Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

218results about How to "Improve structural quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

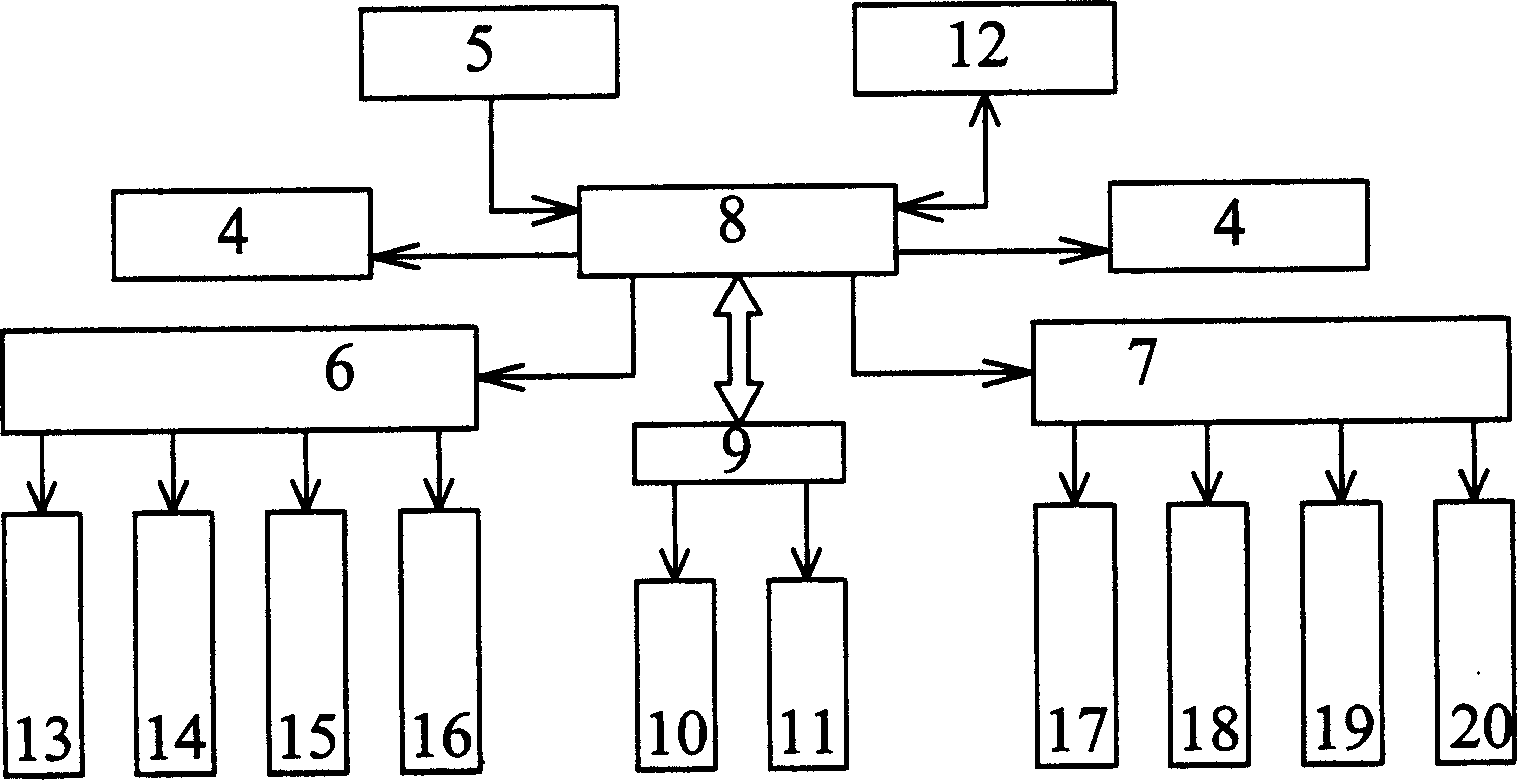

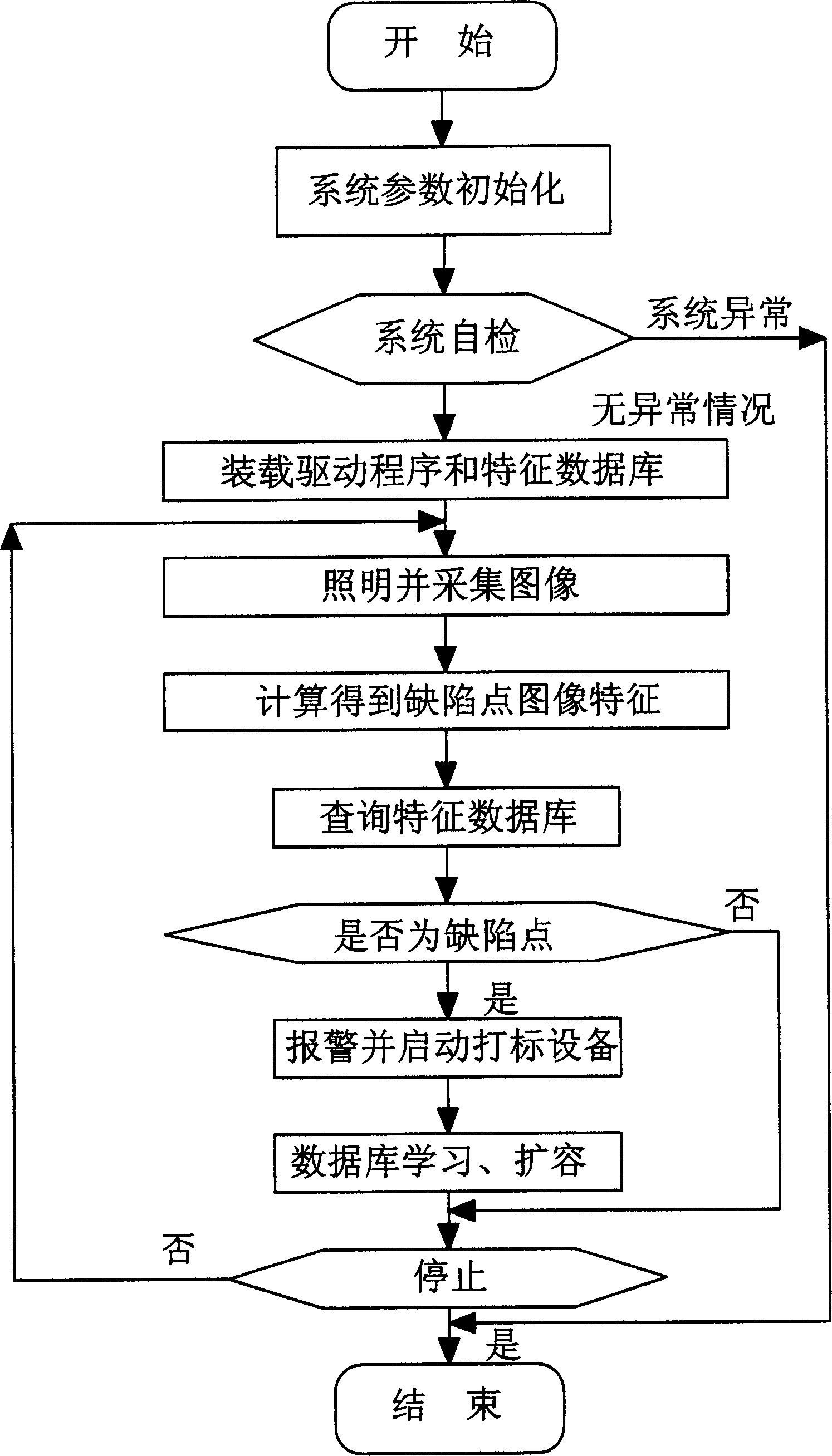

Automatic online detection method for defects on upper and lower surfaces during steel plate pretreatment process

InactiveCN1789990ASafe and reliable workIncrease productivityImage enhancementImage analysisMeasurement deviceEngineering

The invention discloses an on-line self-detecting method of surface defect in the ship formation steel predisposing course, which comprises the following steps: allocating the steel surface luminous equipment to form light field on two faces of on-line steel; setting several cases of independent imaging measuring device corresponding to each light field; proceeding real-time image of two faces of steel simultaneously when the steel moves along horizontal direction; disposing the image and marking the defect point; gathering the image grey scale and colority information separately through grey scale image information collector and colority image signal collector; analyzing and disposing the gathered grey scale and colority information through industrial computer software; adapting image grey scale character to identify and classify the defect point; starting the marking device to mark the defect point when the defect point is detected. The invention shortens the ship formation period greatly, which improves the ship body structure quality and detecting precision.

Owner:BOHAI SHIP HEAVY IND CO LTD

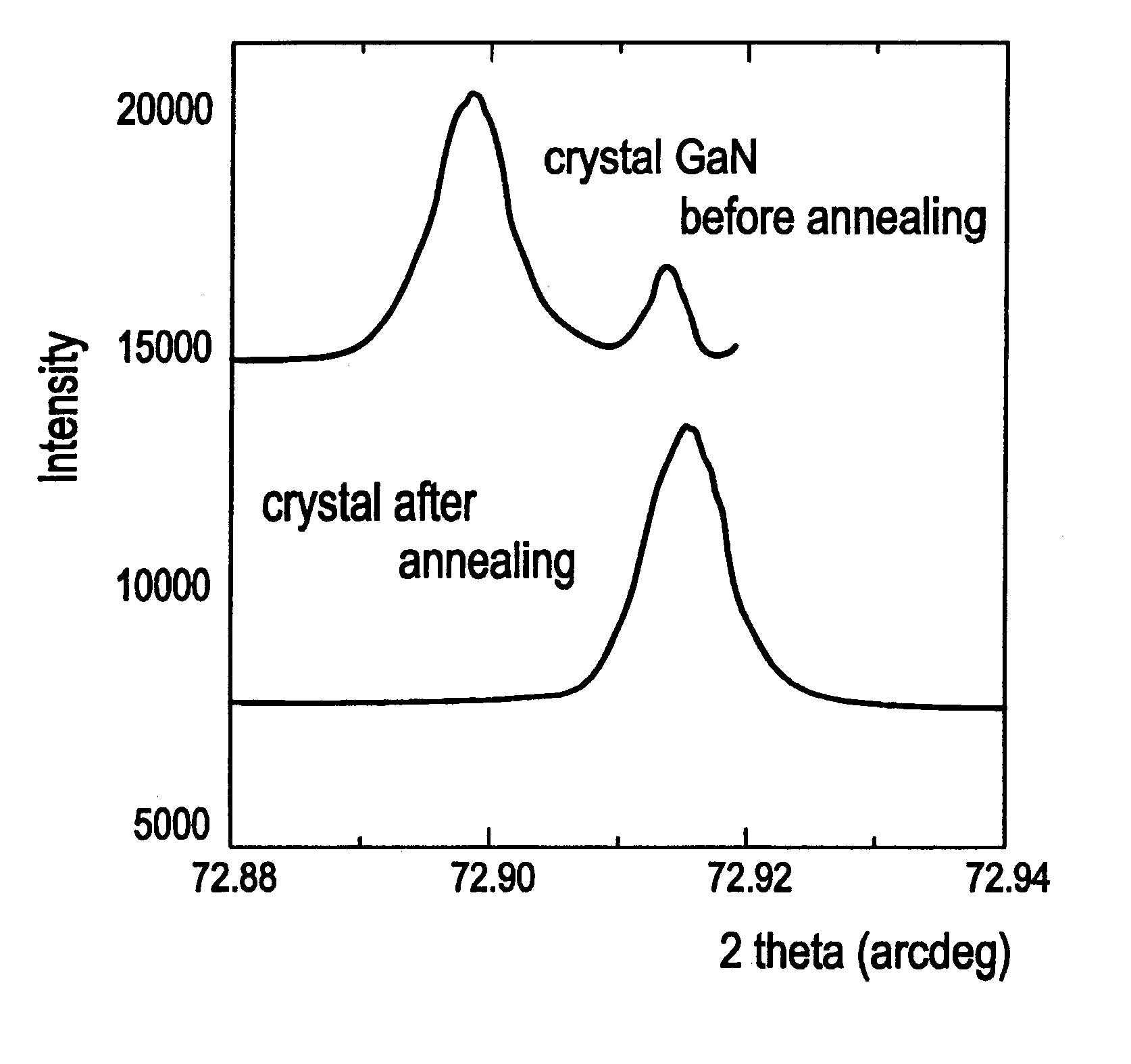

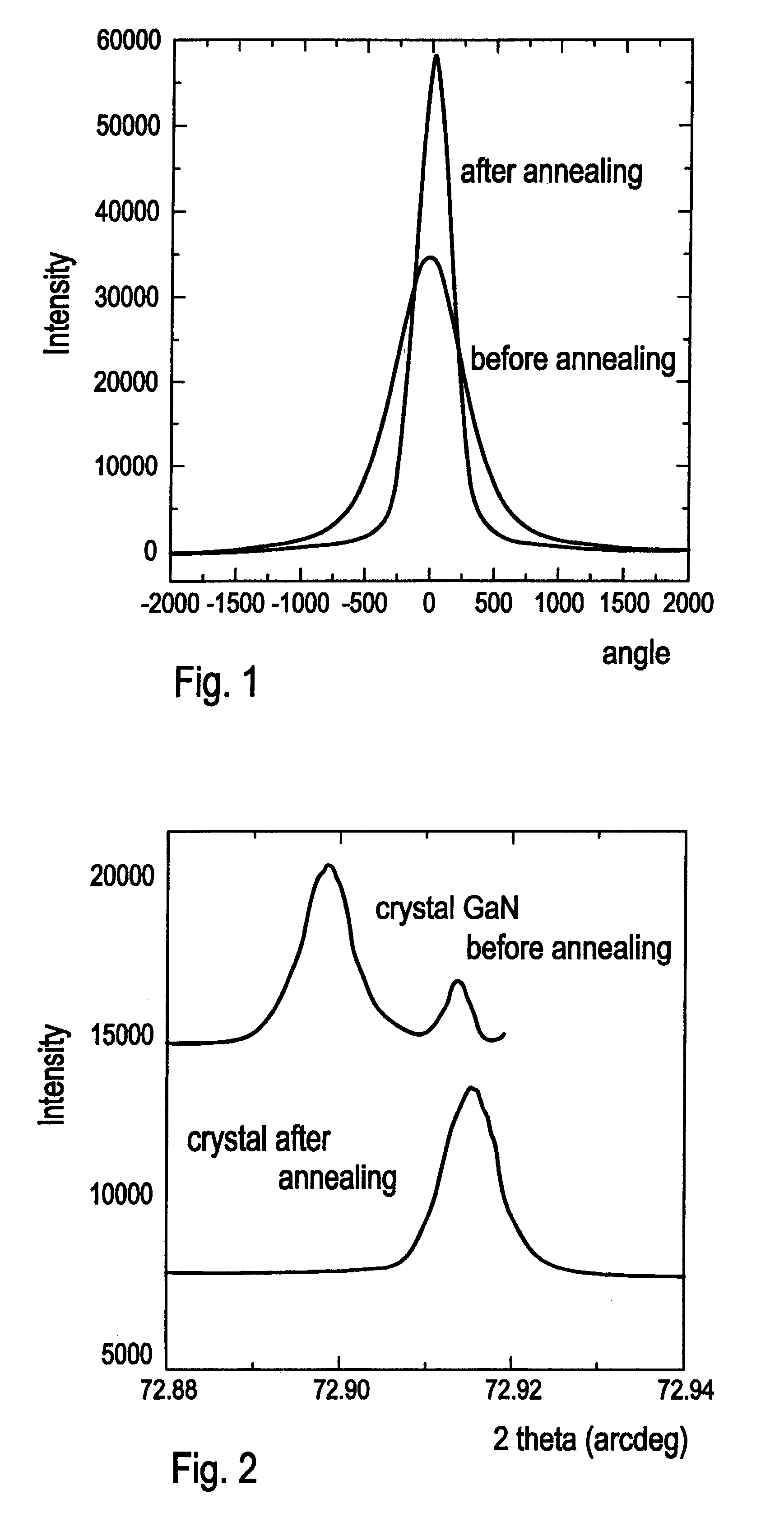

Method of fabrication of semiconducting compounds of nitrides A3B5 of P-and N-type electric conductivity

InactiveUS6329215B1Low resistivityIncrease intensityPolycrystalline material growthLaser detailsHigh power lasersHigh pressure

The subject of the Invention is the method of fabrication of nitride semiconductor A3B5 such as GaN, AlN, InN or their solid solutions, characterized by p- or n-type conductivity, high intensity of emitted light and high structural quality. The semiconductors obtained by this method are applied in the construction of light emitting devices, light detectors and electric current amplifiers such as for example: highly efficient blue and green light diodes, laser diodes and high power lasers, ultraviolet detectors and high temperature field transistors. The method according to the Invention is characterized by the fact that the homoepitaxial or heteroepitaxial layers of nitride semiconductors A3B5 are deposited on the conductive substrate after the introductory processing or isolating substrate, and after that the so prepared structures are located in high pressure diffusional chamber filled with the one or multi-component gas, compressed to pressure in the range 1000-20000 bar, and annealed in the temperature 1000-1800 ° C. in the prescribed time in the presence of the dopant from the external and / or internal source.

