Full-automatic mask packaging equipment

A fully automatic packaging and mask technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of excessive manual participation in mask packaging and low packaging production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

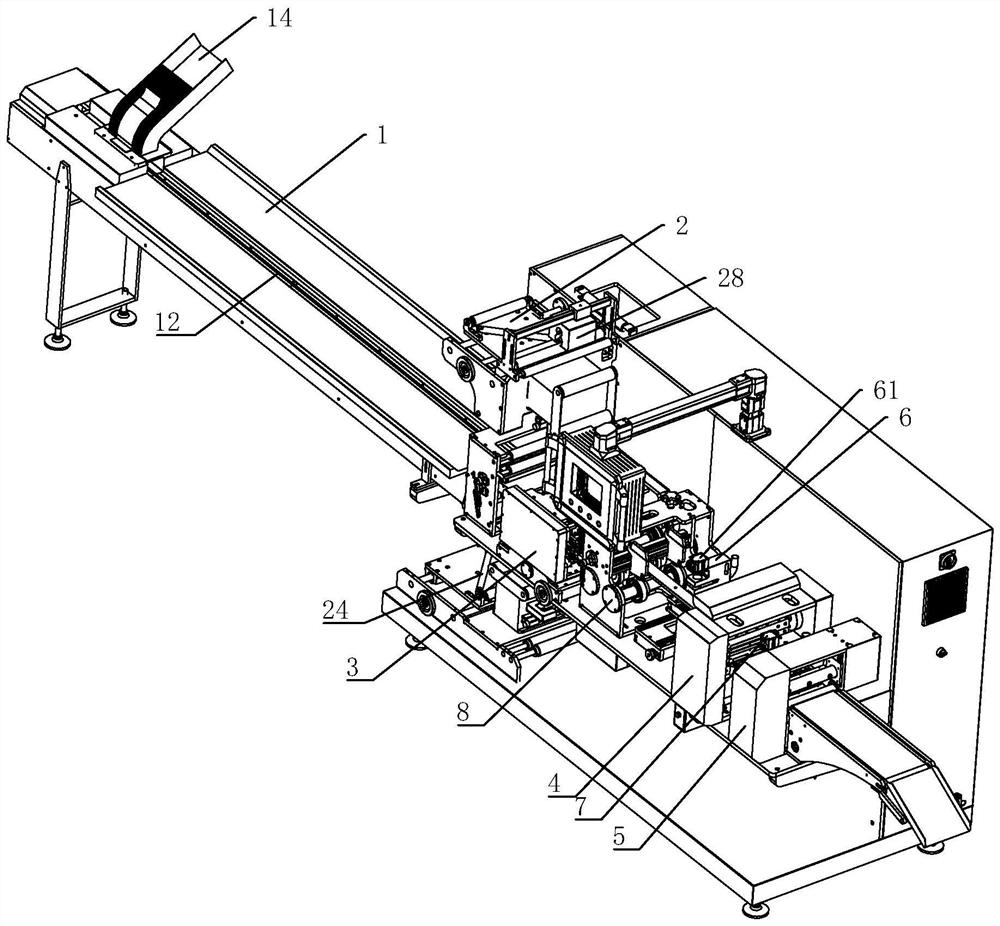

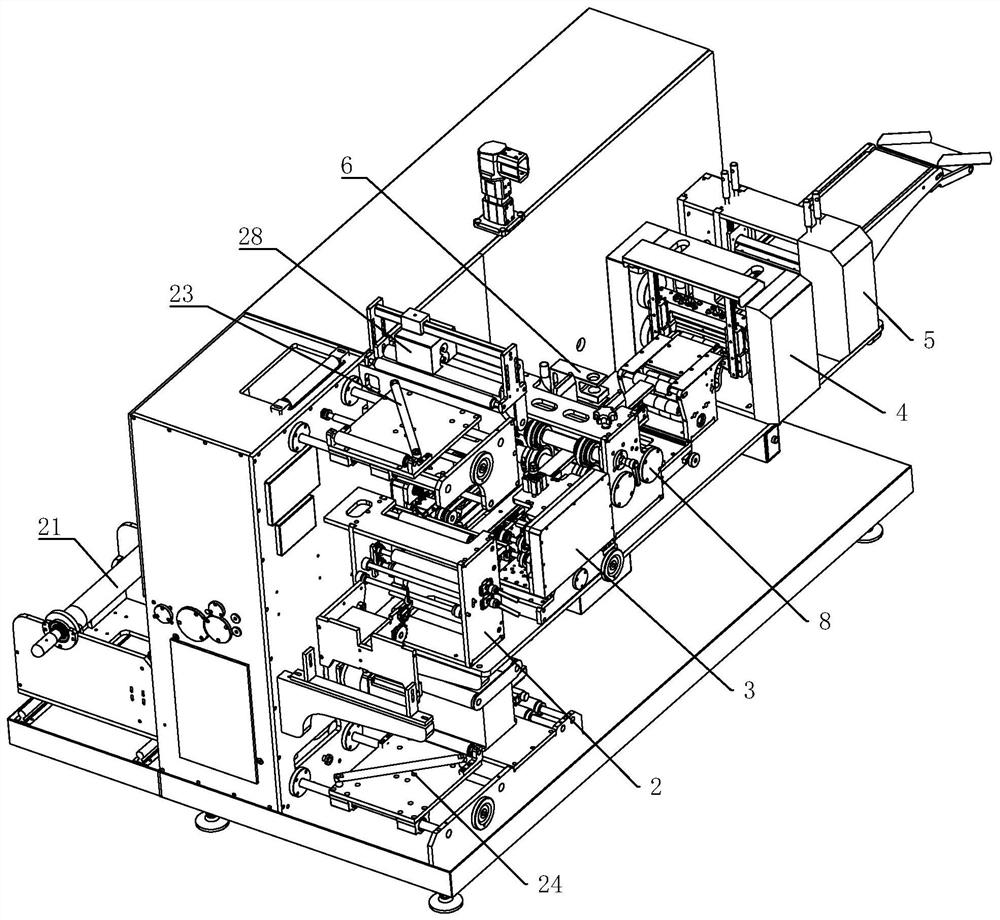

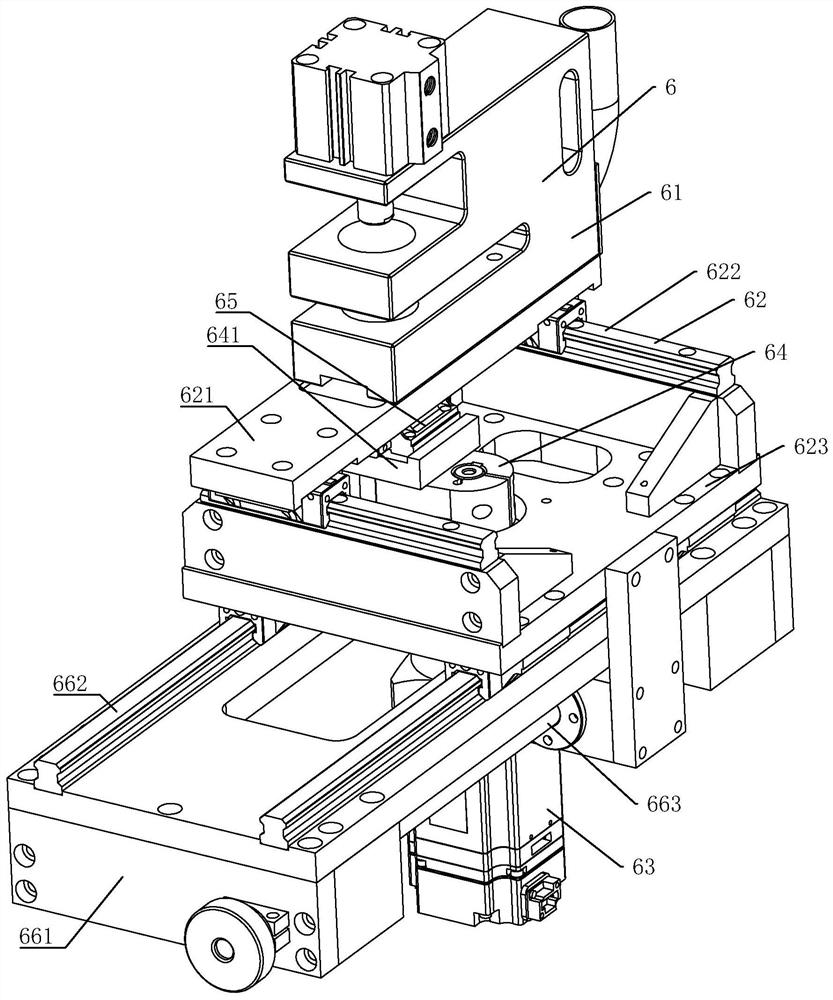

[0036] Such as figure 1 , figure 2 The mask automatic packaging equipment shown in the figure includes mask material distribution and transportation device 1, packaging bag film cutting and feeding device 2, double-sided hot-melt edge-sealing device 3, sealing hot-melt edge-sealing device 4 and The cutting device 5, the mask feeding device 1 arranges the masks and transports them to the packaging bag film cutting and feeding device 2, and the packaging bag film cutting and feeding device 2 supplies and sends out the continuous packaging bag film coated on the upper and lower sides of the mask, both sides The hot-melt edge sealing device 3 receives the packaging bag film sent out by the packaging bag film cutting and feeding device 2 and the mask wrapped in the packaging bag film, and the double-sided hot-melt edge sealing device 3 is used to adjust The hot-melt edge sealing operation is performed on both sides. The sealing hot-melt edge sealing device 4 performs heat-melt ed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com