Customized Bluetooth earphone and manufacturing method thereof

A technology of bluetooth earphones and manufacturing methods, applied in the direction of earpiece/earphone accessories, etc., can solve the problems of dropping, consuming a lot of manpower and material resources, and increasing bad experience, so as to ensure accuracy and restoration, save manpower and material resources, and enhance good quality The effect of experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

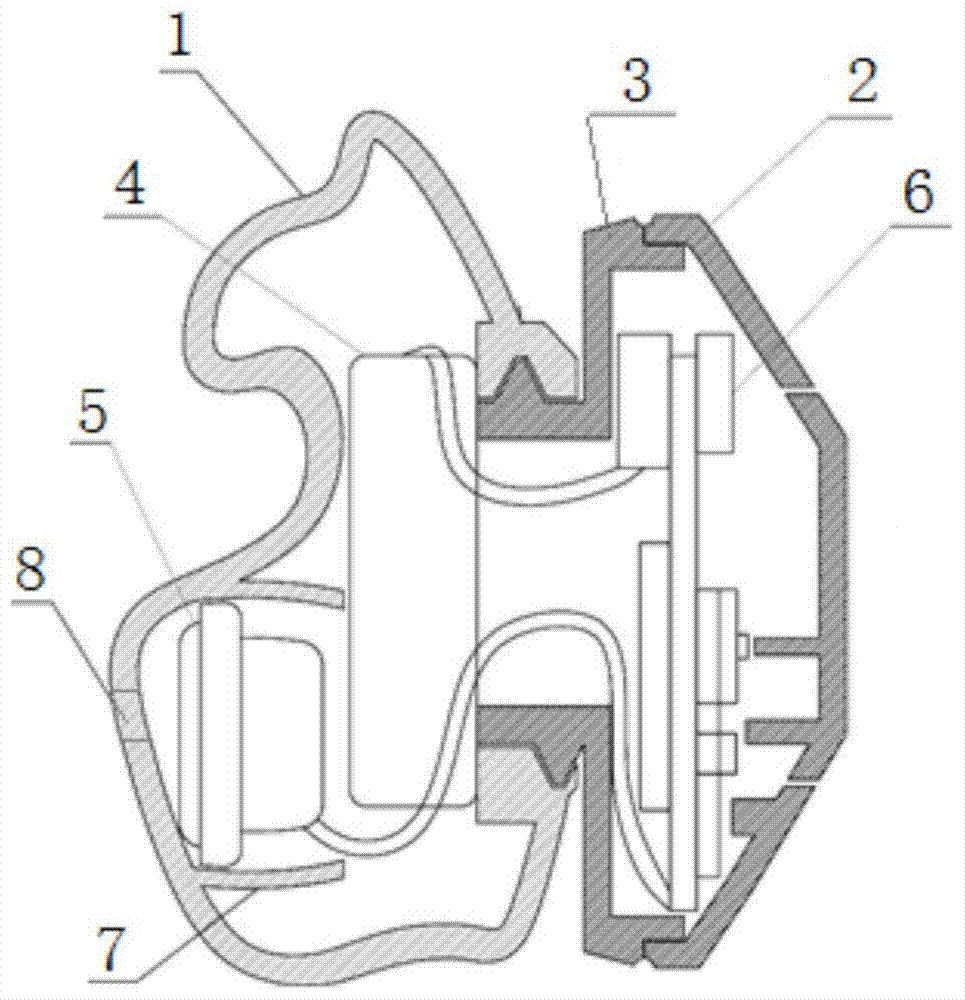

[0022] Such as figure 1 with figure 2 As shown, the present invention provides a customized Bluetooth headset, which includes an ear cavity inner shell 1 , an ear cavity outer shell 2 , a connecting part 3 , a lithium battery 4 , a sound unit 5 and an integrated circuit board 6 . Among them, the ear cavity inner shell 1 is integrally formed by 3D printing technology, and the ear cavity outer shell 2 is processed and assembled from traditional thermoplastic materials; the ear cavity inner shell 1 and the ear cavity outer shell 2 are connected by connecting parts 3 Together, they form a closed space. A semi-closed sound cavity structure 7 is set in the ear cavity inner shell 1 corresponding to the position of the concha cavity of the human ear, and the sound emitting unit 5 is arranged in the sound cavity structure 7, and the side of the ear ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shell thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com