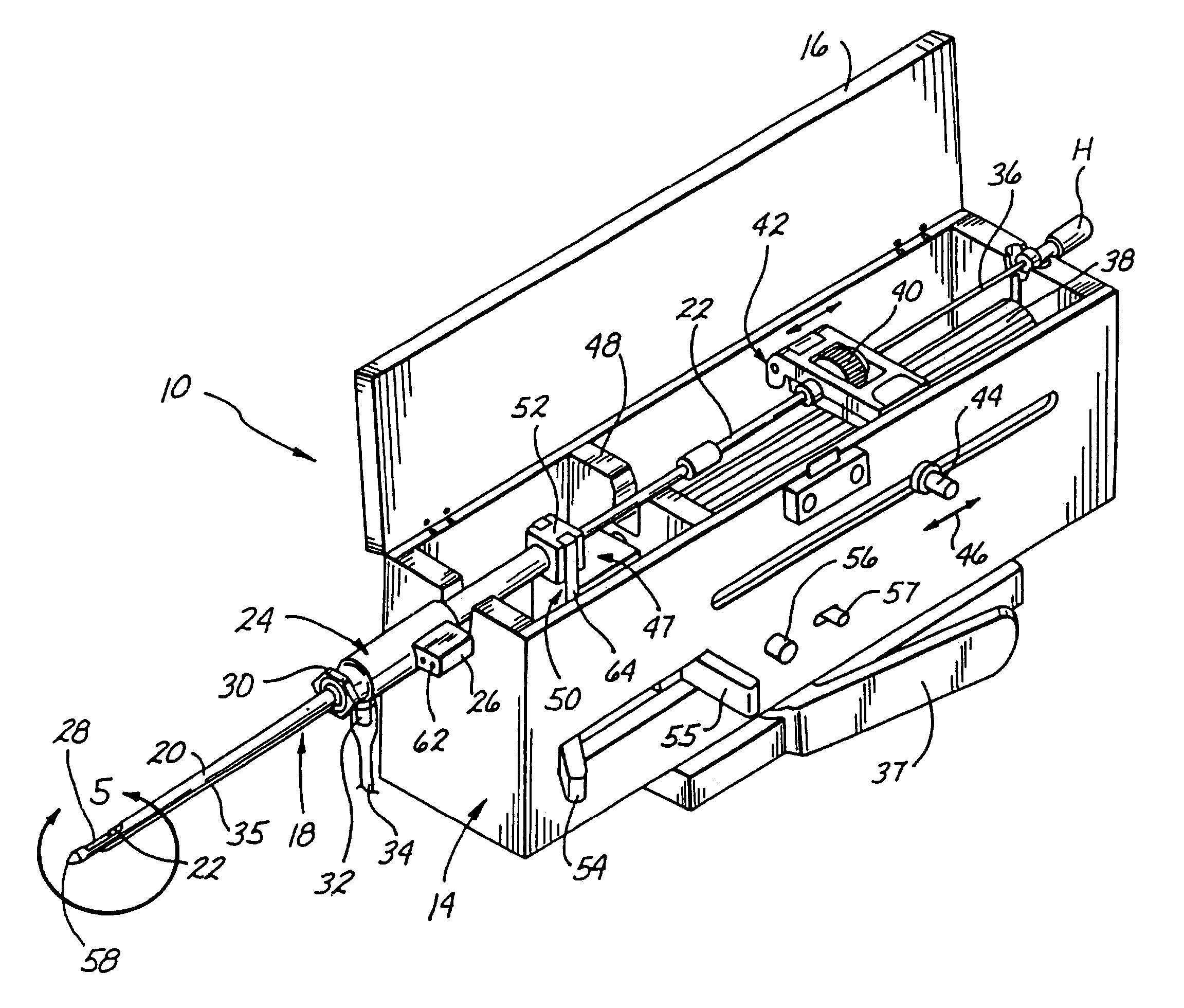

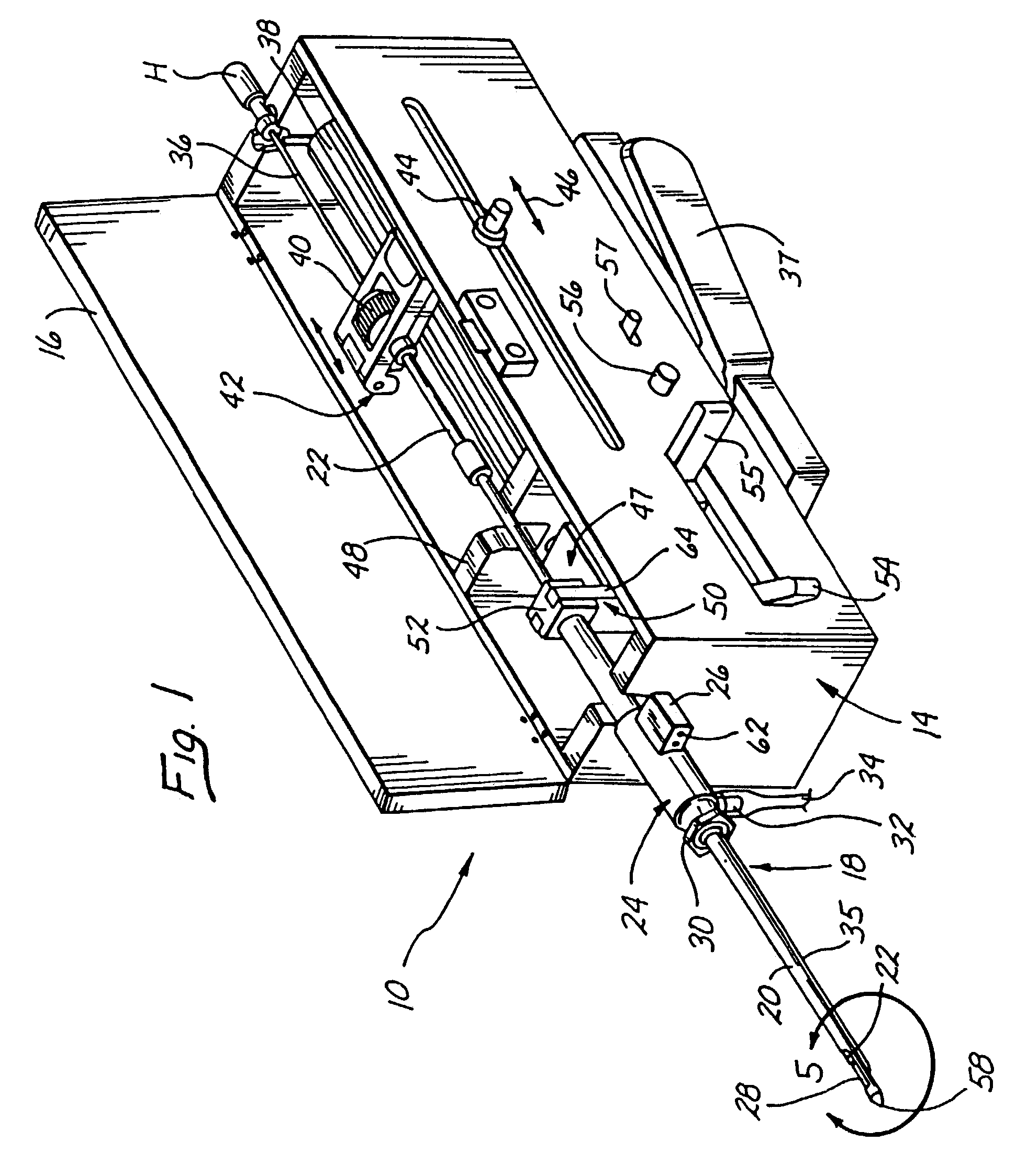

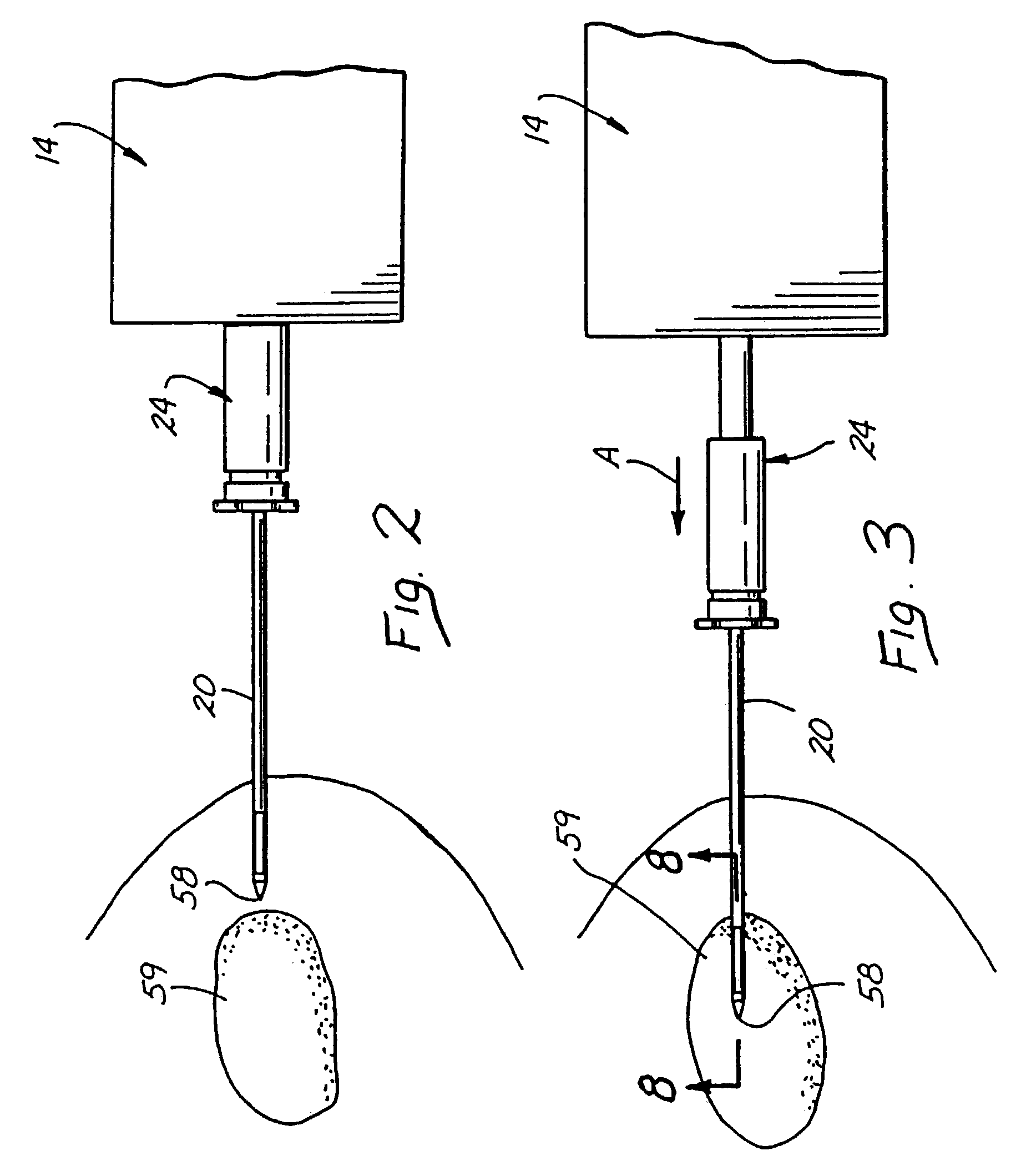

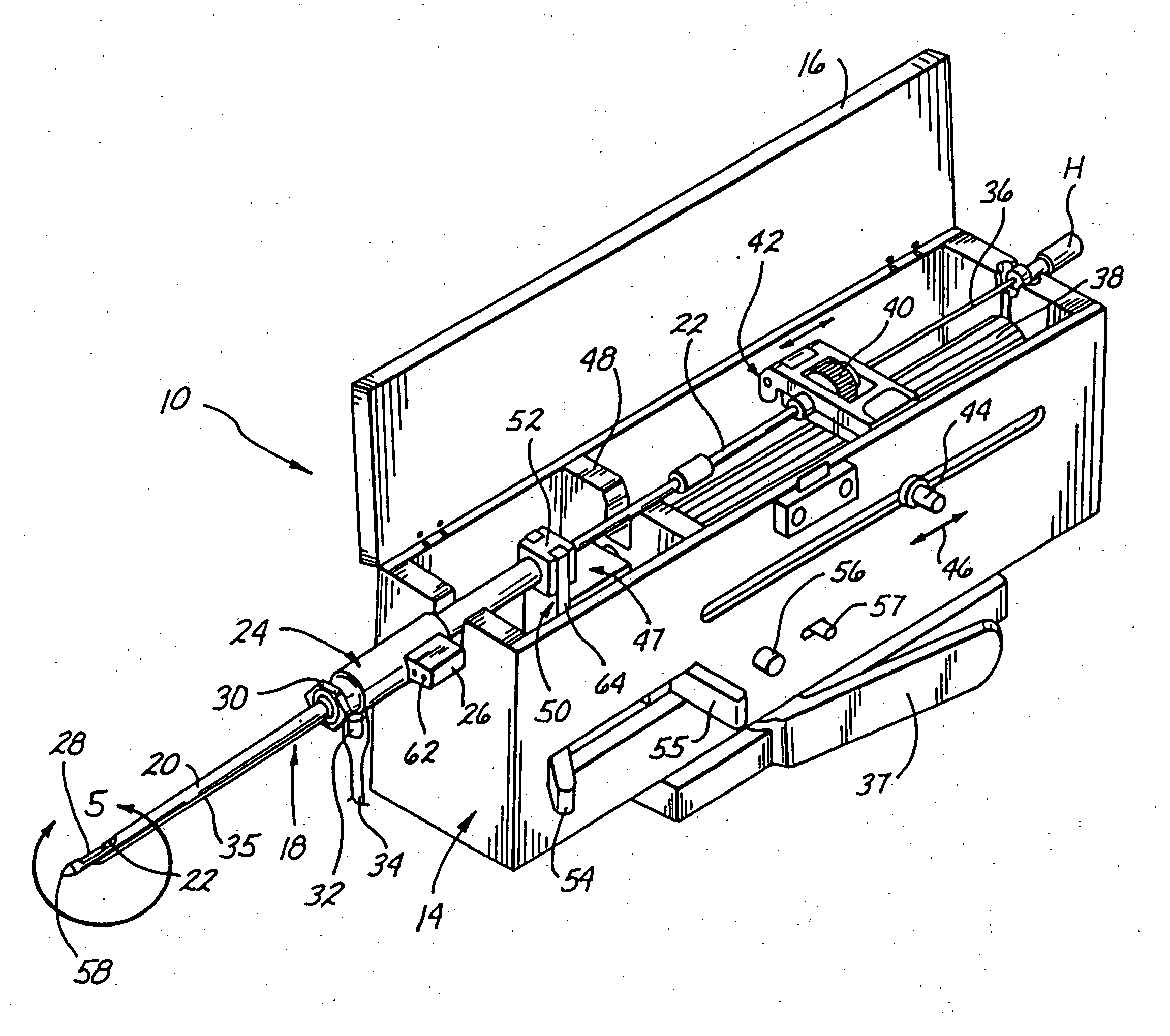

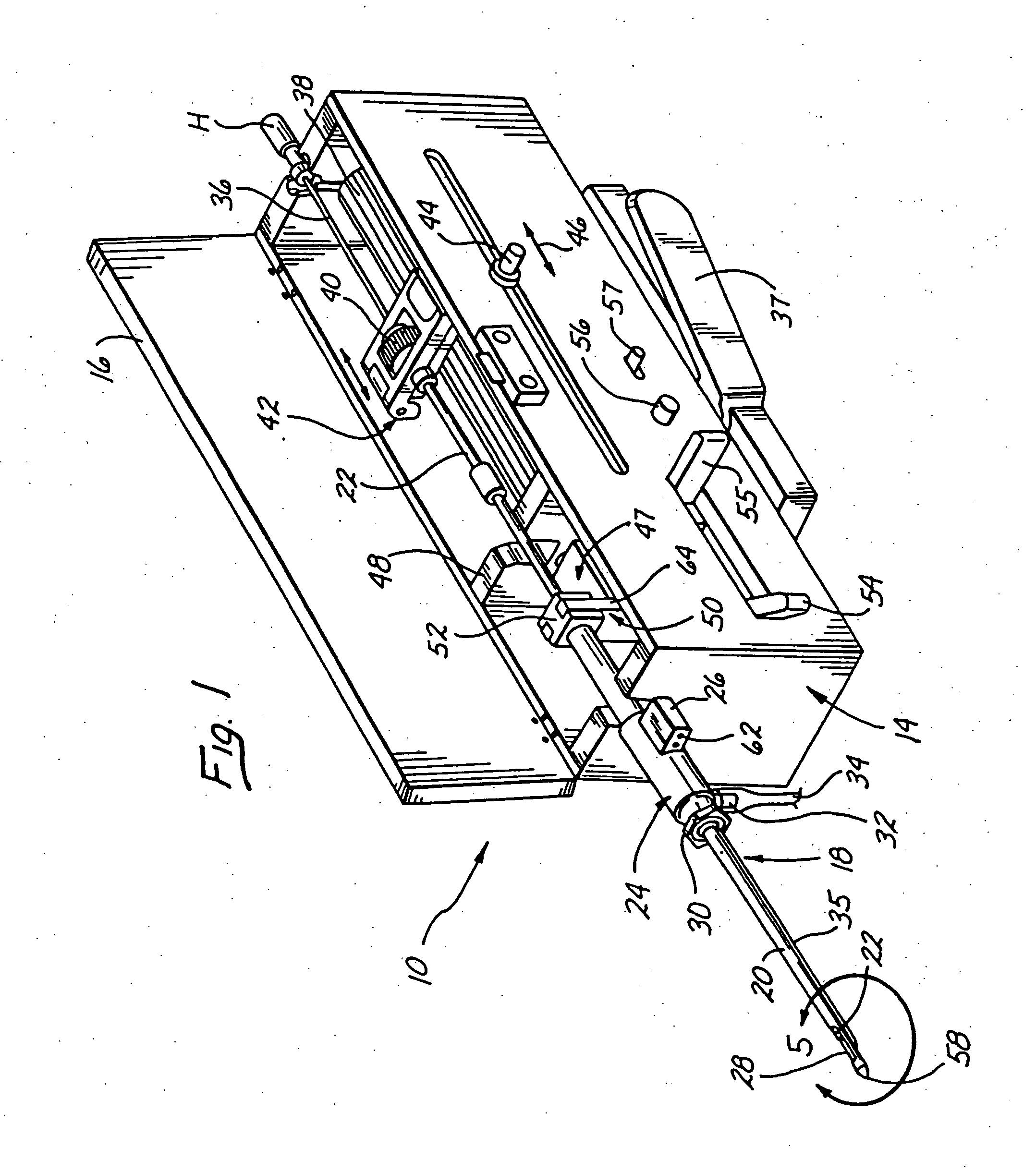

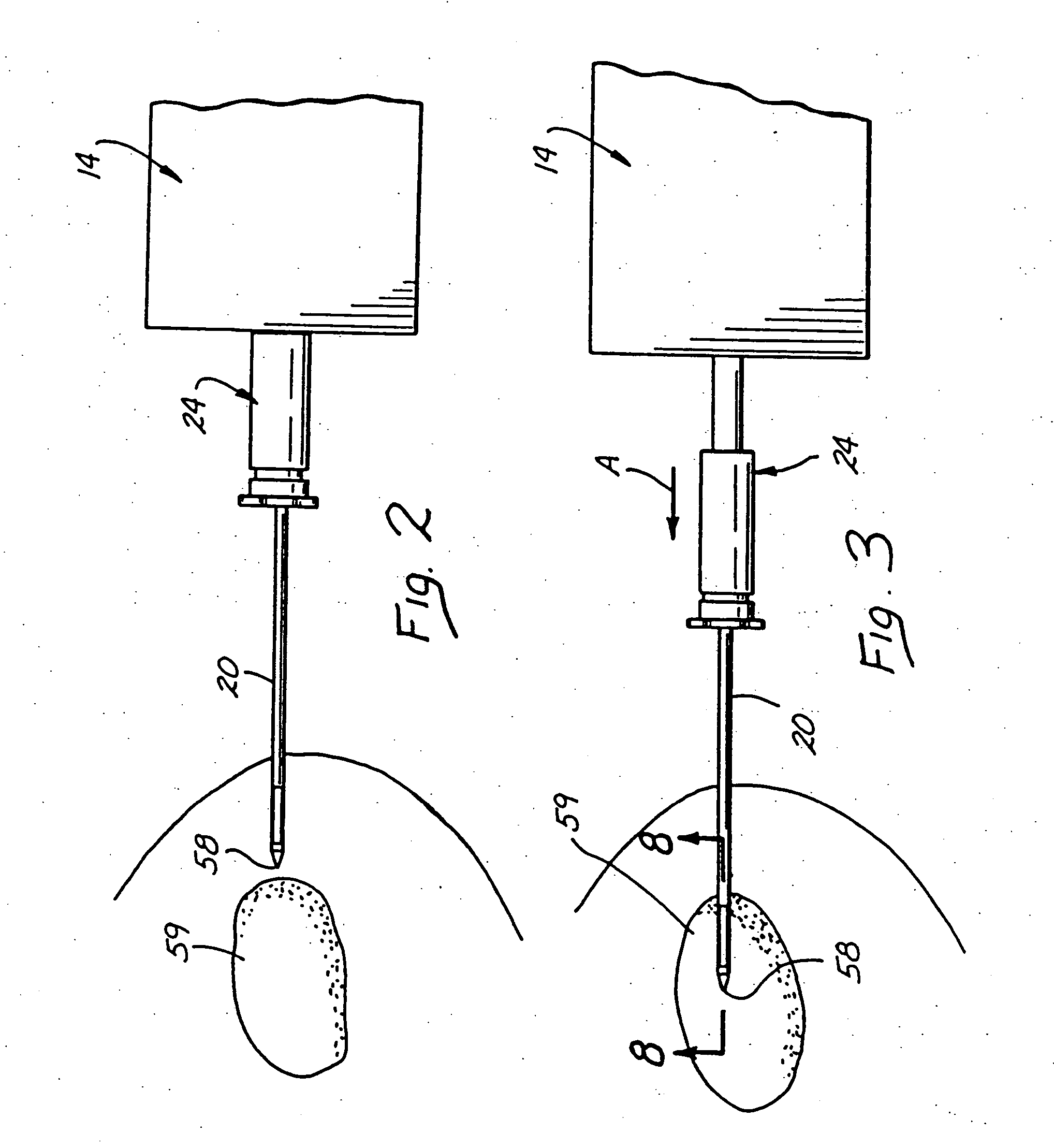

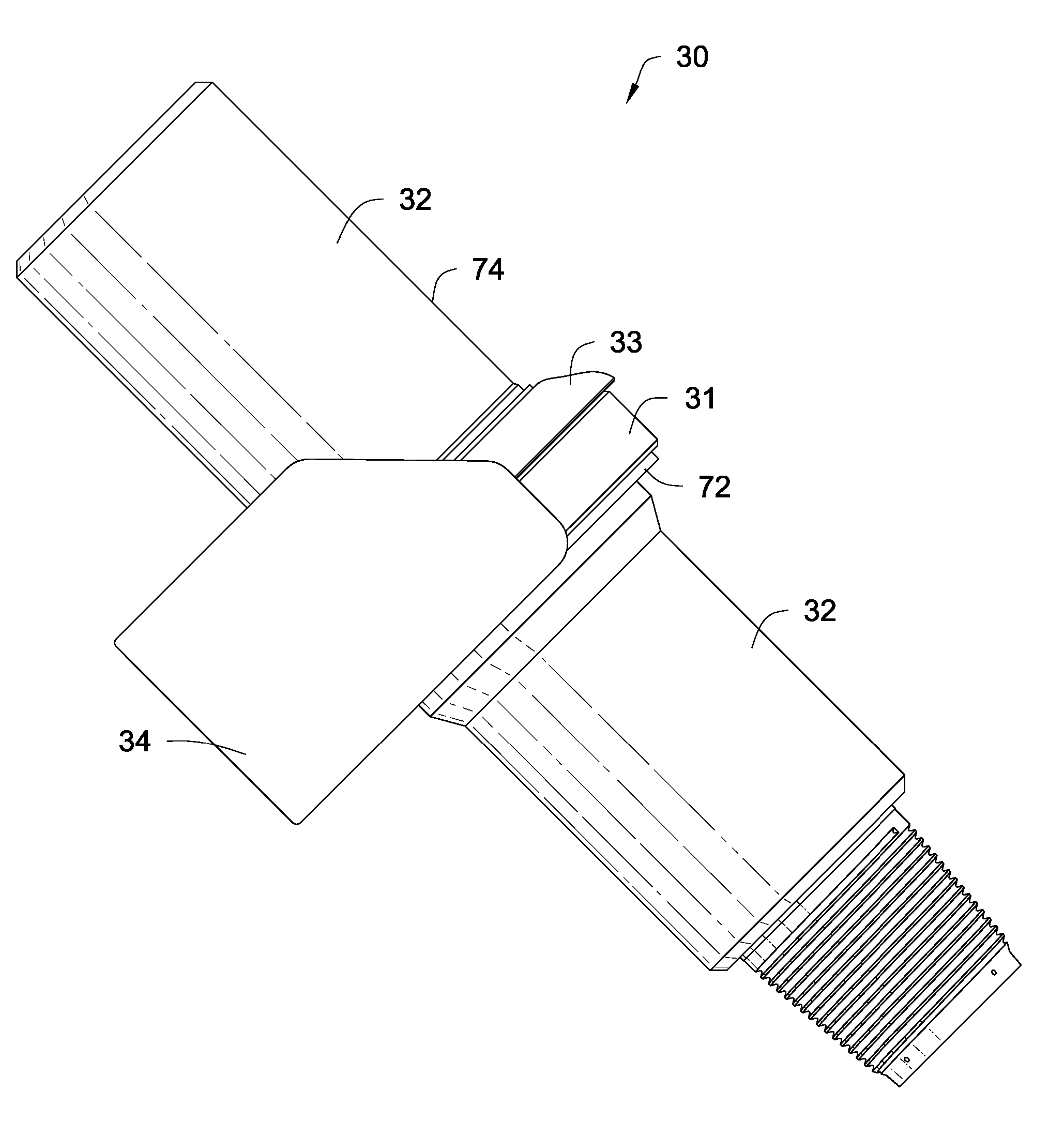

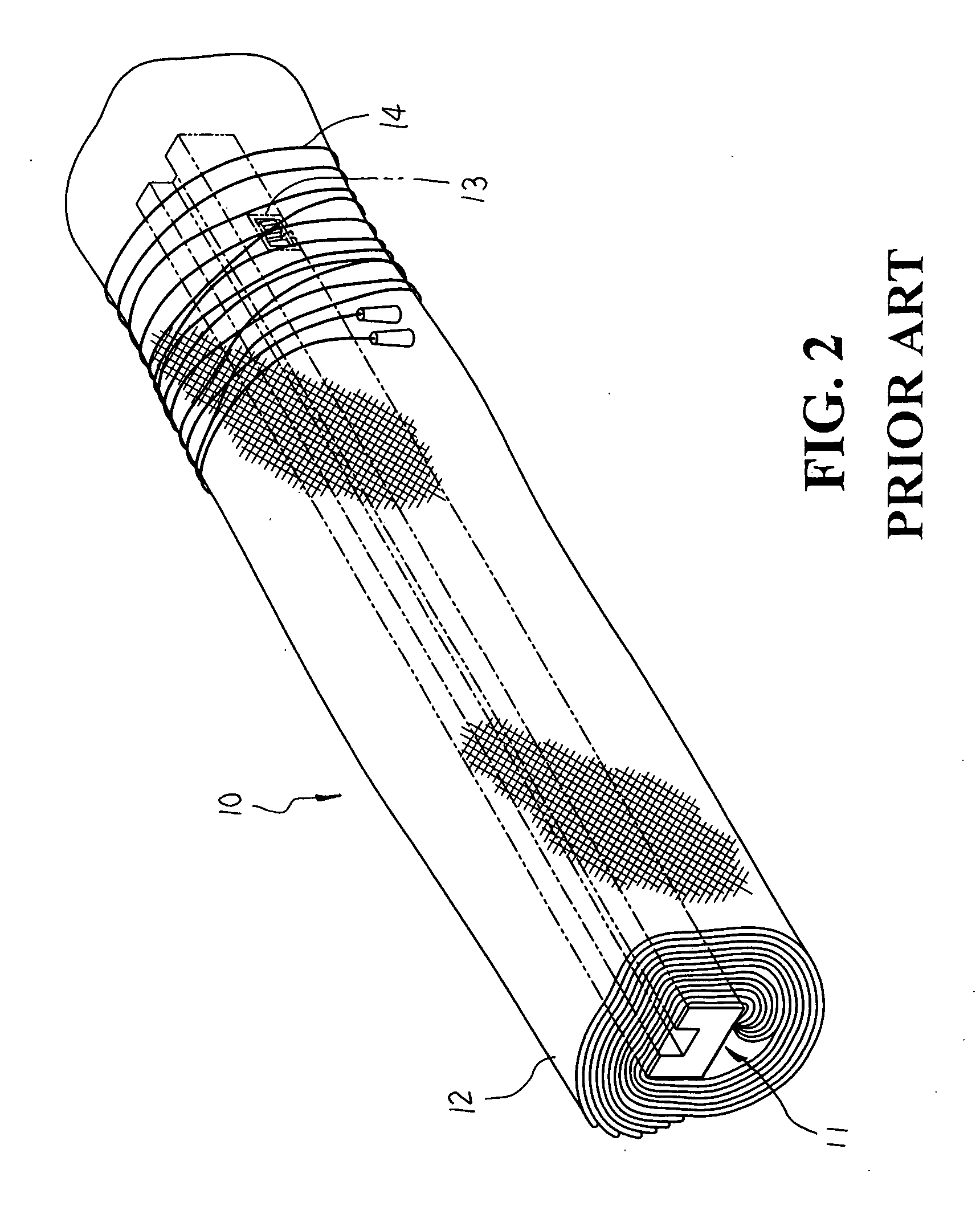

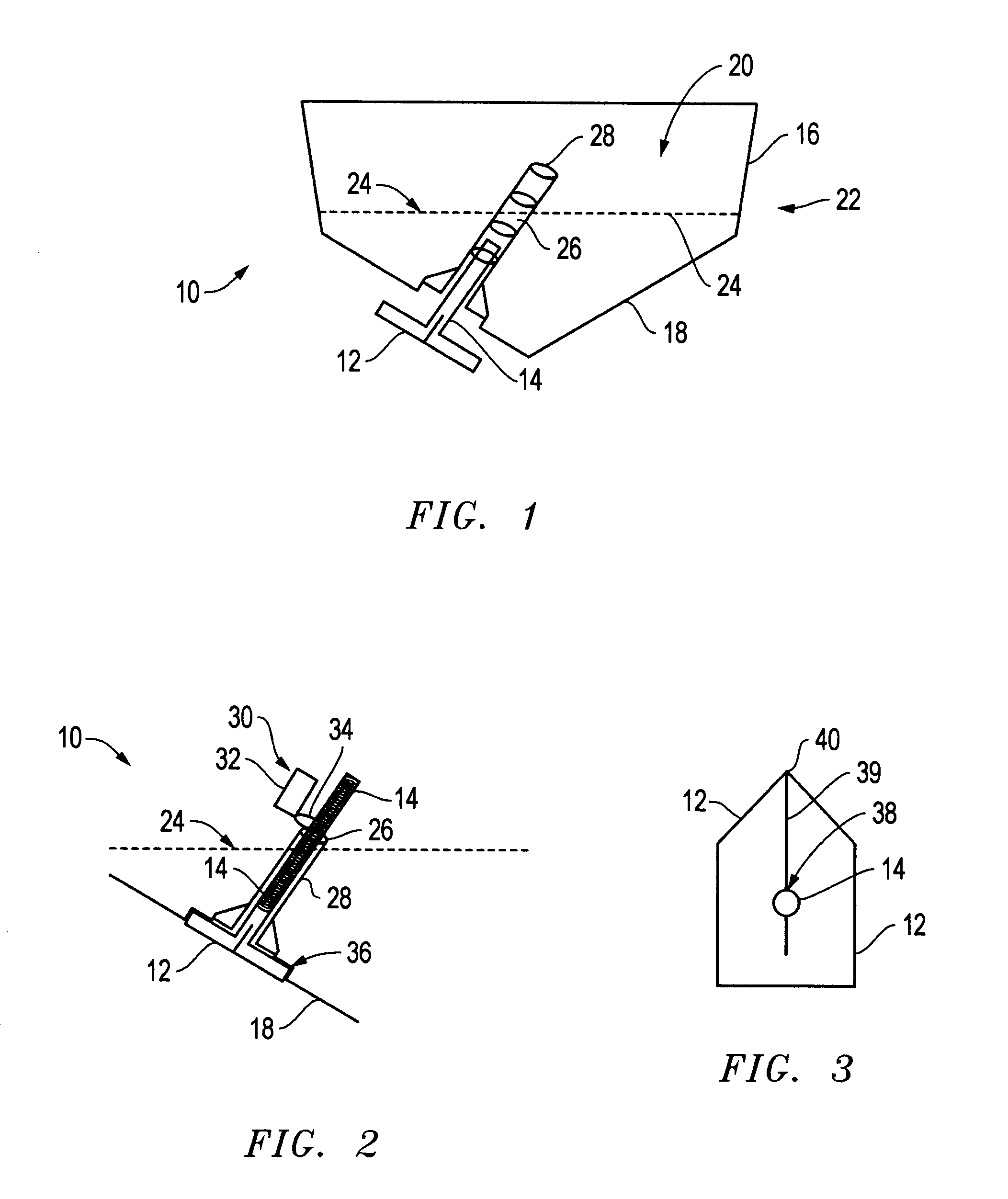

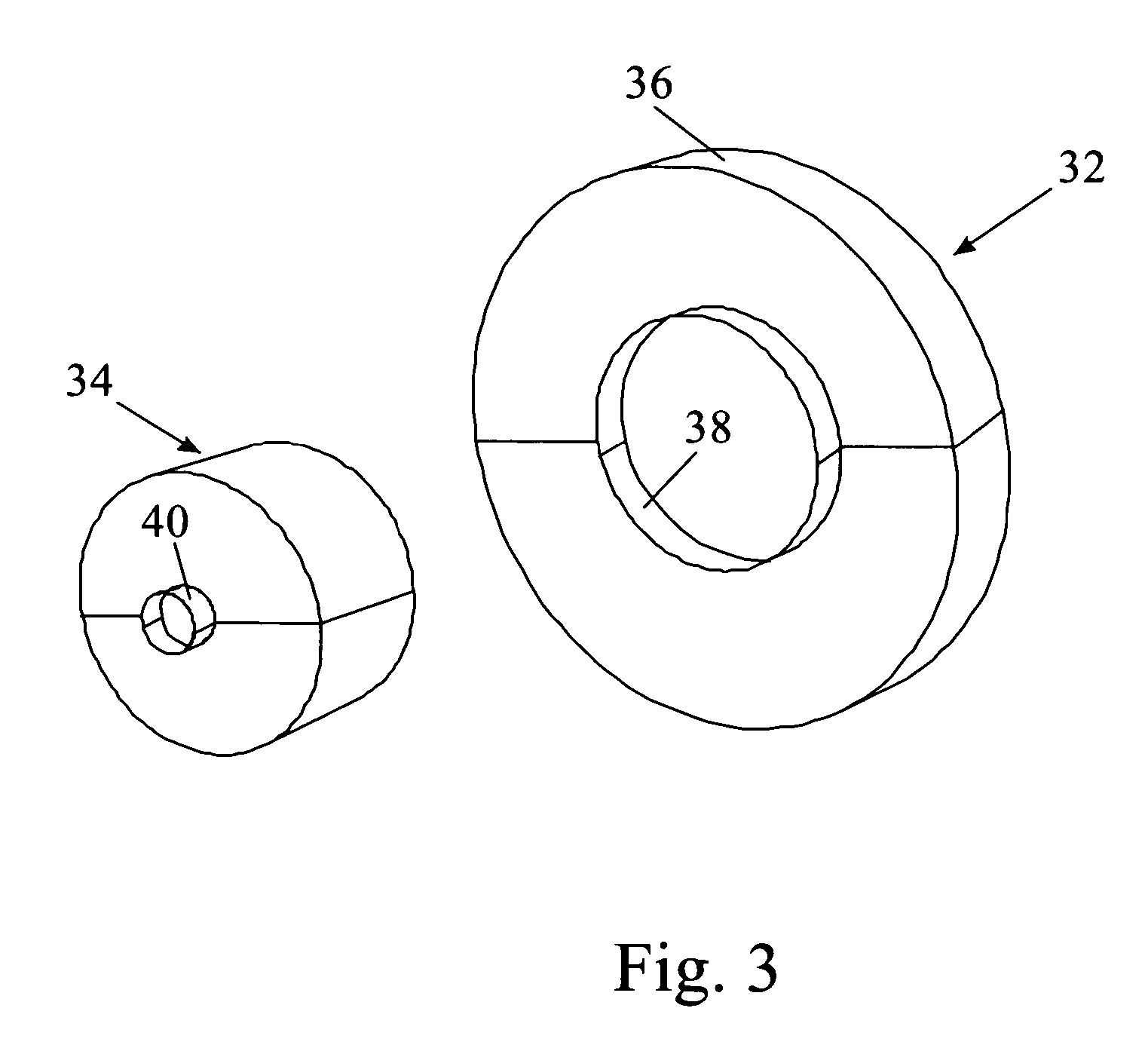

Methods and devices for automated biopsy and collection of soft tissue

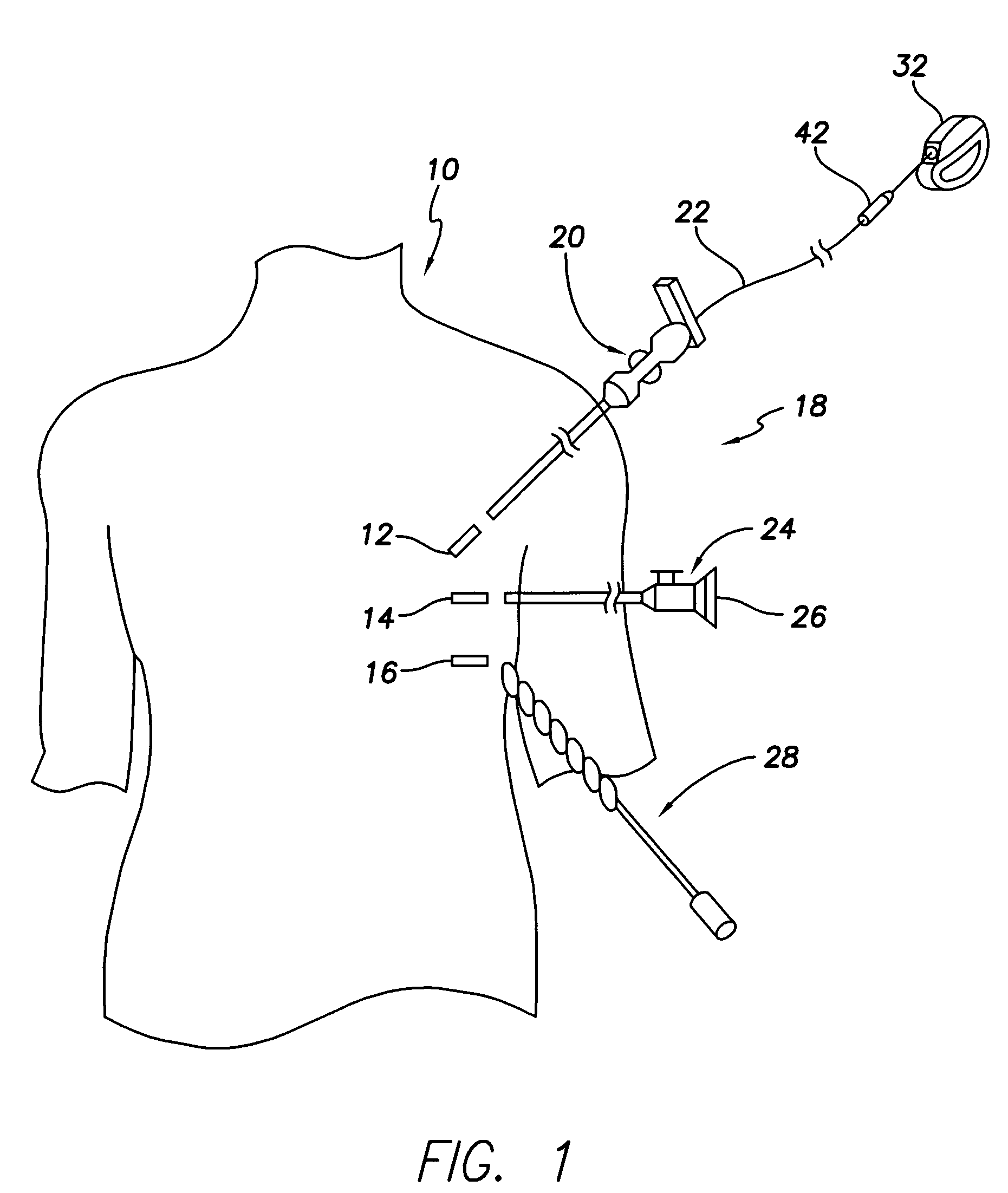

InactiveUS7226424B2Improved and more operationEasy and inexpensive to fabricateUltrasonic/sonic/infrasonic diagnosticsSurgical needlesSingle-Use DeviceMultiple use

Instruments for performing percutaneous biopsy procedures are disclosed, which have advantageous features for improving functionality and performance over prior art devices. These instruments comprise two types, single-use devices, and multiple-use devices having active tissue capture capability. Improved features include the ability to retrieve and evaluate multiple tissue samples during a single insertion procedure, without physical handling of the samples, as well as constructional features, such as a molded tissue cassette housing, variant vacuum port embodiments suited for different tissue environments, and a method for backflushing the instrument to remove biological debris, among others.

Owner:DEVICOR MEDICAL PROD

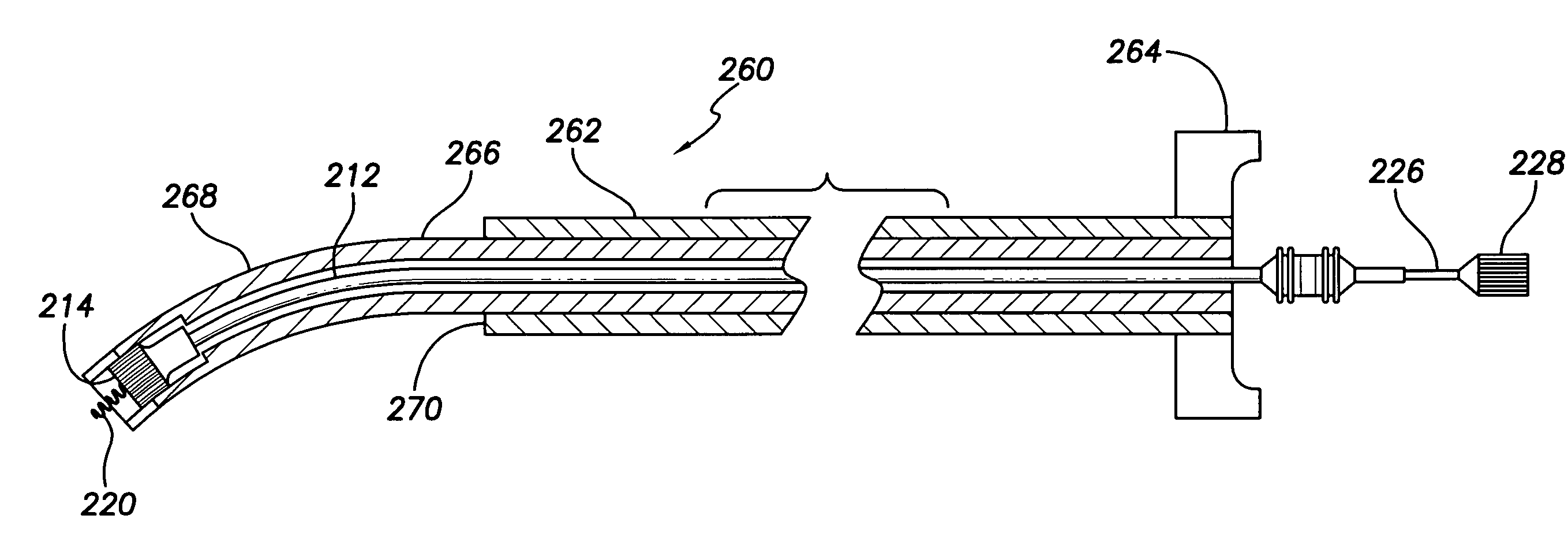

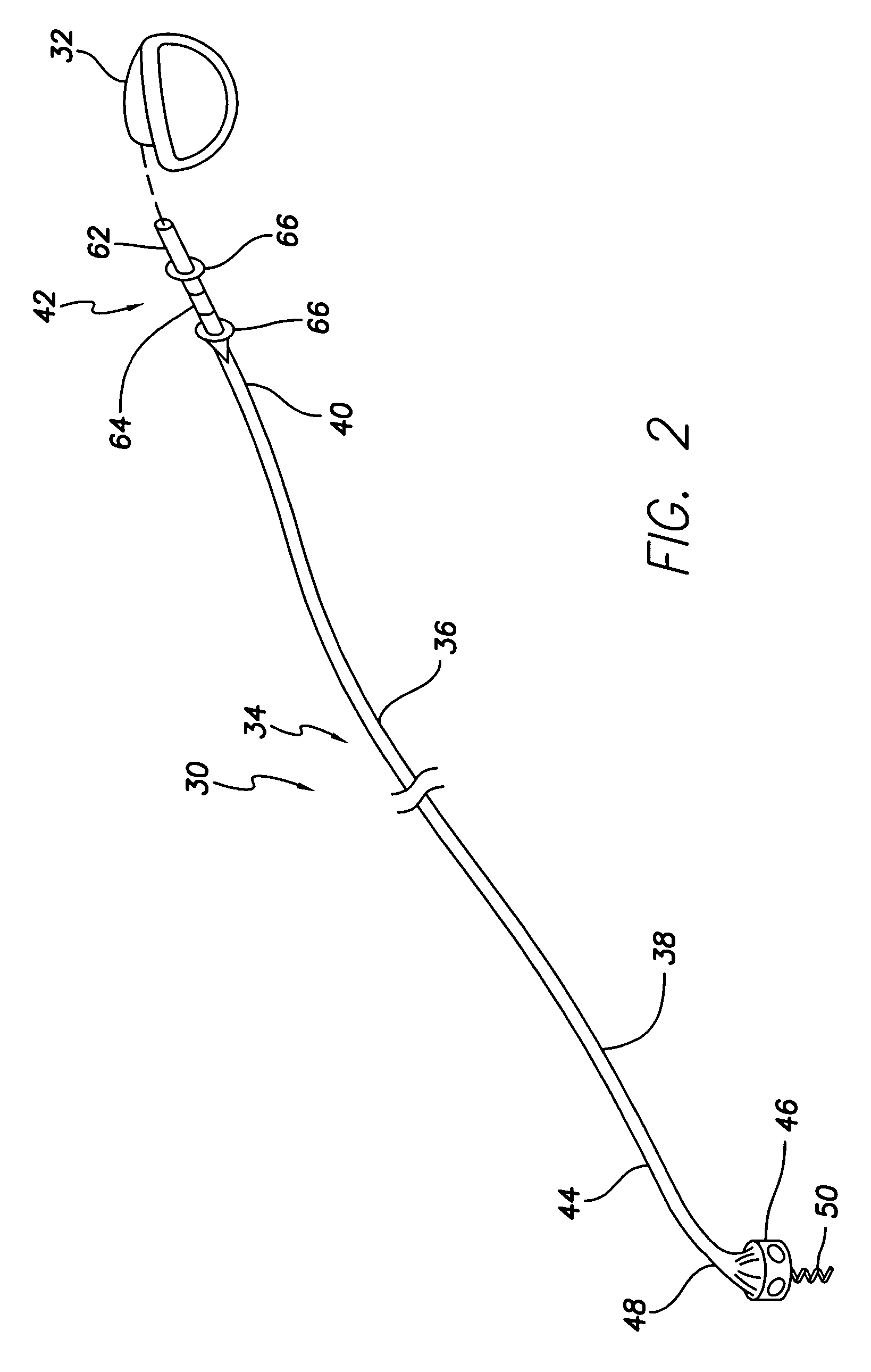

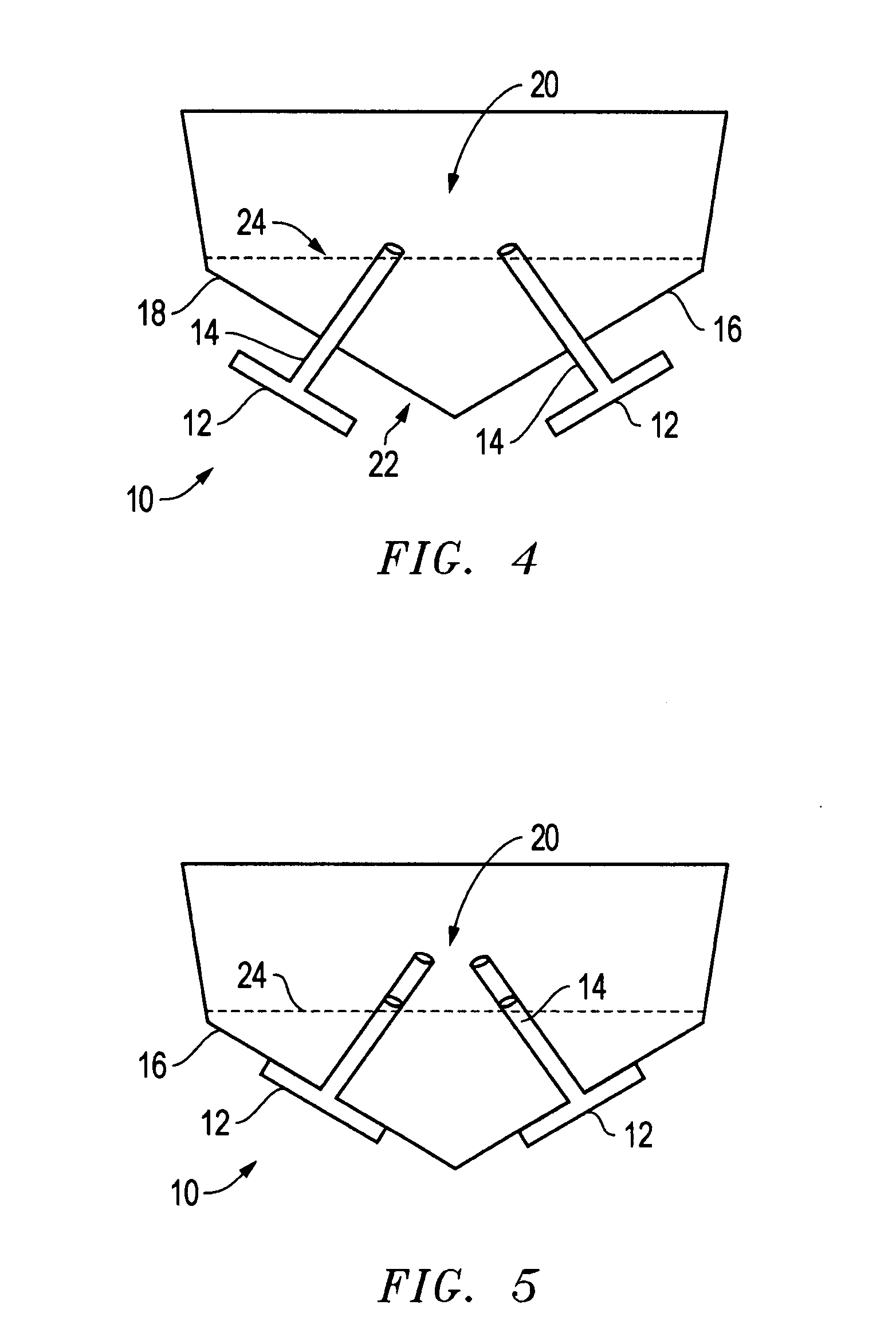

Myocardial lead and lead system

ActiveUS7369901B1Minimizes junctionAvoid packagingEpicardial electrodesHeart stimulatorsCardiac muscleLead system