Owner:INST WYSOKICH CISNIEN POLSKIEJ AKADI NAUK

High quality strain Ge/SiGe super-lattice structure and preparation method thereof

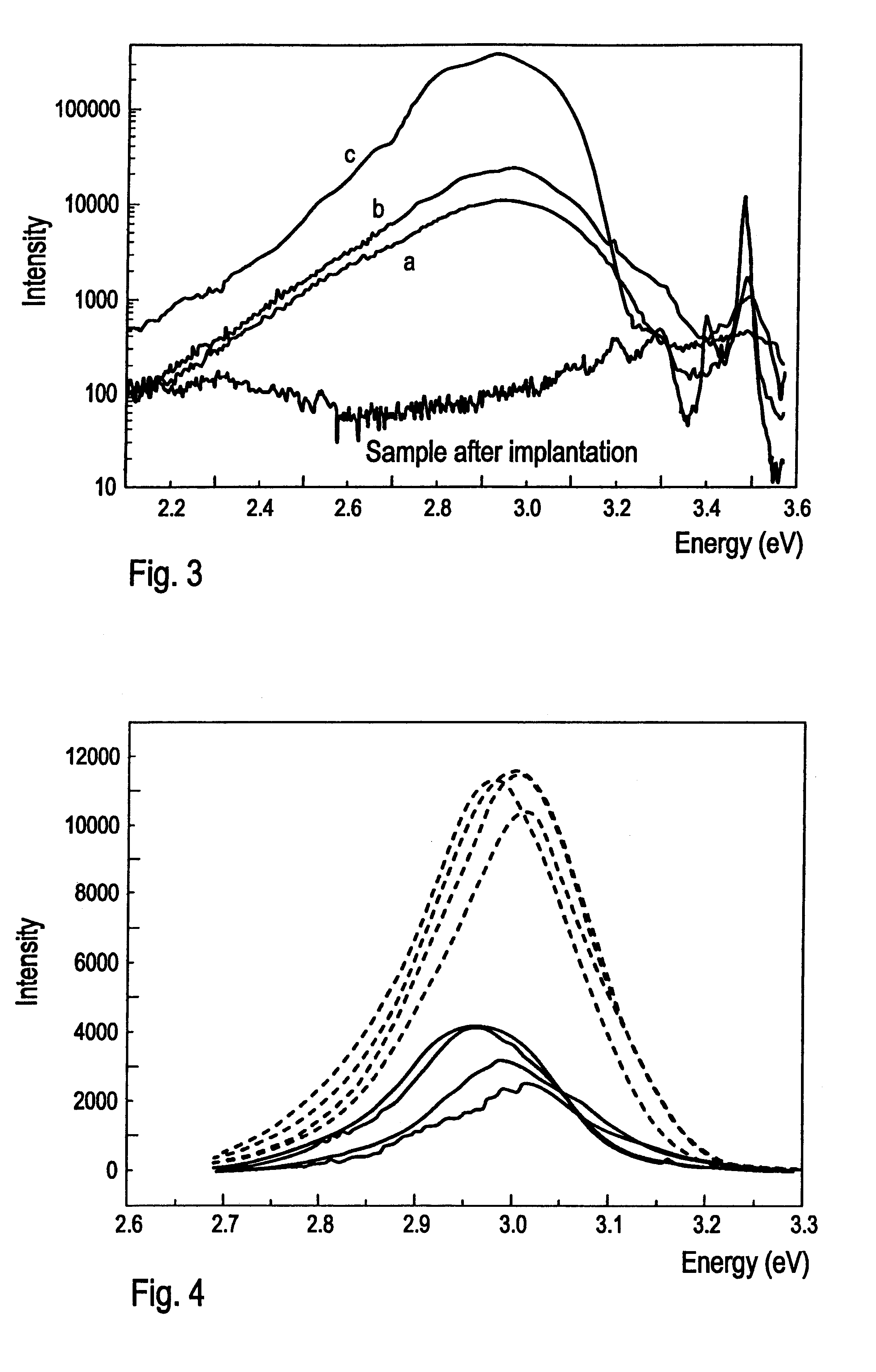

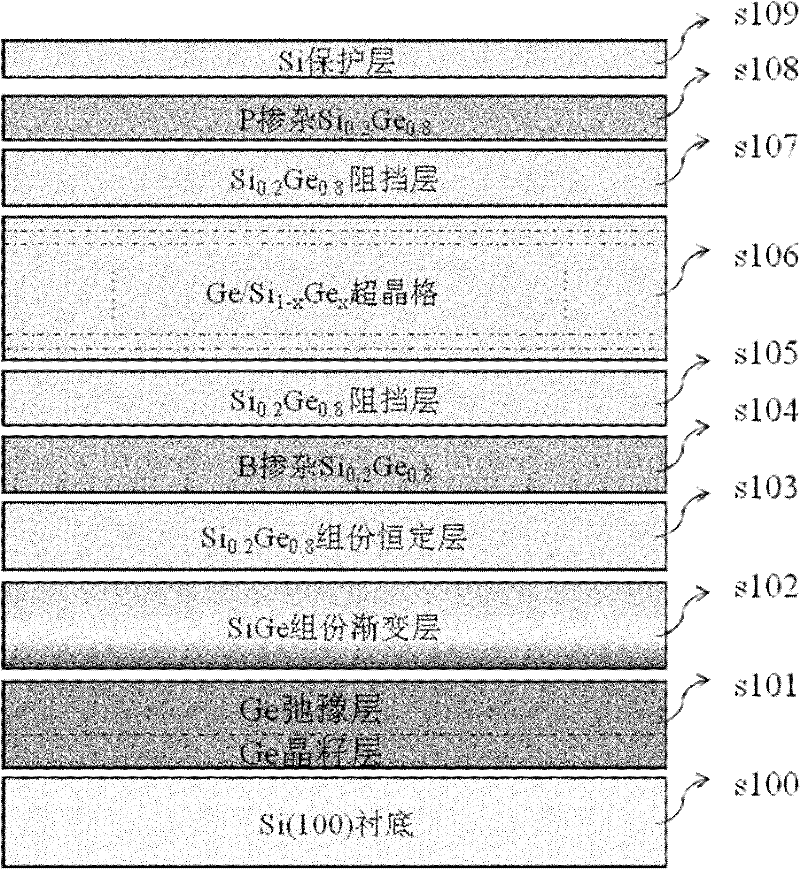

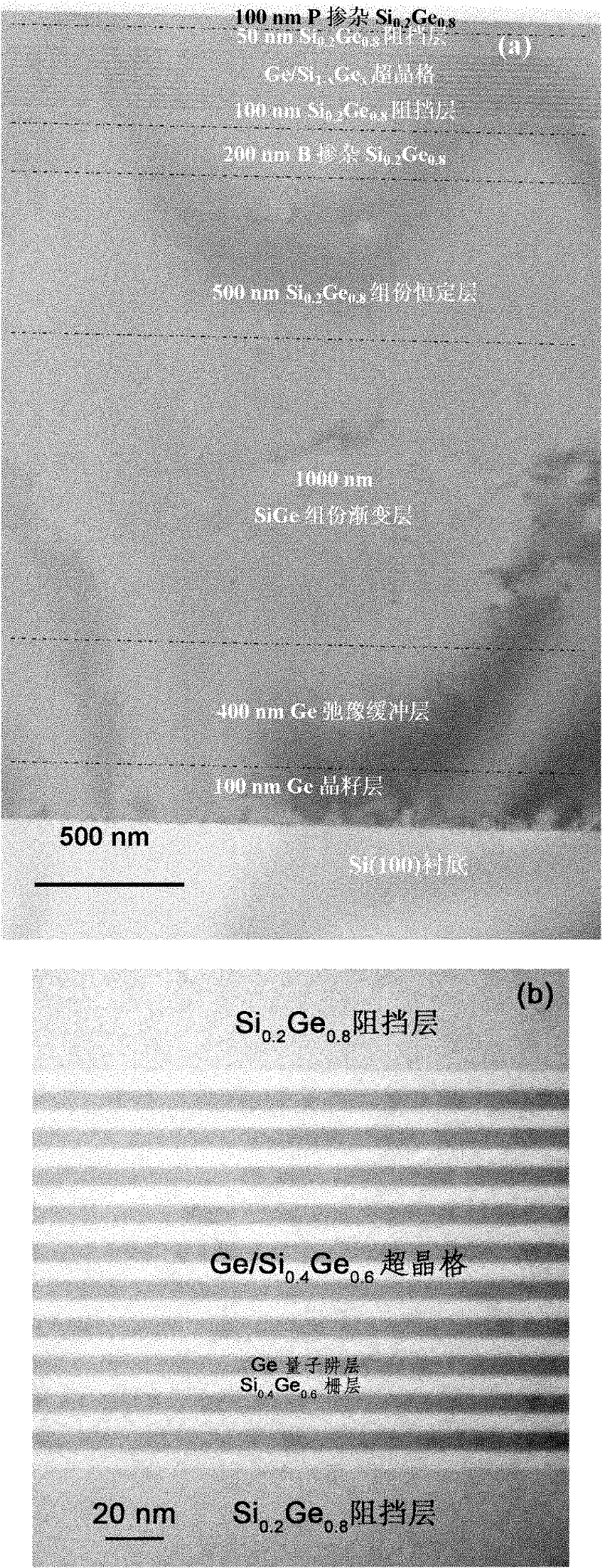

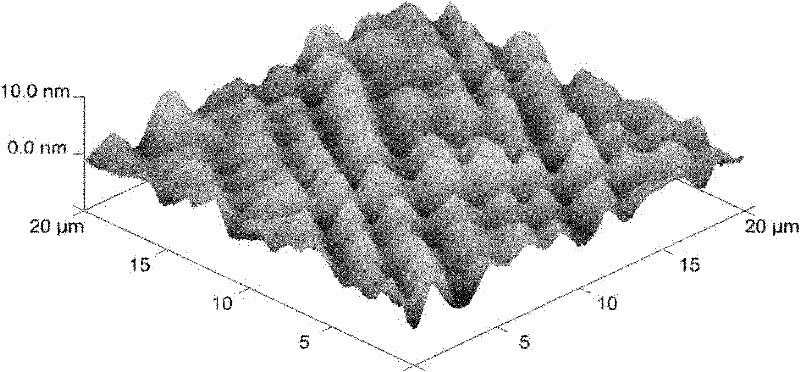

InactiveCN102162137AHigh Ge contentReduce dislocation densityPolycrystalline material growthFrom chemically reactive gasesSemiconductor materialsReduced pressure chemical vapor deposition

The invention belongs to the technical field of semiconductor materials, and relates to a Ge / Si1-xGex super-lattice structure and preparation thereof. The high quality strain Ge / Si1-xGex super-lattice structure comprises a Si substrate, and a Si0.2Ge0.8 virtual substrate layer, a B-doped Si0.2Ge0.8 epitaxial layer, a Si0.2Ge0.8 blocking layer, a Ge / Si1-xGex super-lattice layer, a P-doped Si0.2Ge0.8 epitaxial layer, a Si0.2Ge0.8 blocking layer and a Si protective layer sequentially and epitaxially grown on the Si substrate, wherein x is more than or equal to 0.6 and less than or equal to 0.7. The epitaxial layers are sequentially grown on the Si substrate by adopting a reduced pressure chemical vapor deposition method; the obtained super-lattice structure has the properties of low dislocation defect density, low thickness and flat interface / surface, and the Ge / Si1-xGex super-lattice is in a strain state; and the super-lattice structure has high quality and is particularly suitable for manufacturing silicon-based laser devices and waveguide modulators.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

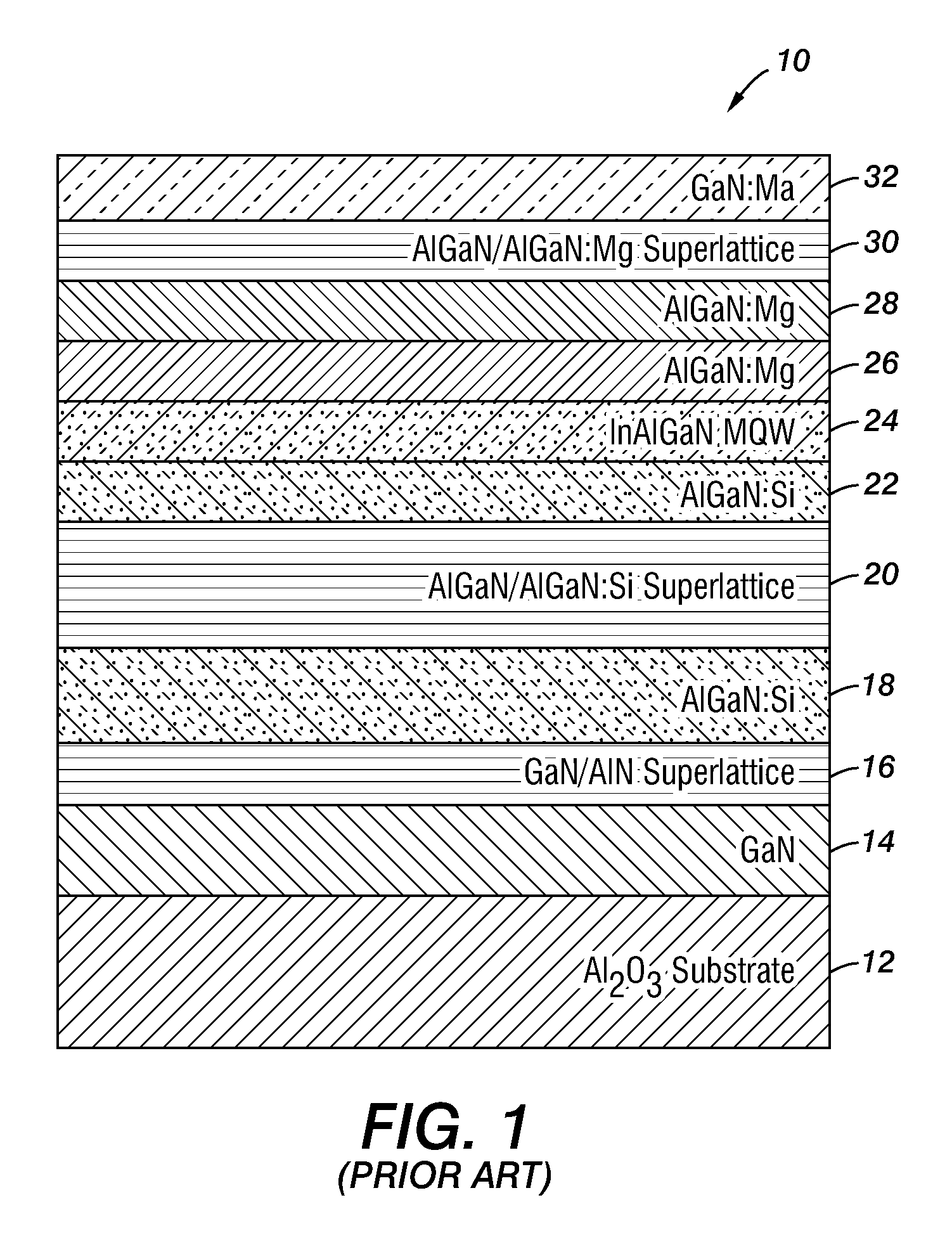

Method for controlling the structure and surface qualities of a thin film and product produced thereby

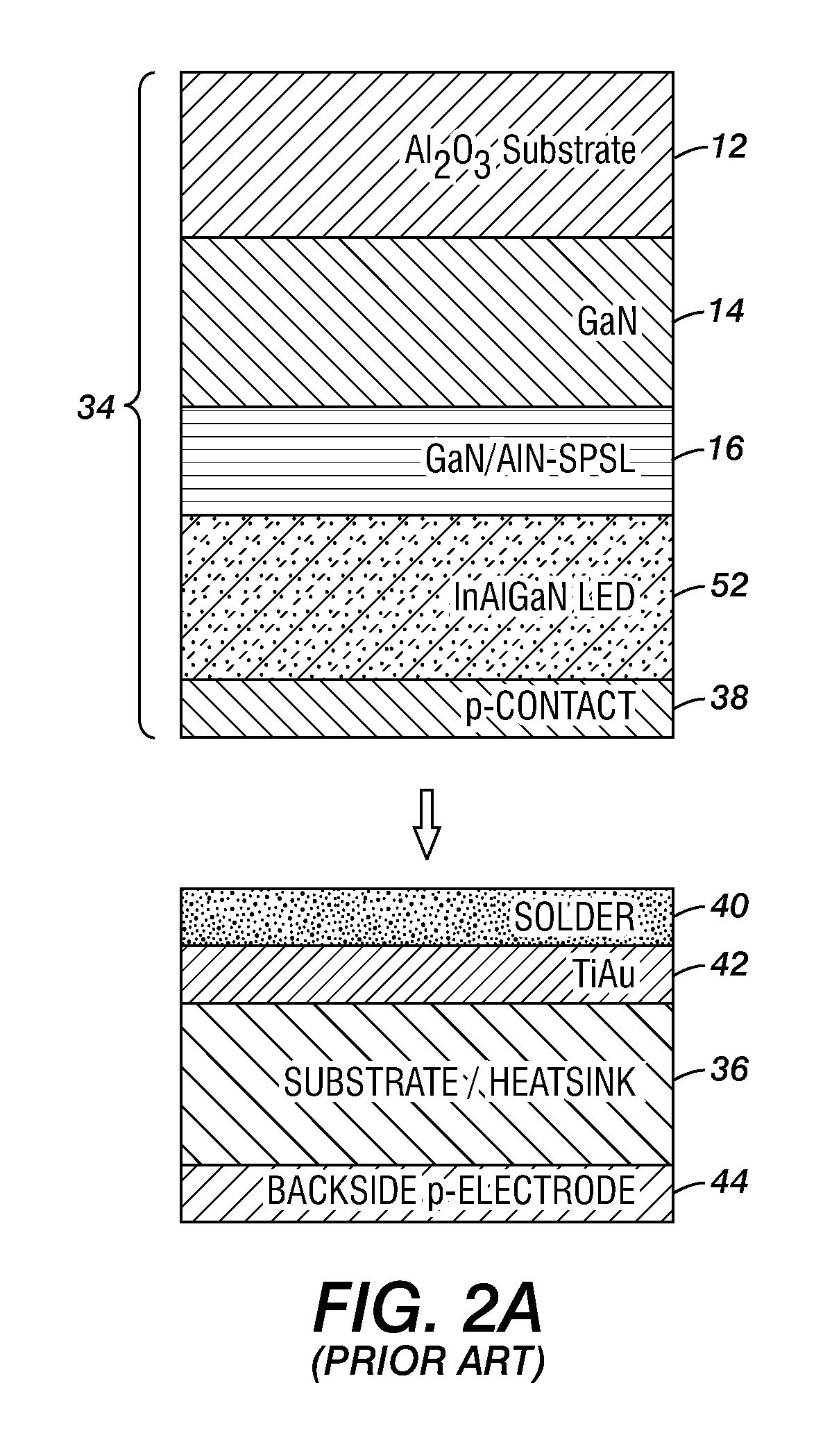

InactiveUS7501299B2Improve structural qualityDevice performance and longevitySemiconductor/solid-state device manufacturingNanoopticsSemiconductor structureQuantum well

A system and method for providing improved surface quality following removal of a substrate and template layers from a semiconductor structure provides an improved surface quality for a layer (such as a quantum well heterostructure active region) prior to bonding a heat sink / conductive substrate to the structure. Following the physical removal of a sapphire substrate, a sacrificial coating such as a spin-coat polymer photoresist is applied to an exposed GaN surface. This sacrificial coating provides a planar surface, generally parallel to the planes of the interfaces of the underlying layers. The sacrificial coating and etching conditions are selected such that the etch rate of the sacrificial coating approximately matches the etch rate of GaN and the underlying layers, so that the physical surface profile during etching approximates the physical surface profile of the sacrificial coating prior to etching. Following etching, a substrate is bonded to the exposed surface which acts as a heat sink and may be conductive providing for backside electrical contact to the active region.