An implantable myocardial stimulation lead comprises a lead body having a distal end and a proximal end, and an electrical connector carried by the proximal end of the lead body. An electrode header carried by the distal end of the lead body has an axis and includes a helical fixation element extending along the axis, the electrode header having a surface configured to receive a driver for rotating the electrode header to screw the helical fixation element into the tissue of the heart. The lead body carries along its length a strain relief member resisting excessive bending of the lead body.

Owner:PACESETTER INC

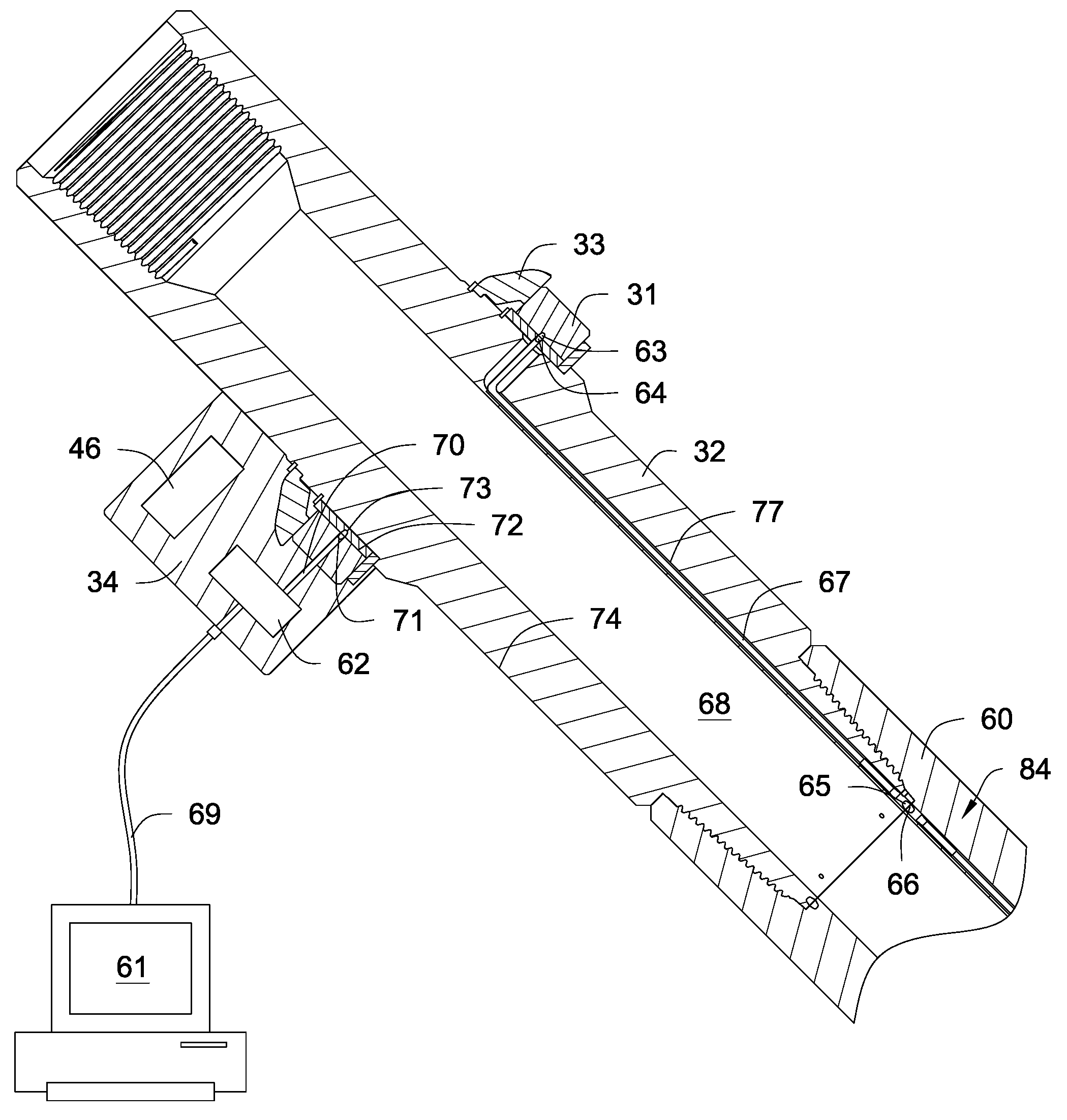

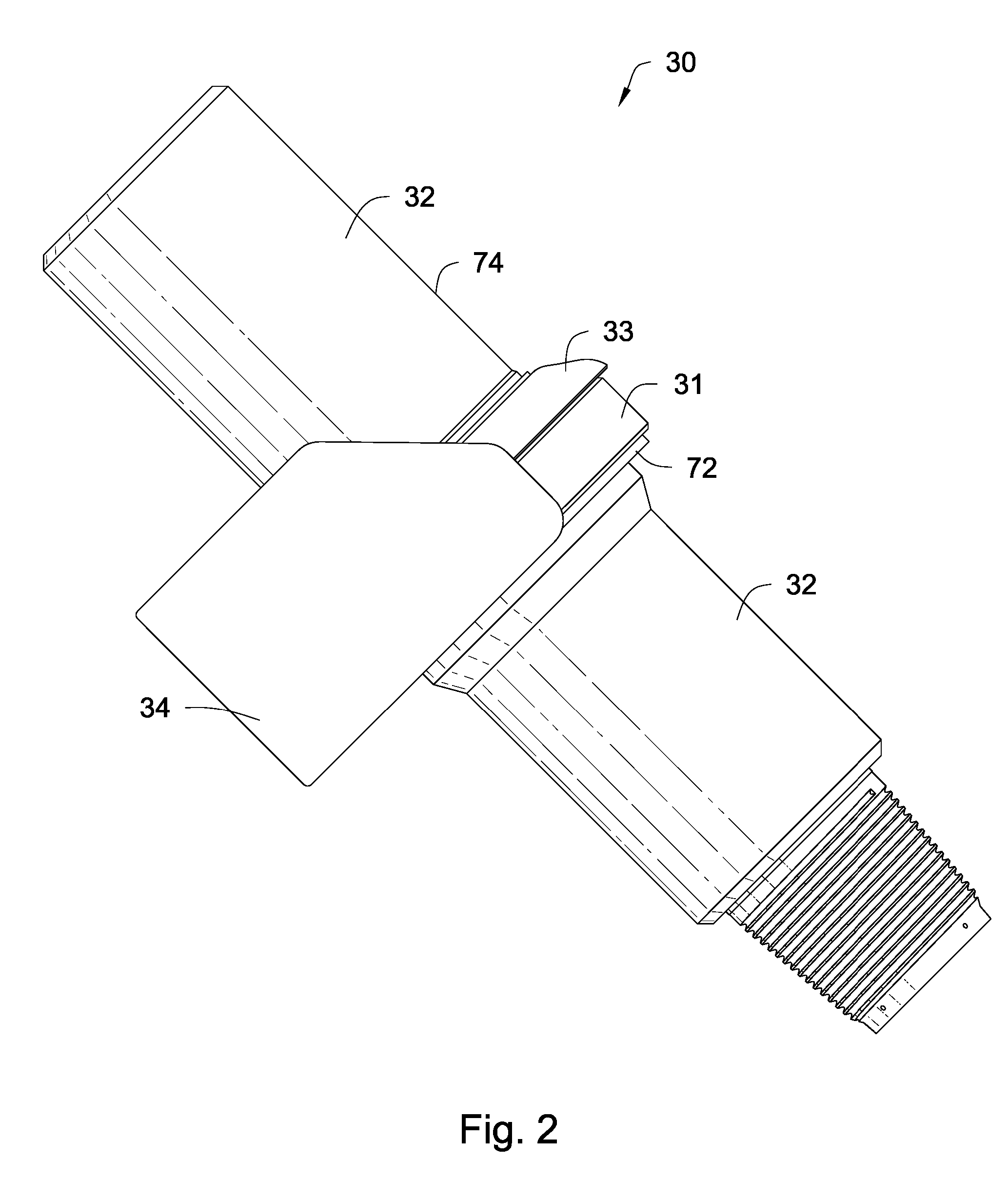

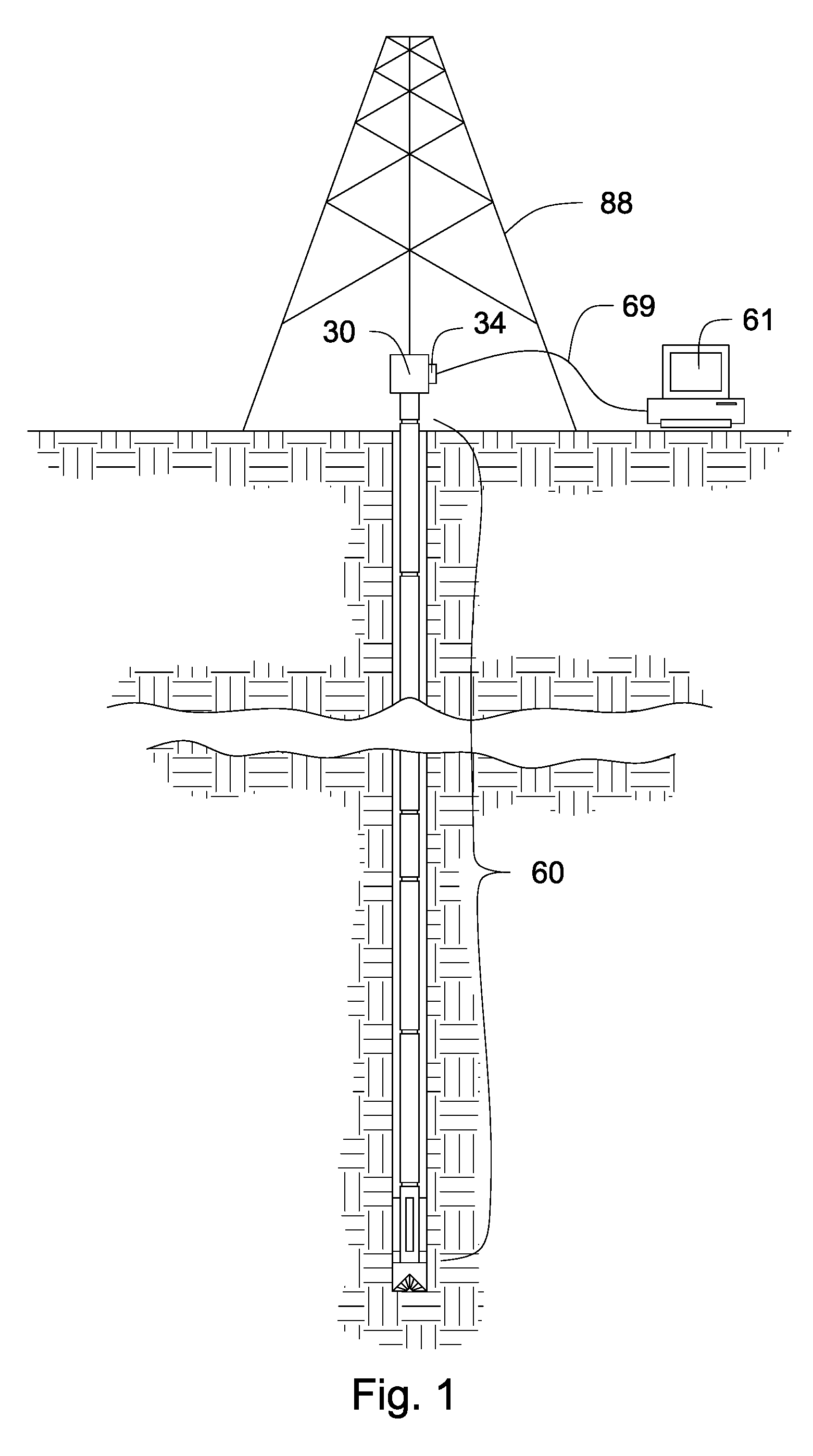

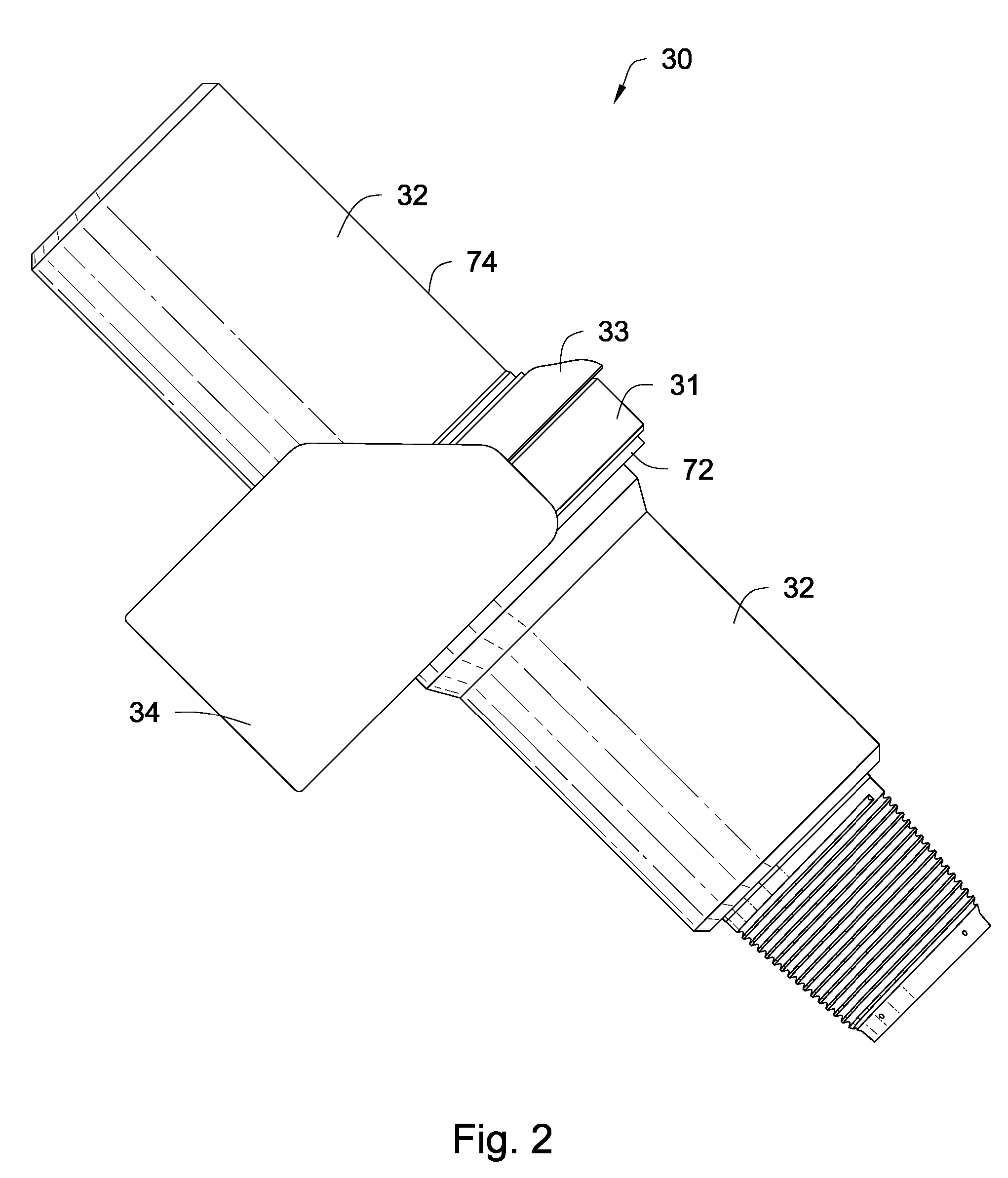

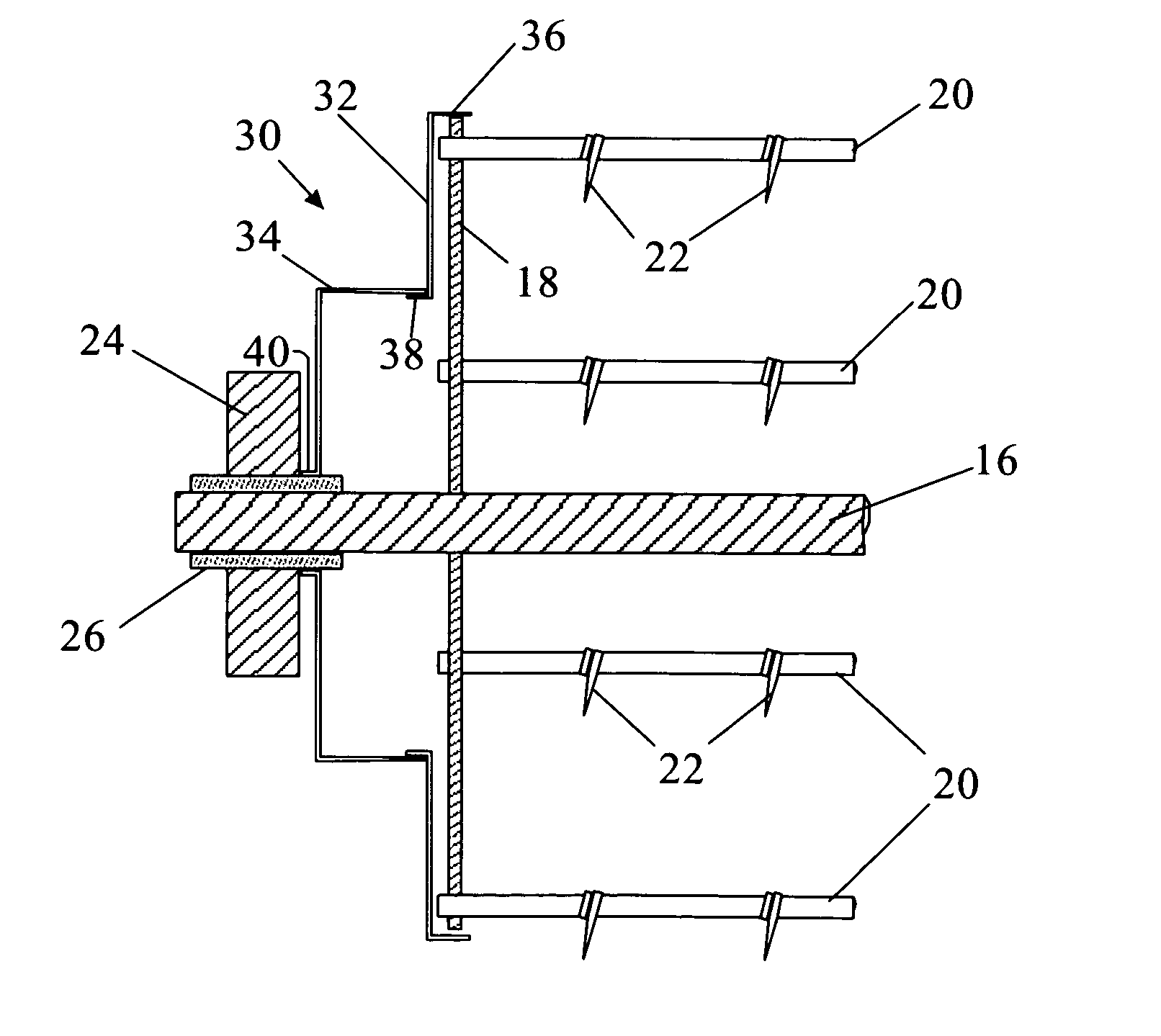

Swivel Assembly

ActiveUS20050046586A1Avoid packagingElectric/magnetic detectionConnectionsSoftware engineeringNetwork communication

A swivel assembly for a downhole tool string comprises a first and second coaxial housing cooperatively arranged. The first housing comprises a first transmission element in communication with surface equipment. The second housing comprises a second transmission element in communication with the first transmission element. The second housing further comprises a third transmission element adapted for communication with a network integrated into the downhole tool string. The second housing may be rotational and adapted to transmit a signal between the downhole network and the first housing. Electronic circuitry is in communication with at least one of the transmission elements. The electronic circuitry may be externally mounted to the first or second housing. Further, the electronic circuitry may be internally mounted in the second housing. The electronic circuitry may be disposed in a recess in either first or second housing of the swivel.

Owner:INTELLISERV

Methods and devices for automated biopsy and collection of soft tissue

InactiveUS20060167377A1Easy and inexpensive to fabricateImproved and more operationUltrasonic/sonic/infrasonic diagnosticsSurgical needlesSingle-Use DeviceInstrumentation

Instruments for performing percutaneous biopsy procedures are disclosed, which have advantageous features for improving functionality and performance over prior art devices. These instruments comprise two types, single-use devices, and multiple-use devices having active tissue capture capability. Improved features include the ability to retrieve and evaluate multiple tissue samples during a single insertion procedure, without physical handling of the samples, as well as constructional features, such as a molded tissue cassette housing, variant vacuum port embodiments suited for different tissue environments, and a method for backflushing the instrument to remove biological debris, among others.

Owner:DEVICOR MEDICAL PROD

Swivel assembly

Owner:INTELLISERV LLC

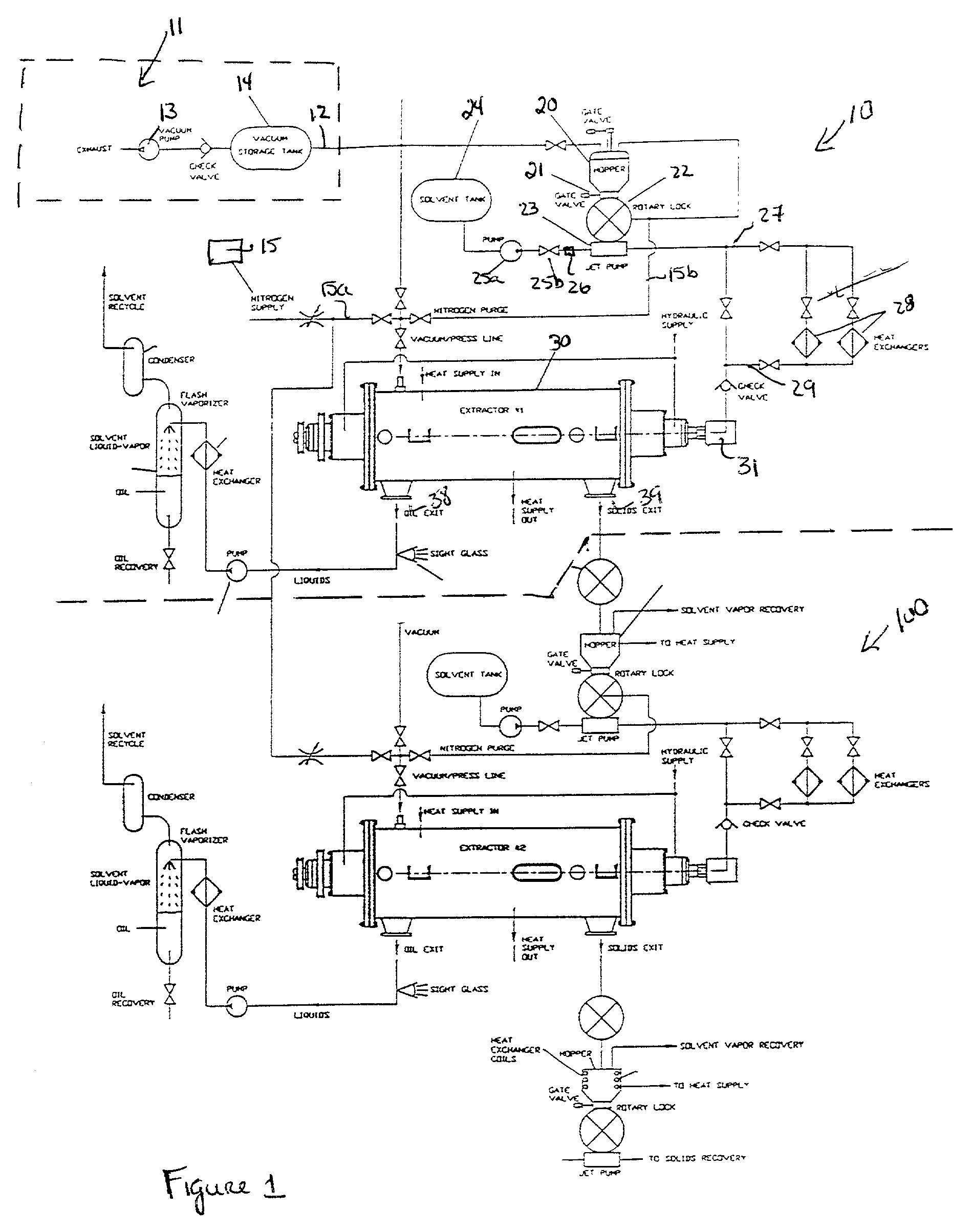

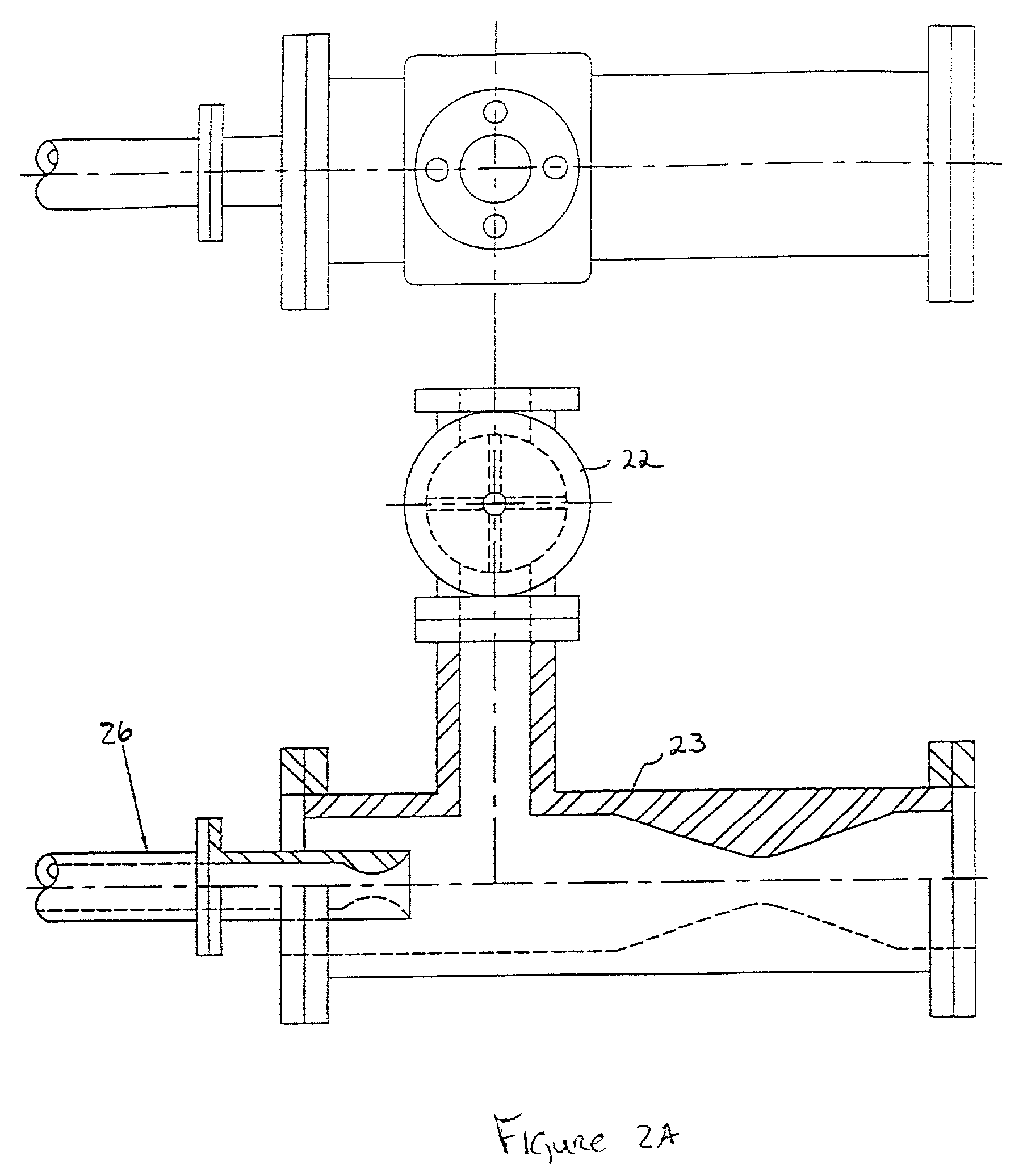

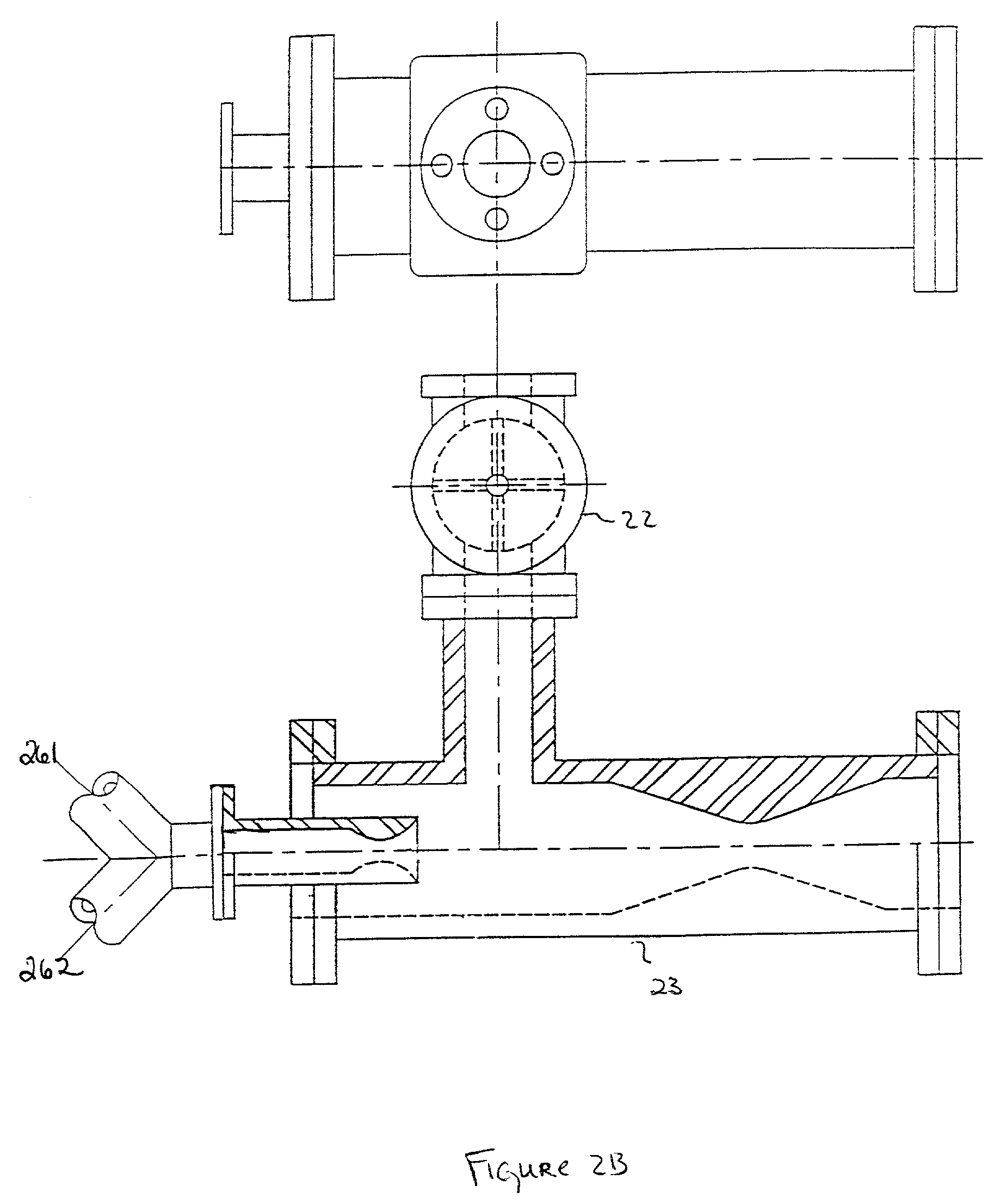

Process and system for continuously extracting oil from solid or liquid oil bearing material

InactiveUS7008528B2Eliminating formationEasy to optimizeRefining with acid-containing liquidsLiquid hydrocarbon mixture productionSufficient timeLiquid state

A process for continuously extracting oil from a solid or liquid oil-bearing material comprises (a) removing air from the extraction system, (b) introducing an inert gas into the extraction system at a pressure sufficient to maintain a normally gaseous solvent in liquid state, (c) introducing an oil-bearing material into a silo, (d) passing the oil-bearing material from the to a jet pump mixing device, (e) introducing a liquified normally gaseous solvent into the jet pump mixing device, (f) mixing the oil-bearing material and the solvent in the jet pump mixing device for a time sufficient to permit complete wetting of oil-bearing material by the solvent to form a mixture, (g) heating the mixture to near supercritical conditions; (h) passing the mixture through an extractor having a screw conveyor adapted to rotate at a first rpm range and a centrifugal drum adapted to rotate at a second rpm range, (i) treating the mixture within the extractor in such a manner that supercritical temperature and pressure are attained, wherein treating the mixture includes a combination of increasing the rpms of the centrifugal drum, increasing the temperature inside the extractor and increasing the inert gas pressure inside the extractor, (j) extracting oil from the mixture by pressure diffusion provided by the combination of increased rpms, increased temperatures and increased inert gas pressures at supercritical conditions, (j) removing liquids extracted from the mixture through a liquids exit port, and (k) removing solids extracted from the mixture through a solids exit port.

Owner:MITCHELL ALLEN R +1

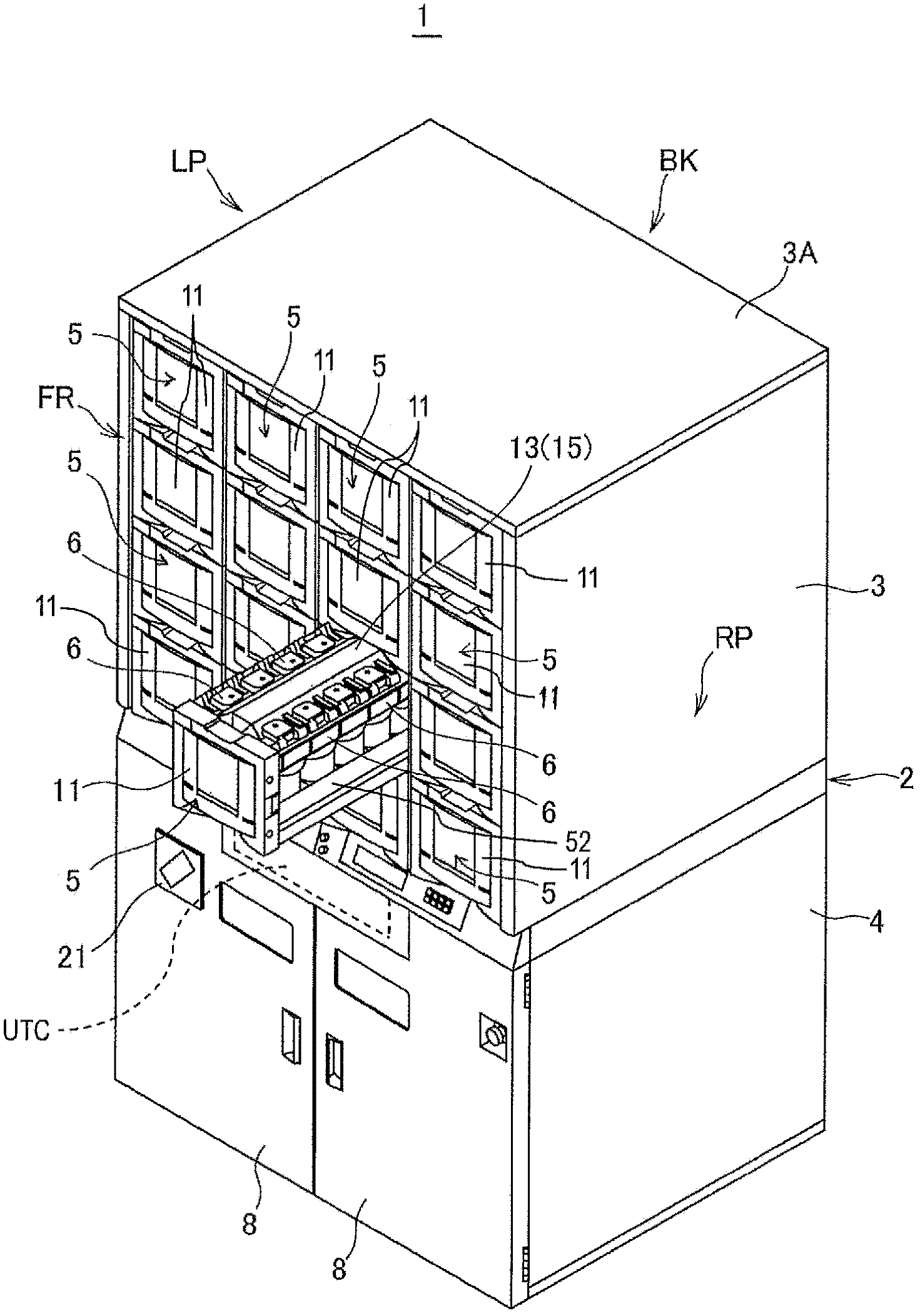

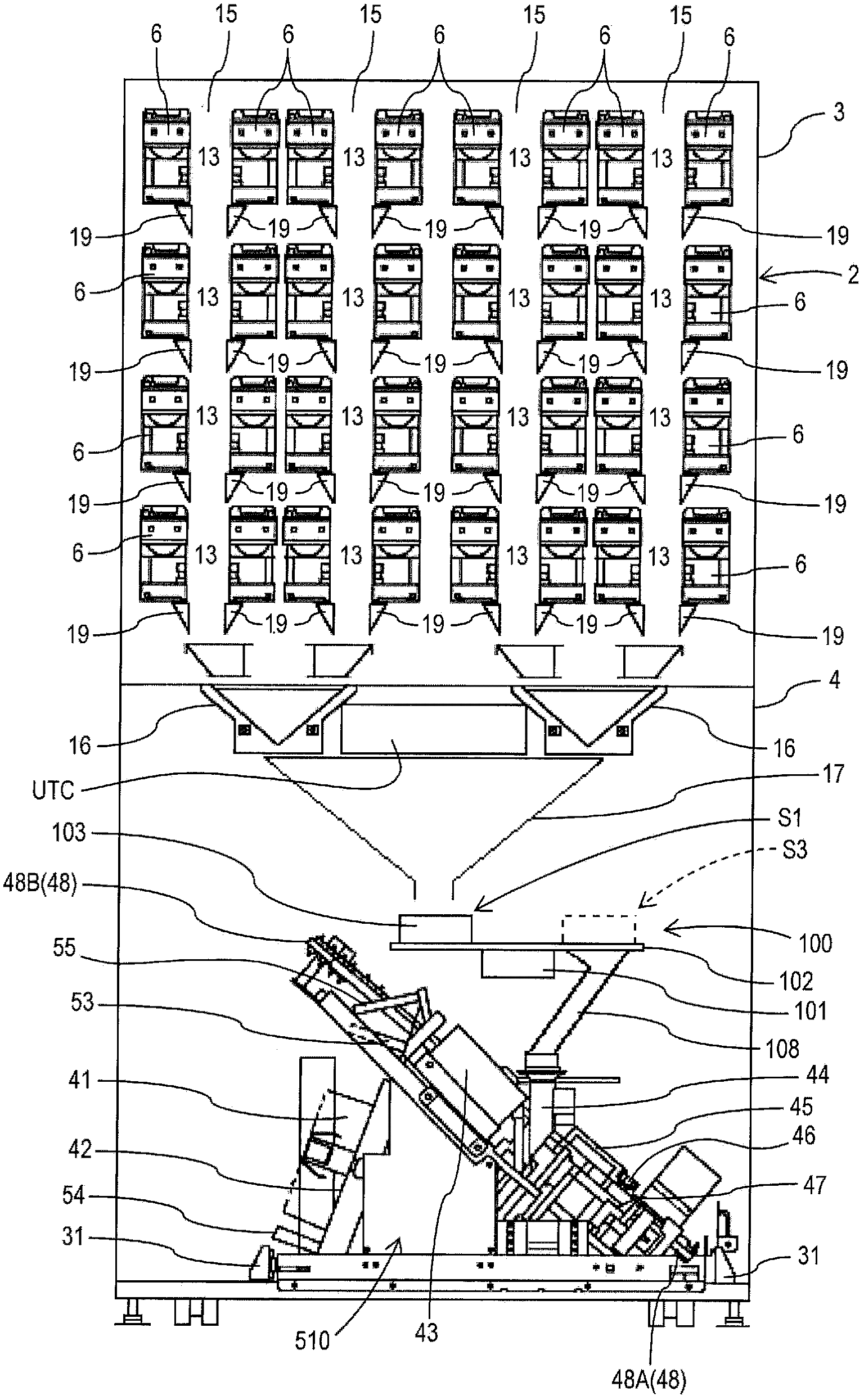

Drug supply device, and drug inspection method in drug supply device

InactiveCN104066415AIncrease supplyShort action timeDrug and medicationsMaterial analysis by optical meansDrug supplyPrescription data

The invention provides a drug supply device and a drug inspection method in the drug supply device. The drug supply device provided with: a hopper that collects solid drugs discharged from a tablet case based on specified prescription data; an inspection device that inspects the solid drugs introduced from said hopper; and a packaging device that fills and packages the inspected solid drugs in a wrapping sheet. The inspection device is provided with: an inspection container that holds the solid drugs discharged from the hopper in single doses; a movement mechanism for moving the inspection container; and an imaging device for imaging the solid drugs inside the inspection container. When, as a result of imaging and inspecting the solid drugs using the imaging device, the number of solid drugs inside the inspection container differs from the prescription data, said solid drugs are discarded. When the number of solid drugs matches the prescription data, the solid drugs are packaged by the packaging device.

Owner:PHC HLDG CORP

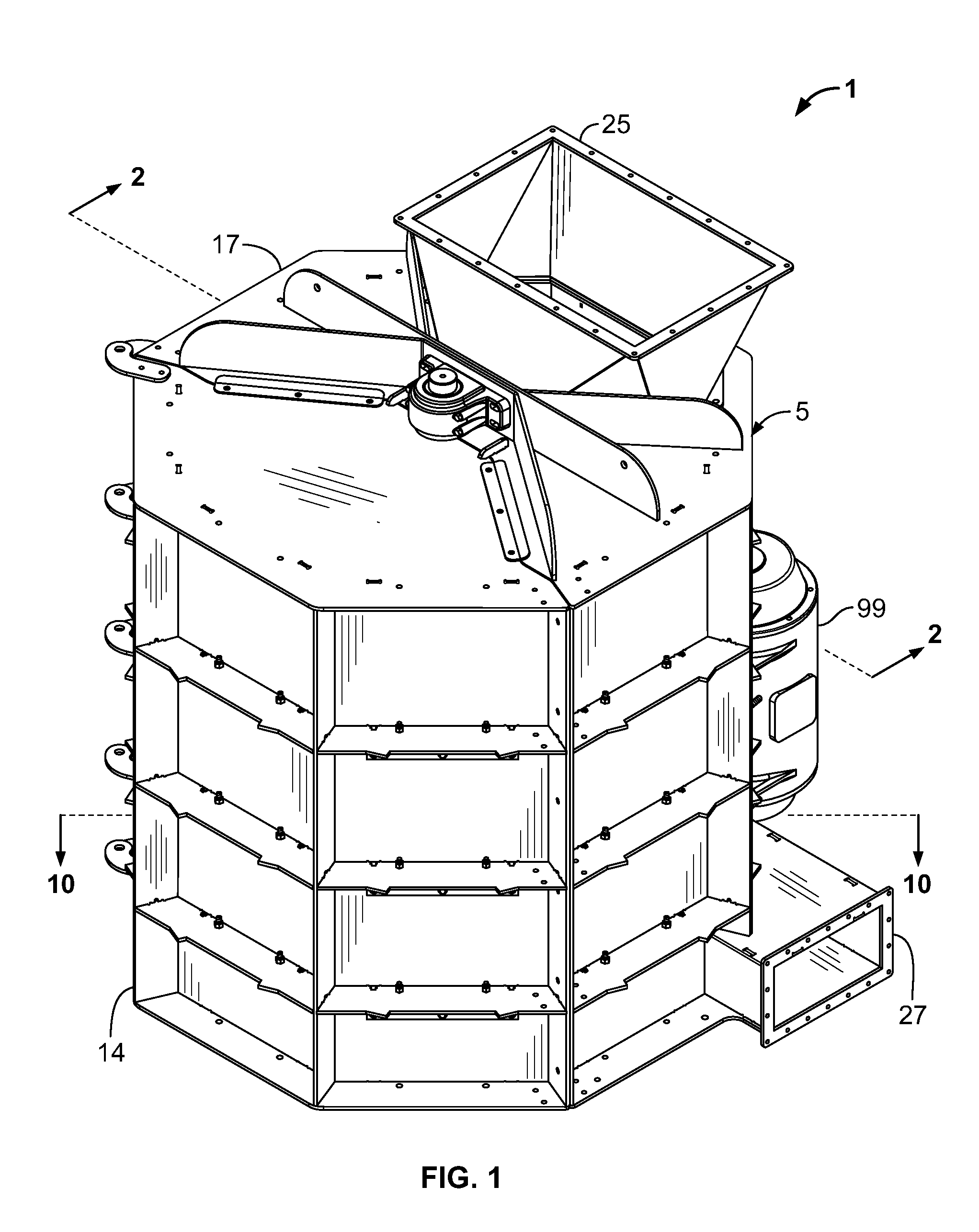

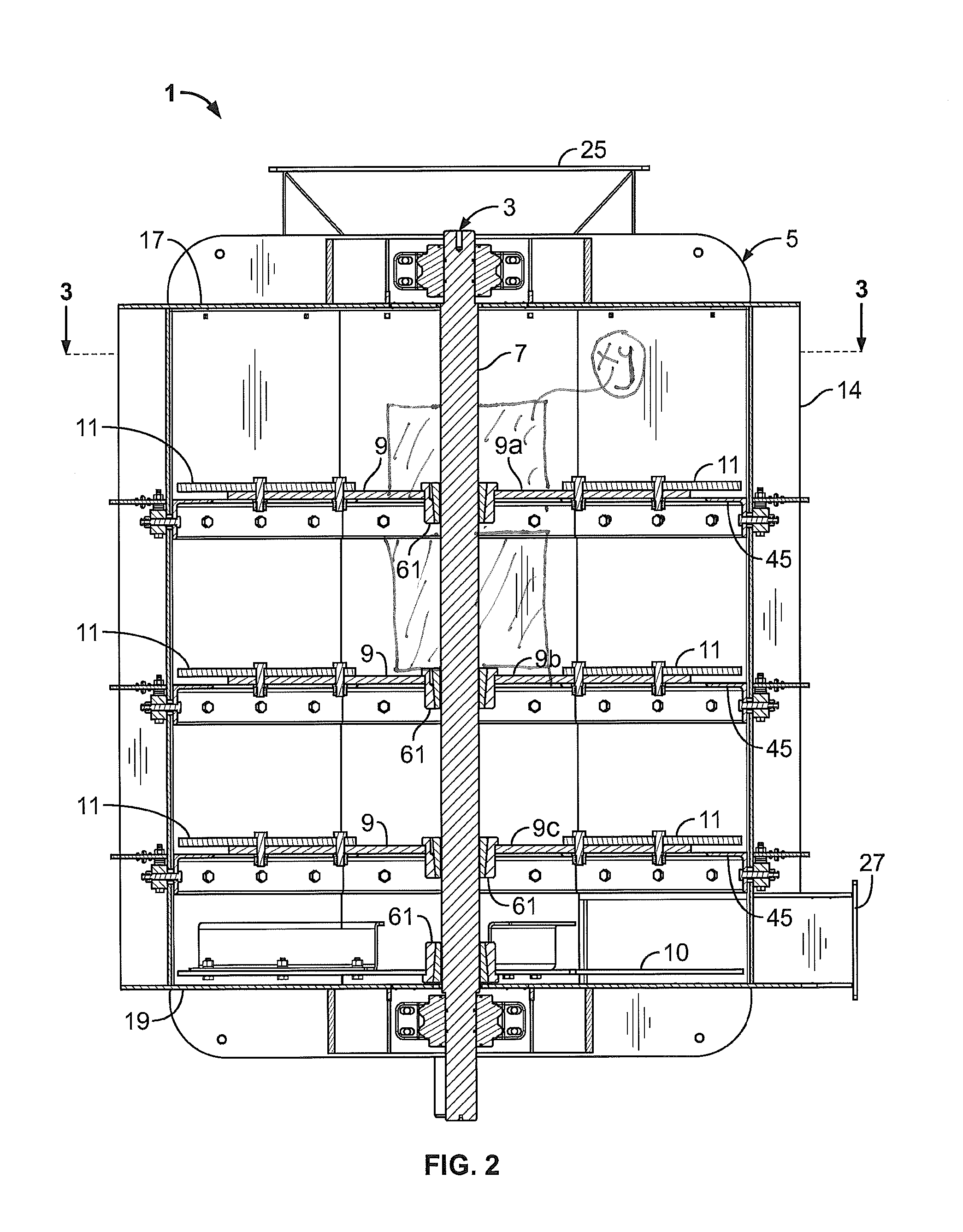

Apparatus and process for demanufacturing materials from composite manufactures

A process for separating carpet fibers from carpet backing uses a grinder of the type having a rotor with a plurality of vertically spaced cutter discs and a fan disc below the cutter discs. Sections of carpet are fed into the grinder which grinds the carpet, separating the fibers from the backing and breaking the backing into relatively small particles. The grinder is connected with a series of ginning equipment for removing the ground backing from the fibers.