Owner:PALO ALTO RES CENT INC

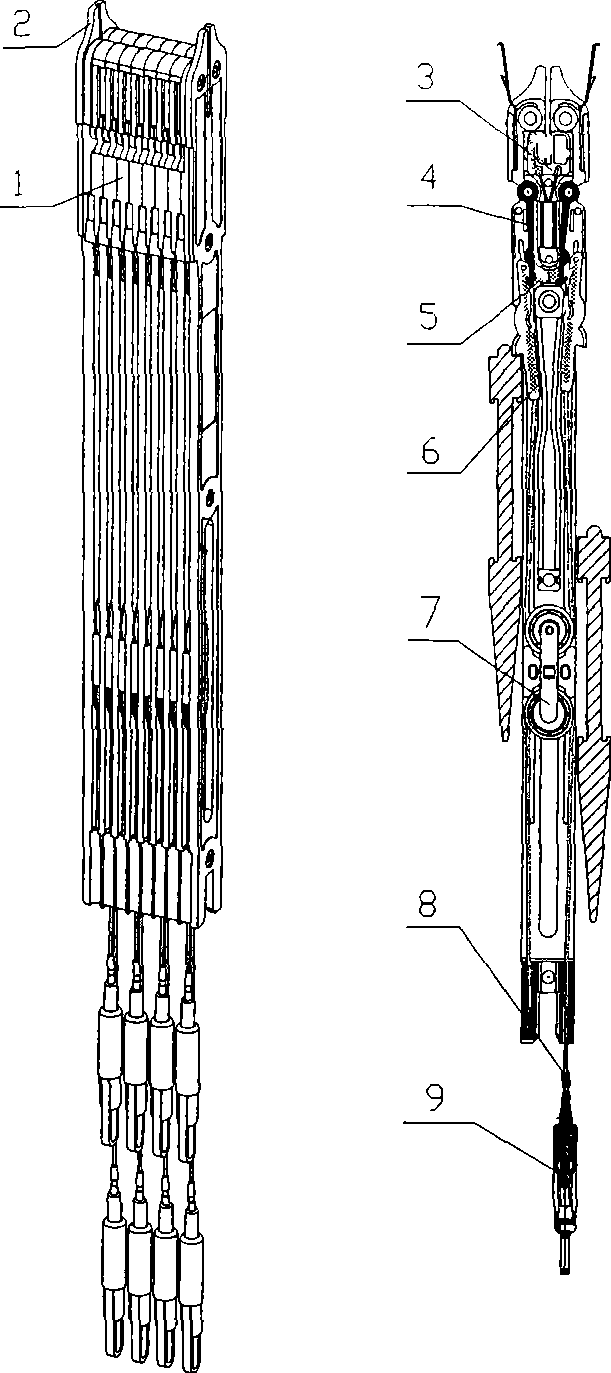

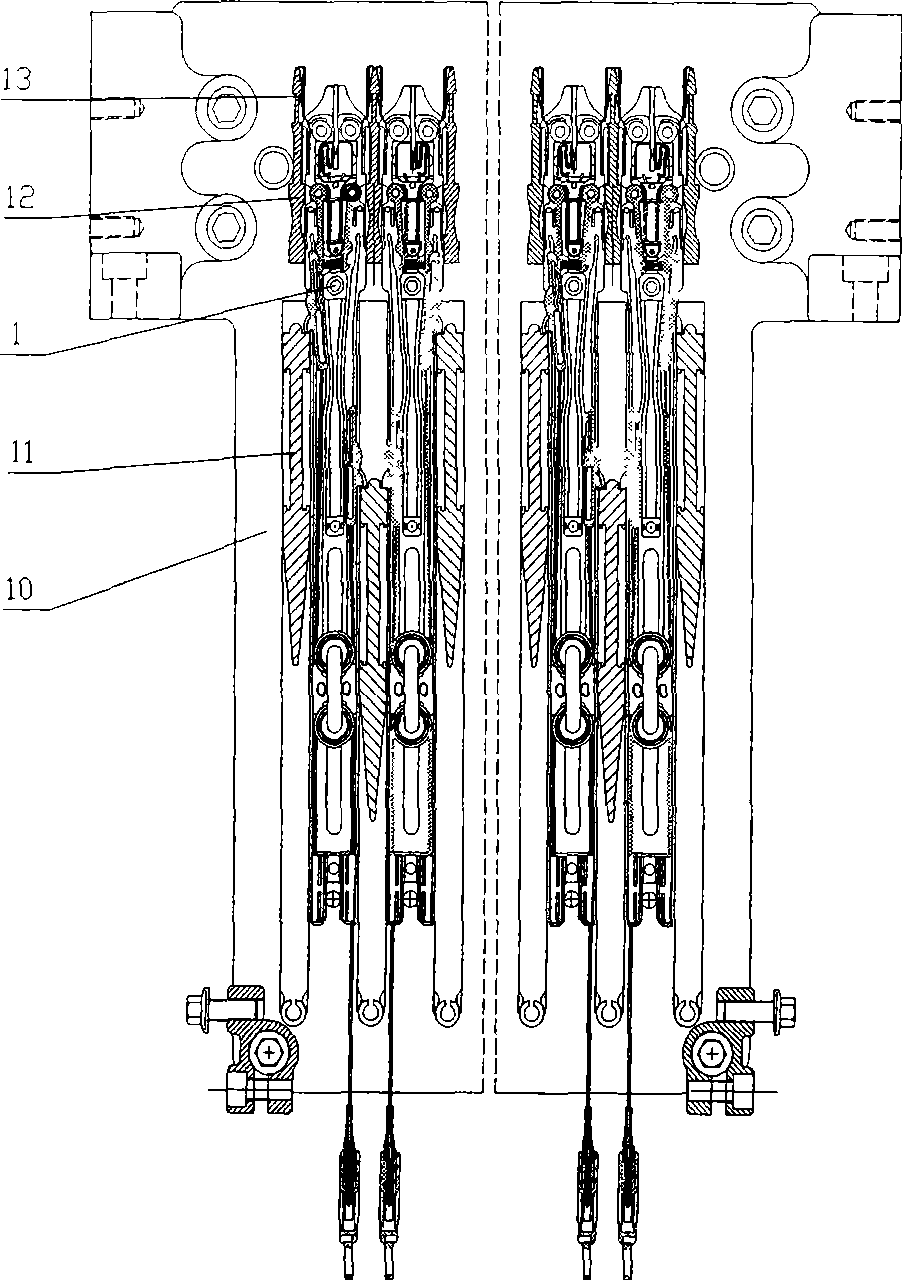

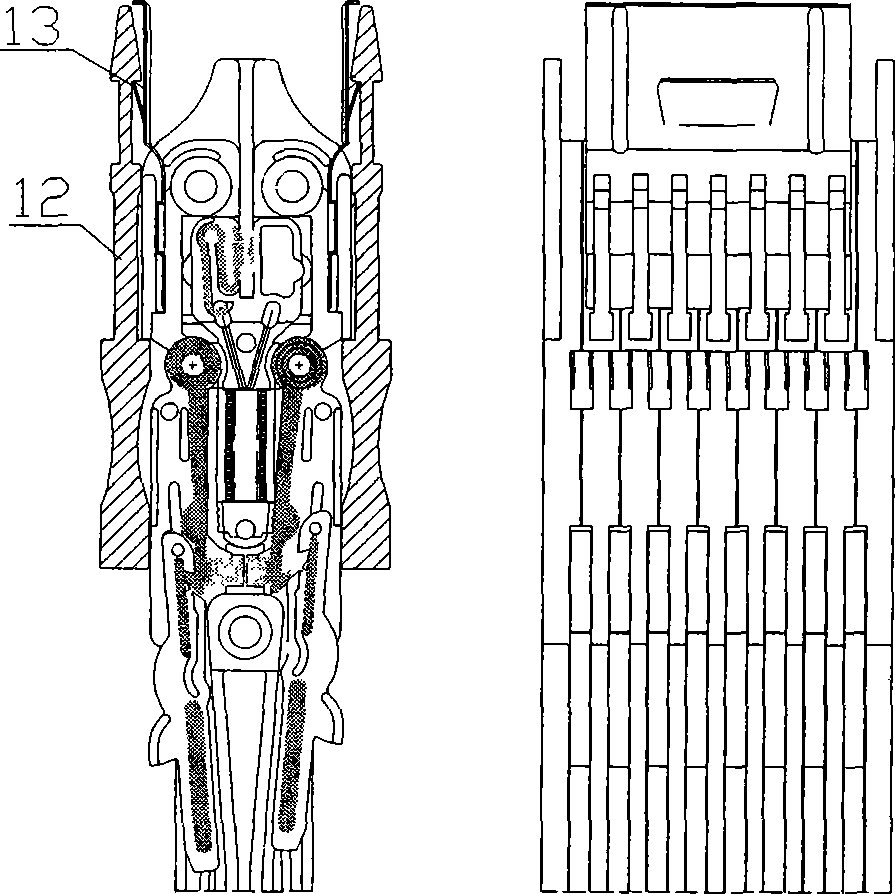

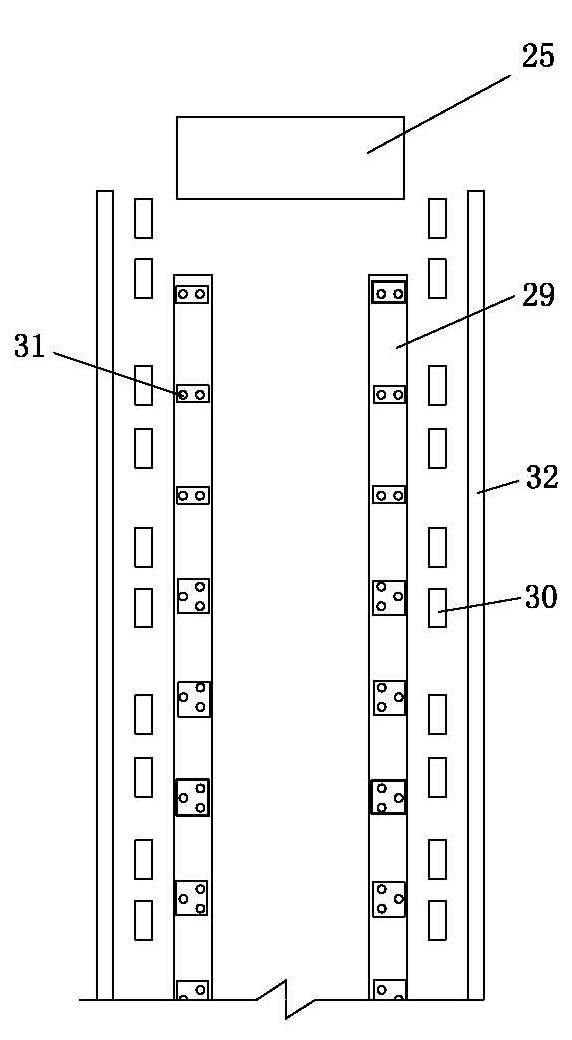

Electromagnetic valve heddle selecting apparatus of electronic jacquard

The invention discloses a heald selecting device for a solenoid valve of an electronic jacquard, which consists essentially of seven pieces of central brackets, two pieces of side brackets, modular solenoid valves, needle selecting hooks, offsetting springs, bidirectional moving hooks, a pulley module, a heald twine hanging cable and a quick coupling, wherein, the modular solenoid valves are arranged among the seven pieces of central brackets as well as between the central brackets and the side brackets; two sides of each modular solenoid valve are provided with a pair of needle selecting hooks, and a pair of offsetting springs and a pair of bidirectional moving hooks are arranged under each modular solenoid valve; and the bidirectional moving hooks, the pulley module, the heald twine hanging cable and the quick coupling are sequentially connected. The heald selecting device for the solenoid valve of the electronic jacquard has small electric power, correct and stable heald selecting and convenient maintenance.

Owner:宁波川一纺织设备有限公司

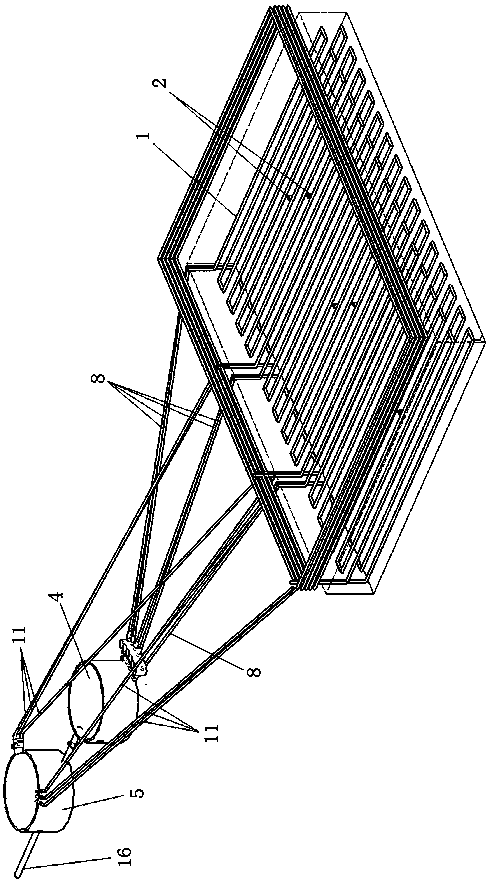

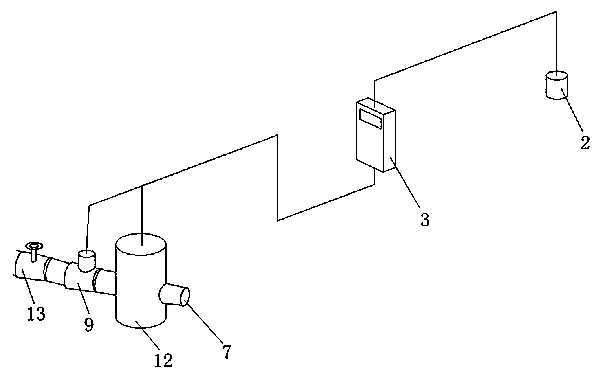

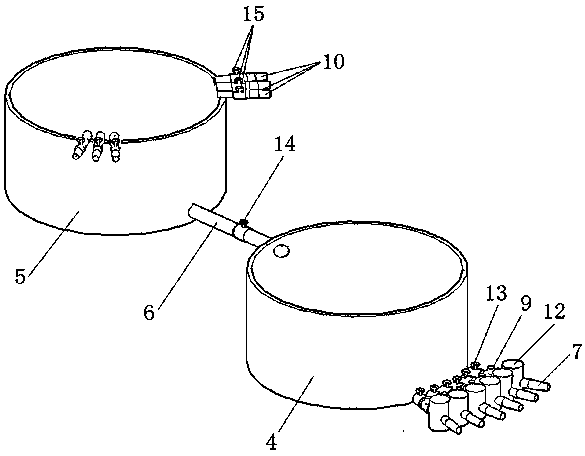

Mass concrete circulating cooling water automatic control cooling system and method

PendingCN107700489AReduce the risk of gapsReduce labor intensityFoundation engineeringBuilding material handlingTemperature controlAutomatic control

The invention discloses a mass concrete circulating cooling water automatic control cooling system and method, and belongs to the technical field of concrete cooling. The system comprises water collection boxes, cooling pipes, temperature measuring elements, a circulating mechanism connected with the water collection boxes and the cooling pipes and temperature switches connected with the temperature measuring elements and the circulating mechanism. The cooling pipes and the temperature measuring elements are pre-buried in mass concrete. The cooling pipes are pre-buried in the mass concrete ina layered manner, and each layer of cooling pipe is composed of multiple independent sub-pipes. Each sub-pipe is provided with the corresponding temperature measuring element. The temperature switchesare used for controlling the magnitude of the water conveying quantity generated after the circulating mechanism is shut down and started up according to the temperature, measured by the temperaturemeasuring elements, in the mass concrete. According to the system, zoning cooling can be carried out on the mass concrete, the temperature difference between various zones and the residual stress difference generated after hardening can be reduced, the risk that clearances appear in a concrete structure can be reduced, and the structural quality of the mass concrete structure can be improved.

Owner:CHINA RAILWAY NO 3 GRP CO LTD +1

Method For Controlling The Structure And Surface Qualities Of A Thin Film And Product Produced Thereby

InactiveUS20090053845A1Improve structural qualityDevice performance and longevitySemiconductor/solid-state device manufacturingNanoopticsSemiconductor structureQuantum well

A system and method for providing improved surface quality following removal of a substrate and template layers from a semiconductor structure provides an improved surface quality for a layer (such as a quantum well heterostructure active region) prior to bonding a heat sink / conductive substrate to the structure. Following the physical removal of a sapphire substrate, a sacrificial coating such as a spin-coat polymer photoresist is applied to an exposed GaN surface. This sacrificial coating provides a planar surface, generally parallel to the planes of the interfaces of the underlying layers. The sacrificial coating and etching conditions are selected such that the etch rate of the sacrificial coating approximately matches the etch rate of GaN and the underlying layers, so that the physical surface profile during etching approximates the physical surface profile of the sacrificial coating prior to etching. Following etching, a substrate is bonded to the exposed surface which acts as a heat sink and may be conductive providing for backside electrical contact to the active region.