Owner:ENERGY CREATES ENERGY LLC

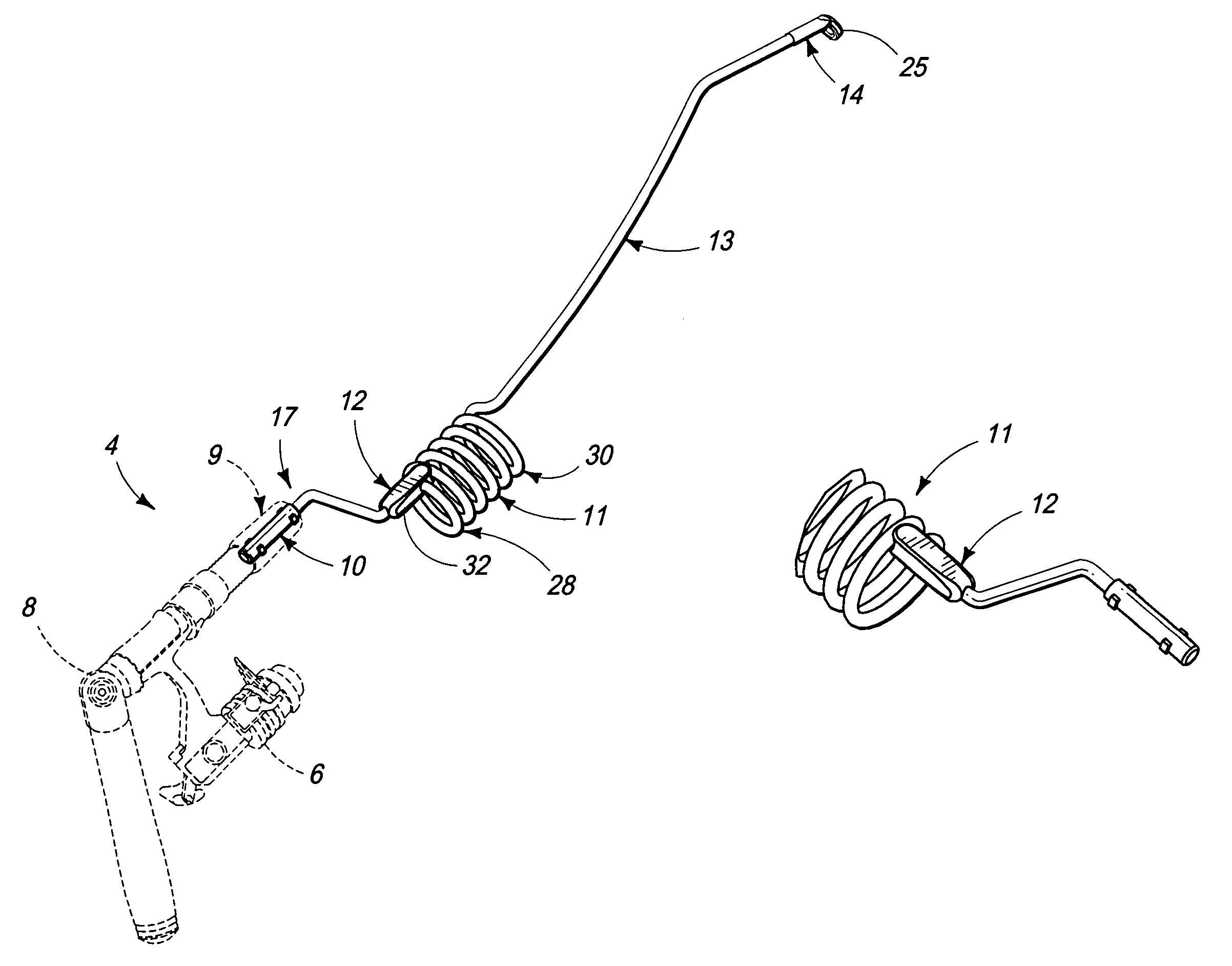

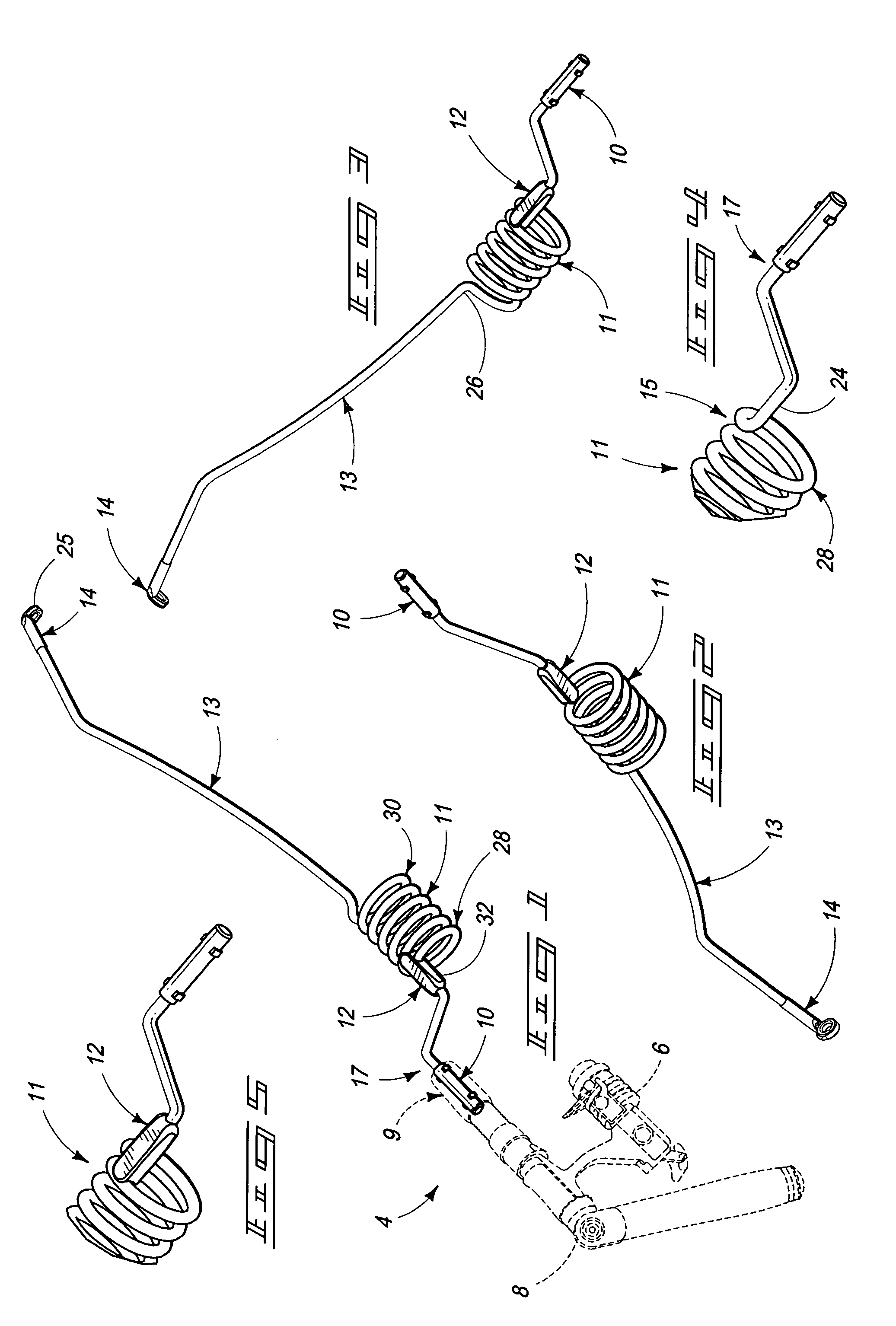

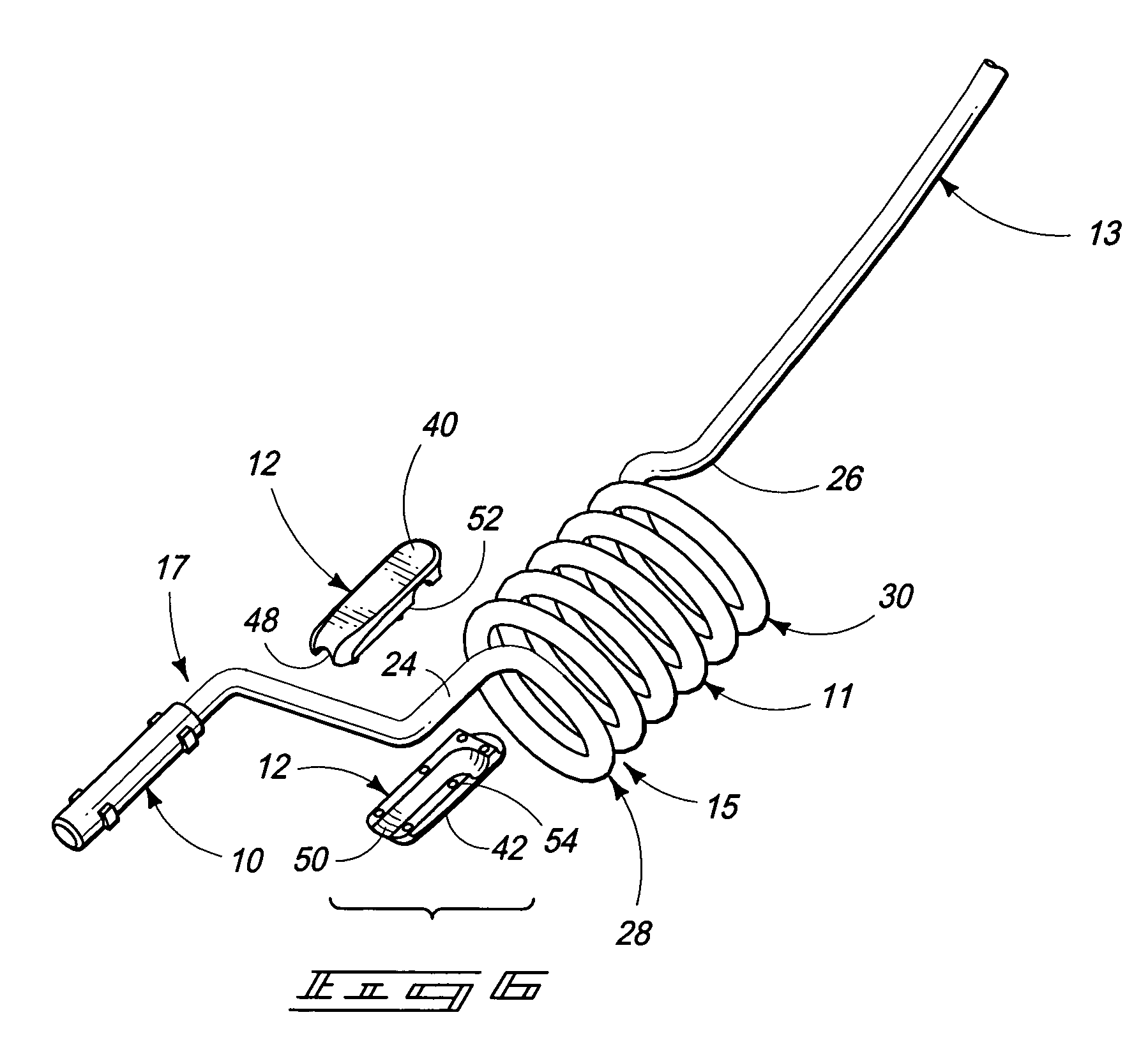

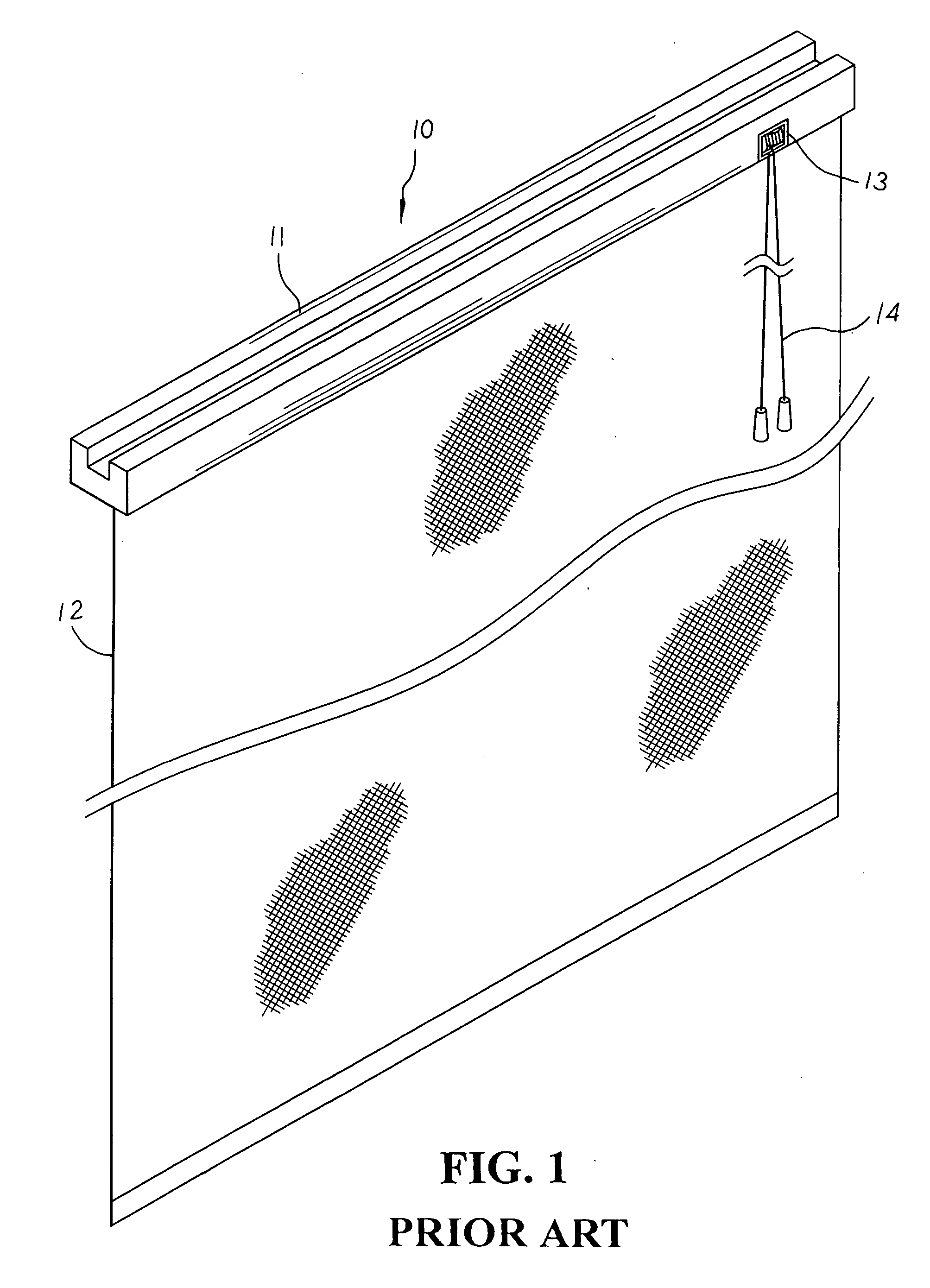

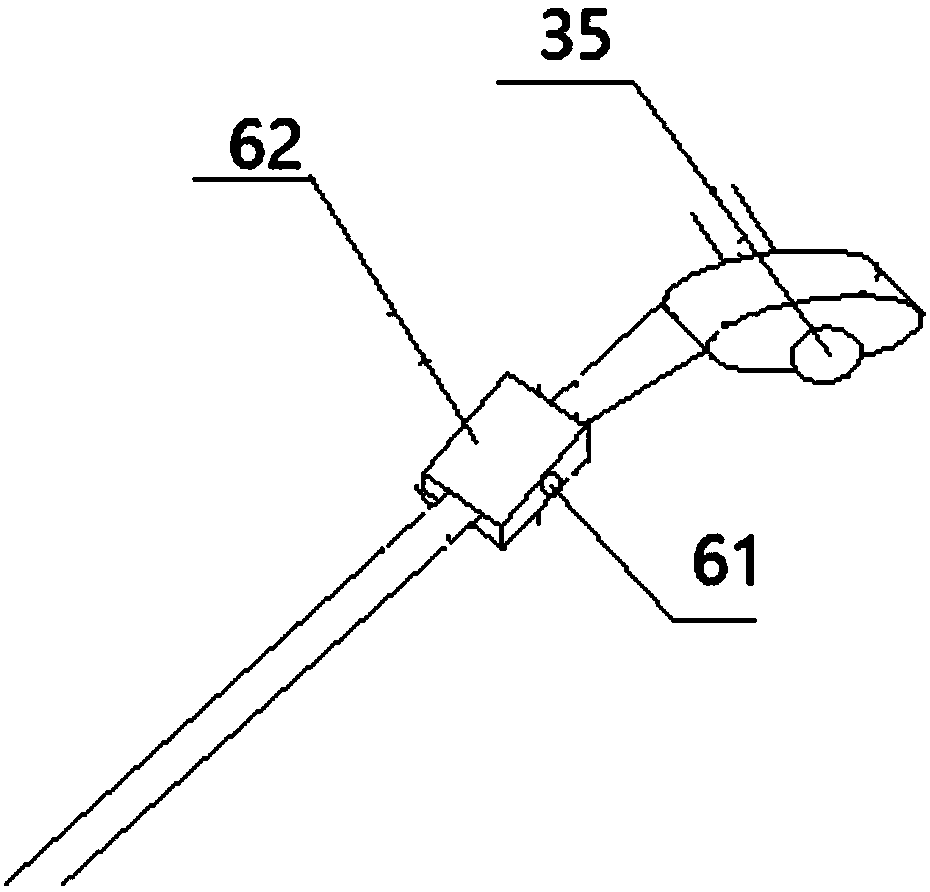

Fishing pole, anti-wrap line guide for a fishing pole, and fishing rod

A fishing pole is provided with a handle, a rod, and a closing segment. The rod has a base, a tip end, and a coil spring provided between the base and the tip end. The coil spring is configured to receive and guide a fishing line. The rod is supported by the handle at the base, and the coil spring has a proximal end winding and a distal end winding. The closing segment is provided on one of the proximal end winding and the distal end winding to close the one of the proximal end winding and the distal end winding to prevent wrapping of the fishing line about the coil.

Owner:EMMROD FISHING GEAR INC

Weed trimmer safety guard

InactiveUS6892461B2Improve cutting performanceAvoid packagingLawn-mowersMetal working apparatusEngineeringMechanical engineering

The present invention provides for an article and method for an improved weed trimmer cover that prevents unwanted projectile and debris distributions. A preferred embodiment of the weed trimmer comprises a domed guard structure that encompasses the effective cutting range of a prior art weed trimmer. Alternative embodiments may comprise elements that protect only portions of front, side and rear cutting areas. Embodiments of the invention also allow a user to lift up a cover element to allow close work among obstructions. Embodiments of the present invention also improve the performance of prior art weed trimmers by increasing cutting performance and preventing flexible materials from wrapping about the cutting elements and shafts.

Owner:PETERSON MARGARET +1

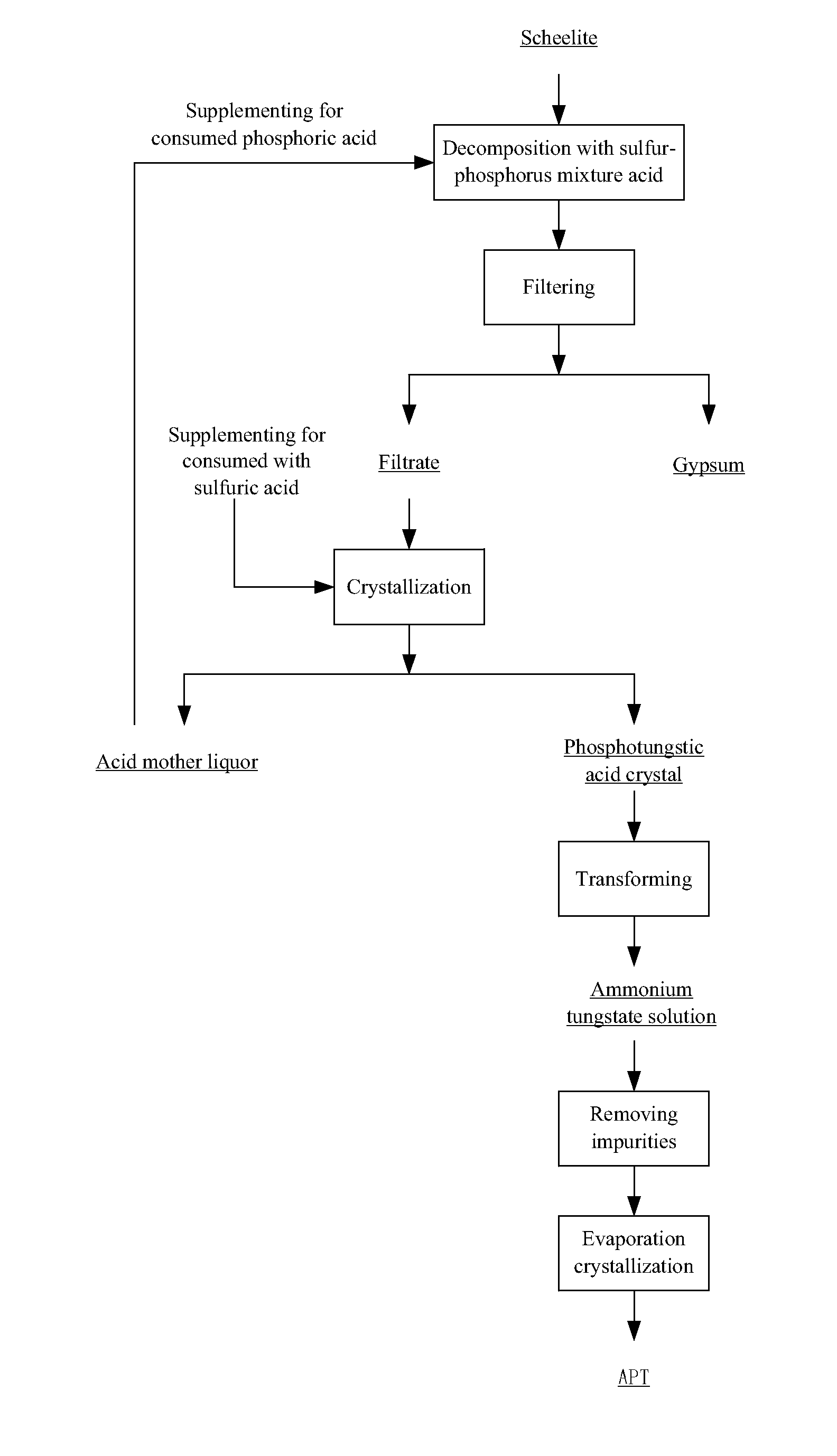

Method for extracting tungsten from scheelite

ActiveUS20130195737A1Increase formation rateAvoid packagingSolvent extractionMolybdeum compoundsDecompositionAmmonium paratungstate

A method for extracting tungsten from scheelite by: 1) adding a mixed acid including H2SO4 and H3PO4 to a decomposition reactor; 2) heating the mixed acid to a temperature of 70-100° C.; adding scheelite while controlling the liquid-solid ratio at about 3:1-8:1 L / kg; allowing the components in the decomposition reactor to react for 1-6 h, and filtering to obtain a filtrate; 3) supplementing the filtrate with sulfuric acid consumed in the reaction; 4) crystallizing the filtrate to obtain phosphotungstic acid crystals and mother liquor; 5) dissolving the phosphotungstic acid crystals in water to obtain phosphotungstic acid solution; 6) transforming the phosphotungstic acid solution into an ammonium tungstate solution for the purpose of preparing ammonium paratungstate; and 7) supplementing the mother liquor with phosphoric acid and water to an initial level and reusing the mother liquor for ore leaching.

Owner:CENT SOUTH UNIV

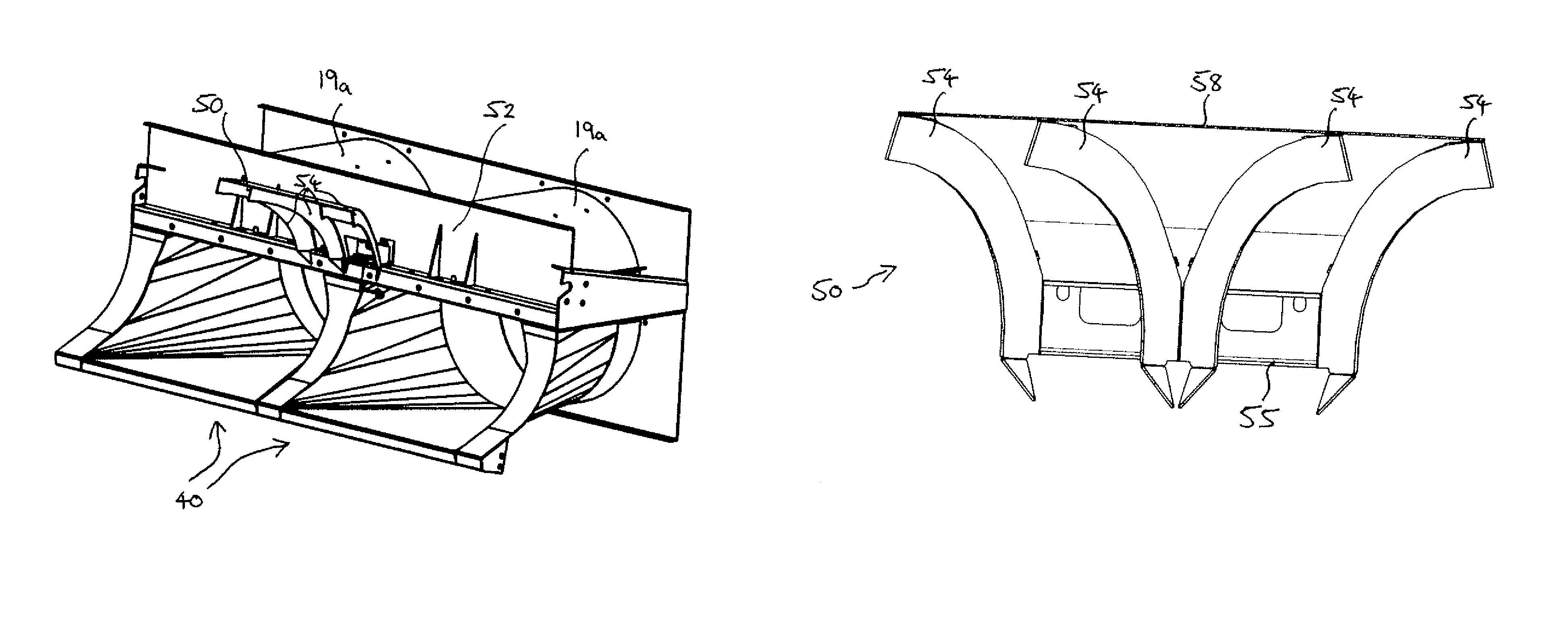

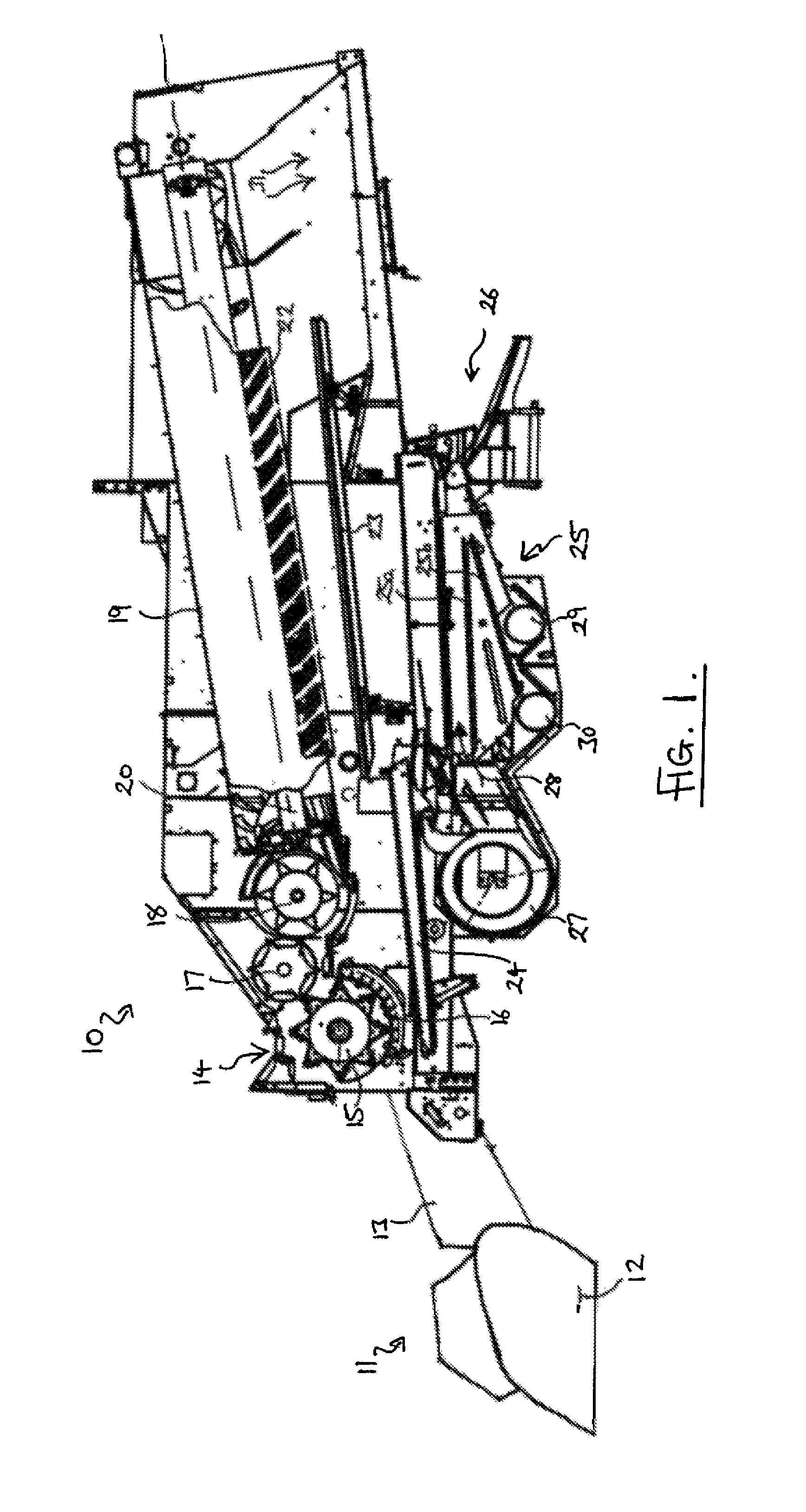

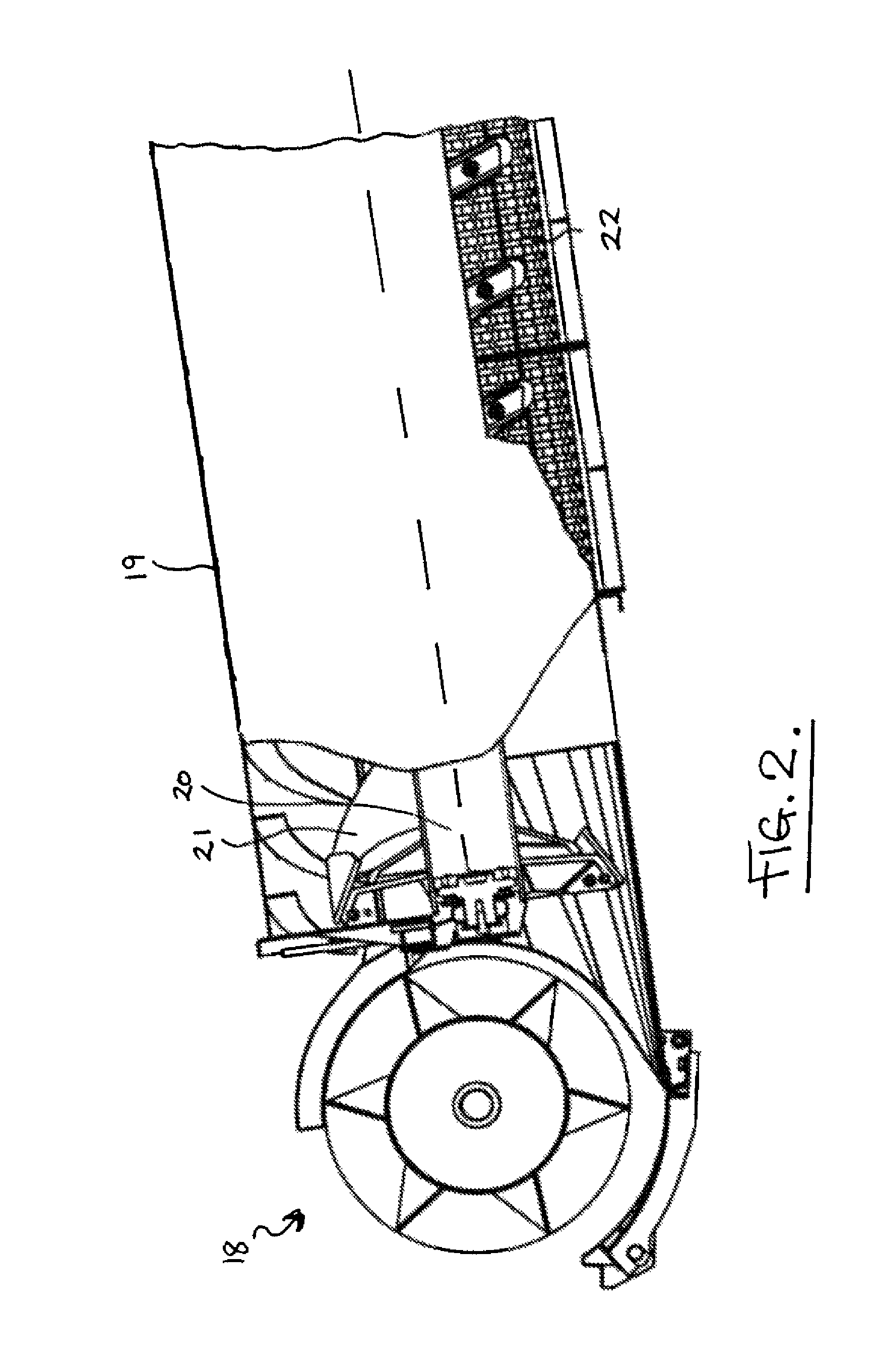

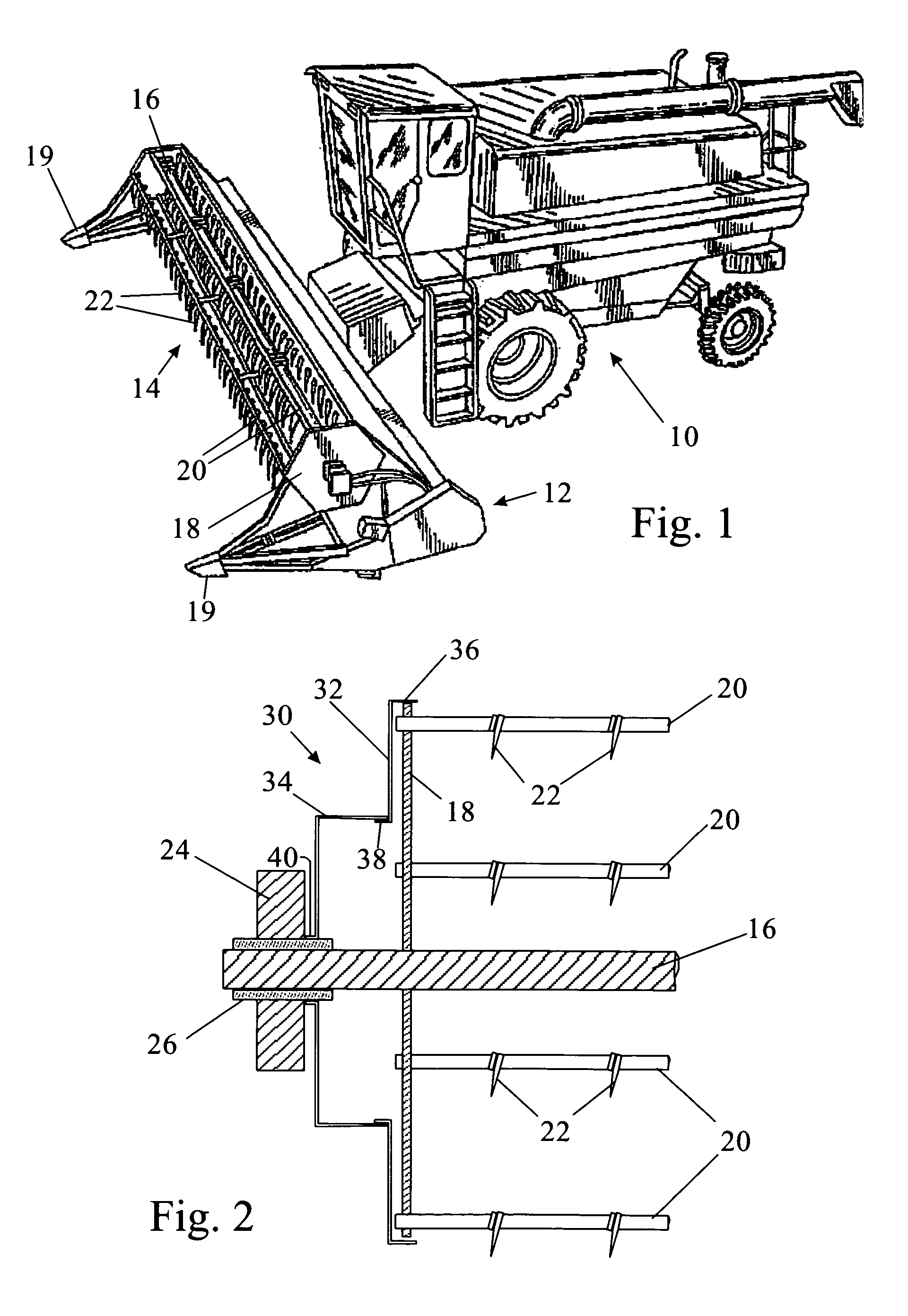

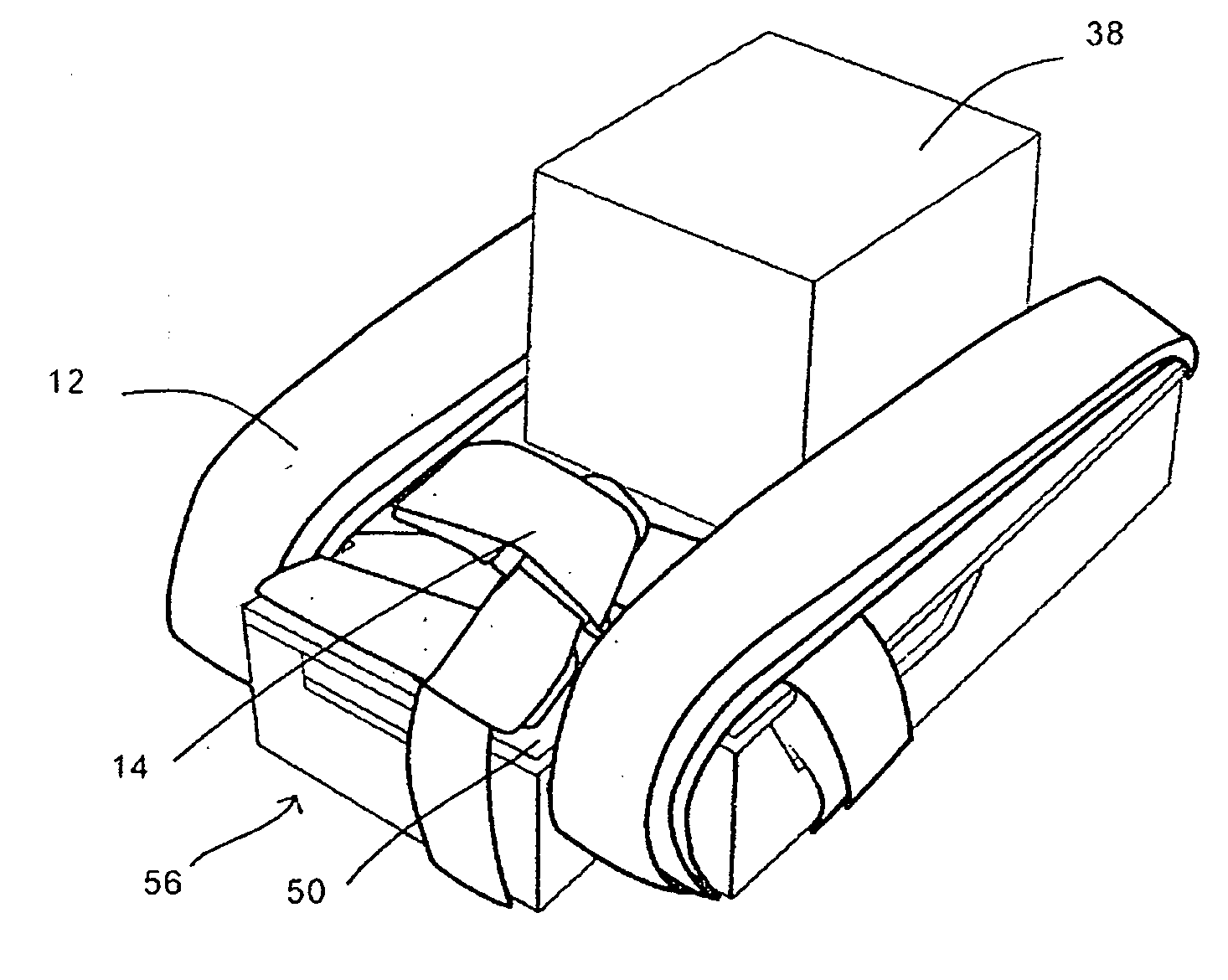

Feed beater directional vanes and scraper vanes

ActiveUS8556690B2Reduce downtimeReduce probabilityGrain huskingGrain polishingTransverse axisEngineering

A combine harvester (10) comprising a pair of axial separating rotors (20) each extending side-by-side within respective housings (19) in a longitudinal direction and serving to separate grain from straw. A feed beater (18) is provided which rotates on a transverse axis (X) and is located in front of the separating rotors to direct a crop flow rearwardly under the feed beater. Directional vanes (34) on the feed beater direct the crop flow away from a central zone of the beater and toward respective crop streams associated with the two rotors. Scraper apparatus (50) comprising stationary vanes (54) are provided above the beater. Crop material which back feeds over the top of the beater is scraped free of the beater and directed outwardly by the stationary vanes so that the scraped material is re-fed under the beater away from the central zone.

Owner:AGCO AS

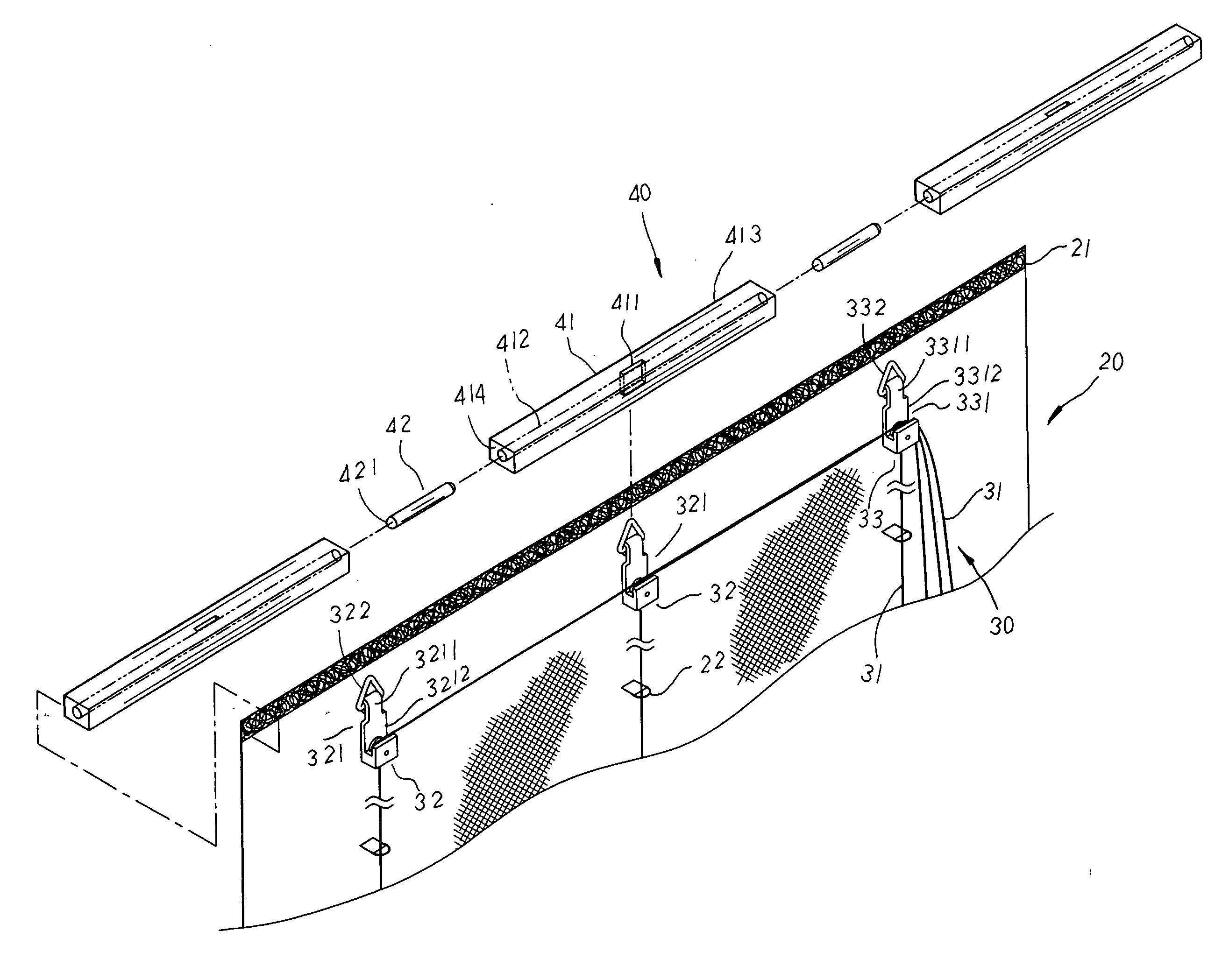

Collapsible window blinds structure

InactiveUS20070163723A1Avoid packagingAmount of the connection rods and the linking elements can be flexibly increased or reducedExtensible doors/windowsCurtain accessoriesWindow shutterWindow covering

A collapible window blinds structure comprises a blind body, a lift cord set, and a head rail assembly wherein the blind body has a fastening portion at the top edge, and limiting hoops evenly spaced and fixed at the rear side surface for the running of lift cords there-through to wind around pulley seats and a positioning pulley unit respectively. The head rail assembly includes multiple connection rods and linking elements flexibly assembled according to the size of a widow frame. Each connection rod has a vertical thru-hole for the registration of a fitting portion of the pulley seats and the positioning pulley unit, and a fastened portion at a vertical side surface for the attachment of the fastening portion of the blind body thereto. Therefore, the head rail assembly and the blind body can be easily stacked and bundled up into smaller volume for convenient carriage and the storage.

Owner:CHING FENG BLINDS INC CO LTD

Stabilizer apparatus and method

InactiveUS7555992B1Avoid packagingVessel partsVessel movement reduction by foilsEngineeringMechanical engineering

In a water craft, a stabilizer apparatus and method includes a stabilizer surface with a retractable arm connected with the stabilizer surface. An extension / retractor is connected with the retractable arm for extending and retracting the retractable arm beneath the water craft.

Owner:MCCAUGHAN MARK

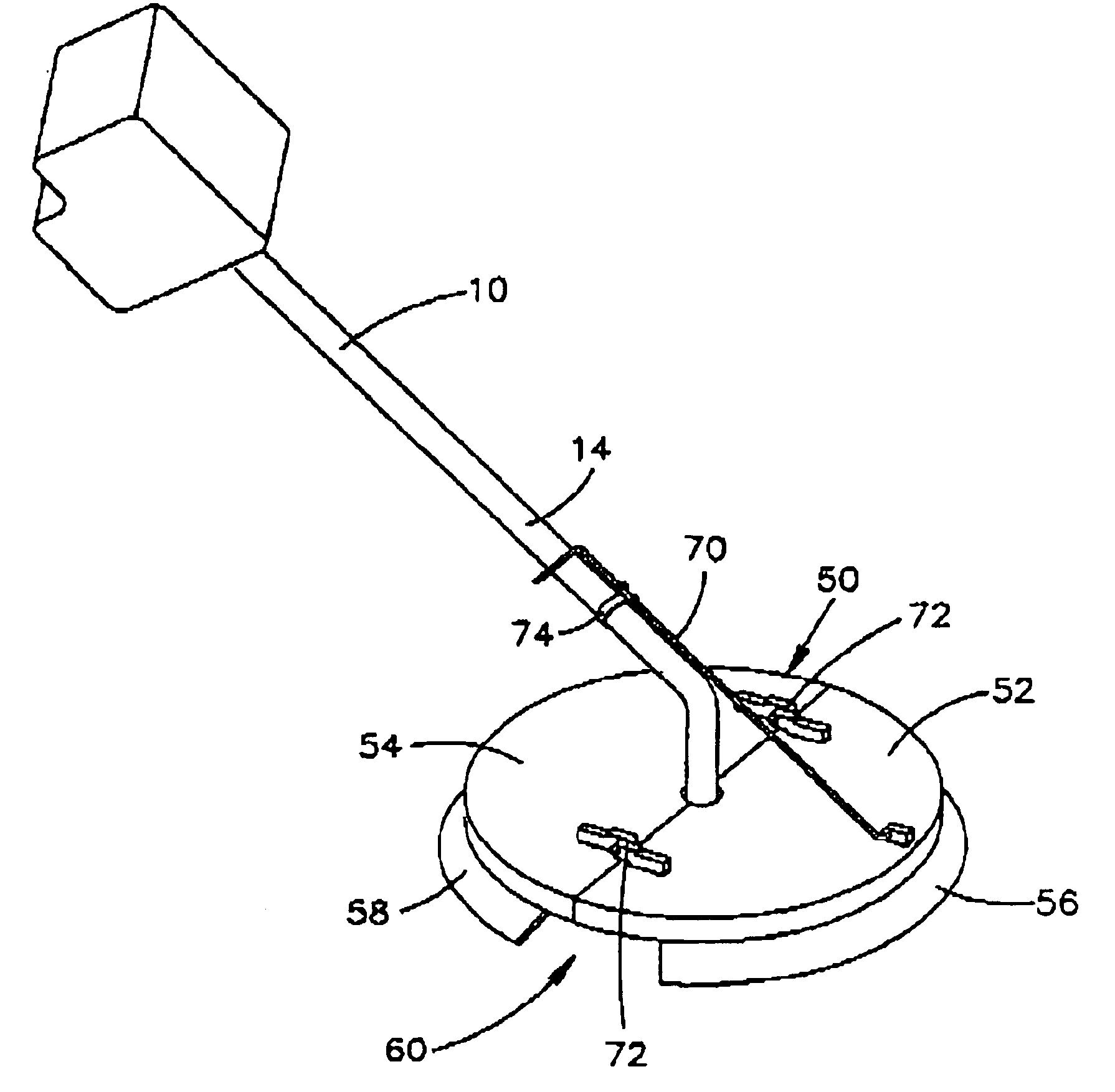

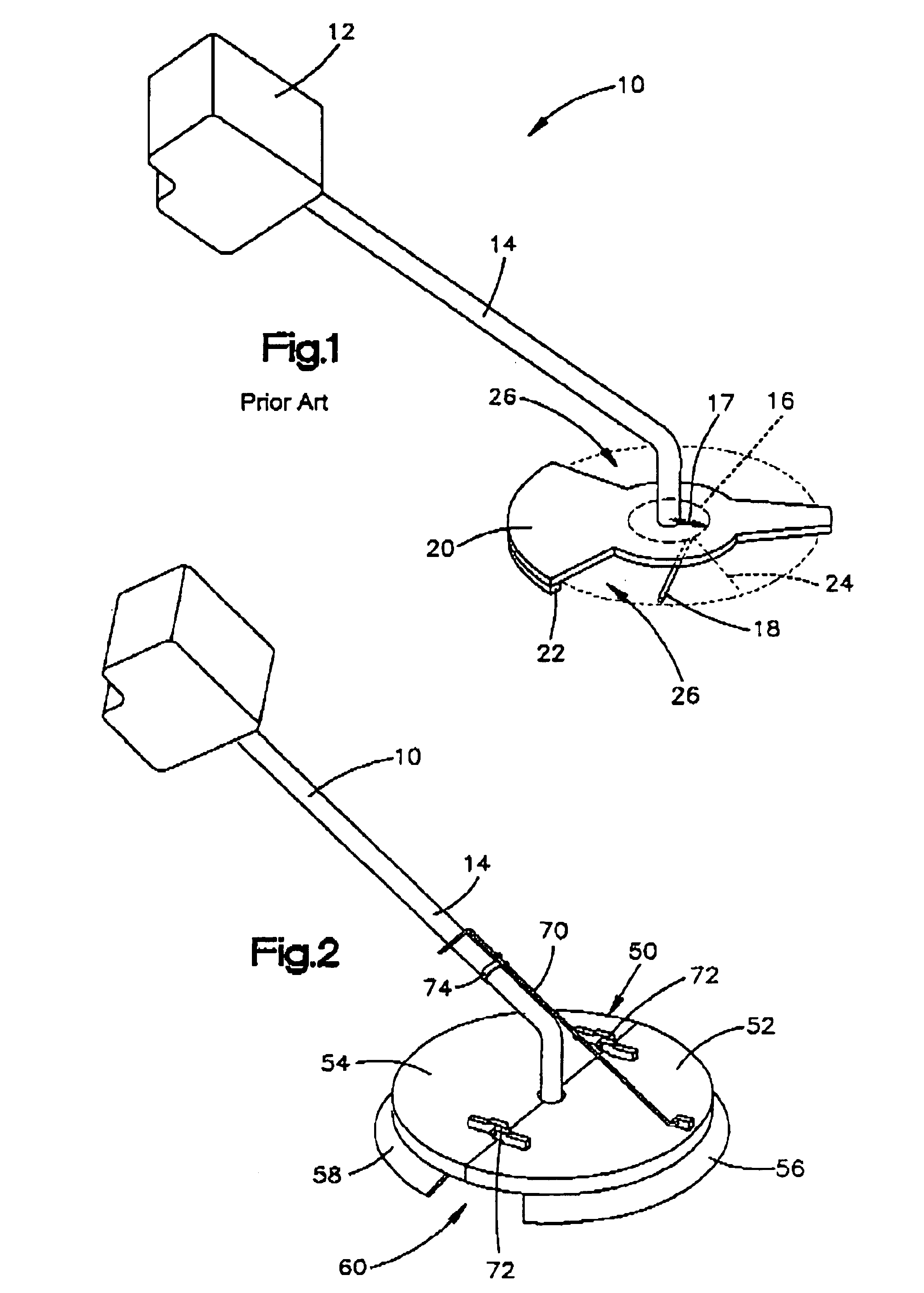

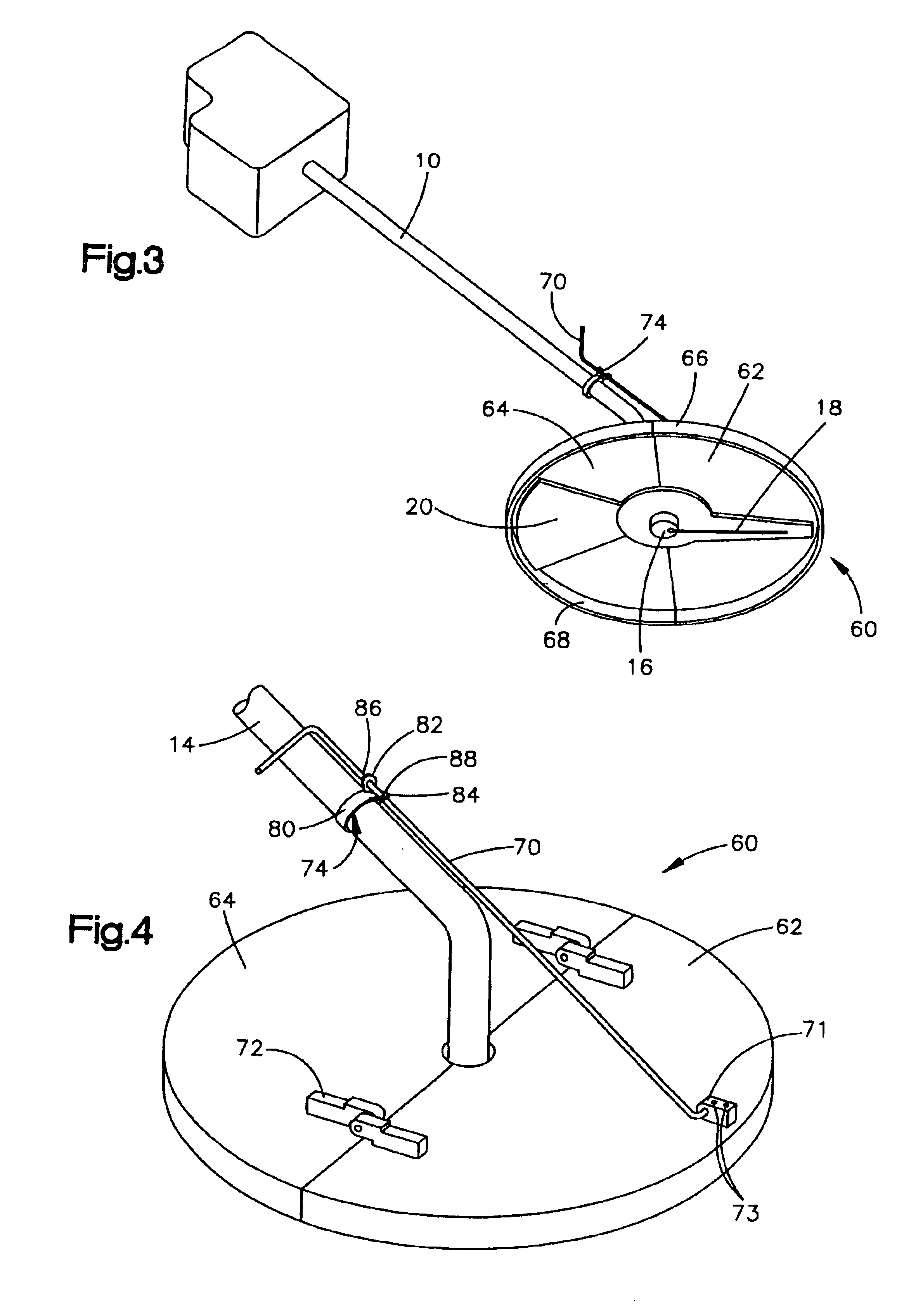

Combine harvesters

An anti-wrapping device is described for preventing crop from being wrapped about the central shaft of a reel rotatably supported on side arms of a header of a combine. The device comprises an annular cover plate for securing to the axial end of the reel to prevent the crop from becoming entangled with projections from the reel and a tubular shroud for mounting on the header support arm to surround the central shaft of the reel, the axial end of the shroud being positioned when in use in close proximity to the annular cover plate of the reel to avoid any crop being caught therebetween.

Owner:BLUE LEAF I P INC

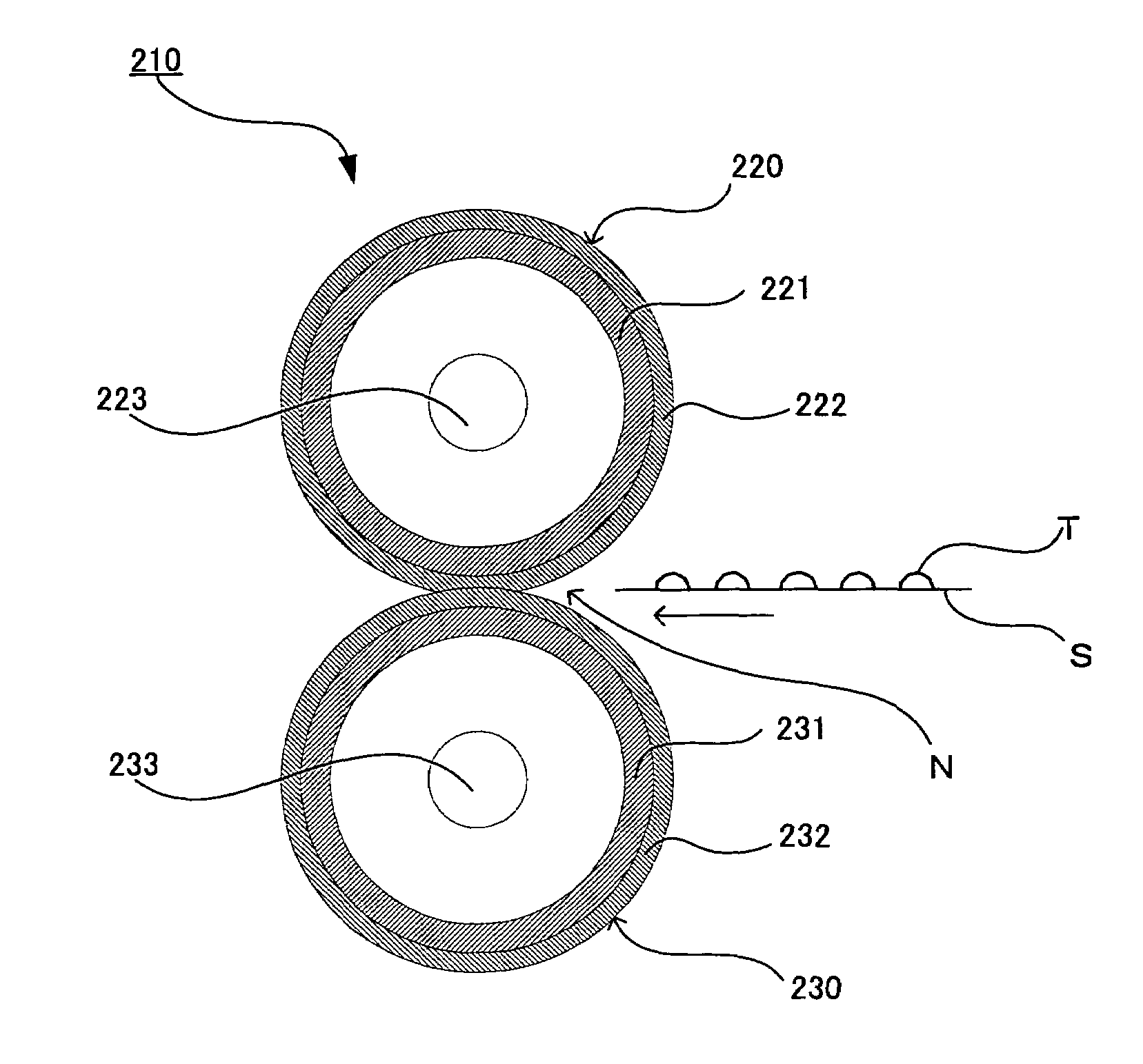

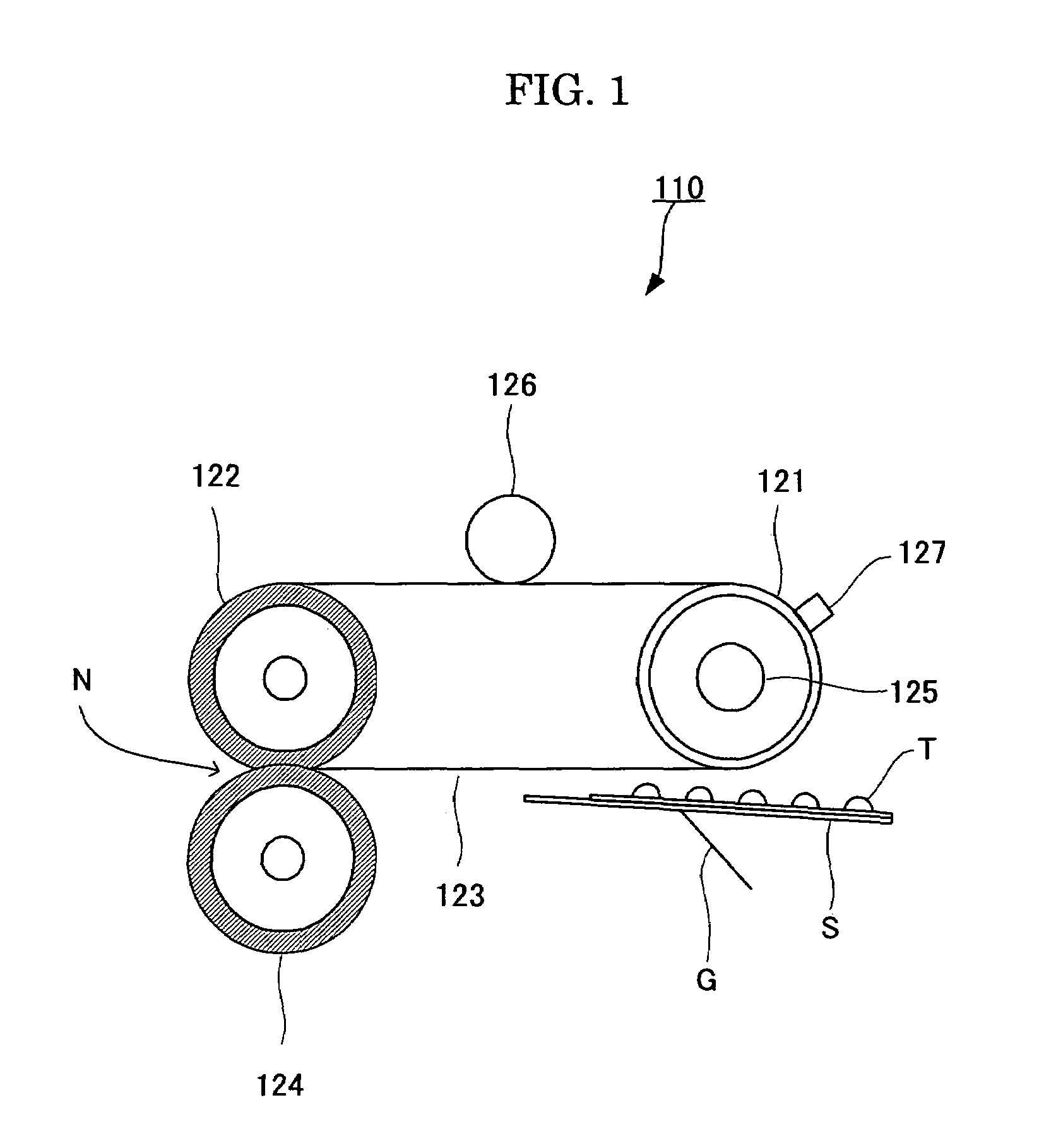

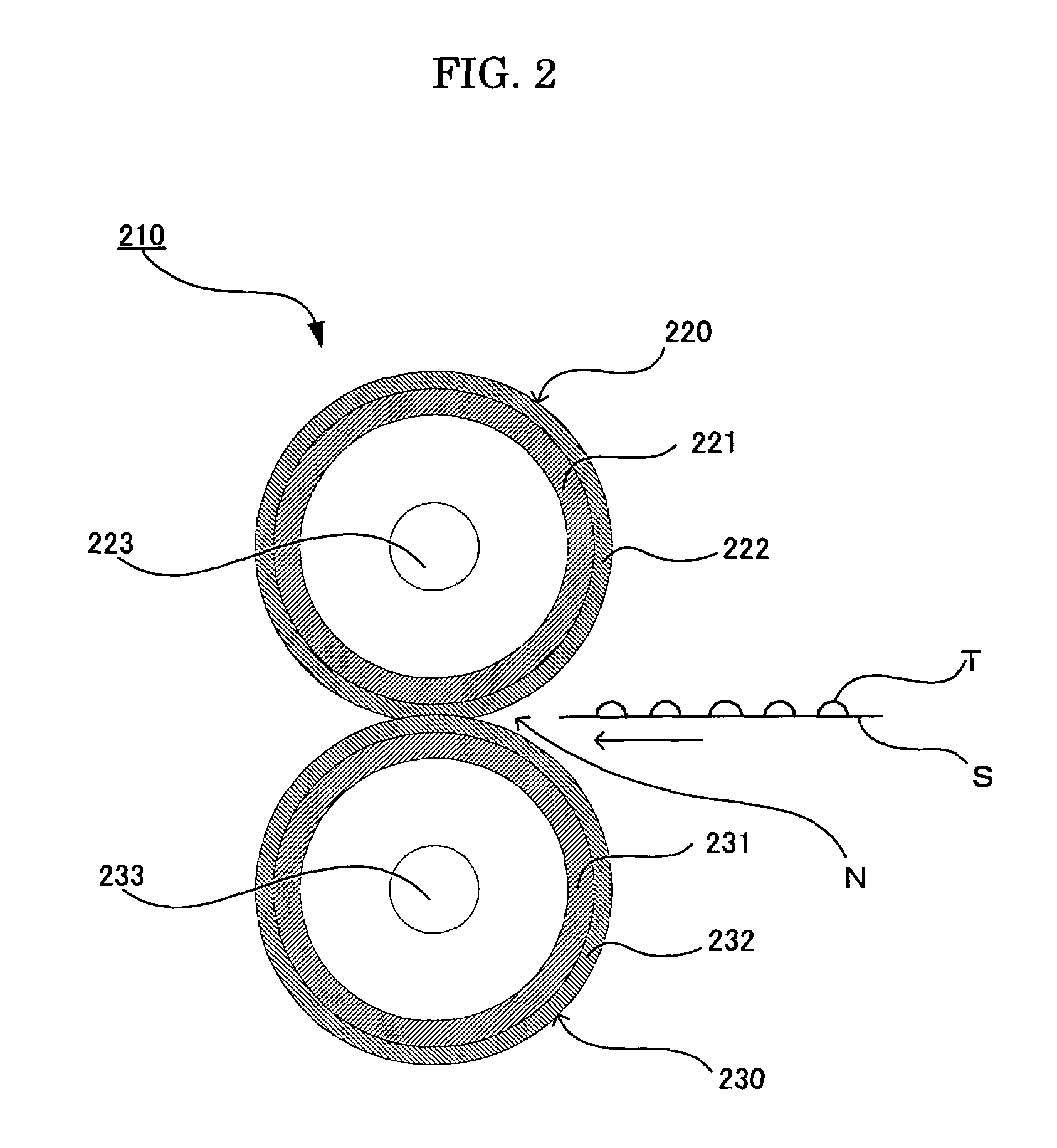

Image-fixing method and image-fixing device, and, image-forming method and image-forming apparatus

ActiveUS7560216B2Excellent glossinessReduce surface hardnessDevelopersElectrographic process apparatusWaxAliphatic hydrocarbon

An image-fixing method contains: passing a recording medium bearing an image through a nip between two or more fixing members to fix the image onto the recording medium; and ejecting the recording medium along with the fixing member contacting with a non-image-bearing surface of the recording medium, wherein the fixing member contacting with an image-bearing surface of the recording medium has a lower surface hardness than that of the fixing member contacting with the non-image-bearing surface, the image is comprised of a toner containing toner particles, each toner particle contains wax having an aliphatic hydrocarbon chain, and polyester resin having an aromatic ring, a total amount of the wax in the toner particle is 1 to 20 mass %, determined by DSC, an amount of the wax located in the specific region of the toner particle is 0.05 to 0.40 that is an intensity ratio (P2850 / P828) determined by FTIR-ATR, and the wax is partially or entirely encapsulated in the toner particle as dispersed particles.

Owner:RICOH KK

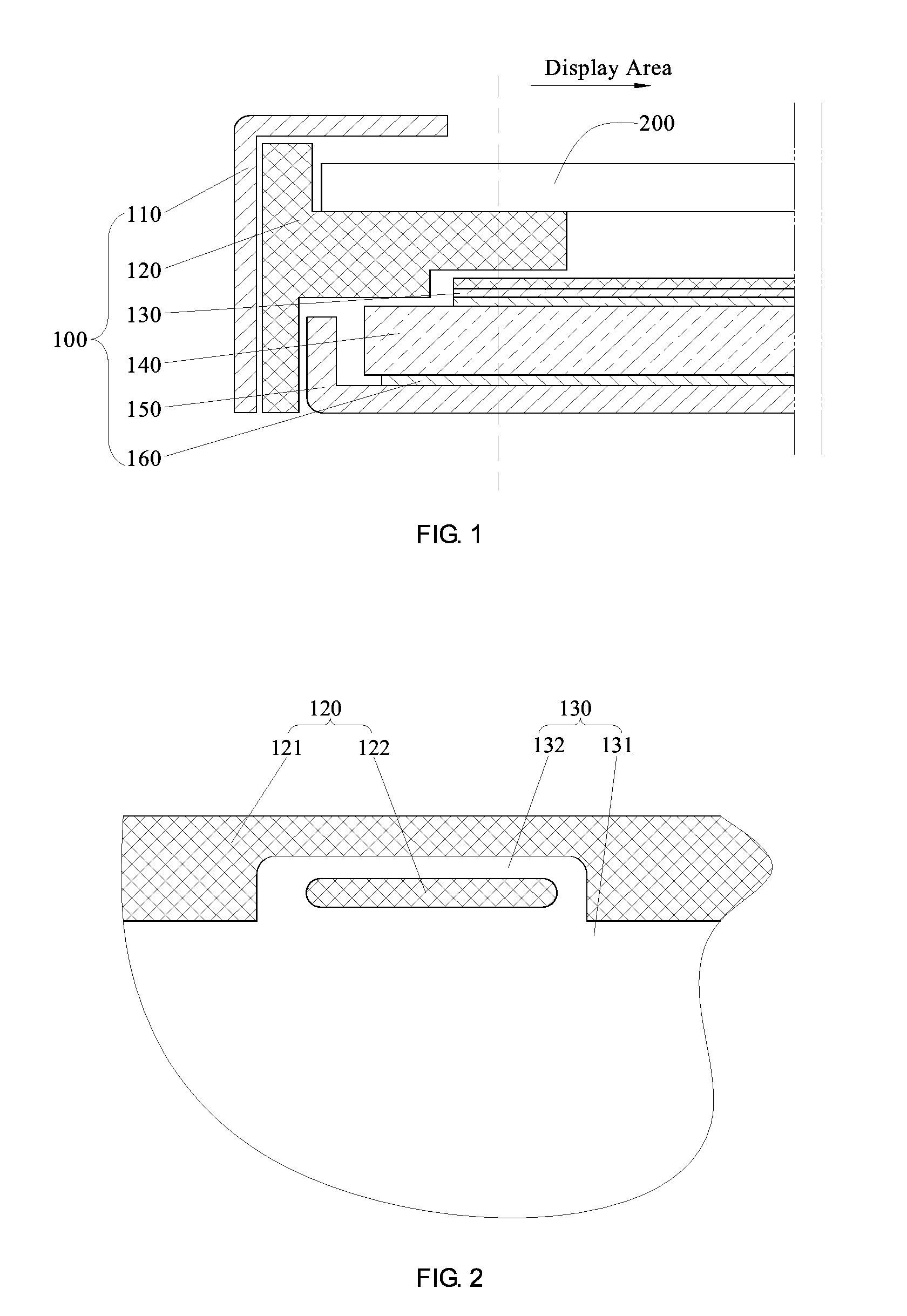

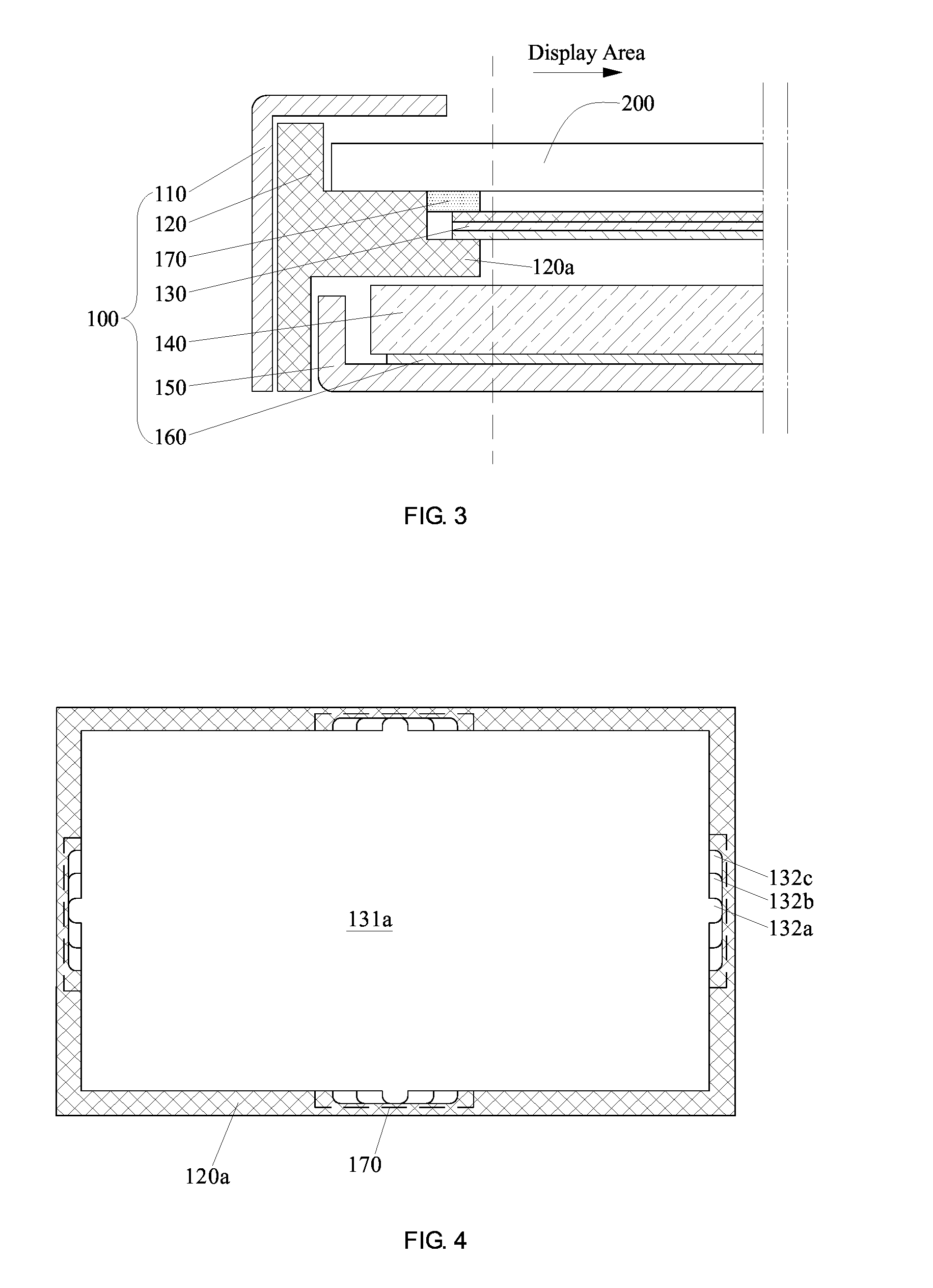

Backlight and Display Device

ActiveUS20150355484A1Small widthPrevented from appearingMechanical apparatusPlanar/plate-like light guidesDisplay deviceLight source

The present invention provides a backlight and a display device. The backlight includes a frame and an optical film set including a plurality of optical films that are successively stacked. Each optical film in the optical film set includes a film body and an ear part. In any two adjacent optical films, the boundary of at least one side of the ear part of the lower optical film extends beyond the boundary of the same side of the ear part of the upper optical film. A fixing member covers the ear parts of the plurality of optical films, such that the optical film set is fixed on the frame, and the fixing member can fix the relative positions among the plurality of optical films in the optical film set. In the backlight, the optical film set is reliably fixed without affecting the normal display on the display device.