Owner:PALO ALTO RES CENT INC

Real-time secondary ray tracing concurrent rendering method

InactiveCN101826215AImprove structural qualityShallow depthProcessor architectures/configuration3D-image renderingConcurrent computationMaterial type

The invention discloses a real-time secondary ray tracing concurrent rendering method, which comprises the following steps: (1) by constructing an octree, partitioning the scene data of the model space to be rendered; (2) when the proportion of the effective rays in a ray packet is higher than the threshold, carrying out step (3), otherwise, carrying out step (5); (3) traversing the ray packet along the three coordinate axes of the model space; (4) orderly carrying out intersection testing on ray subpackets and facets in the leaf node to obtain a ray having an intersection relationship with the facets; (5) carrying out intersection testing on each ray in the ray packet to obtain a triangular facet which is nearest to the starting point of the ray and intersects with the ray; and (6) according to the material type of the model to be rendered in the model space, classifying the rays in the ray subpackets, and orderly rendering. The concurrent rendering method can reduce the ray traversal time and the time required by intersection by effectively utilizing the concurrent computation capability of hardware.

Owner:ZHEJIANG UNIV

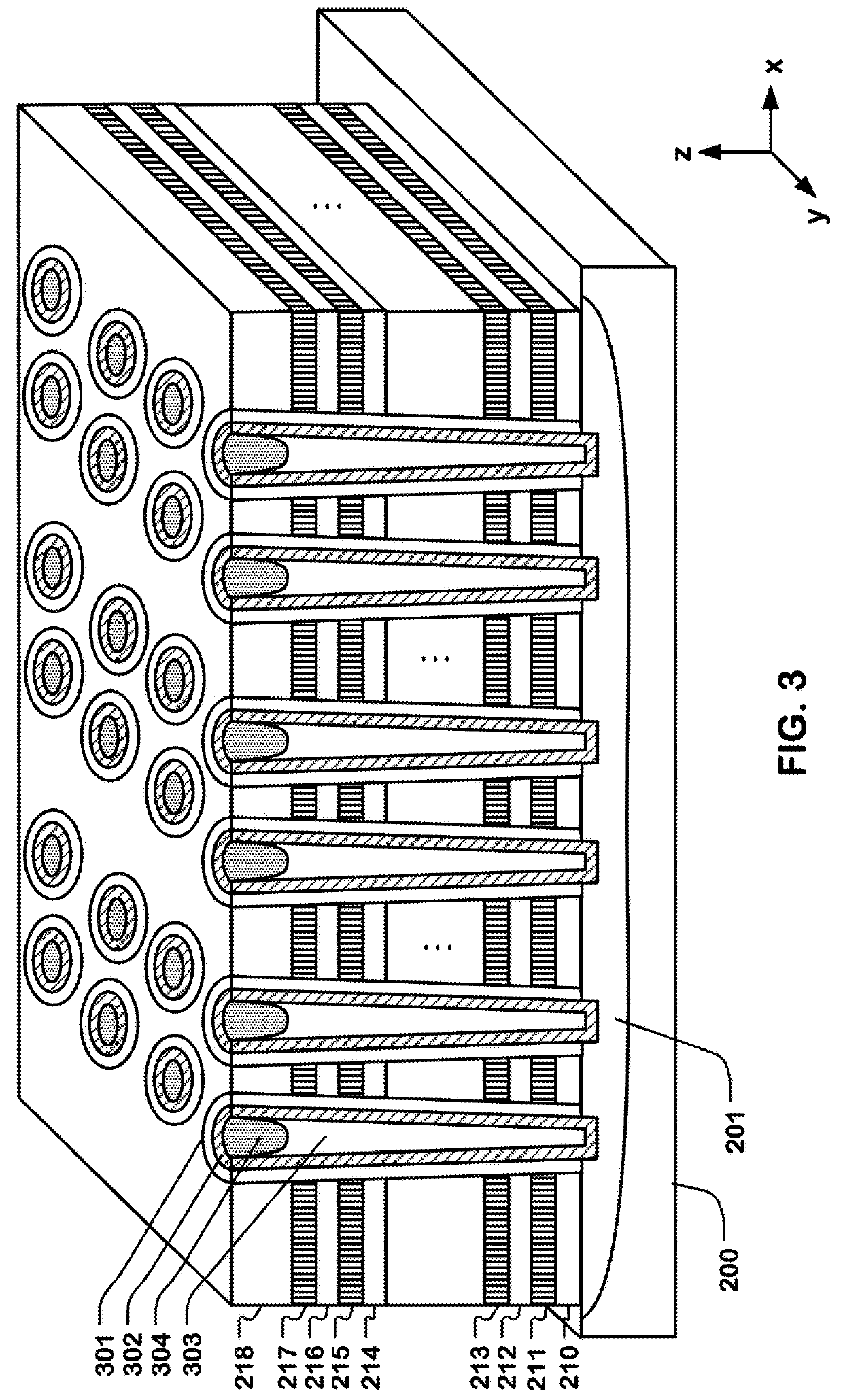

Integrated circuit device with layered trench conductors

ActiveUS20180269225A1Reduce stress induced deformationImprove structural qualitySemiconductor/solid-state device detailsSolid-state devicesIntegrated circuitEngineering

An integrated circuit includes a multilayer stack, and a plurality of layered conductors extending in the multilayer stack and into a conductor layer beneath the multilayer stack. The layered conductor has a bottom conductor layer in ohmic electrical contact with the conductive layer in a substrate, an intermediate conductive liner layer over the bottom conductor layer and lining a portion of sidewall of the corresponding trench, and a top conductor layer on the top conductive liner layer.

Owner:MACRONIX INT CO LTD

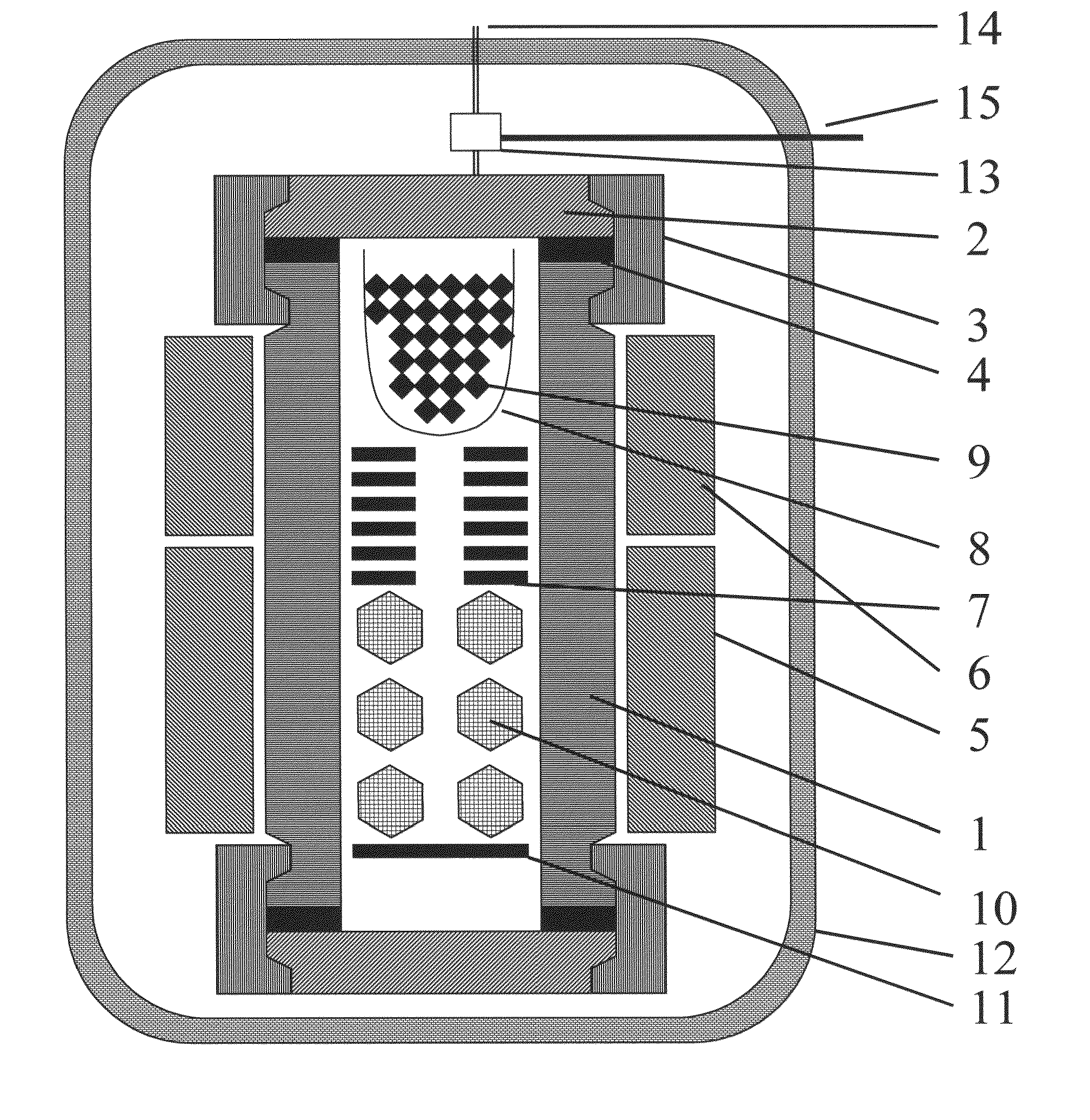

High-pressure vessel for growing group III nitride crystals and method of growing group III nitride crystals using high-pressure vessel and group III nitride crystal

ActiveUS8236267B2Reduce depositionQuality improvementAfter-treatment apparatusPolycrystalline material growthOxygen contaminationEtching

Owner:SIXPOINT MATERIALS

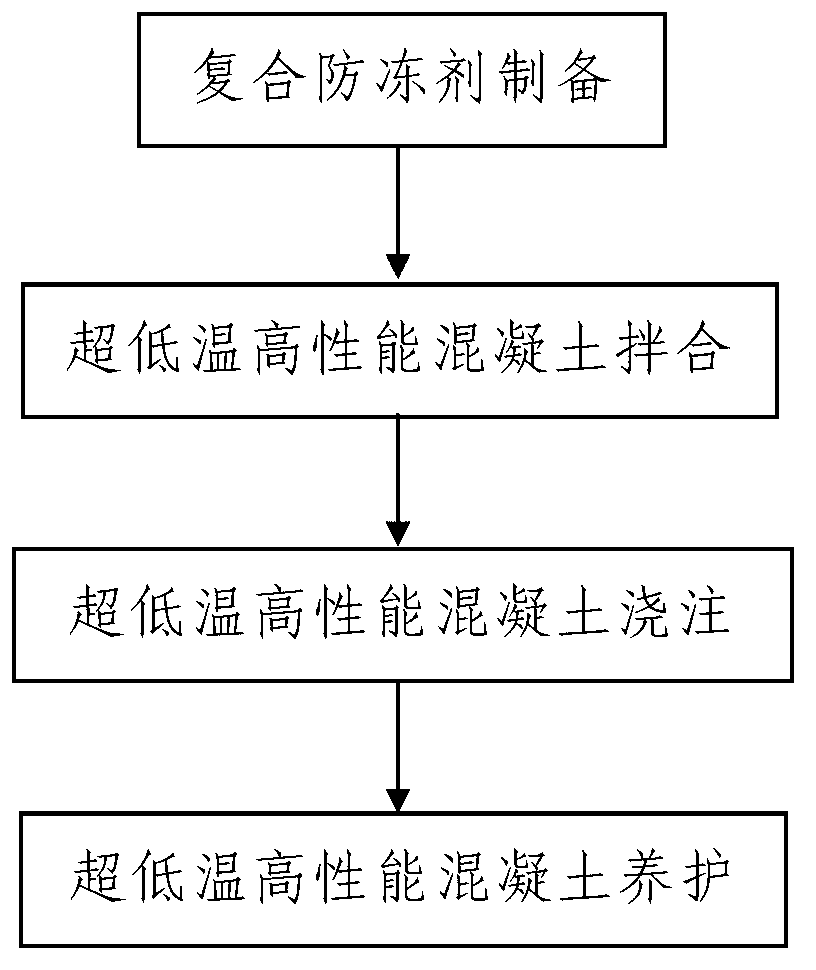

Construction technique for ultralow-temperature high-property concrete for railway construction in frigid areas

ActiveCN102797358AThe process steps are simpleEasy to operateBuilding material handlingCalcium formateSuperplasticizer

The invention discloses a construction technique for ultralow-temperature high-property concrete for railway construction in frigid areas. The construction technique comprises the steps as follows: A, mixing ultralow-temperature high-property concrete: gelled materials, sand, crushed stone, an efficient water reducing agent, compound antifreeze and water are evenly mixed to obtain the ultralow-temperature high-property concrete; the gelled materials are made by evenly mixing cement and mineral admixtures in the weight ratio of (88-78):(12-22); the weight ratio of the compound antifreeze to the mineral admixtures is (3-6):100; the compound antifreeze comprises 30 to 35 wt% of nitrate, 30 to 33 wt% of organic compound, 0.5 to 1wt% of calcium formate, and water as the rest; the nitrate is calcium nitrate or calcium nitrite; and the organic compound is methanol or alcohol; B, pouring the ultralow-temperature high-property concrete; and C, curing the ultralow-temperature high-property concrete. The construction technique has the advantages of reasonable design, simplicity in construction steps, convenience in operation, fast construction progress, low construction cost, and good structural quality of concrete used in construction.

Owner:CHINA RAILWAY 20 BUREAU GRP

Method for controlling the structure and surface qualities of a thin film and product produced thereby

InactiveUS20070111345A1Improve surface qualityImprove structural qualitySemiconductor/solid-state device manufacturingNanoopticsSemiconductor structureQuantum well

A system and method for providing improved surface quality following removal of a substrate and template layers from a semiconductor structure provides an improved surface quality for a layer (such as a quantum well heterostructure active region) prior to bonding a heat sink / conductive substrate to the structure. Following the physical removal of a sapphire substrate, a sacrificial coating such as a spin-coat polymer photoresist is applied to an exposed GaN surface. This sacrificial coating provides a planar surface, generally parallel to the planes of the interfaces of the underlying layers. The sacrificial coating and etching conditions are selected such that the etch rate of the sacrificial coating approximately matches the etch rate of GaN and the underlying layers, so that the physical surface profile during etching approximates the physical surface profile of the sacrificial coating prior to etching. Following etching, a substrate is bonded to the exposed surface which acts as a heat sink and may be conductive providing for backside electrical contact to the active region.

Owner:PALO ALTO RES CENT INC

Tunnel shield propulsion and inside double-layer road synchronous construction method

The invention relates to a method used for synchronously performing tunnel shield thrusting construction and internal double deck road construction, which can perform construction to the internal road of the tunnel when the shield is thrust, and takes prefabricated parts of the well-laid lower deck road as the transportation channel to perform flow production for in-situ casting the upper deck road. The method comprises the following steps: in all the operating areas behind the thrusting shield, the construction working procedures which are arranged in sequence and according to the longitudinal sequence and are synchronously performed are as follows: first, the lower deck rod is laid by adopting the prefabricated parts; second, the structural parts on both sides of the prefabricated parts of the lower deck road are cast; third, in-situ concrete casting construction is performed to the supporting parts of the upper deck road; fourth, in-situ concrete casting construction is performed to the upper deck road. The method performs synchronous construction to the internal road structure by combining the prefabricated parts and the cast-in-situ concrete structure. Therefore, not only the construction period is reduced, but also the construction flexibility and the integrity and the shock resistance of the engineering structure are improved; meanwhile, the influence of the tunnel quality to the structural quality of the internal rod is reduced. The method is especially suitable for the large diameter long distance double-decked tunneling construction.

Owner:SHANGHAI TUNNEL ENGINEERING CO. LTD.