Owner:BOE TECH GRP CO LTD +1

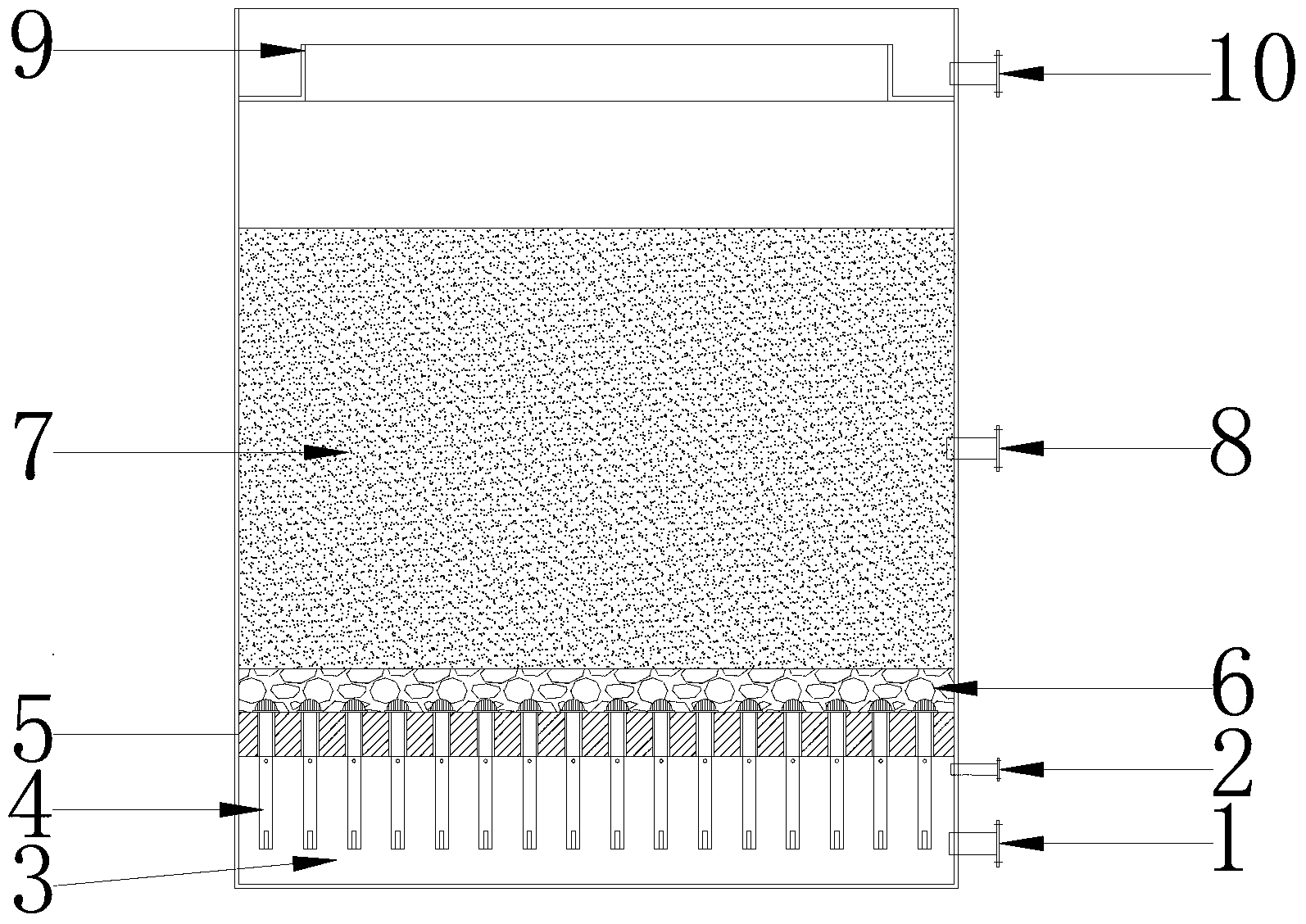

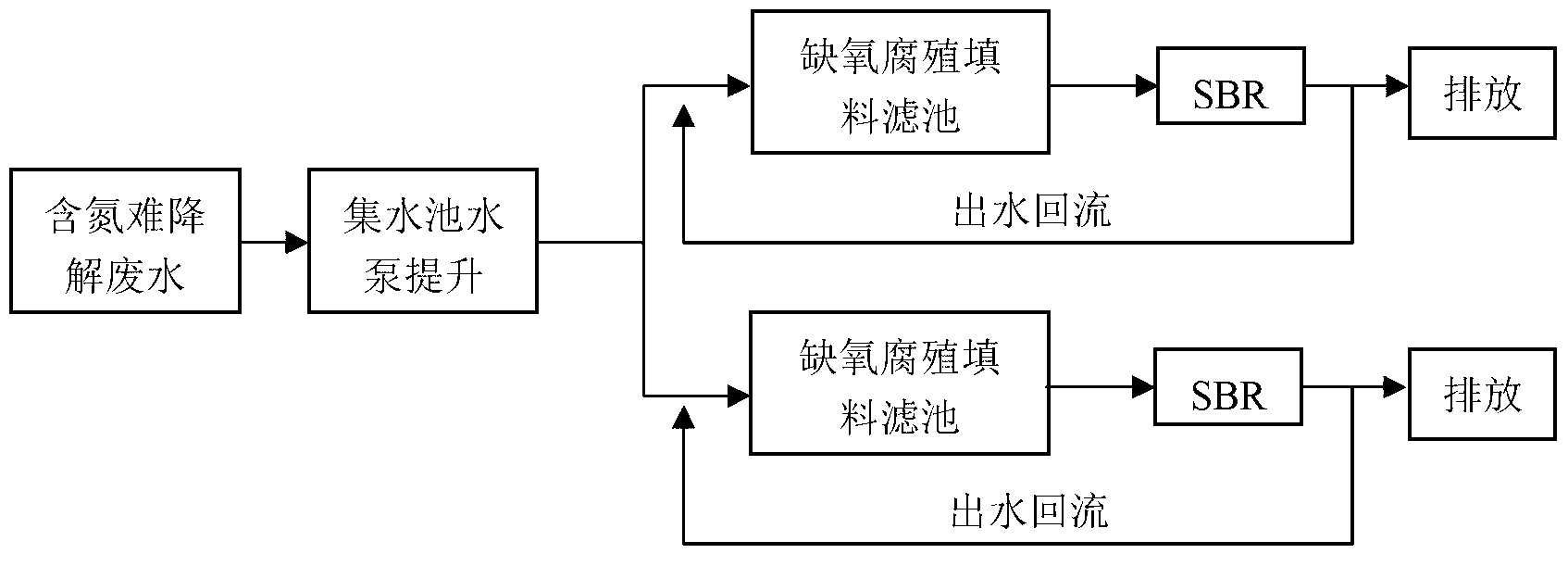

Anoxic humic filler filter tank and method for treating nitrogen containing degradation-resistant wastewater

InactiveCN103214090AStir wellSimple structureTreatment with anaerobic digestion processesMultistage water/sewage treatmentDraining tubeSludge

The invention discloses an anoxic humic filler filter tank and a method for treating nitrogen containing degradation-resistant wastewater, and belongs to the field of environmental protection. The anoxic humic filler filter tank comprises a tank body, a water inlet pipe, a water distributing room, a bearing layer, a filler layer, a filler casting pipe and a drainage pipe. The anoxic humic filler filter tank further comprises a gas inlet pipe, a long handle filter head, a water distributing pore plate and a downflow weir. The water inlet pipe and the gas inlet pipe are connected with the water distributing room. The water distributing pore plate, the bearing layer and the filler layer are sequentially arranged from bottom to top along the distributing room in the tank body. The long handle filter head passes through the water distributing pore plate. According to the invention, limited space is reasonably utilized, occupied area is saved to the maximum extent, and treated nitrogen containing organic wastewater can satisfy the emission standard of wastewater in industries. According to the method for treating nitrogen containing degradation-resistant wastewater in the anoxic humic filler filter tank, biological removal of nitrogen and adsorption of hardly degradable substances are organically combined by combining the anoxic humic filler filter tank and an active sludge process, so that the removal efficiency of total nitrogen and hardly degradable substances is improved.

Owner:NANJING UNIV

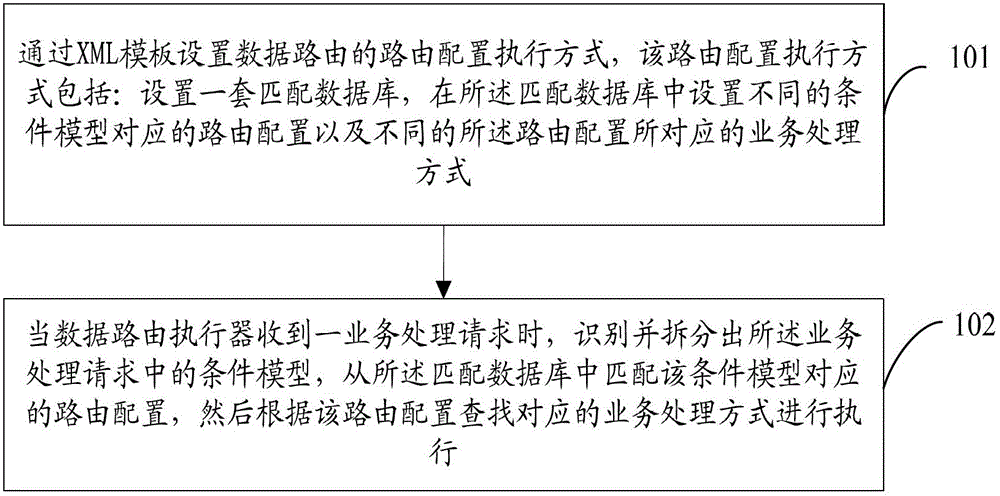

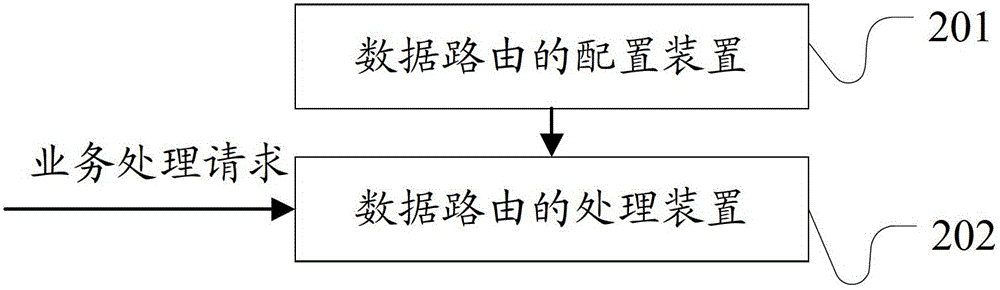

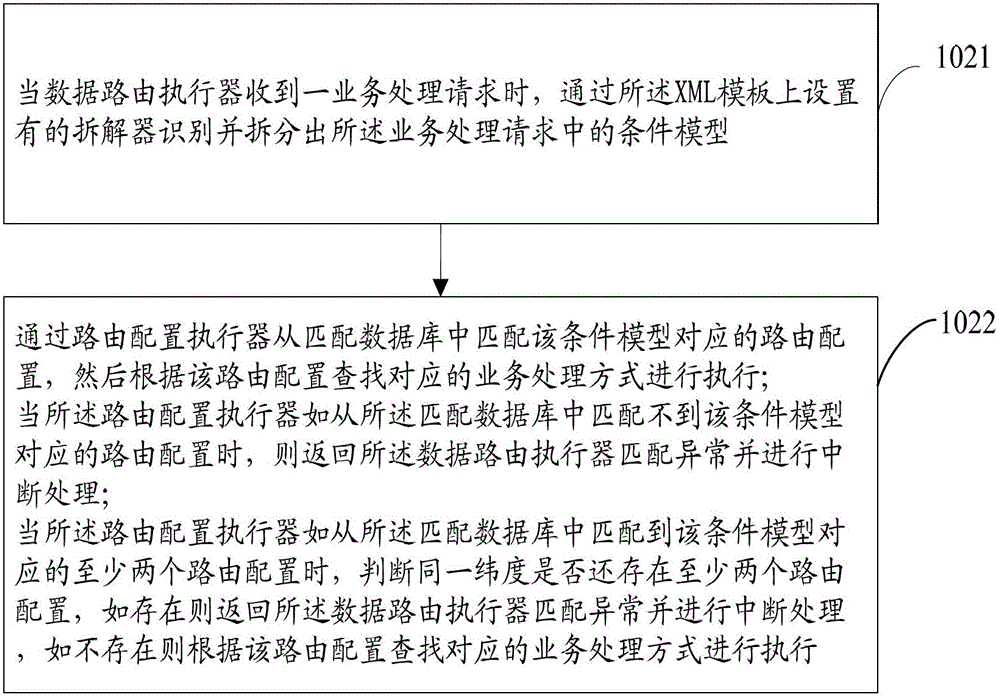

Execution method, configuration apparatus and processing apparatus for data route

InactiveCN104038356AAvoid recompilationAvoid packagingData switching networksSpecial data processing applicationsSystem configurationActuator

The invention discloses an execution method, configuration apparatus and processing apparatus for a data route. The method comprises: arranging a route configuration execution mode of the data route through an XML template, wherein the route configuration execution mode comprises arranging a matching database and arranging route configuration corresponding to different condition models and service processing modes corresponding to the different route configuration in the matching database; and when a data route executor receives a service processing request, identifying and splitting the condition models in the service processing request, matching the route configuration corresponding to the condition models from the matching database, and then searching for the corresponding service processing modes according to the route configuration for execution. According to the invention, maintenance can be realized through the XML template, modification of JAVA codes is unnecessary, and the problems of code repeated compiling, packing, disposition and the like are avoided.

Owner:ALIBABA GRP HLDG LTD

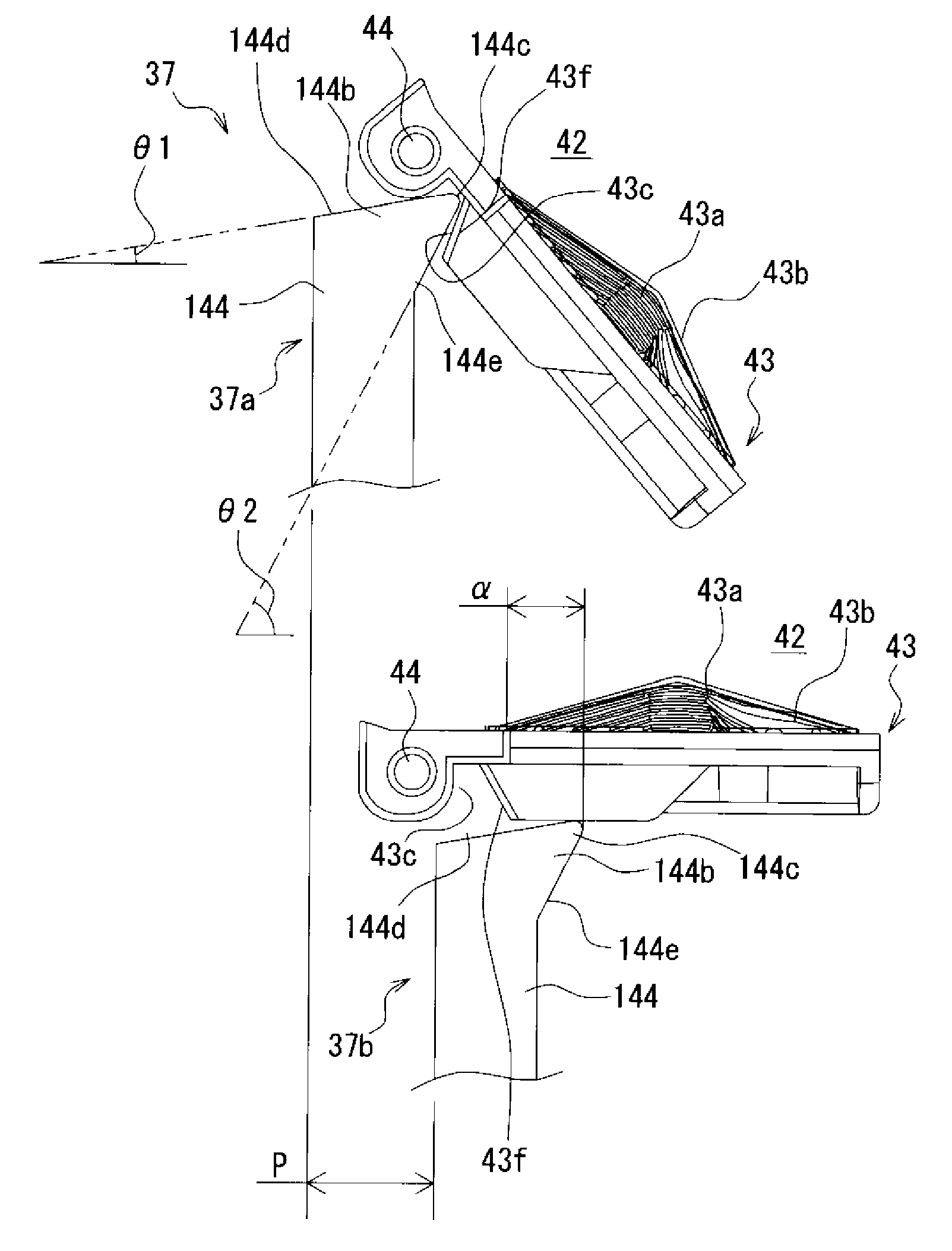

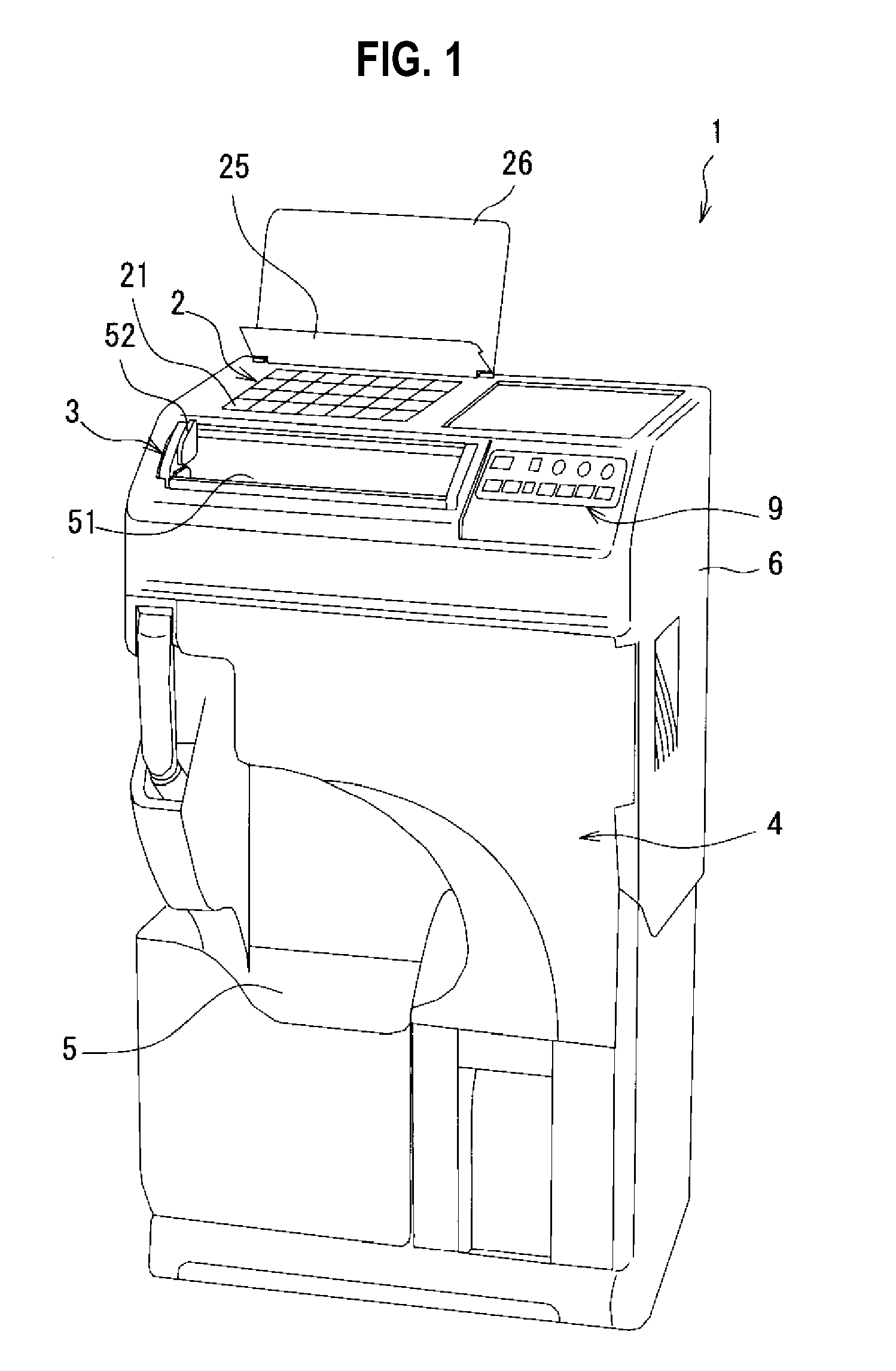

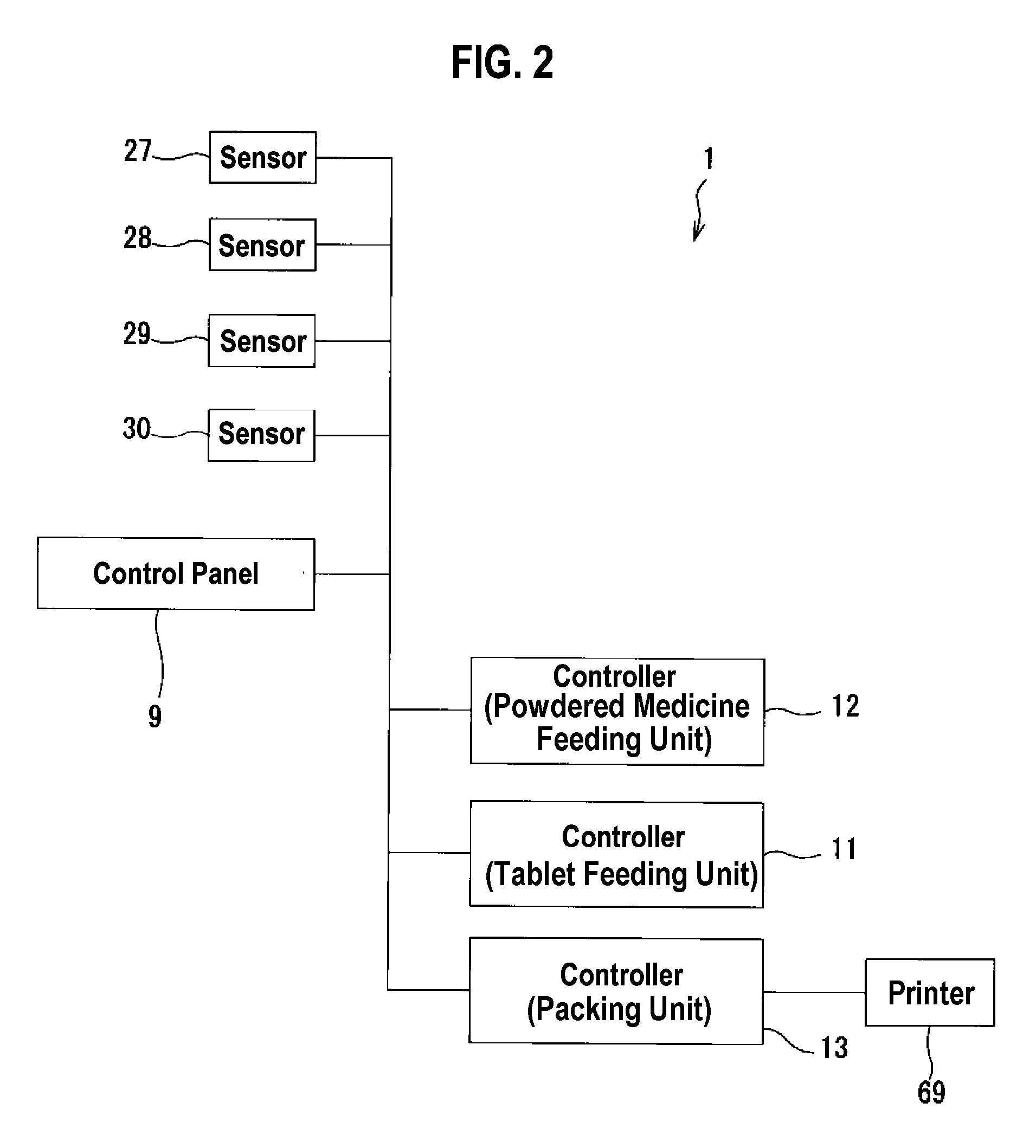

Medicine Packing Device

InactiveUS20100237089A1Avoid failureReduce movement distanceSmall article dispensingRacksEngineeringMechanical engineering

There is provided a medicine packing device, which prevents a free end of a bottom plate of a tablet dispensing measure from tilting due to its own weight. A bottom plate 43 is provided at a lower opening of a tablet dispensing measure 42. The bottom plate 43 includes a pin 44 at its base end. A leading end of the bottom plate is a free end. When the tablet dispensing measure 42 reaches corresponding stepped portions 37a to 37d by a movement of a tablet dispensing member 36, an opening protrusion 144b of a fixed plate 37 is fitted to an opening recess 43c of the bottom plate 43 and thus the bottom plate 43 pivots about the pin 44 from a closed position to an open position. If the bottom plate 43 moves to the open position, then tablets in the tablet dispensing measure 42 drop.

Owner:YUYAMA MFG CO LTD

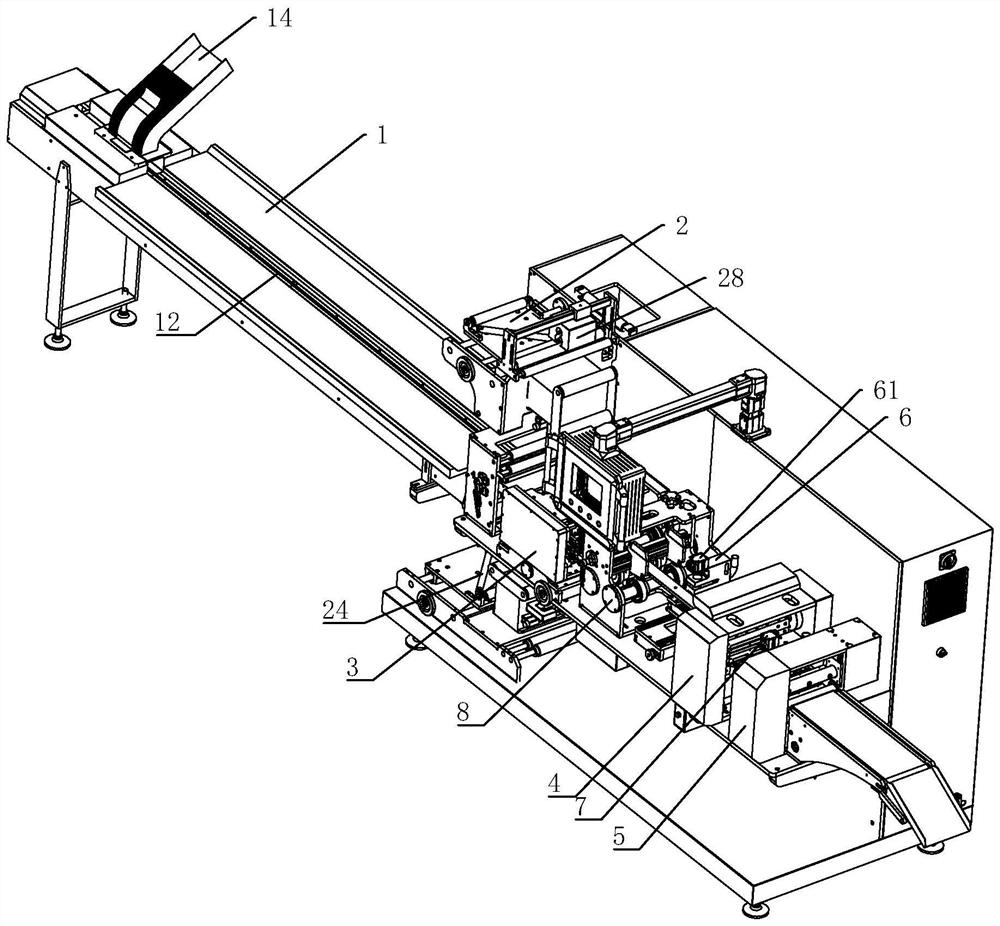

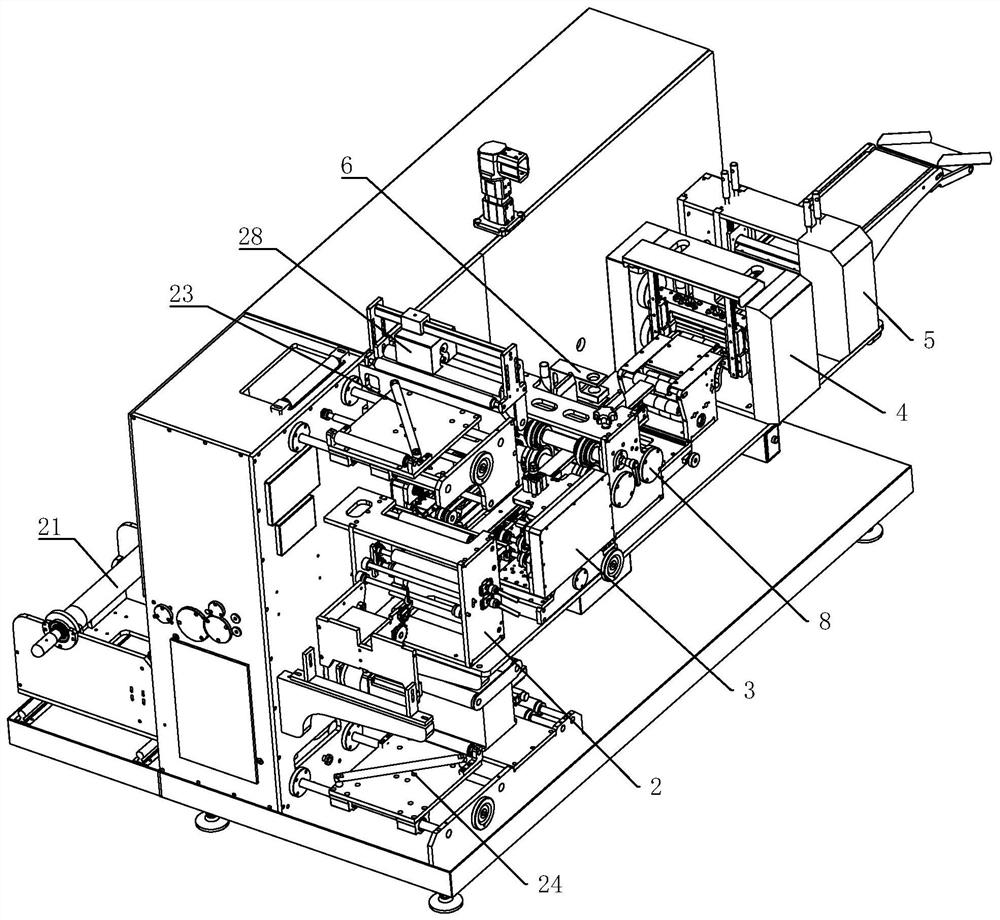

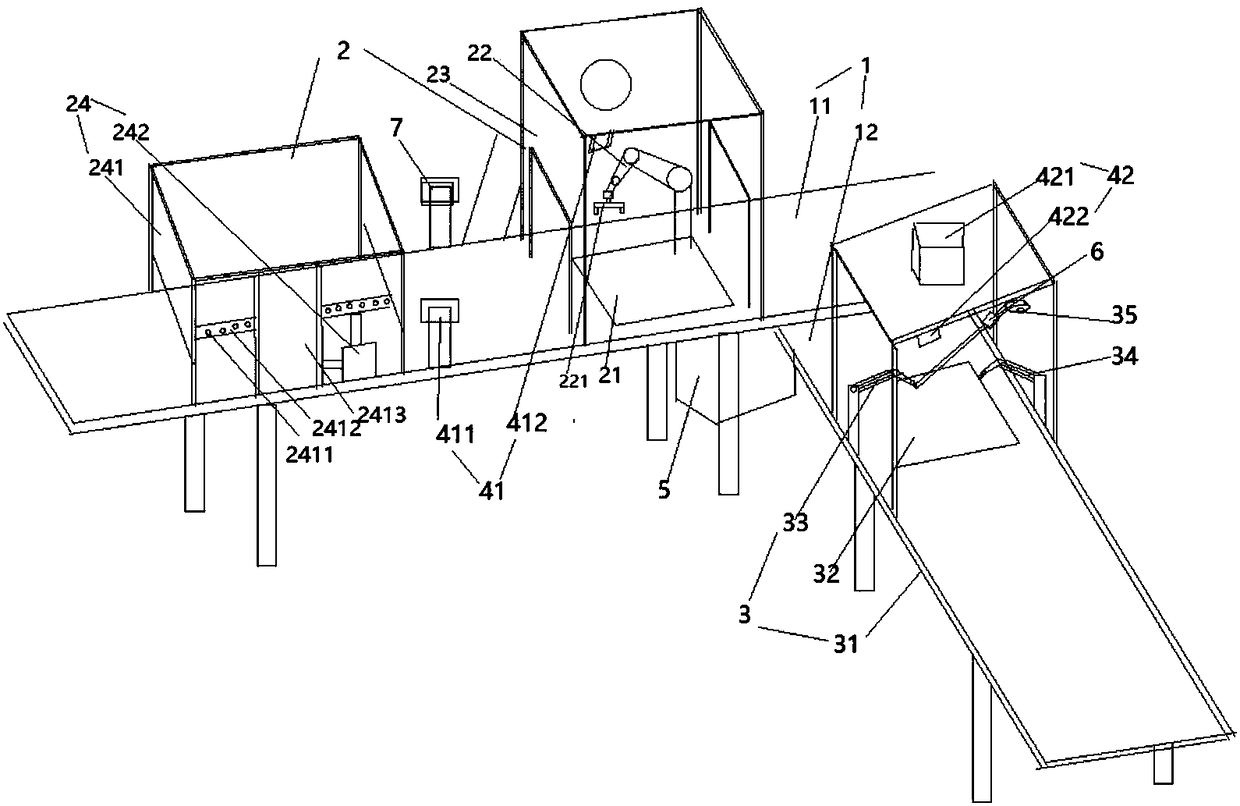

Full-automatic mask packaging equipment

PendingCN112810909AImprove cleanlinessLabor savingWrapping material feeding apparatusWrapper twisting/gatheringMechanical engineeringIndustrial engineering

The invention discloses full-automatic mask packaging equipment, and aims to solve the problems of excessive manual participation in mask packaging, low packaging production efficiency and the like. The full-automatic mask packaging equipment sequentially comprises a mask distributing and conveying device, a packaging bag film slitting and feeding device, a double-side hot melting and edge sealing device, a sealing opening hot melting and edge sealing device and a cutting device according to the mask conveying sequence, wherein the mask distributing and conveying device arranges and conveys masks to the packaging bag film slitting and feeding device for upper and lower film covering of the masks, then the masks are subjected to hot melting and edge sealing operation in four directions through the double-side hot melting and edge sealing device and the sealing opening hot melting and edge sealing device, and finally sealing openings are cut and separated to produce independently-packaged masks. Automatic operation of wrapping heat sealing and independent cutting of the masks is realized, manual participation is reduced, the production cost is lowered, manual packaging is avoided, the cleanliness of the masks is maintained, the requirement for packaging the masks on a large scale is met, and the packaging efficiency is improved.

Owner:温州一辉机械有限公司

High-adaptability building formwork fastening device

PendingCN111005560AStrengthen fasteningAvoid Concrete LeakageForms/shuttering/falseworksStructural engineeringArchitectural engineering

Owner:金继余

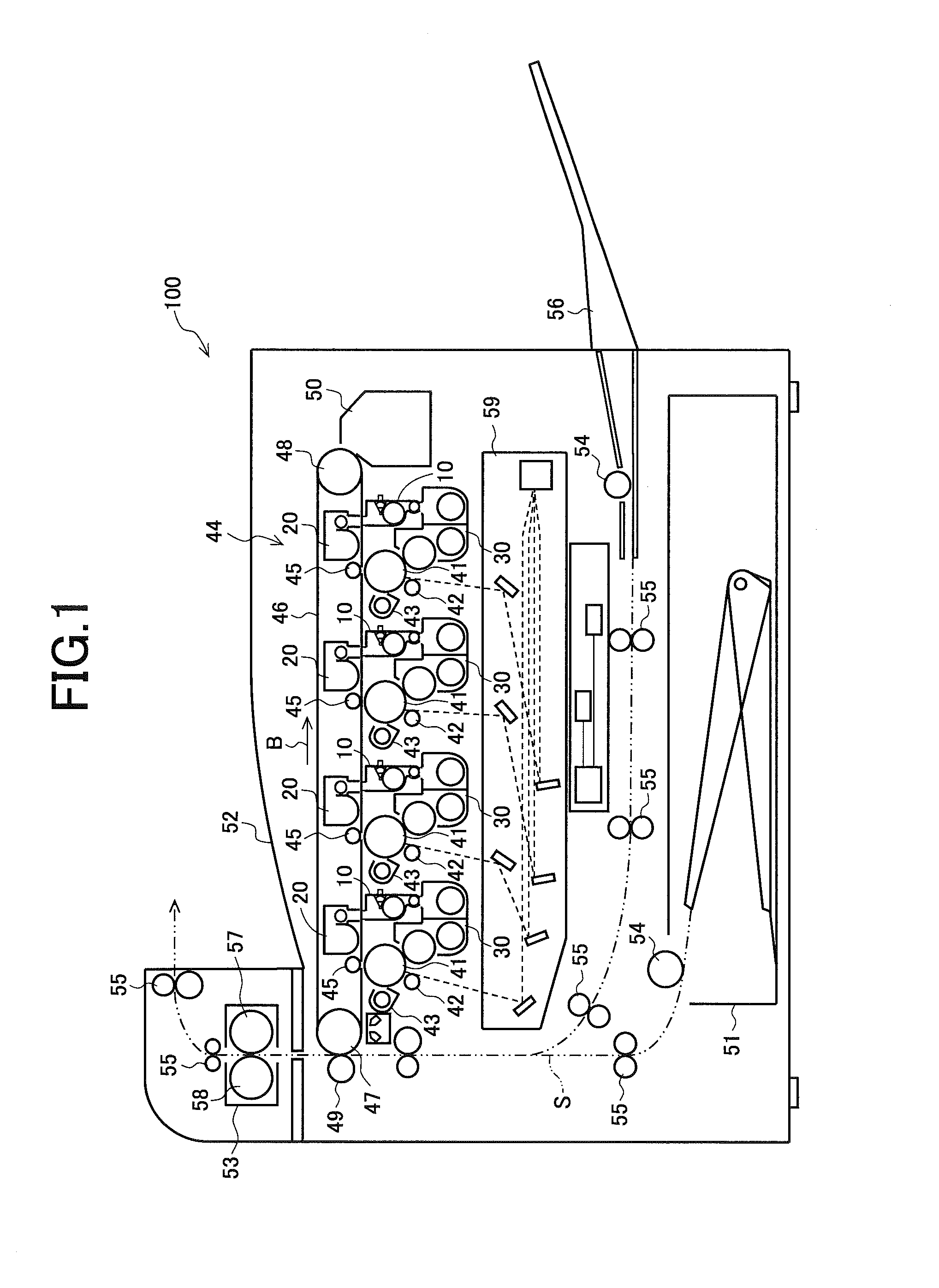

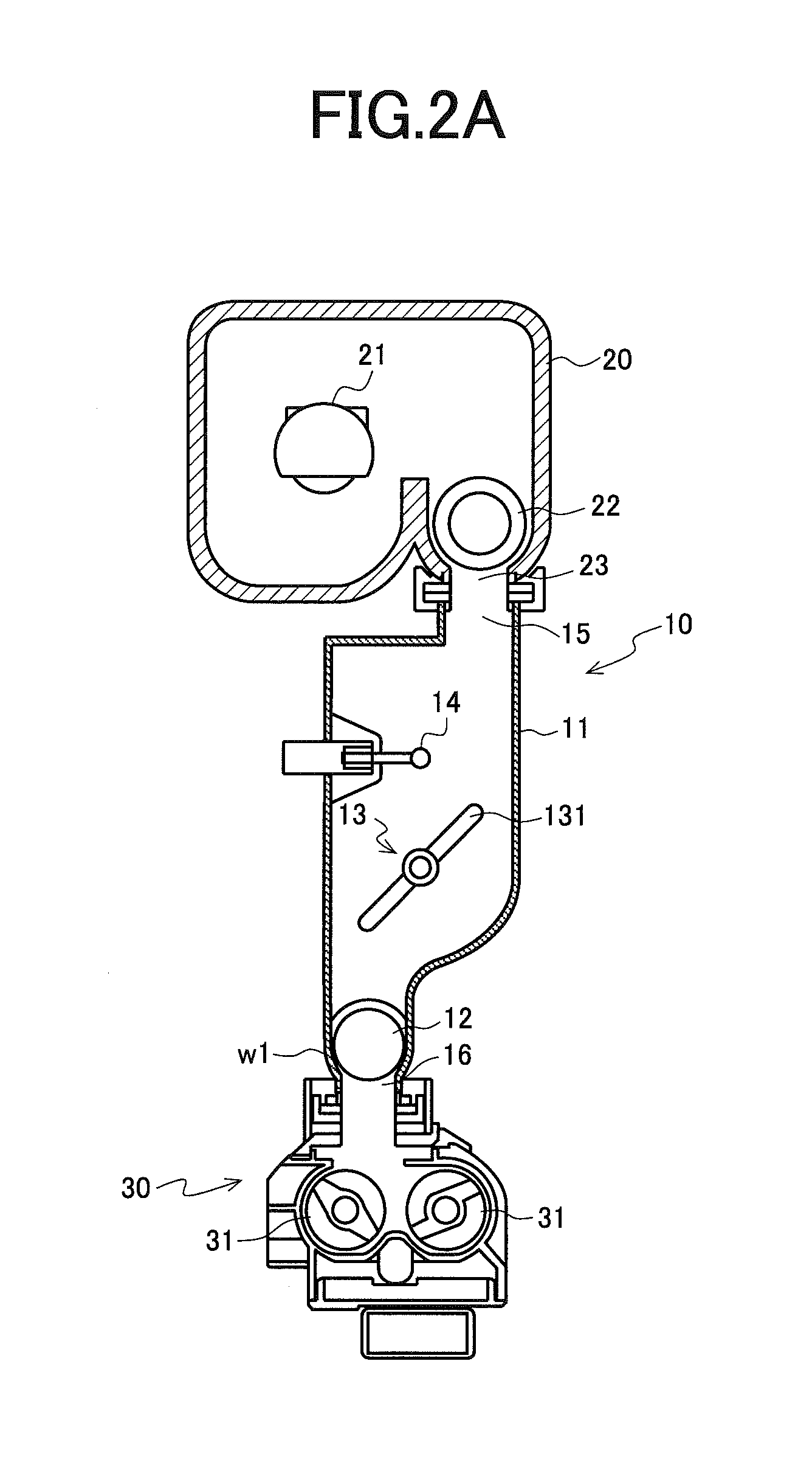

Toner supplying device and image forming apparatus

ActiveUS20150277293A1Stable supplyAvoid packagingElectrographic process apparatusEngineeringMechanical engineering

It is enabled to prevent packing of toner and supply toner stably. A toner supplying device has a toner cartridge attached to an upper part thereof a storage tank in which toner supplied from the toner cartridge is stored temporarily and discharges the toner from a toner discharge port provided in a lower end of the storage tank. A conveyance screw for discharging the toner from the toner discharge port is provided inside the storage tank and the storage tank has a shaft support hole for supporting a shaft of the conveyance screw that coincides with a rotational center axis of the conveyance screw. The shaft support hole is formed as along hole in which the shaft is able to be displaced in one direction or a direction opposite to the one direction.

Owner:SHARP KK

Intelligent integrated packaging system

ActiveCN108528812ASave handling timeAvoid damagePackaging automatic controlEngineeringMechanical engineering

The invention discloses an intelligent integrated packaging system. The packaging system comprises a conveying belt, a packing device, a adhesive tape sealing mechanism, a detection mechanism and a control device; the conveying belt is provided with a goods supply conveying belt body and a packaging conveying belt body; the packing device is arranged at the end of the supply conveying belt; the adhesive tape sealing mechanism is arranged on the packaging conveying belt; the goods supply conveying belt is arranged on one side of the packaging conveying belt; the detection mechanism is providedwith a packaging detection mechanism and a adhesive tape sealing detection mechanism; and the conveying belt, the packing device, the adhesive tape sealing mechanism and the detection mechanism are all connected with a control device. According to the packaging system, the packaging device and the adhesive tape sealing mechanism are installed on the goods supply conveying belt and the packaging conveying belt respectively, furthermore, the goods supply conveying belt and the packaging conveying belt are connected with each other, after a product are packed by the packaging device, the box bodyof the product is sealed through the glue sealing mechanism directly, so that the carrying time of the product is saved, the integration of the whole device is achieved, the working efficiency is improved, and meanwhile, due to the arrangement of the detection mechanism, the packing and adhesive tape sealing precision is greatly improved.

Owner:薛寓怀

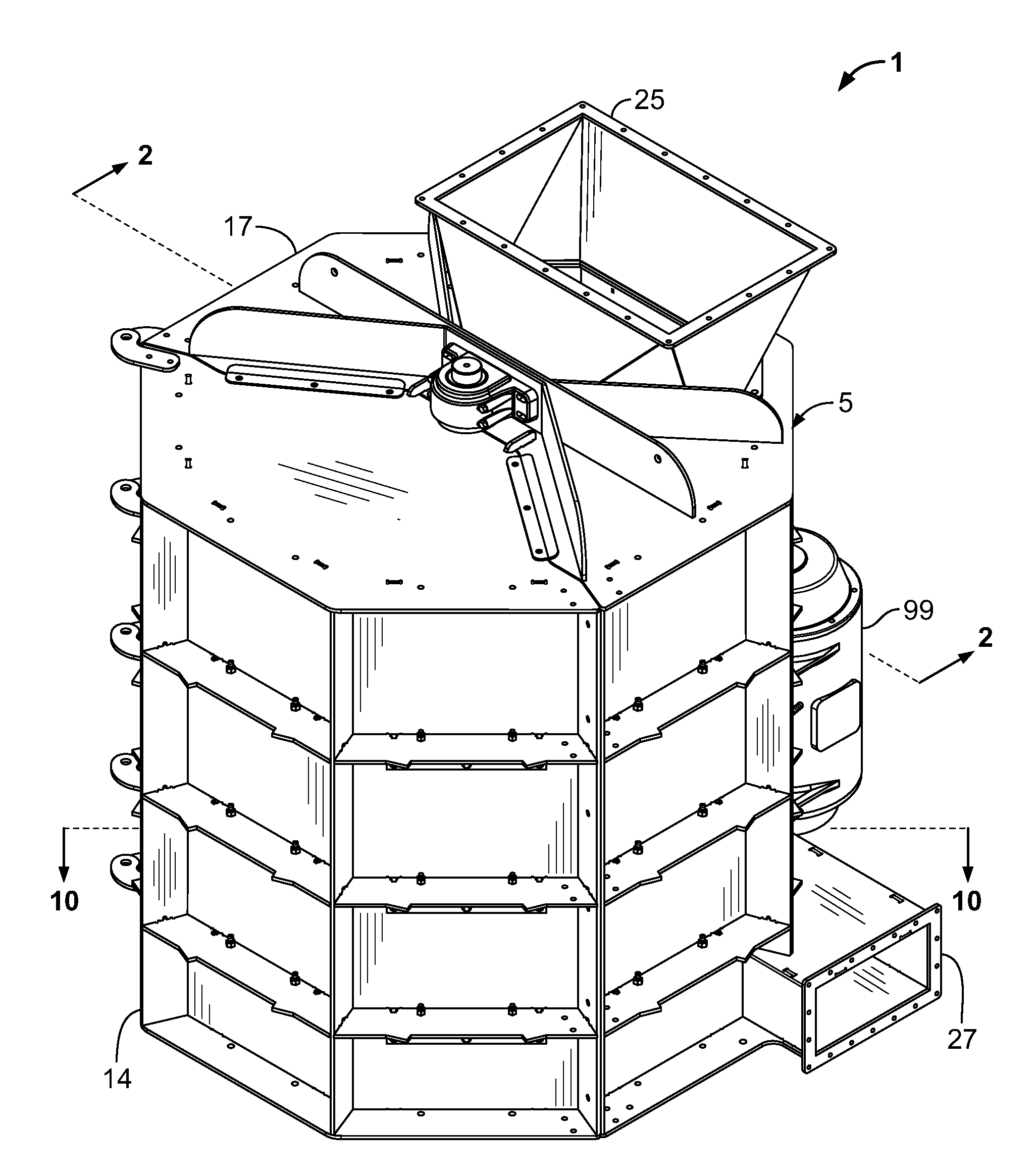

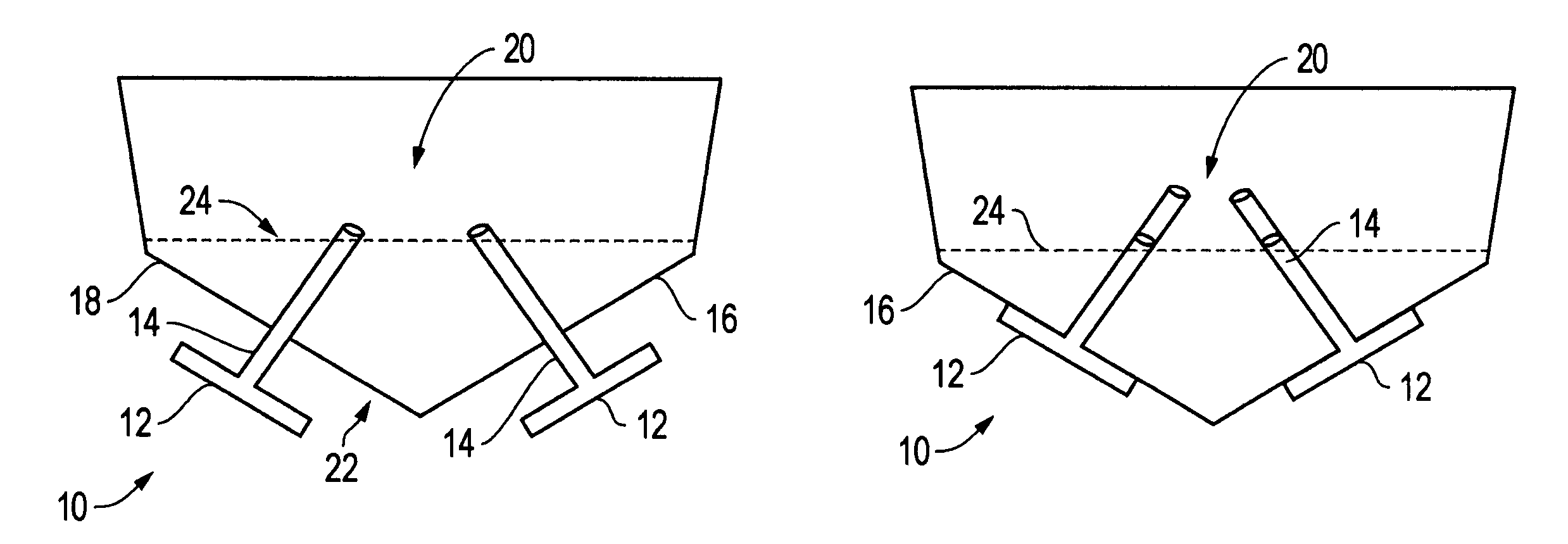

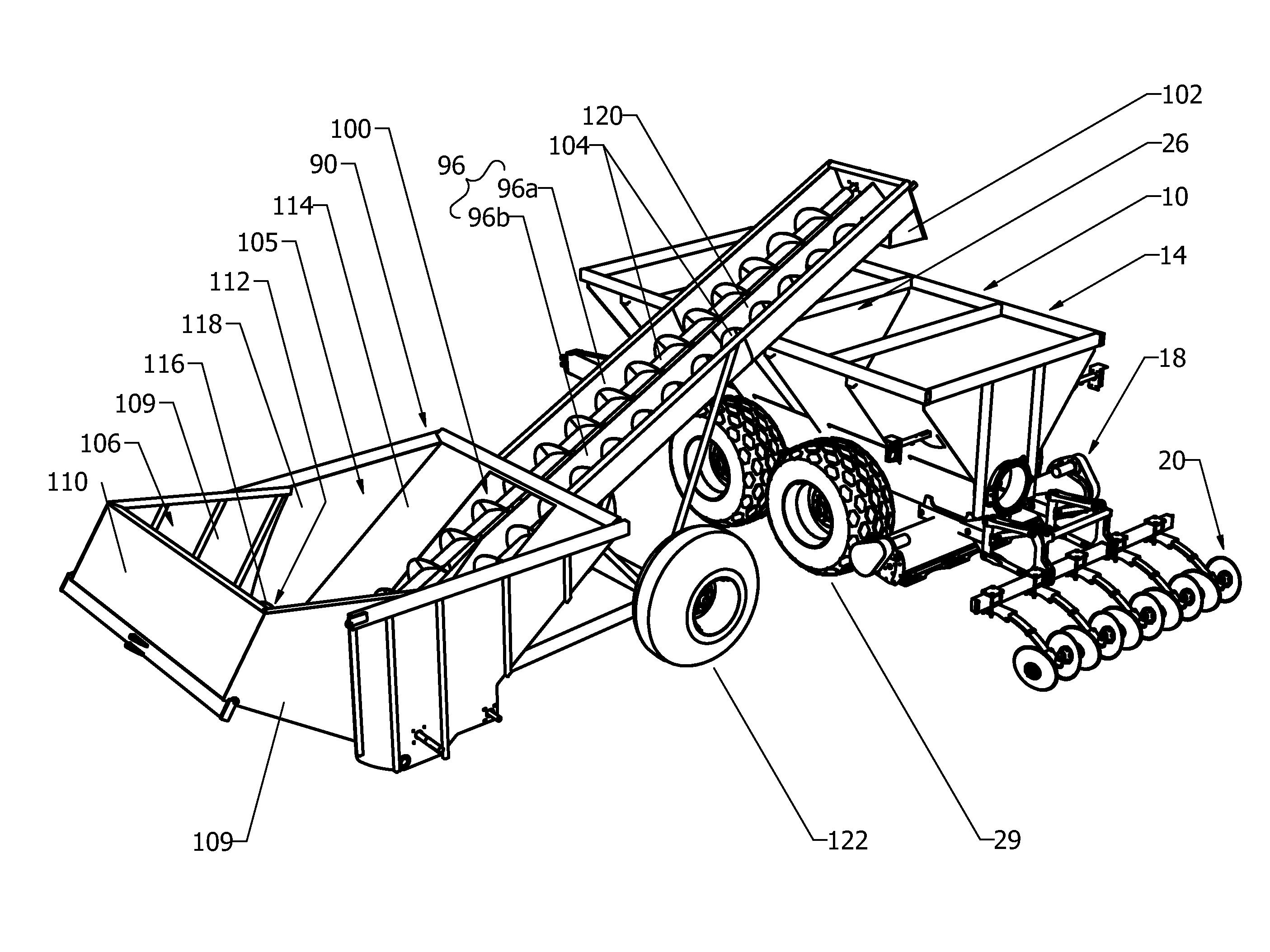

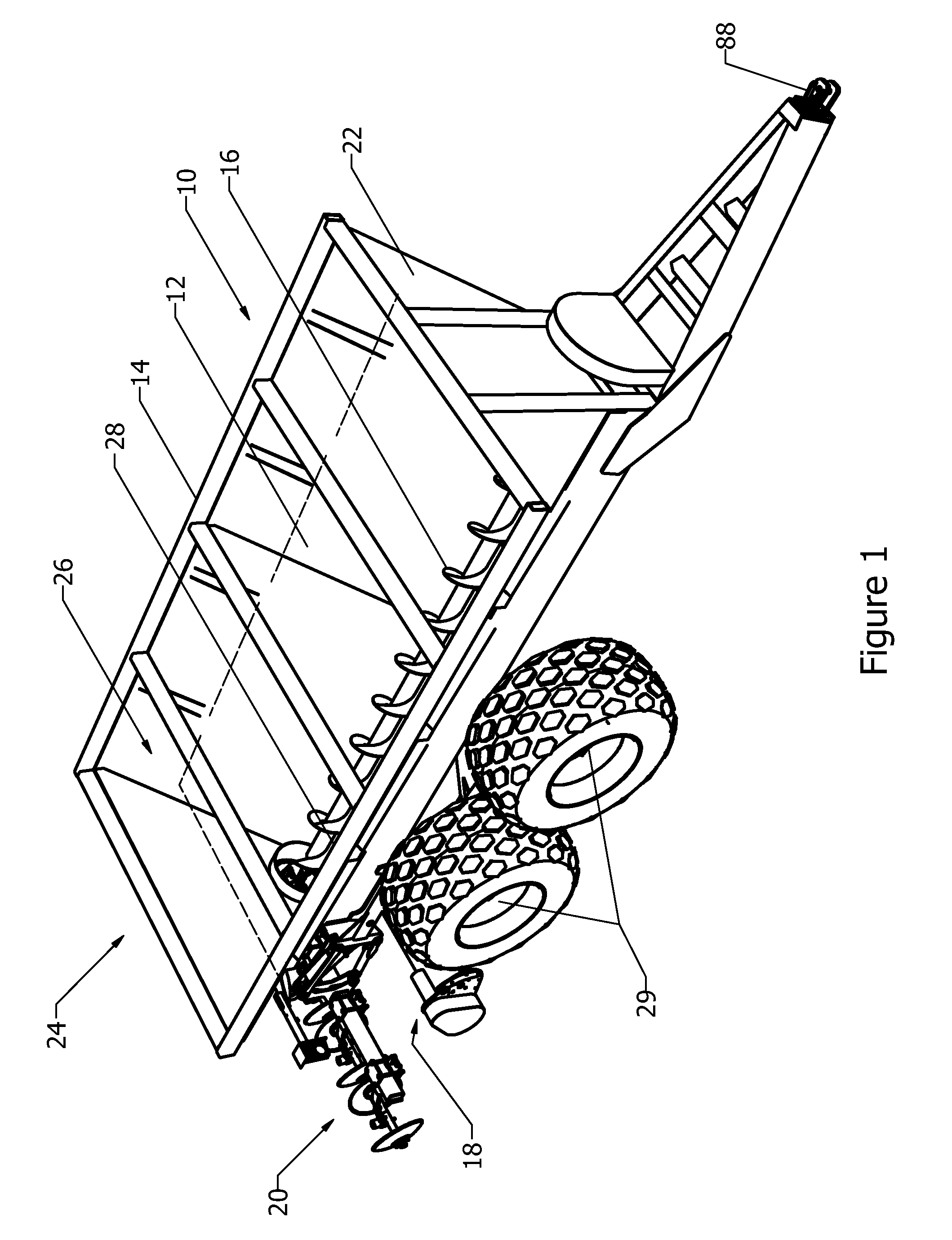

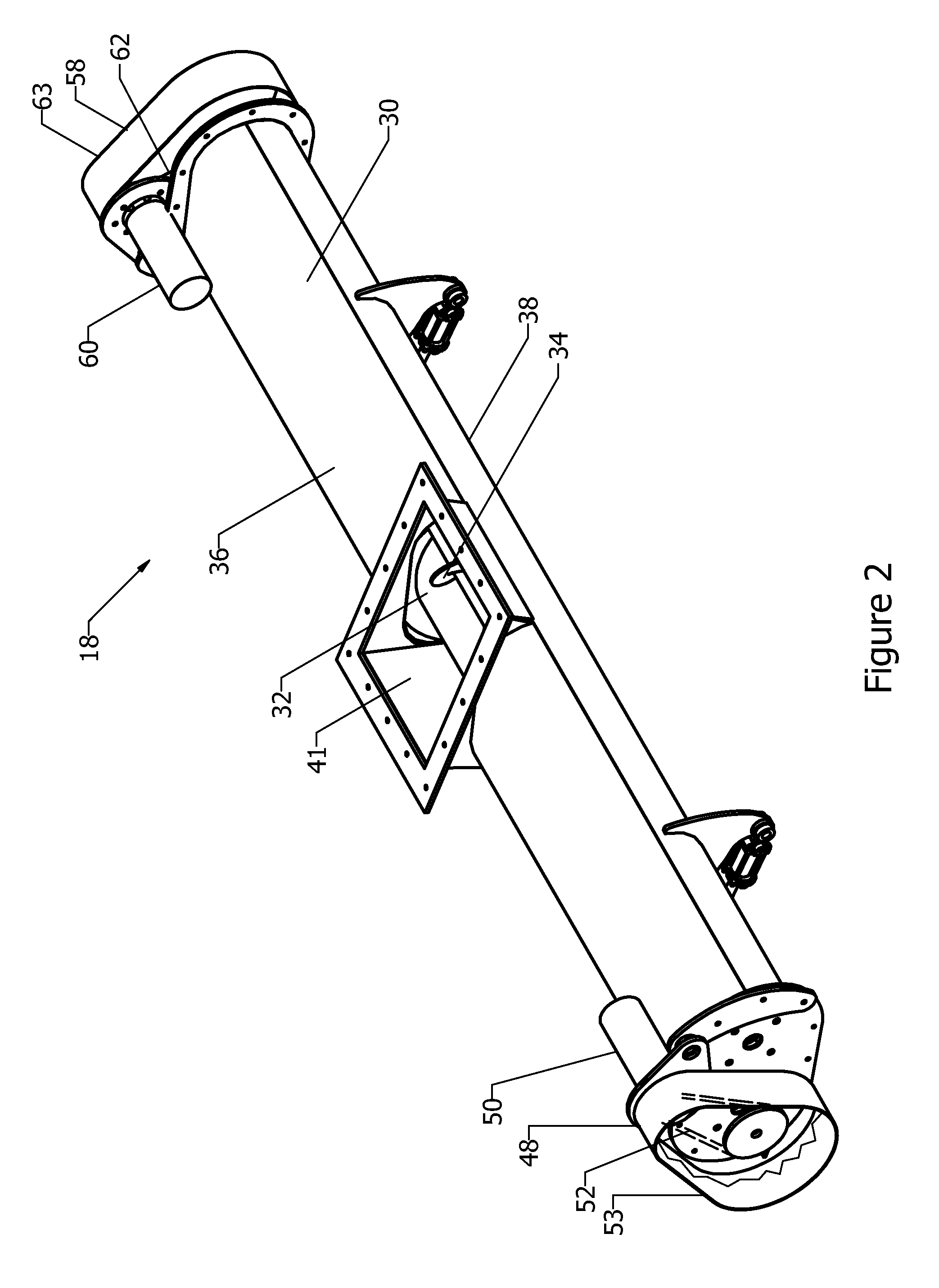

Land application vehicle, loading apparatus and material handling system and method for semi-solid material

InactiveUS20100019072A1Avoid packagingEqually distributedFertiliser distributersSowingSolid massSemi solid

According to an aspect of the invention, there is provided a land application vehicle for a semi-solid material, such as bio-solids. The vehicle includes a hopper and a distributor. The distributor includes a housing having a distributor inlet and at least one distributor outlet, a first distributor auger in the housing configured for transferring semi-solid material away from the distributor inlet towards the at least one distributor outlet and a second distributor auger in the housing configured for transferring semi-solid material back towards the distributor inlet. This creates re-circulation of the semi-solid material within the distributor, which inhibits packing of the semi-solid material at the ends of the distributor and generally aids in uniform distribution of the material.

Owner:NUHN INDS

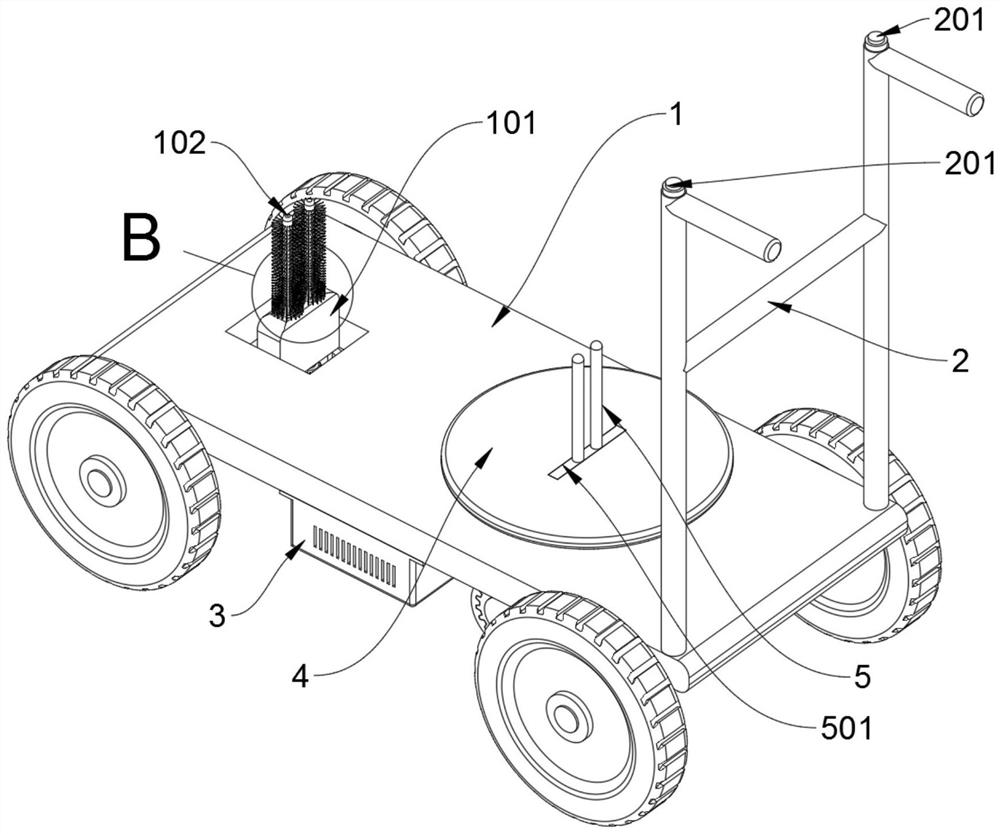

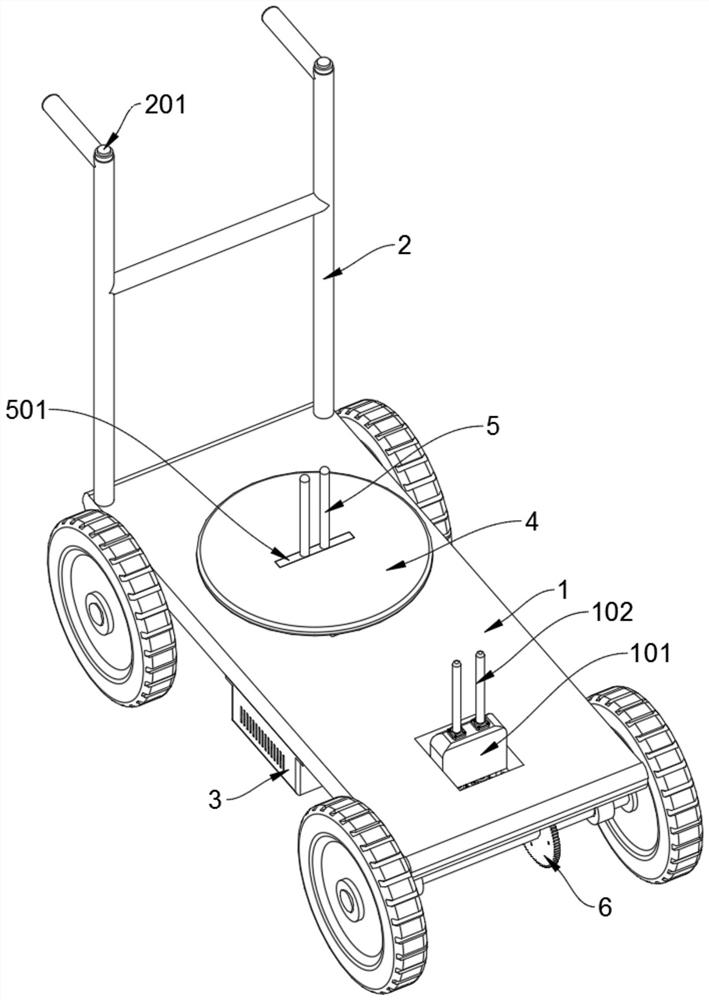

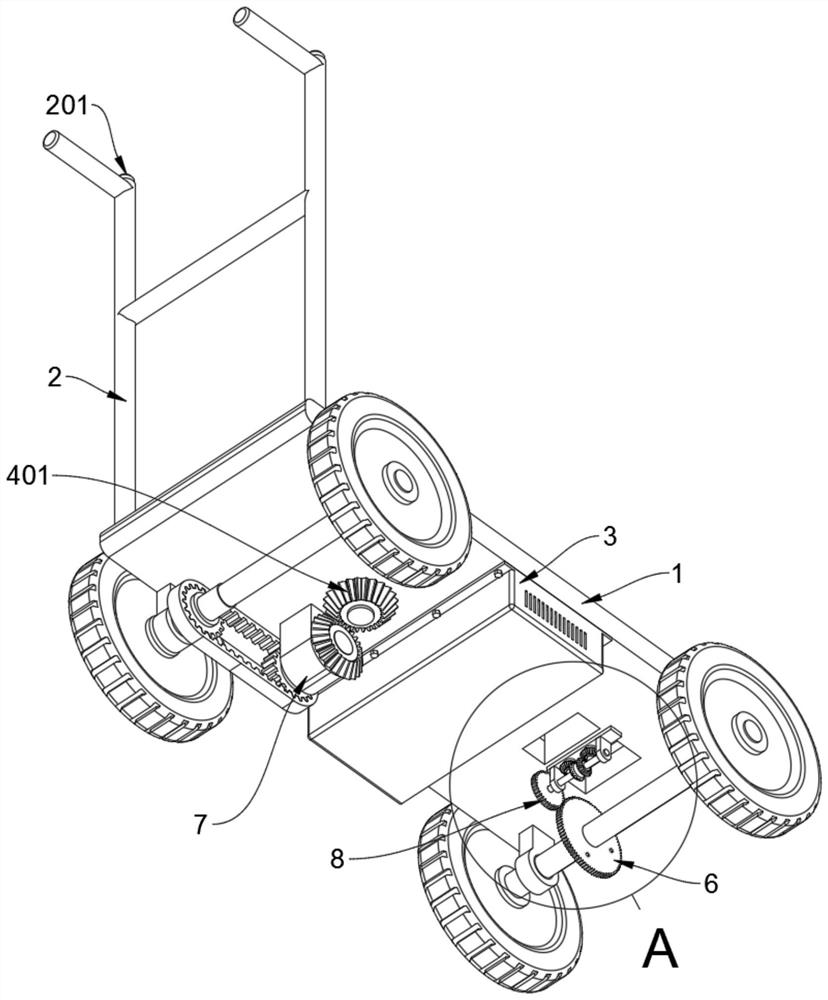

Rubber hose portable laying and collecting coiled pipe device based on garden irrigation

InactiveCN111634759AReduce dosageEliminates the hassle of manual cleaningWatering devicesCleaning using toolsElectric machineryContactor

The invention discloses a rubber hose portable laying and collecting pipe coiling device based on garden irrigation. The device comprises a chassis, positioning clamping rods, a rotating shaft gear and a positioning insertion frame, wherein the chassis comprises a vertical support mounting block and two vertical support rotating shafts; four wheels are rotationally mounted at the bottom of the chassis through a front wheel shaft and a rear wheel shaft, a square groove is formed in the middle of the front half section of the chassis in a penetrating manner, and the vertical support mounting block is fixedly welded in the square groove; and a pushing frame is welded to the top end of the rear side of the chassis in a supporting mode, pressing switches are fixedly mounted at the top ends of aleft vertical support rod and a right vertical support rod of the pushing frame, and the two pressing switches are electrically connected with two contactors inside a control electric box and used for controlling starting and stopping of a motor. According to the portable rubber hose laying and collecting pipe coiling device based on garden irrigation, vertical support brush wires at the bottomsof the two vertical support rotating shafts can rotate to wipe soil falling on the top surface of the vertical support mounting block, so that the plug accumulation of the soil at the top end of the vertical support mounting block is avoided, and then the problem that a rubber hose cannot pass smoothly is solved.