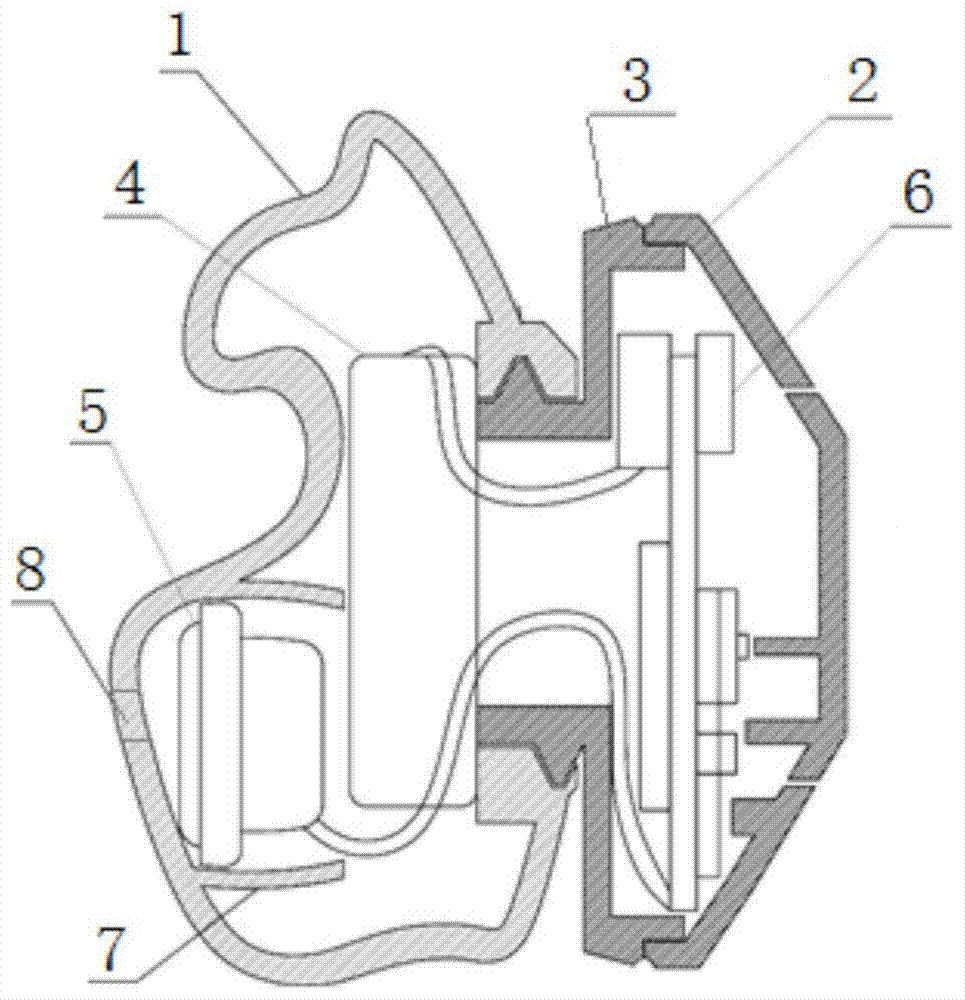

Customized Bluetooth earphone and manufacturing method thereof

InactiveCN104853273AImprove good experienceSave manpower and material resourcesEarpiece/earphone attachmentsIntegrated circuitMicrophone

The invention relates to a customized Bluetooth earphone and a manufacturing method thereof. The customized Bluetooth earphone comprises an ear cavity inner shell, a connection component, an ear cavity outer shell, a lithium battery, a sounding unit and an integrated circuit board, wherein the ear cavity inner shell is molded integrally through a 3D printing process; the ear cavity inner shell is connected with the ear cavity outer shell through the connection component; a sound cavity structure is arranged at a position corresponding to the cavity of auricular concha in the ear cavity inner shell; the sounding unit is arranged in the sound cavity structure; the side wall of the ear cavity inner shell is provided with a sound guide hole; the lithium battery is arranged in the ear cavity inner shell; the integrated circuit board comprises an antenna, a Bluetooth module, a decoding chip, a power amplifying module and a microphone which are arranged in the ear cavity outer shell and a switch, an answering button, a charging port and an LED (Light-Emitting Diode) indicating lamp which are arranged on the side wall of the ear cavity outer shell; and the lithium battery and the sounding unit are connected with the integrated circuit board respectively. The customized Bluetooth earphone and the manufacturing method thereof have the beneficial effects that customized delivery is not limited by regions anymore; the user experience can be enhanced; and a large amount of labor force and materials is saved.

Owner:长兴悦瑞三维科技有限公司 +3

Method in use for conticaster for controlling solidification structure of casting block

A method for the conticaster to control the solidified structure of cast blank includes providing a HF pulse power supply with positive and negative electrodes, inserting its negative electrode into the molten steel in the crystallizer or tundish of conticaster, electrically connecting its positive eletrode with the steel base of conticaster, and conticasting while regulating the voltages, current and frequency to improve the performance of cast blank.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Method for forming superhydrophobic surface of solid material

InactiveCN1775380ADoes not affect physical and chemical propertiesImprove structural qualityCoatingsSpecial surfacesCross-linkMass ratio

The present invention relates to a method for forming superhydrophobic surface of solid material, belonging to the field of solid material surface modification technology. Said method includes the following steps: firstly, uniformly mixing performed polymer and cross-linking agent according to a certain mass ratio, pouring the obtained mixture onto the superhydrophobic surface, standing still, then heating, solidifying and stripping to obtain elastic soft stamp; dissolving soluble polymer material in solvent, then using prepared elastic soft stamp to stamp the above-mentioned solution on the surface of solid material.

Owner:TSINGHUA UNIV

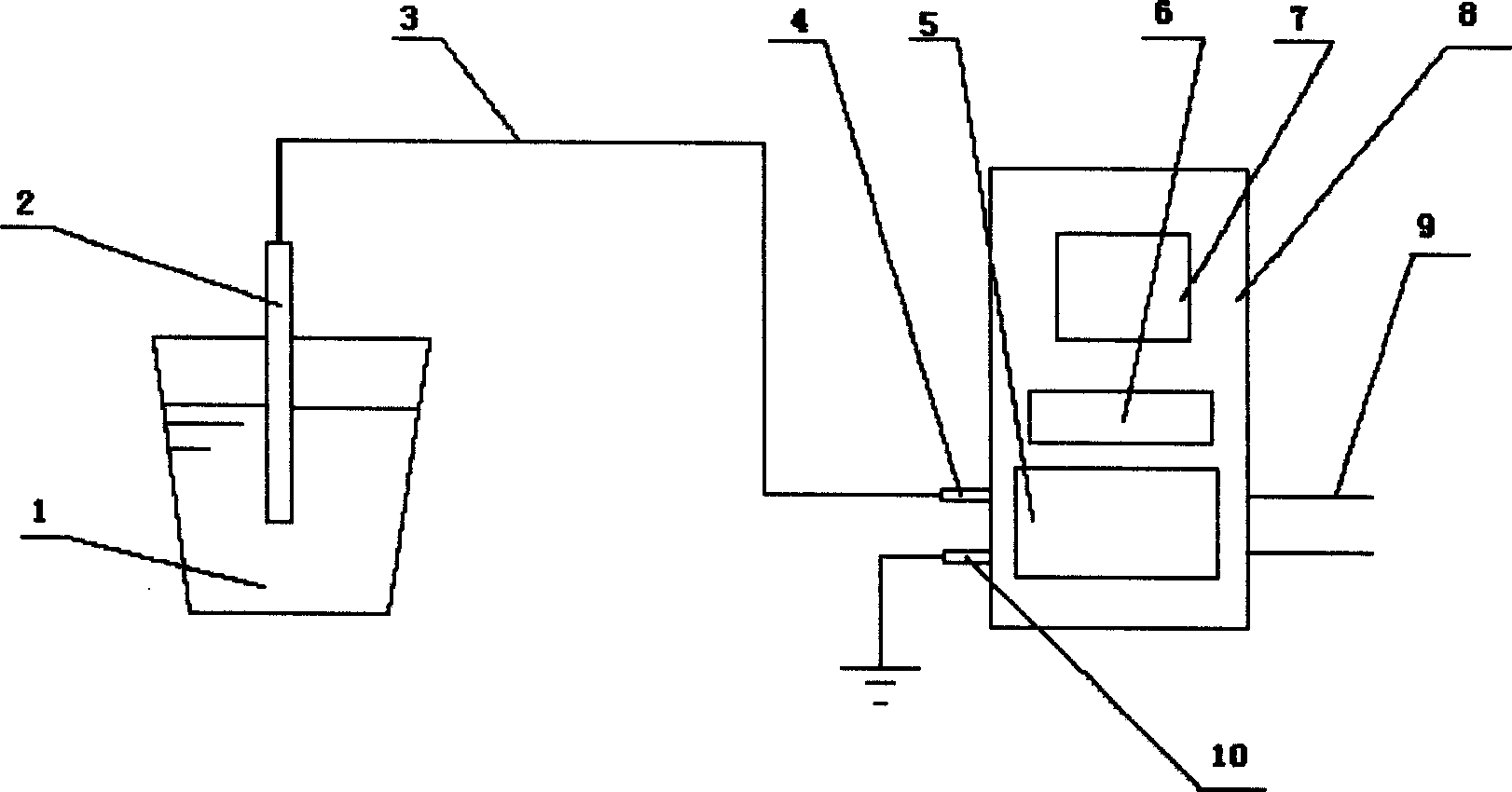

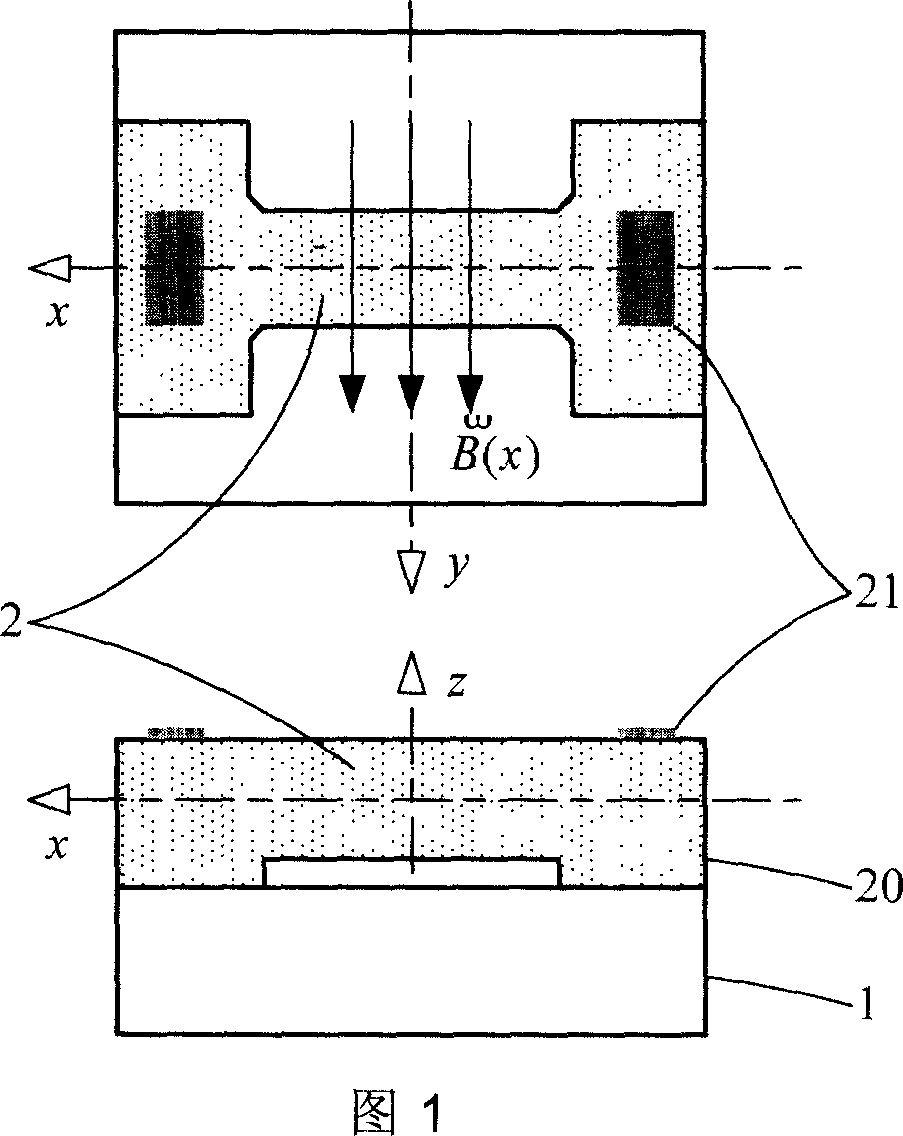

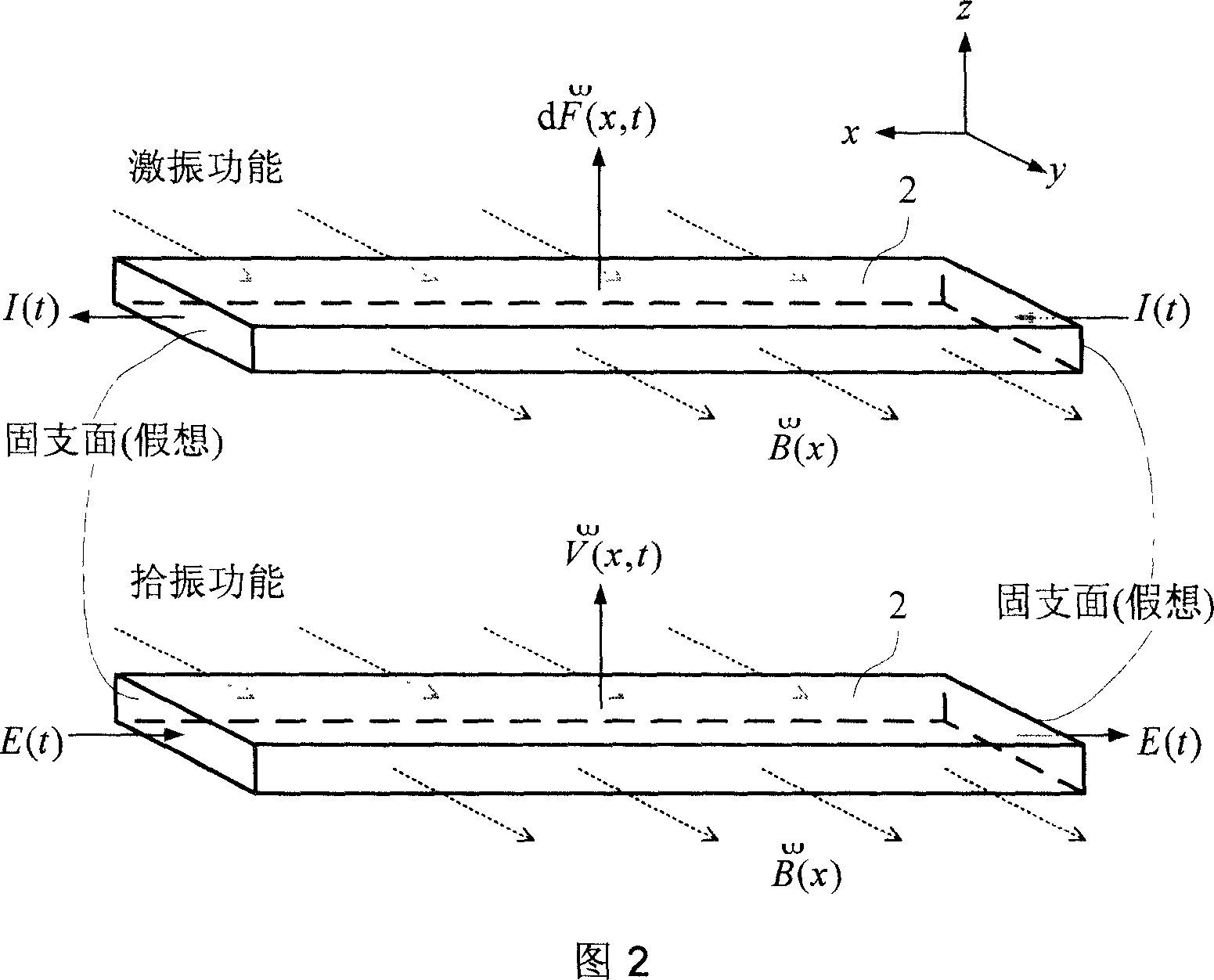

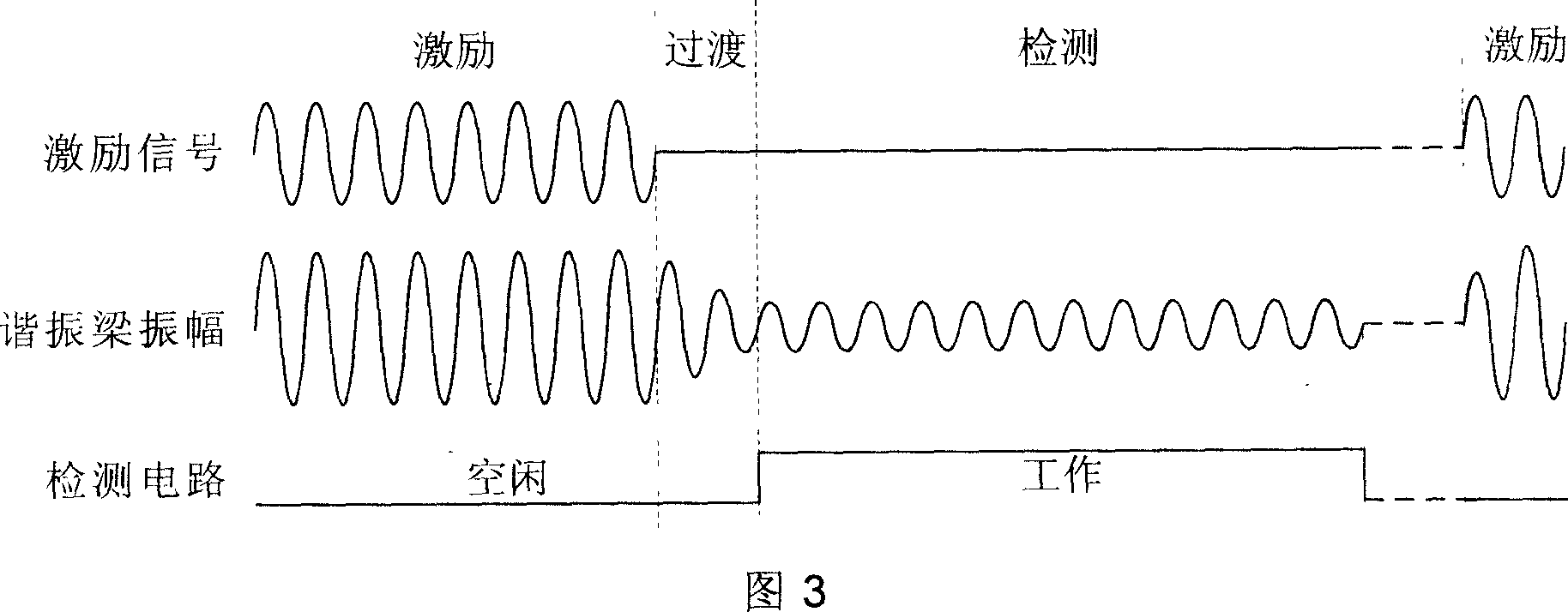

Electromagnetic-magnetoelectric type micro mechanical resonant beam structure

InactiveCN1944235AAchieve decouplingSimple processForce measurement by measuring frquency variationsTelevision system detailsElastic matrixResonance

The electromagnetic-magnetoelectric micro mechanical resonant beam structure consists of matrix and resonant beam in magnetic field, and the composite sensitive structure comprising elastic matrix membrane and double-ended built-in simple resonant beam realizes the resonant measurement of physical quality. Both the matrix and the resonant beam are made with SOI wafer and through epitaxial and etching process, and the matrix with low doping and the simple resonant beam of N type doping in 1x10<19> / cu cm form an integral monocrystalline silicon structure. The resonant beam with electrodes in its two ends is orthogonal with the magnetic field and produces ampere force in the thickness direction during when some current flows in and induced voltage across it during resonance. One closed-loop system is formed based on intermittent principle to eliminate coupling interference trouble. The present invention has simple structure, improved mechanical performance and high stability.