Owner:林景生

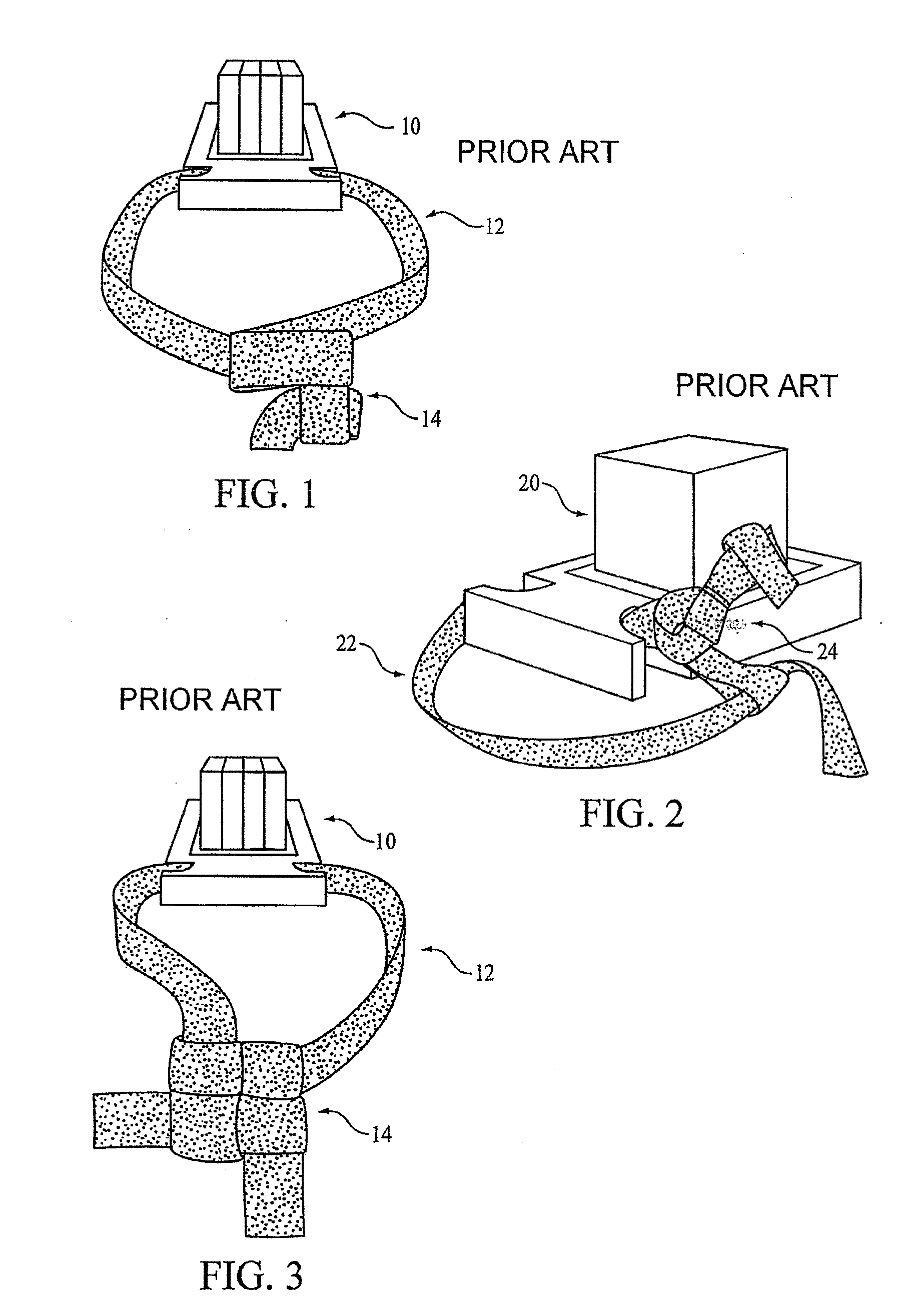

Protective covers for phylacteries

InactiveUS20120000799A1Avoid packagingOther accessoriesContainer/bottle contructionEngineeringLateral extension

Protective covers for Phylacteries including an upper shell member and a lower shell member at least partially separable from one another and which, when together, define a hollow interior contoured to fit the Phylactery. One or two lateral extension portions, depending on whether the protective cover is for a head Phylactery or an arm Phylactery, are situated partly on each of the upper and lower shell members outward from a respective plane including a side surface of the cube-shaped portion and have a width of at least about 1.2 centimeters. A supplemental platform or support surface may be arranged alongside a rear side of a cube-shaped portion of the upper shell member facing the slot of the protective cover to support for a knot of the strap of the head Phylactery when the head Phylactery is housed in the protective cover.

Owner:ADLER IRA N

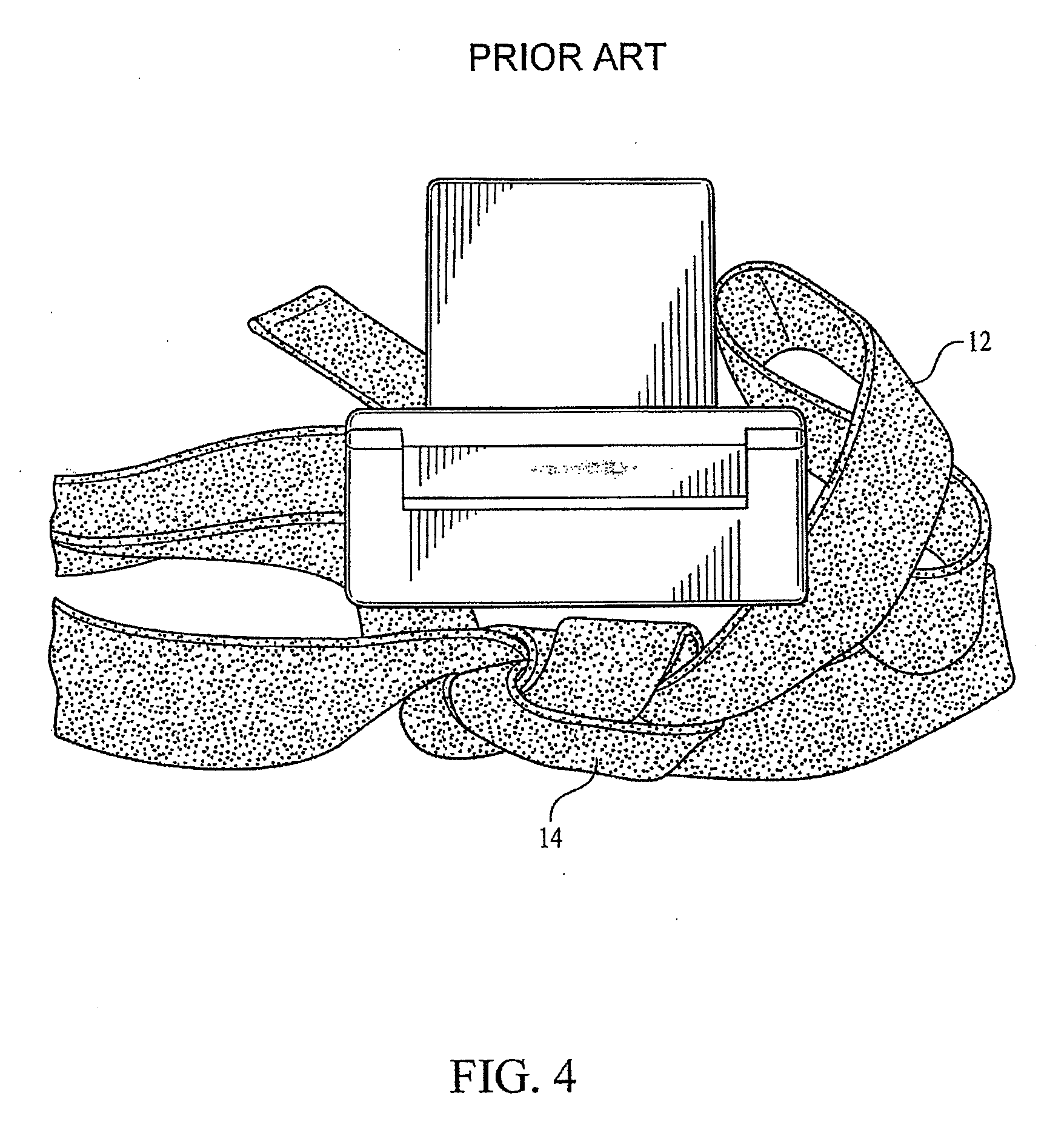

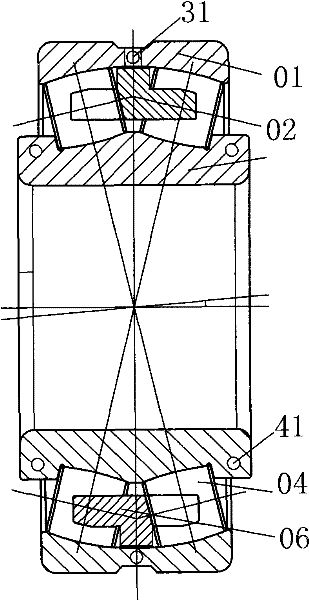

Split bearing

InactiveCN102478071AReduce processing stepsReduce weightBearing componentsManufacturing convertersButt jointEdge structure

The invention relates to a split bearing. The bearing which comprises an outer ring, an inner ring, a retaining support, a spherical surface roller and an inner ring locking ring is characterized in that the symmetrical outer ring is formed by the butt joint of two half-edge structures; and the joint of the outer ring and a position which is on the outer diameter, perpendicular to the outer diameter and close to the subdivision part are respectively provided with two circular holes, two circular grooves perpendicular to the two circular holes are milled on the other half of the subdivision part, and a connecting piece connects the two half outer rings into one body. According to the invention, the outer ring is fixed on the outer diameter without an outer ring locking ring, so the processing operation of the bearing is reduced, the weight of the bearing is reduced, the manufacturing cost is reduced, the whole packaging of the split bearing is solved, and a grinding catching / gripping problem is solved, thereby the bearing of the invention brings great conveniences for manufacturers and users.

Owner:瓦房店福斯特轴承科技开发有限公司

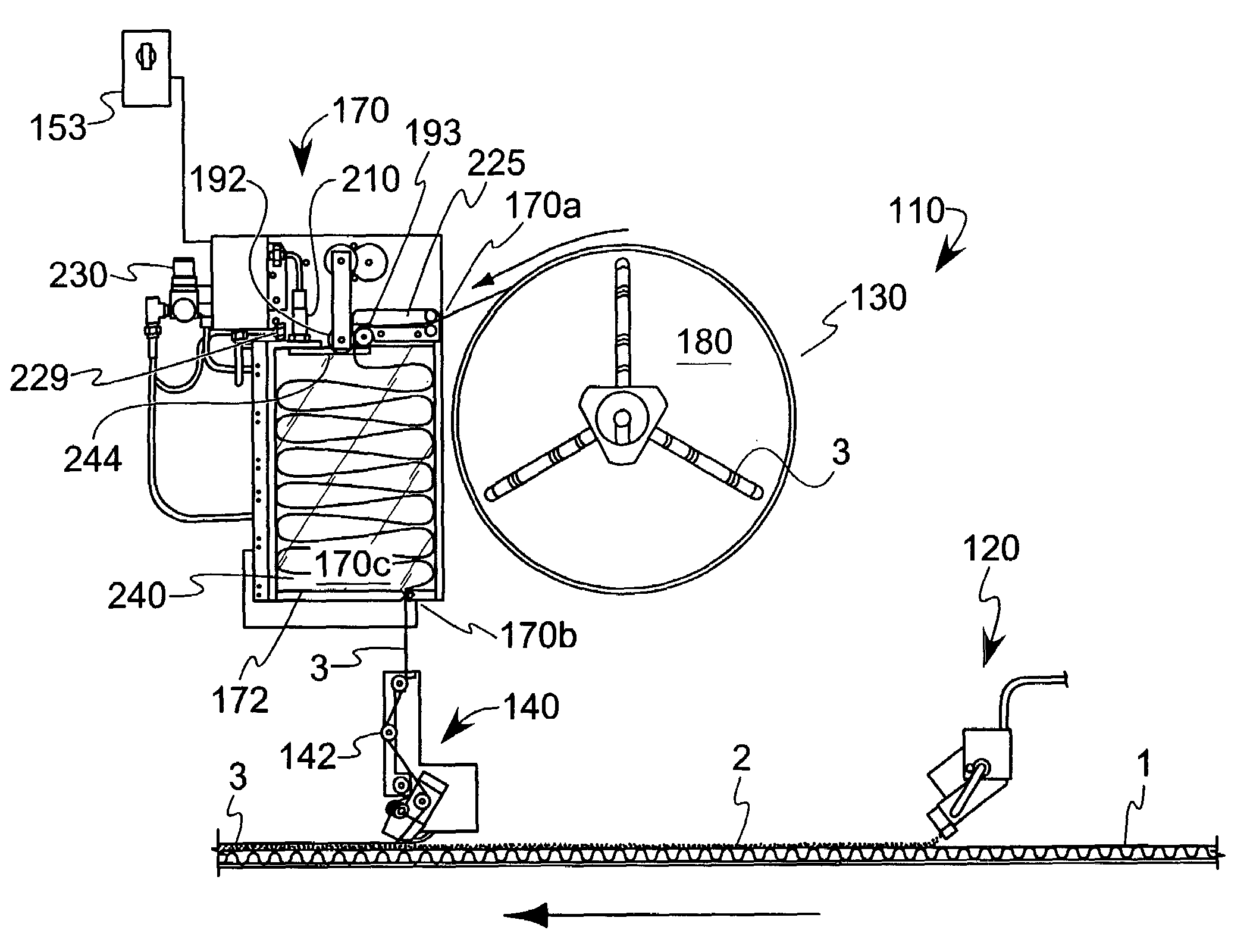

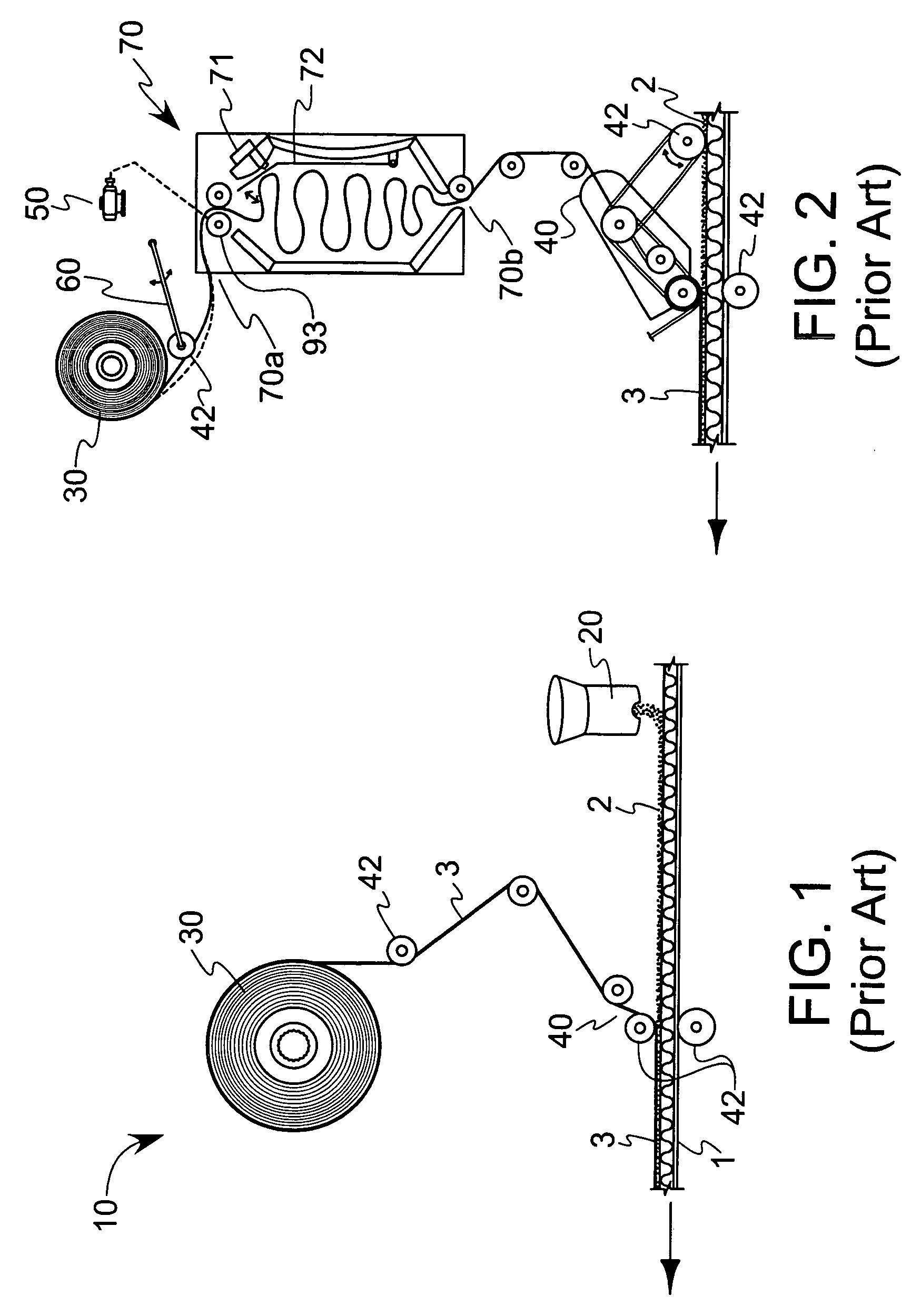

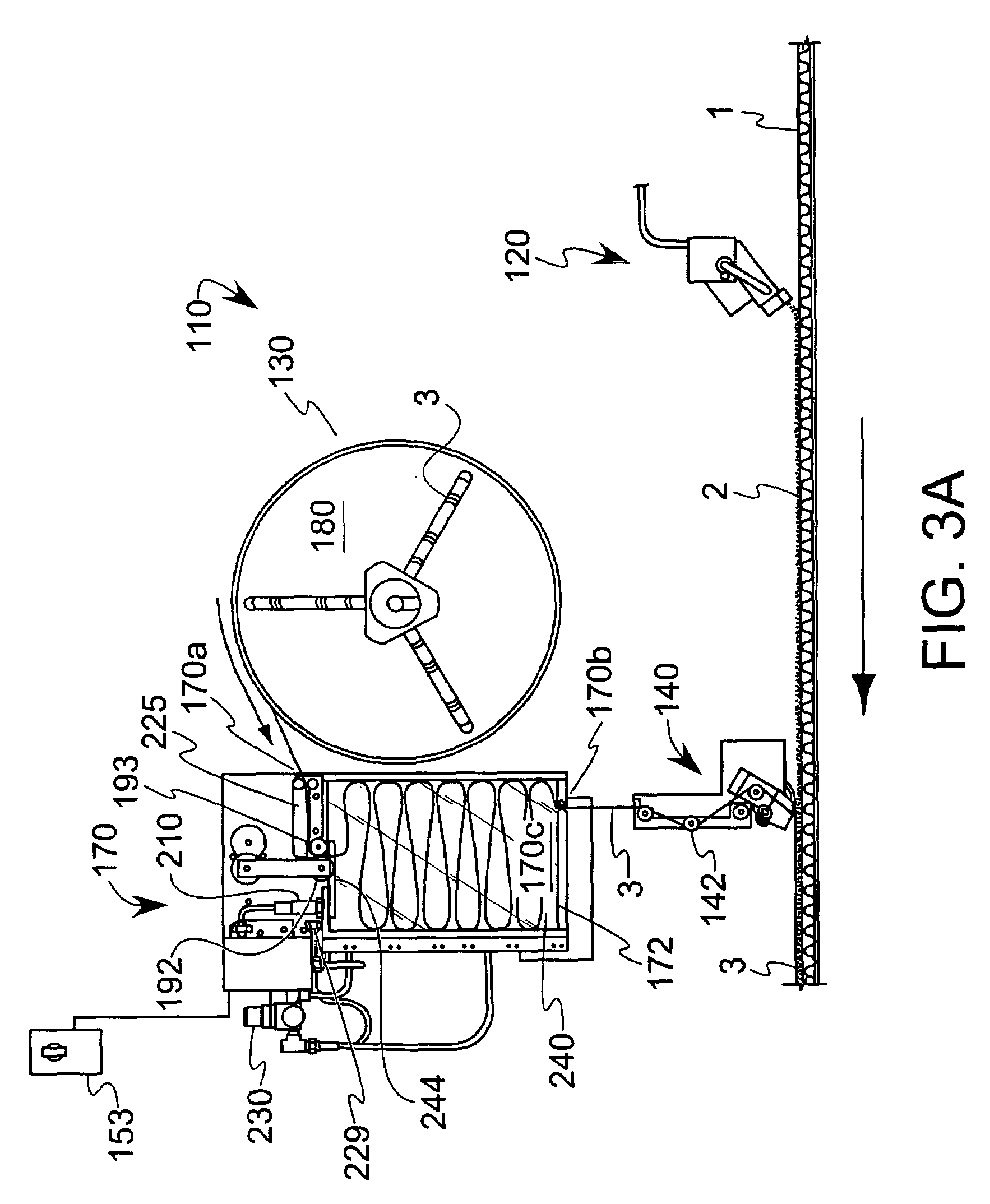

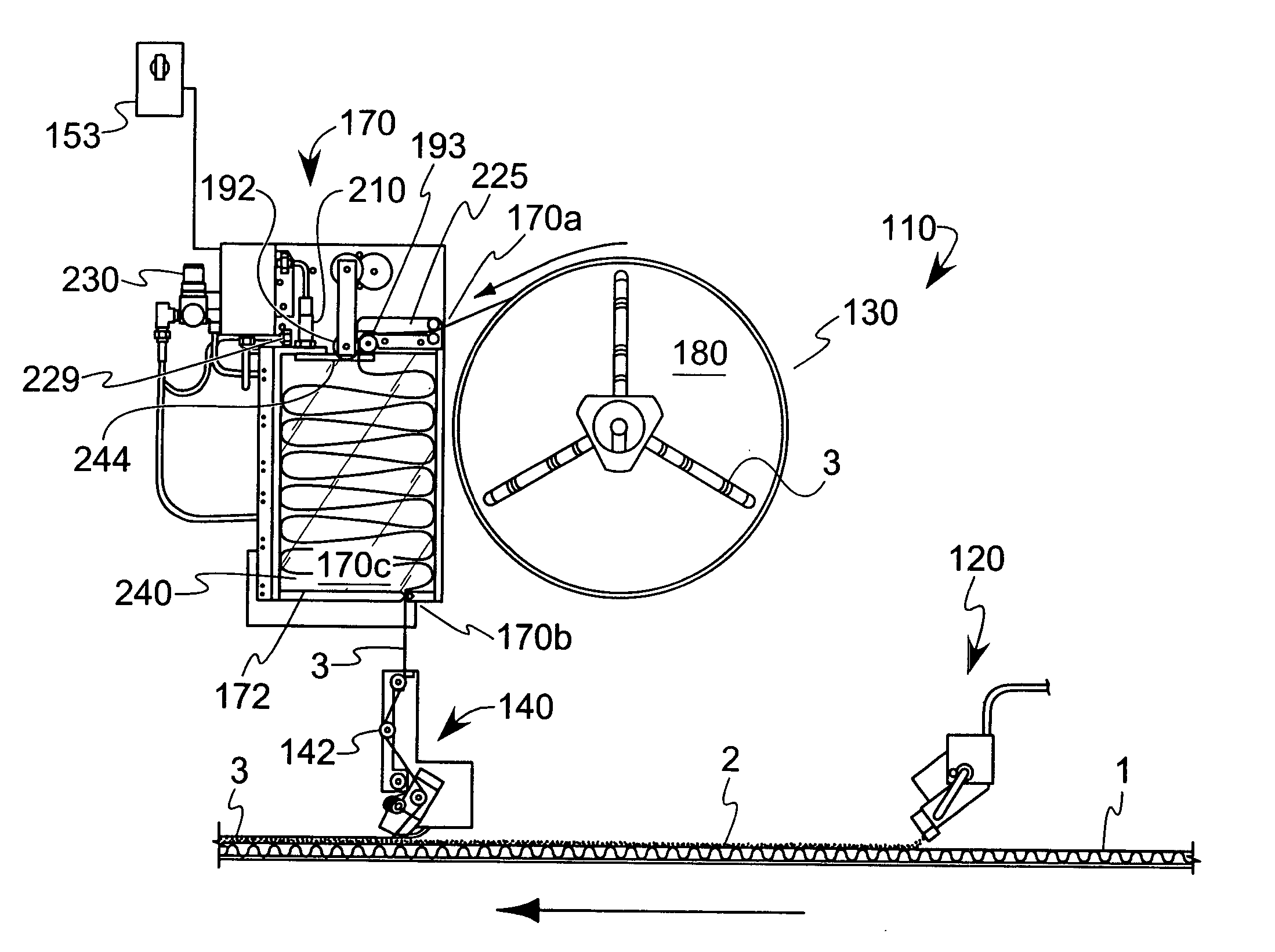

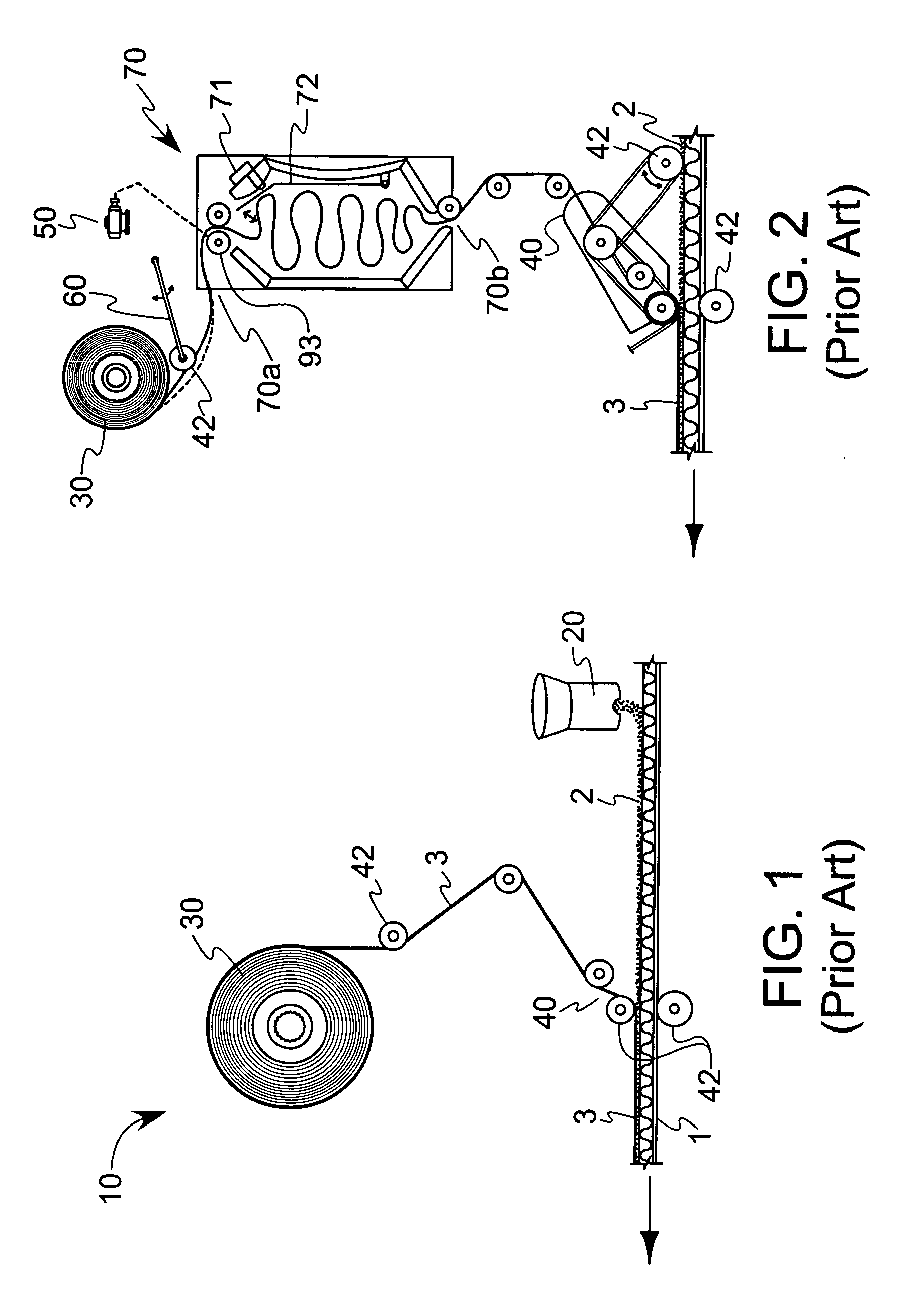

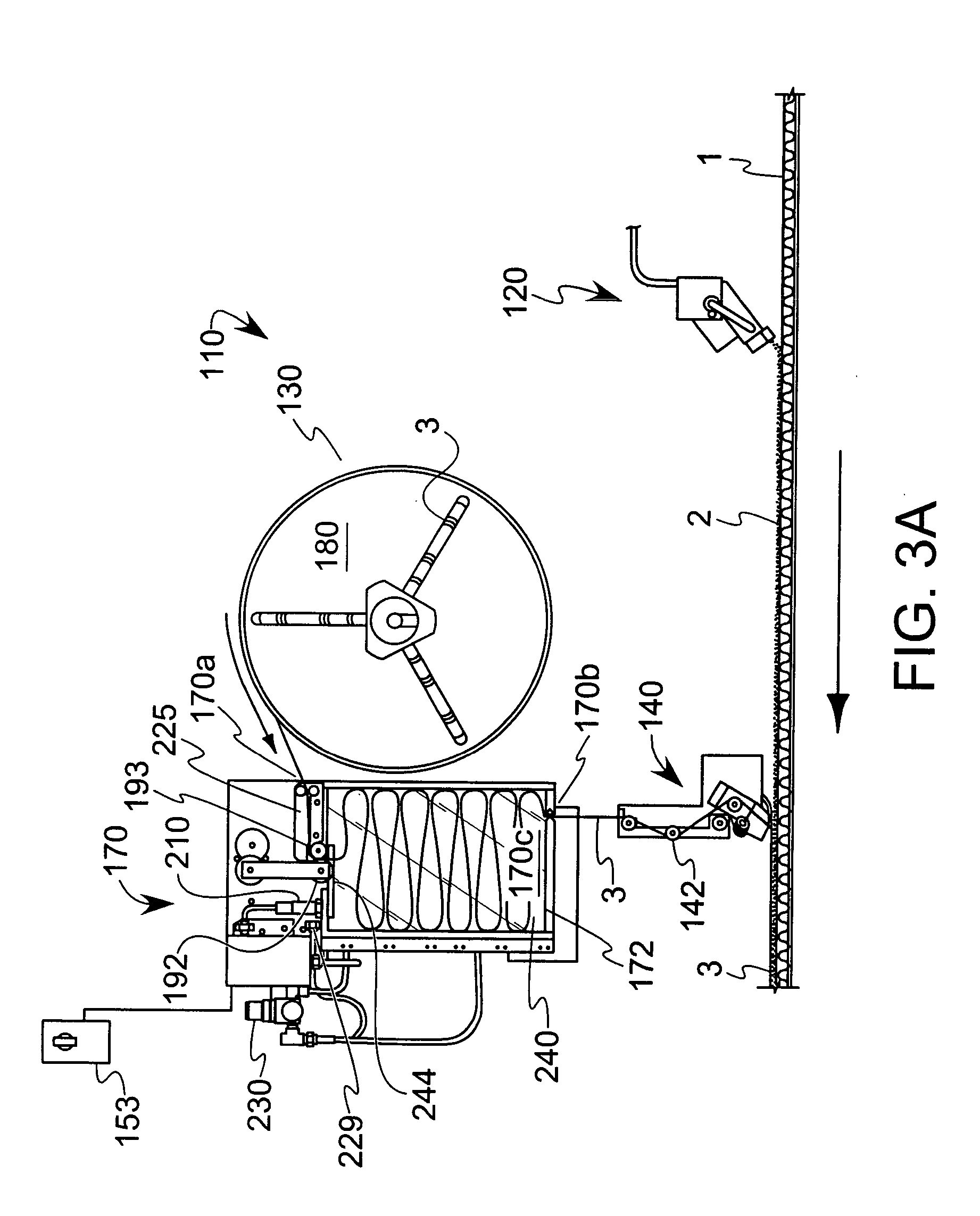

Release liner staging unit and system incorporating same

ActiveUS7441578B2Avoid distortionFacilitate cleaning and threadingLamination ancillary operationsControlling laminationSaturated LevelTime delays

Owner:VALCO CINCINNATI

Release liner staging unit and system incorporating same

ActiveUS20050252597A1Avoid distortionFacilitate cleaning and threadingLamination ancillary operationsControlling laminationSaturated LevelTime delays

A release liner staging unit for depositing a release liner onto an adhesive layer. The unit includes an accumulator that creates a buffer between an amount of release liner supplied and an amount needed for covering a layer of adhesive. The tendency of release liner placed within the accumulator to settle allows additional release liner to be introduced, thereby producing a slightly saturated level of release liner in the accumulator. Time delays can be accounted for to reduce the number of times a drive mechanism needs to operate, thereby reducing wear on such componentry. The unit may also form part of a larger release liner application device and adhesive application system.

Owner:VALCO CINCINNATI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com