Owner:BEIHANG UNIV

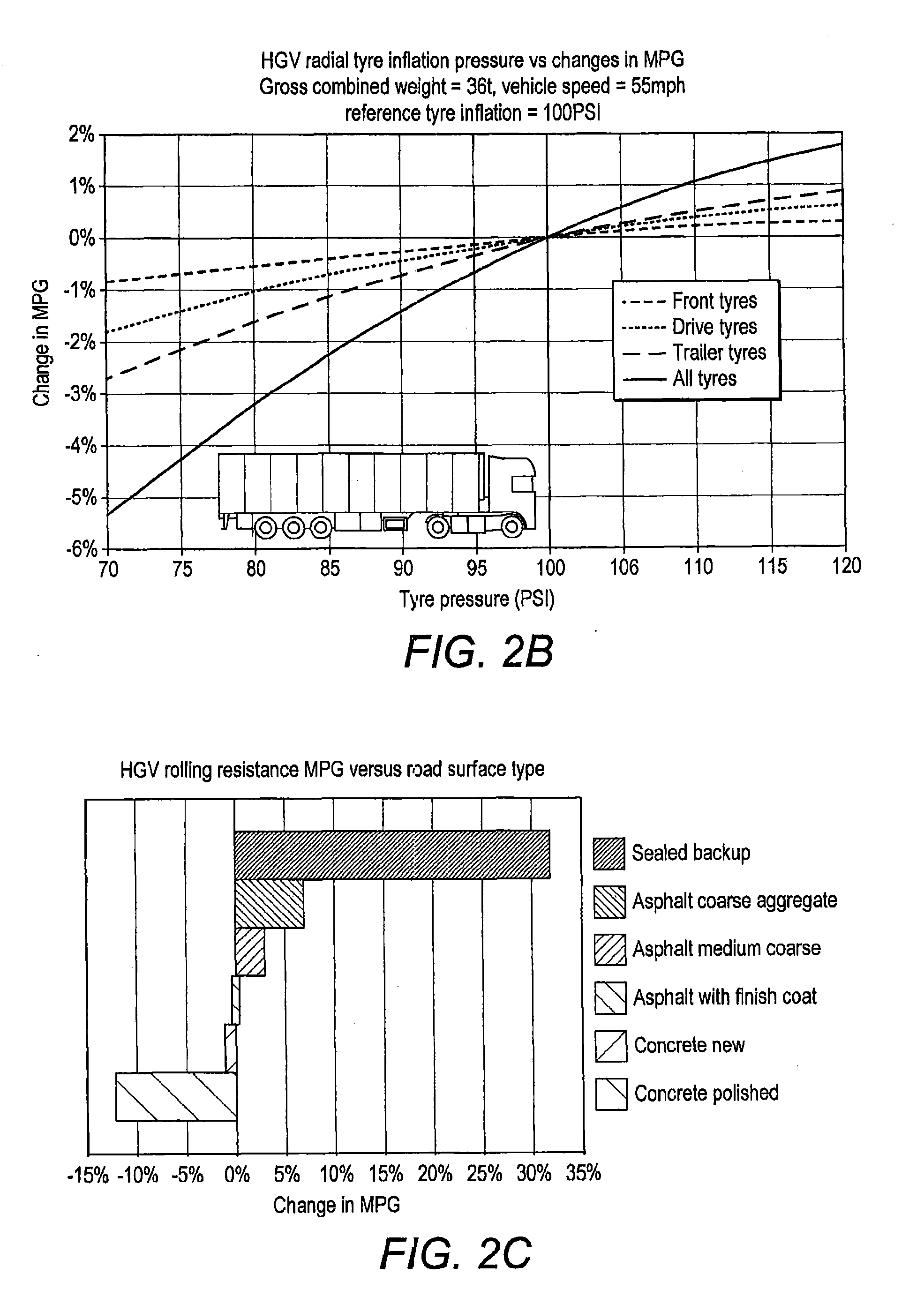

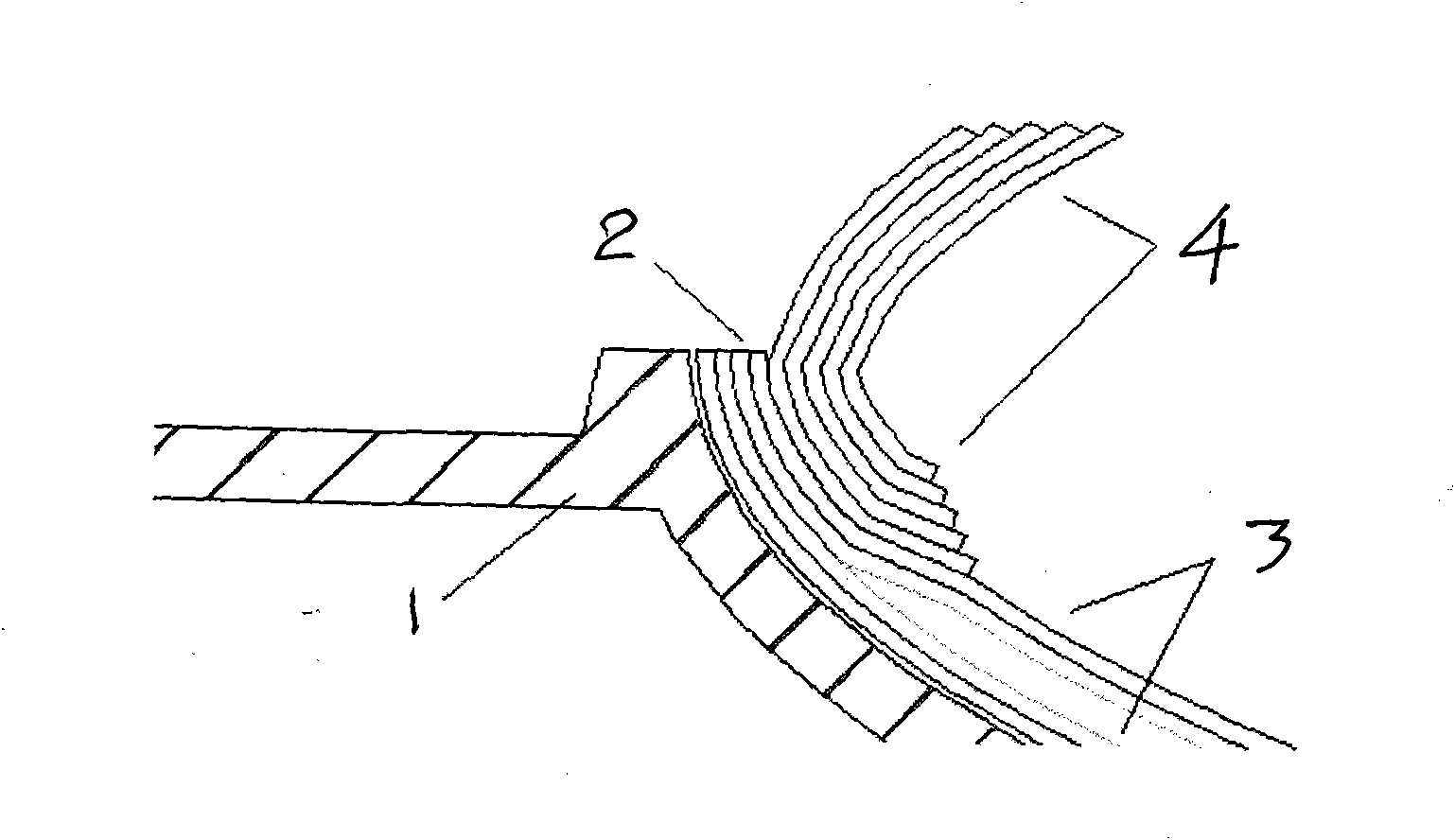

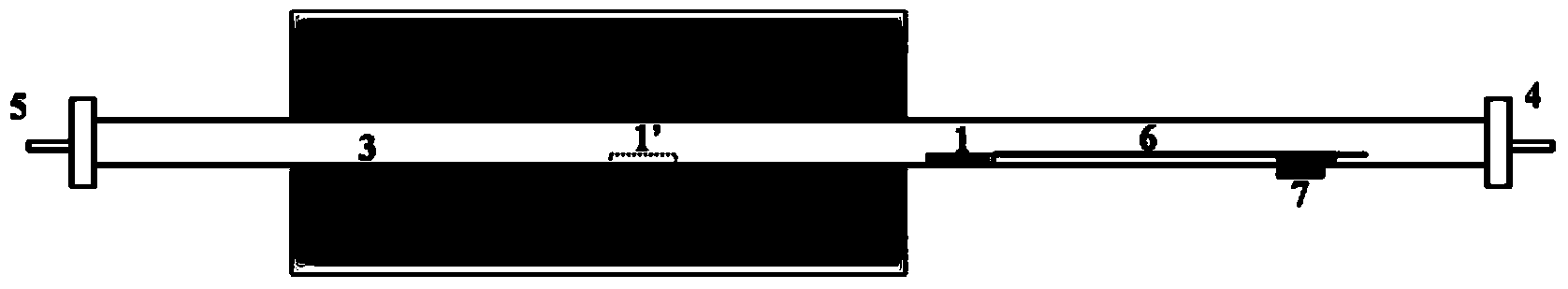

Tyre apparatus

ActiveUS20160332486A1Superior structureImprove structural qualityHeavy duty tyresHeavy duty vehicleEngineeringMaterial structure

A tyre apparatus is provided, the apparatus including a tyre body for attachment to a wheel rim to define a first inflatable volume. An inner chamber defines a second inflatable volume which is located within the first inflatable volume of the tyre body. A first fluid communication path is provided between the first and second inflatable volumes and a second fluid communication path is provided between the first inflatable volume and the atmosphere. A first valve opens and closes the first fluid communication path, and a second valve opens and closes the second fluid communication path. The tensile strength and pressure-containing capacity of the material structure of the second inflatable volume is greater than that of the tyre first inflatable volume. A first fluid pressure within the first inflatable volume of the tyre body is optimisable by opening the first valve to allow pressure transfer from the second inflatable volume into the tyre body, and / or opening the second valve to allow pressure to vent from the tyre body to atmosphere. A vehicle wheel and active tyre pressure control system incorporating the tyre apparatus are also provided.

Owner:PERKINS ENGINES

Integrated infusion molding method for front and rear edge flanges and shell of wind turbine blade

ActiveCN102092134ASolve potential hidden dangers of unstable qualityReduce the impactFinal product manufactureDomestic articlesTurbine bladeAdhesive

The invention discloses an integrated infusion molding method for front and rear edge flanges and a shell of a wind turbine blade, which comprises the following steps of: preparing materials and a mold; laying the materials and arranging the mold; laying a second layer of vacuum bag; infusing parts; and trimming the parts. Through technical innovation, the parts which are separately manufactured originally are fused into a whole through a vacuum infusion technology, so that efficiency is improved, energy is saved, environment is protected and the stability of the structural quality is ensured. The new technology avoids hidden trouble of instable quality. The dimension is stable and provides guarantee for subsequent adhesion. The method is little influenced by external environment, and ensures continuous and stable output. The material utilization rate can be further improved and the cost of 8,400,000 RMB can be saved. The production efficiency is improved; and the infusion mode is adopted, personnel is prevented from contacting resin and an adhesive, energy is saved, environment is protected and the long-term stable development of a worker team is ensured. The method is easy to operate, the service life of the mold is prolonged, the mold loss is nearly zero, and the mold investment cost is reduced.

Owner:东方电气(天津)风电叶片工程有限公司

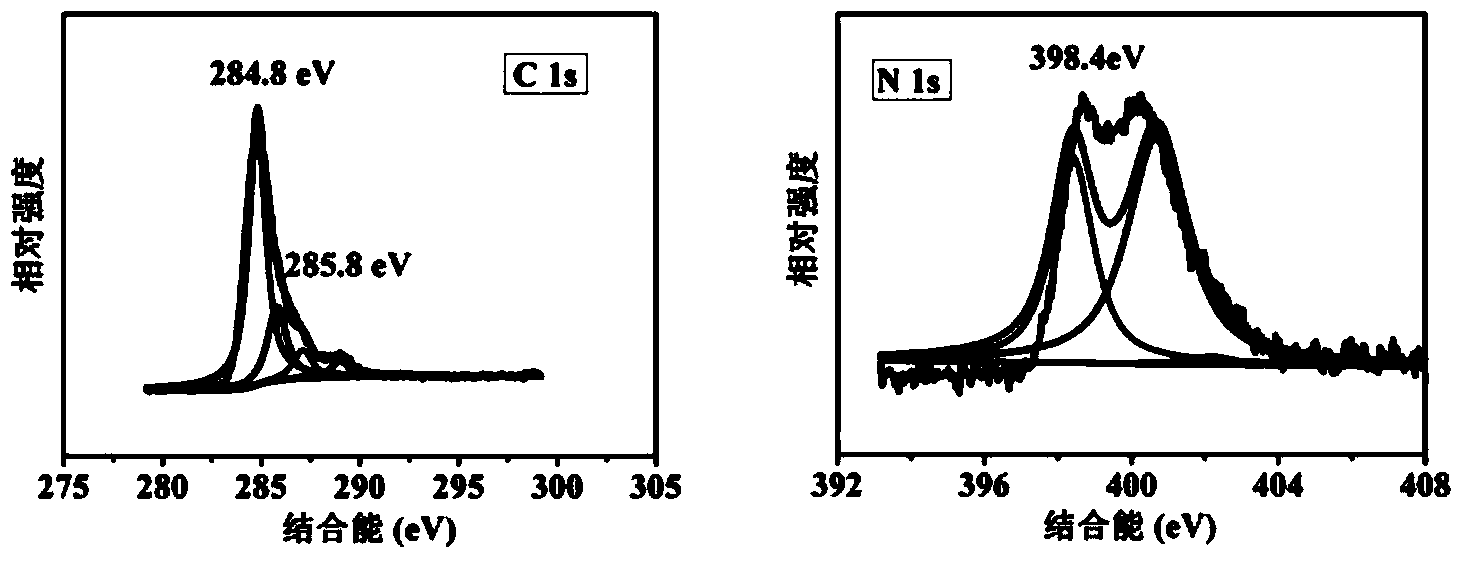

Large-area high-quality nitrogen-doped graphene as well as preparation method and application thereof

The invention discloses a preparation method of large-area high-quality nitrogen-doped graphene. The nitrogen-doped graphene is prepared by taking a nitrogen-containing polymer as a precursor. The method comprises the following steps: coating a carbon and nitrogen source on the surface of a copper catalyst or putting on the copper catalyst, and then reacting under the condition of 600 DEG C to 900 DEG C in a non-oxidizing atmosphere so as to obtain the nitrogen-doped graphene, wherein the copper catalyst can be of elemental copper, a copper alloy or a copper-containing compound. The prepared nitrogen-doped graphene is of 1 to 10 layers of large-area films with high-quality crystal structures, and has the electrical characteristics of N-field effects and the light transmittance no matter under air or vacuum environment. The method provided by the invention is simple in process, economical, low in cost, simple and convenient to operate and suitable for large-scale production.

Owner:INST OF CHEM CHINESE ACAD OF SCI

High-pressure grouting molding manufacturing process of toilet bowl, molding die of high-pressure grouting molding manufacturing process and ceramic toilet bowl

InactiveCN105365030AImprove structural strengthImprove structural qualityWater closetsAuxillary shaping apparatusHigh pressureToilet

The invention relates to the field of manufacturing processes, molding dies and finished products of sanitary ceramic products, and provides a high-pressure grouting molding manufacturing process of a toilet bowl. The high-pressure grouting molding manufacturing process comprises the steps of arranging of horizontal type high-pressure grouting equipment, arranging of a plurality of molding die bodies, die closing, grouting, die opening, die releasing and bonding and molding. Each molding die body comprises two female dies and a male die between the female dies. The molding die bodies are arranged on a bearing system of the horizontal type high-pressure grouting equipment in the horizontal direction. Two half-edge blanks are obtained every time die opening and die releasing are carried out. A complete toilet bowl blank is molded after each step of bonding and molding. Thus, according to the high-pressure grouting molding manufacturing process of the toilet bowl, the grouting molding yield and efficacy can be increased, and equipment cost is reduced; and a double-face grout eating manner can also be adopted so that the product yield and quality can be increased, the grout return manufacturing process is omitted, and the grouting molding time is greatly shortened.

Owner:GLOBE UNION INDAL

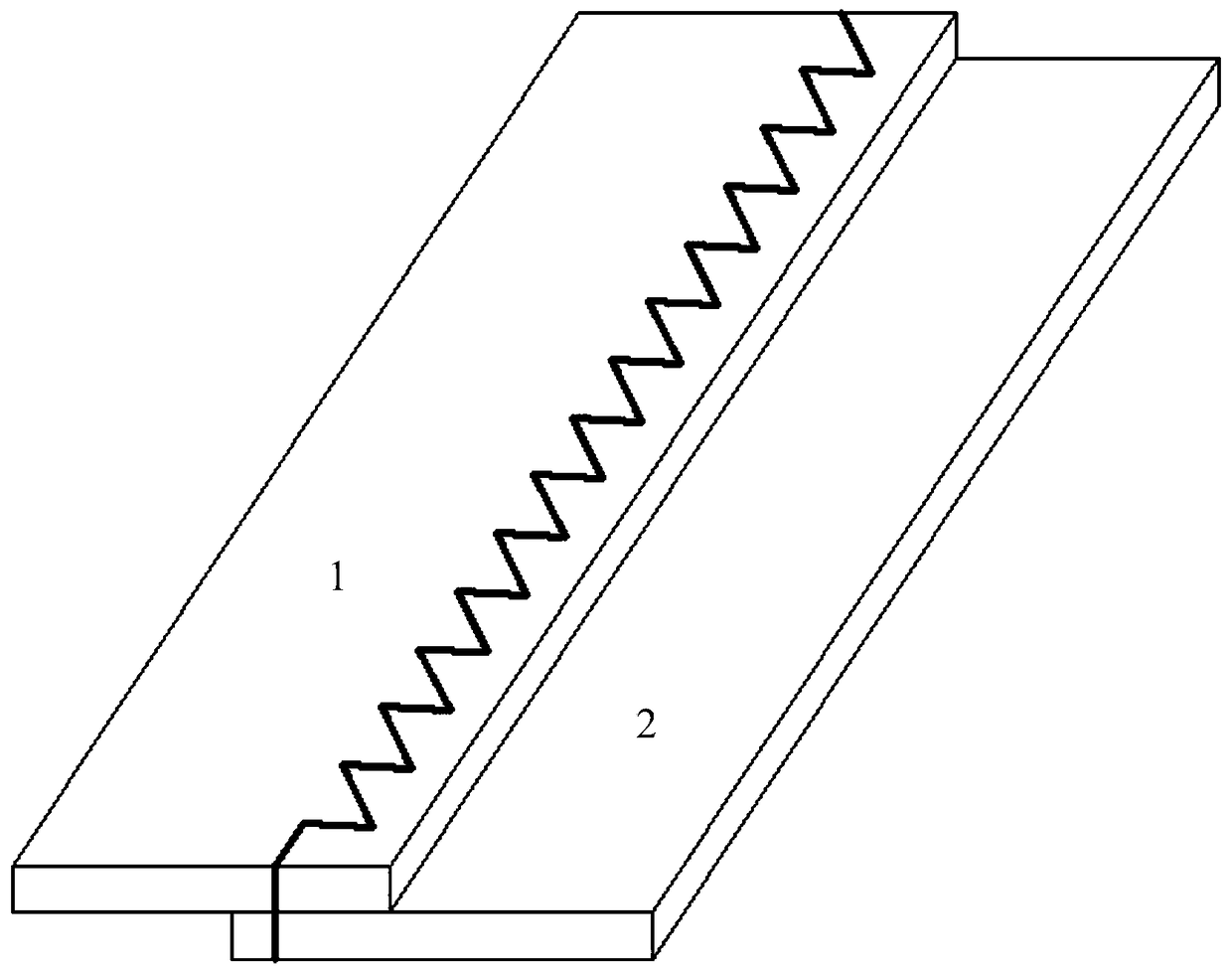

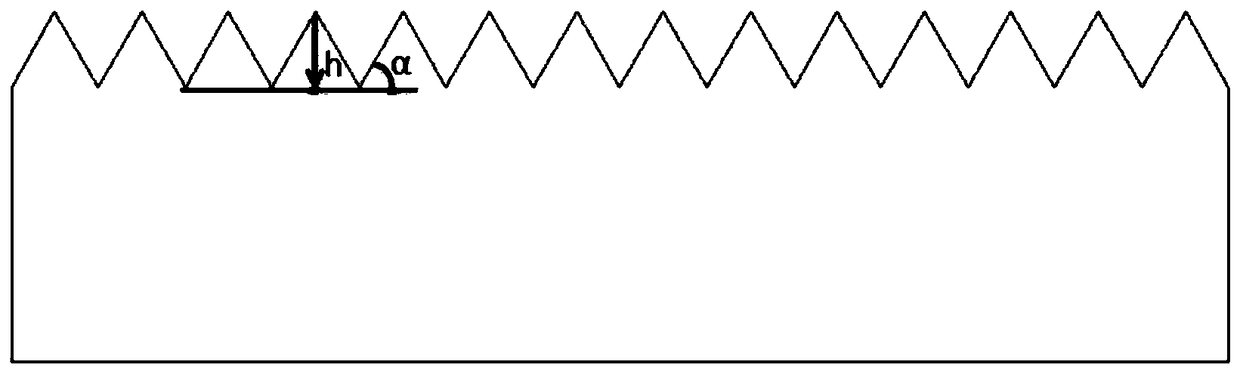

Titanium-steel dissimilar metal structure and manufacturing method thereof

ActiveCN108817647AHigh strengthHigh tensile strengthWorkpiece edge portionsNon-electric welding apparatusRelative motionEngineering

The invention provides a titanium-steel dissimilar metal structure and a manufacturing method thereof. The meshing-corresponding sawtooth structure with high integrating degree is obtained by a stacking-and-lapping mode; a composite plate is obtained by meshing-connection; and high-quality welding of titanium-steel dissimilar metal is achieved by a stirring-friction welding method. The influence on the performance of a dissimilar metal stirring-friction welding connector by deviation is not necessarily to be considered; and asymmetry of a forward side and a backward side in the traditional butt joint process is eliminated. The sawtooth meshing structure is adopted, and therefore action of welding force on materials during the welding process is improved to assist material smashing, the linear contact area of the dissimilar metal is increased, relative movement distance of metal atoms is shortened so that more atoms can move under the same energy, the mutual flow and mutual mixing capacity of the dissimilar metal materials can be improved, the problem of nonuniform connector tissue mixing is avoided, interlocking mixing of weld joint materials is improved, and strength of the connector is greatly improved.

Owner:NANCHANG HANGKONG UNIVERSITY

Stringed musical instrument with multiple bridge-soundboard units

InactiveUS7288706B2Enjoys a freedom of vibrationPossibility of interferenceGuitarsEngineeringMusical instrument

A stringed musical instrument having multiple bridge-soundboard units, each unit substantially acoustically independent from other bridge-soundboard units. Said bridge soundboard units are coupled to a set of strings such that a number of the strings within the set are sounded through the first bridge-soundboard unit, others are sounded through a second bridge-soundboard unit, and so on. The process of division of set of strings among several bridge-soundboard units allows greater ability to bear tension, greater sustain, and greater variety of tonal color by allowing a greater number and variety of soundboards.

Owner:GAFFGA CHRISTOPHER MOORE

Profile steel framework structure concrete floor slab suspension mould pouring construction method

ActiveCN103758348AFast constructionShorten the construction periodBuilding material handlingFloor slabRebar

The invention relates to a profile steel framework structure concrete floor slab suspension mould pouring construction method. The profile steel framework structure concrete floor slab suspension mould pouring construction method comprises the steps of installing and correcting profile steel components, measuring a released line, designing and manufacturing a suspension mould system, manufacturing and installing a hoisting bar, installing main rods, installing secondary rods, laying formwork panels, tying floor slab steel bars, pouring and maintaining concrete, and detaching the suspension mould system. Compared with the prior art, the profile steel framework structure concrete floor slab suspension mould pouring construction method has the advantages of being high in construction speed, being stable in quality of a concrete structure, reducing the use of circulation materials, relieving vertical conveying pressure, improving labor efficiency and relieving labor intensity. Compared with a traditional steel pipe whole-building supporting frame, the profile steel framework structure concrete floor slab suspension mould pouring construction method improves the labor efficiency by about 2.5 times. Due to the fact that labor intensity is largely relieved, the work of operators is continuous.

Owner:芜湖立宇建设有限公司

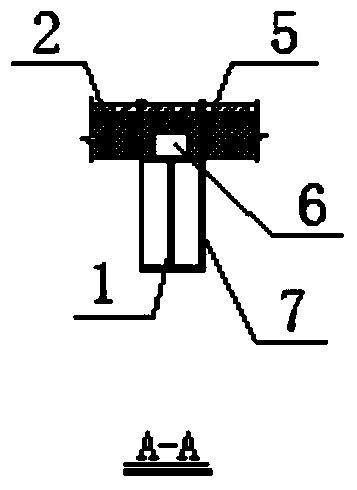

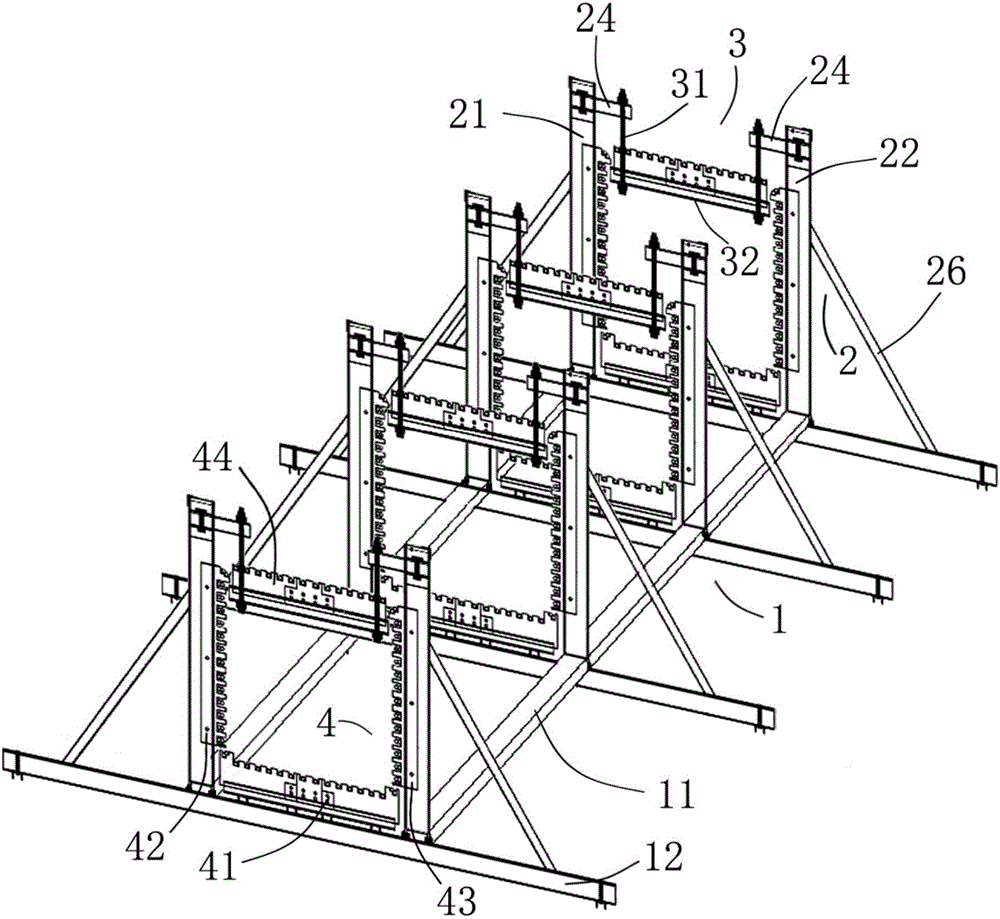

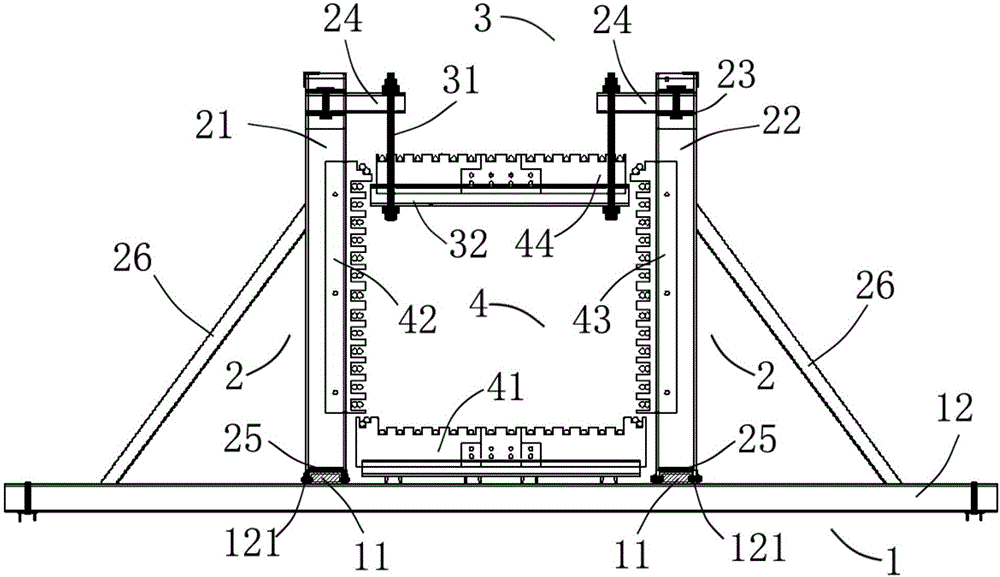

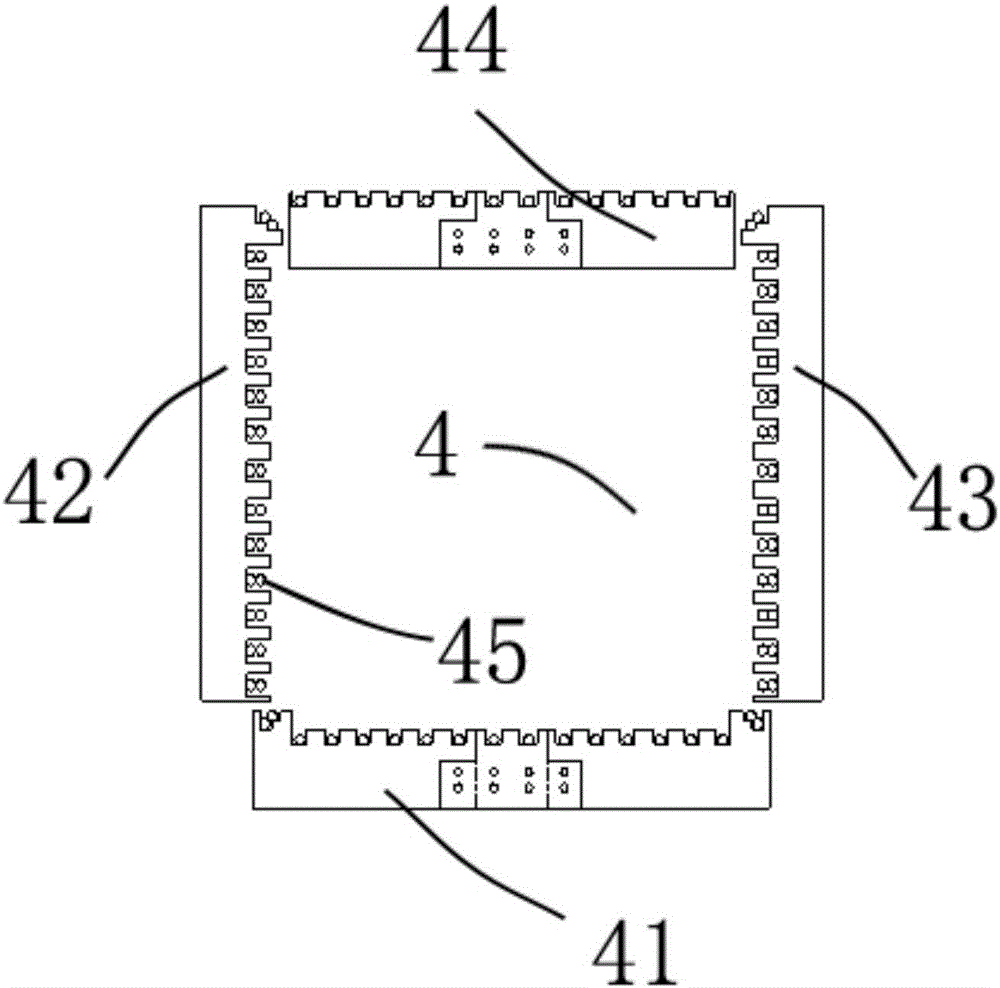

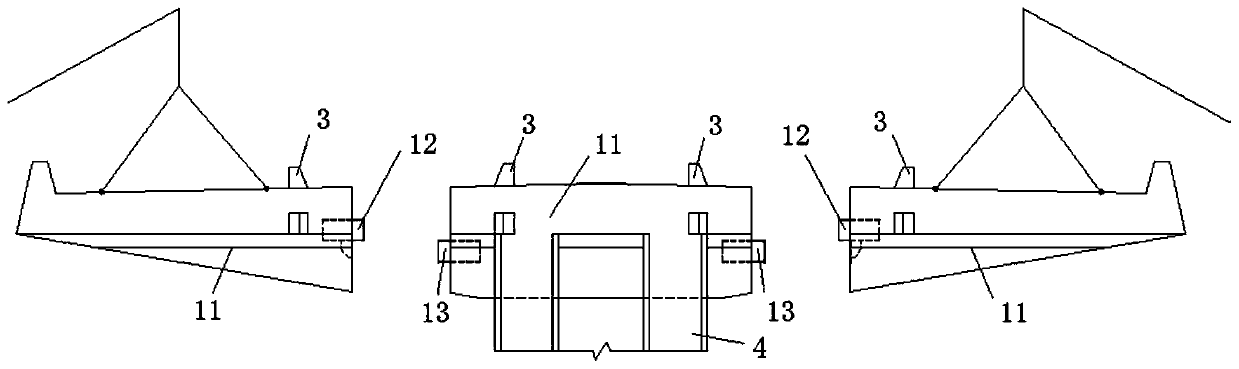

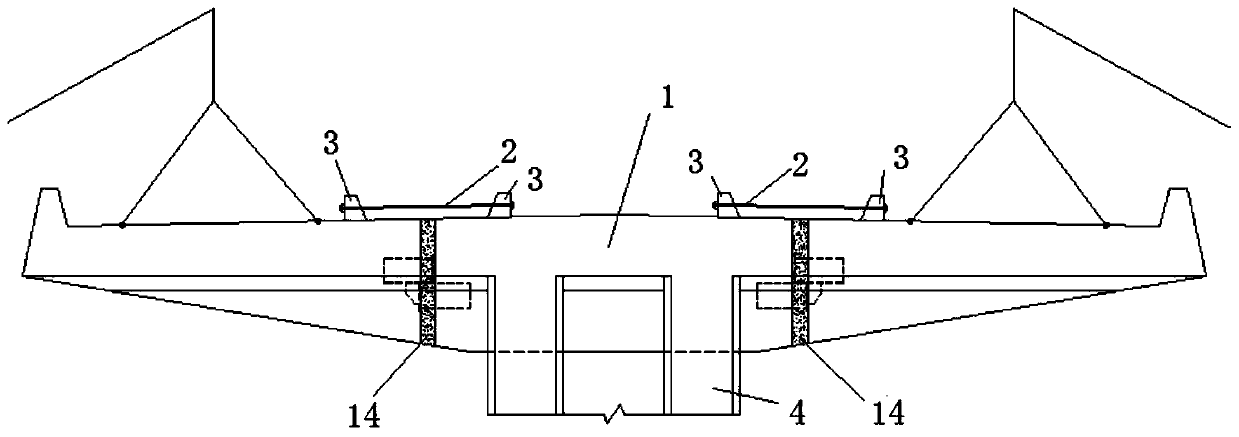

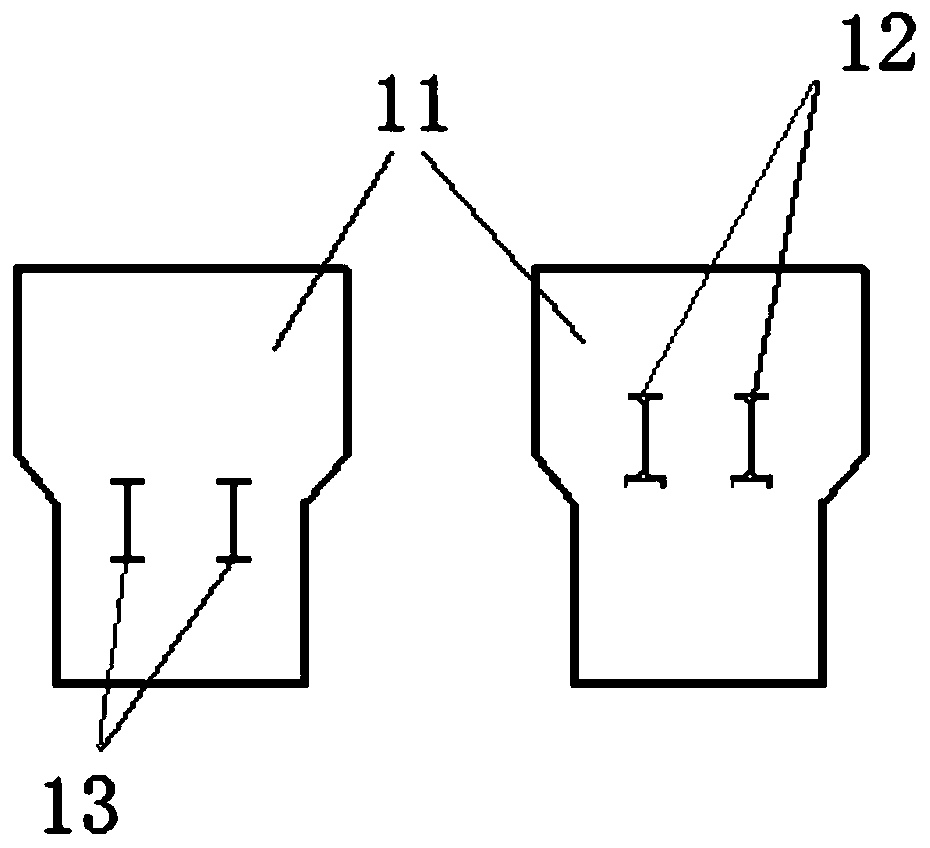

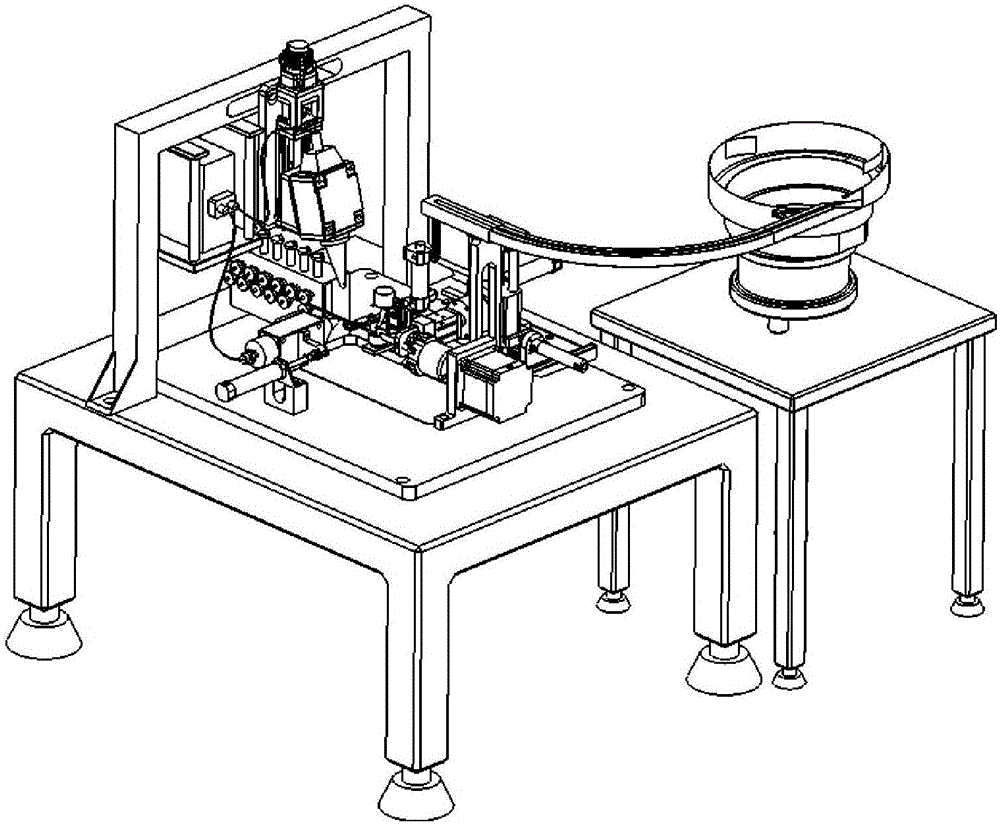

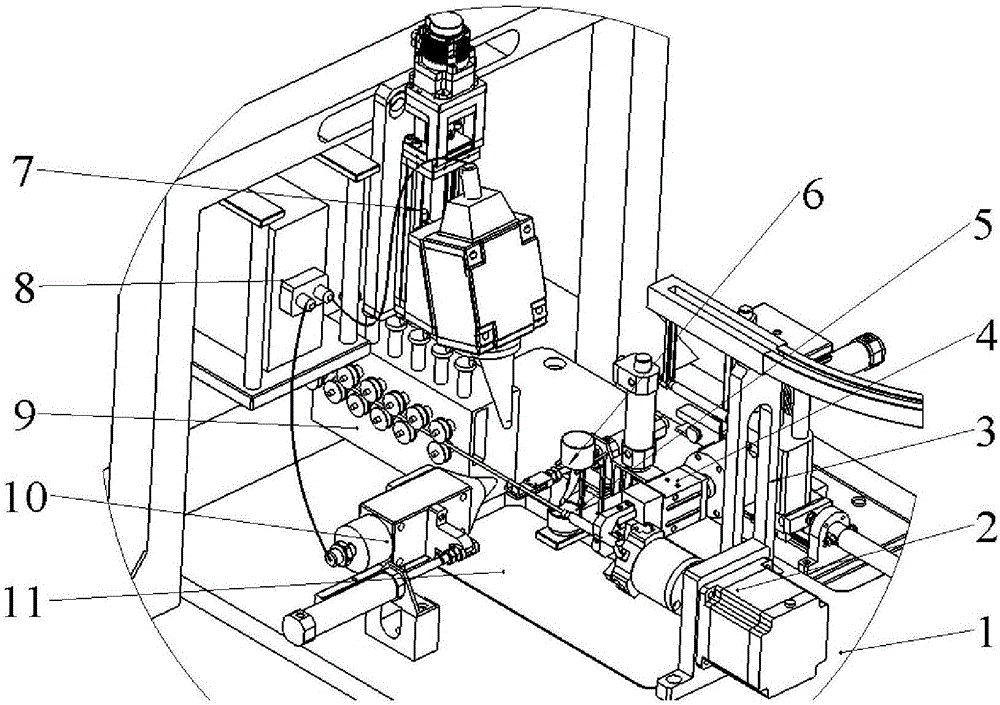

Manufacturing method of reinforcing steel bar section and adjustable reinforcing steel bar section splitting jig frame thereof

ActiveCN106400690AOperational securityConstruction environment safetyBridge erection/assemblyRebarSupport plane

The invention discloses a manufacturing method of a reinforcing steel bar section and an adjustable reinforcing steel bar section splitting jig frame thereof. The adjustable reinforcing steel bar section splitting jig frame comprises a bearing platform, a vertical supporting frame, a suspension frame and a toothed plate set, wherein the bearing platform comprises a pair of longitudinal bearing steels, and a plurality of transverse bearing steels which are orthogonally connected below the longitudinal bearing steels; the vertical supporting frame comprises a plurality of pairs of left supports and right supports; the left supports and the right supports are vertically arranged on the transverse bearing steels; the suspension frame comprises hoisting ribs, and suspension plates which are connected with the left supports and the right supports through the hoisting ribs in a suspension manner; the toothed plate set comprises lower toothed plates which are connected with the corresponding transverse bearing steels, left toothed plates which are connected with the corresponding left supports, right toothed plates connected with the corresponding right supports, and upper toothed plates connected with the corresponding suspension plates. With the adoption of the adjustable reinforcing steel bar section splitting jig frame, a safe and reliable construction environment is provided; in addition, the adjustable reinforcing steel bar section splitting jig frame can be transferred to use and has the characteristics of being fast to bind and manufacture, high in reinforcing steel bar mounting accuracy, and small in workload of aloft work.

Owner:ROAD & BRIDGE SOUTH CHINA EINGINEERING CO LTD +1

Group iii nitride crystals, their fabrication method, and method of fabricating bulk group iii nitride crystals in supercritical ammonia

ActiveUS20160153120A1Improve structural qualitySimple structurePolycrystalline material growthFrom normal temperature solutionsBulk crystalAmorphous phase

In one instance, the invention provides a group III nitride crystal having a first side exposing nitrogen polar c-plane of single crystalline or highly oriented polycrystalline group III nitride and a second side exposing group III polar surface, polycrystalline phase, or amorphous phase of group III nitride. Such structure is useful as a seed crystal for ammonothermal growth of bulk group III nitride crystals. The invention also discloses the method of fabricating such crystal. The invention also discloses the method of fabricating a bulk crystal of group III nitride by ammonothermal method using such crystal.

Owner:SEOUL SEMICONDUCTOR

High Electron Mobility Transistor with Periodically Carbon Doped Gallium Nitride

ActiveUS20160099345A1Improve breakdown performanceImprove structural qualityTransistorSemiconductor/solid-state device manufacturingCarbon dopedGallium nitride

A method for forming a high electron mobility transistor (HEMT) device with a plurality of alternating layers of one or more undoped gallium nitride (GaN) layers and one or more carbon doped gallium nitride layers (c-GaN), and an HEMT device formed by the method is disclosed. In one embodiment, the method includes forming a channel layer stack on a substrate, the channel layer stack having a plurality of alternating layers of one or more undoped gallium nitride (GaN) layers and one or more carbon doped gallium nitride layers (c-GaN). The method further includes forming a barrier layer on the channel layer stack. In one embodiment, the channel layer stack is formed by growing each of the one or more undoped gallium nitride (GaN) layers in growth conditions that suppress the incorporation of carbon in gallium nitride, and growing each of the one or more carbon doped gallium nitride (c-GaN) layers in growth conditions that promote the incorporation of carbon in gallium nitride.

Owner:KK TOSHIBA

Transverse segmental prefabricated prestressed concrete bent cap structure and assembling method thereof

PendingCN111206492AEasy to manufactureEasy to transportBridge structural detailsBridge erection/assemblyPre stressArchitectural engineering

The invention discloses a transverse segmental prefabricated prestressed concrete bent cap structure and an assembling method thereof. The transverse segmental prefabricated prestressed concrete bentcap structure comprises a bent cap body and prefabricated stand columns. The bent cap body comprises a plurality of prefabricated sections spliced in the transverse direction; a hole through which a steel strand penetrates is reserved in each prefabricated section; every two adjacent prefabricated sections are connected through a wet joint section; an upper profile steel lap joint structure and alower profile steel lap joint structure which are matched with each other are pre-buried in the joint surfaces, close to the two sides of the wet joint section, of every two adjacent prefabricated sections respectively; the transverse steel bars on the top face, the bottom face and the vertical face of each prefabricated section extend into the range of the corresponding wet joint section, and thetransverse steel bars of each prefabricated section and the transverse steel bars of another adjacent prefabricated section are arranged in a staggered lap joint mode. The small-tonnage segmented prefabricated assembly of the large-volume prestressed concrete bent cap is achieved, stress of the bent cap structure can be better ensured, the structure quality is improved, and the construction speedis increased.

Owner:SHANGHAI URBAN CONSTR DESIGN RES INST GRP CO LTD

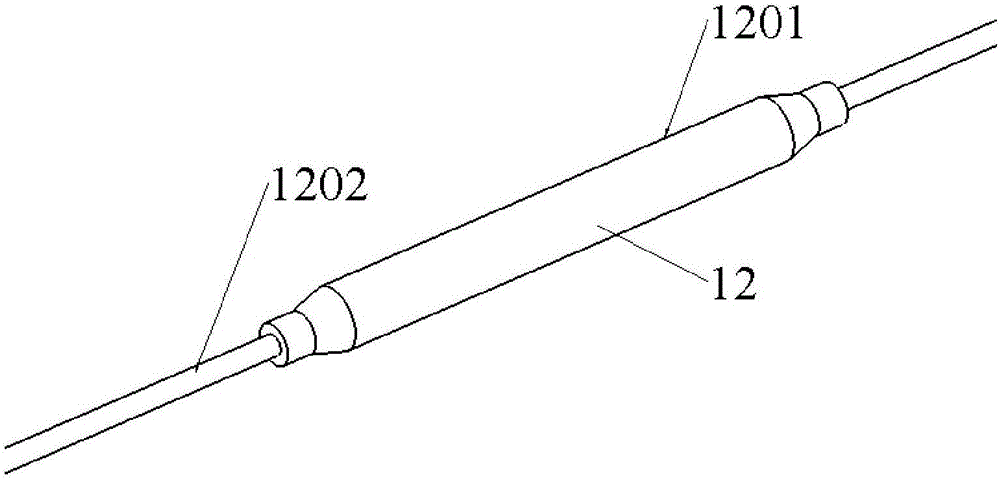

Cup joint hollow copper pipe manufacturing method and device based on laser cutting and welding

ActiveCN106624362AGuaranteed tightnessPrevent leakageMetal working apparatusLaser beam welding apparatusBeam splitterStructural engineering

The invention provides a cup joint hollow copper pipe manufacturing method based on laser cutting and welding. The cup joint hollow copper pipe manufacturing method includes the following steps that one end of a hollow copper core is inserted into a hollow copper pipe; an electronic optical shutter beam splitter is connected to the output end of a laser device; welding laser beams are output to conduct fixed point welding; cutting laser beams are output to cut off the hollow copper core; a pipe side end laser circumferential weld of a cup joint section is welded; the cup joint section continuously rotates at a constant speed, and fusion brazing filler metal is controlled to drop into a core side end of the cup joint section from a flow guide pipe in an inclined manner; welding laser beams are output, and laser fusion brazing is achieved; the hollow copper pipe with one welded end is overturned horizontally by 180 degrees; and the above steps are repeatedly executed, and welding of the other end of the hollow copper pipe is completed. A cup joint section welding connector obtained through the method comprises the high-quality pipe side end laser circumferential weld and one smooth laser fusion soldered seam, the problem that leakage is easy is solved, and the sufficient overall strength mechanical property of the cup joint connector is guaranteed. The invention further provides a cup joint hollow copper pipe manufacturing device.

Owner:瑞安市聚邦汽车零部件有限公司

Arch-after-girder construction method of large-span steel box tacked arch bridge

ActiveCN102154988AReduce construction investmentThe structural force is clearBridge structural detailsFoundation engineeringSurface engineeringFalsework

The invention relates to an arch-after-girder construction method of a large-span steel box tacked arch bridge. The construction method comprises the following steps of: respectively building two temporary reinforced concrete bar-shaped bases on the ground at the bottom parts of steel girders on two sides of a to-be-built steel-structure bridge; mounting a plurality of temporary supporting piers on the reinforced concrete bar-shaped bases; respectively mounting steel girder assembling platforms on two external sides of the two bar-shaped bases; and paving portal crane rails on two sides of the steel girder assembling platforms and mounting two portal cranes. In the construction method, arch ribs, lifting rods and bridge surfaces engineering are carried out after system girders, end transverse girders and vertical transverse girders are mounted to form a whole stressed system by combining with temporary main supporting piers. The construction method has the advantages of low construction investment, specific structure stress, and simple and convenient construction process, and can realize parallel construction; all the steel components are hoisted by adopting the running-type portal canes, thereby reducing a great amount of mounting and dismantling work of the scaffoldings in the high altitude, and reducing the mounting period of the box girders; and the steel components can beassembled under the bridge during the transporting time of thebox girders, which increases the safety coefficients, and improves the structural quality.

Owner:CCCC TUNNEL ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com