Electromagnetic-magnetoelectric type micro mechanical resonant beam structure

A magnetoelectric and resonant beam technology, applied in the field of resonant sensitive components, can solve problems such as difficult coupling interference, achieve the effects of eliminating self-doping effects, good structural accuracy and surface quality, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

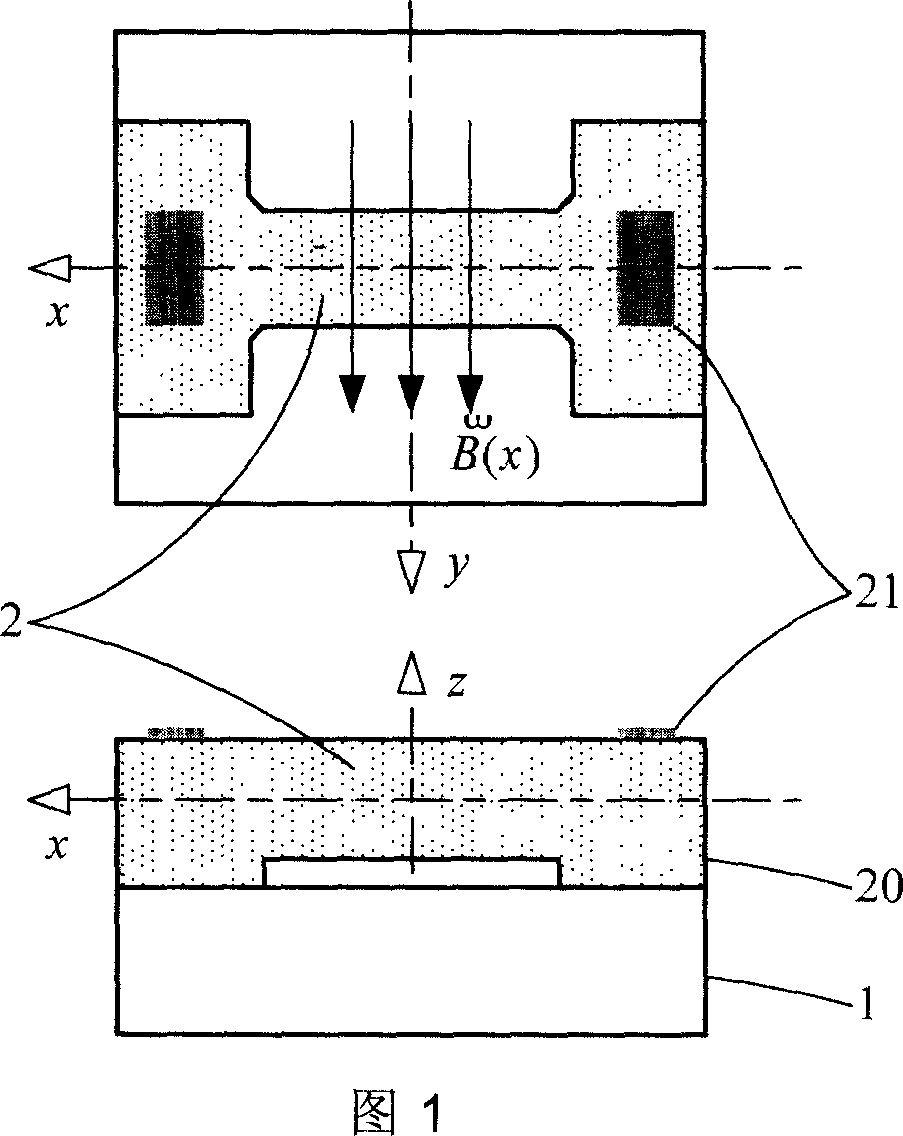

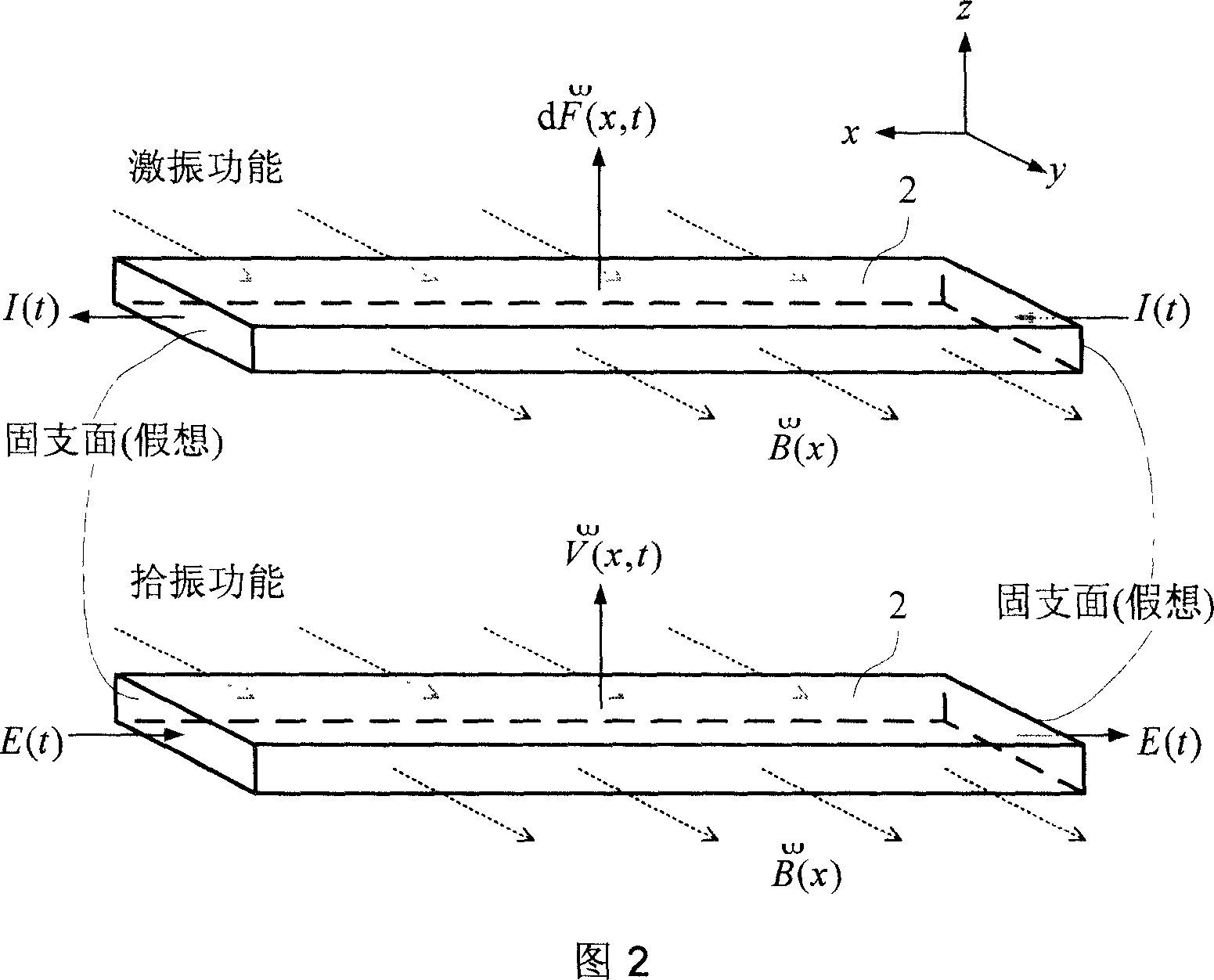

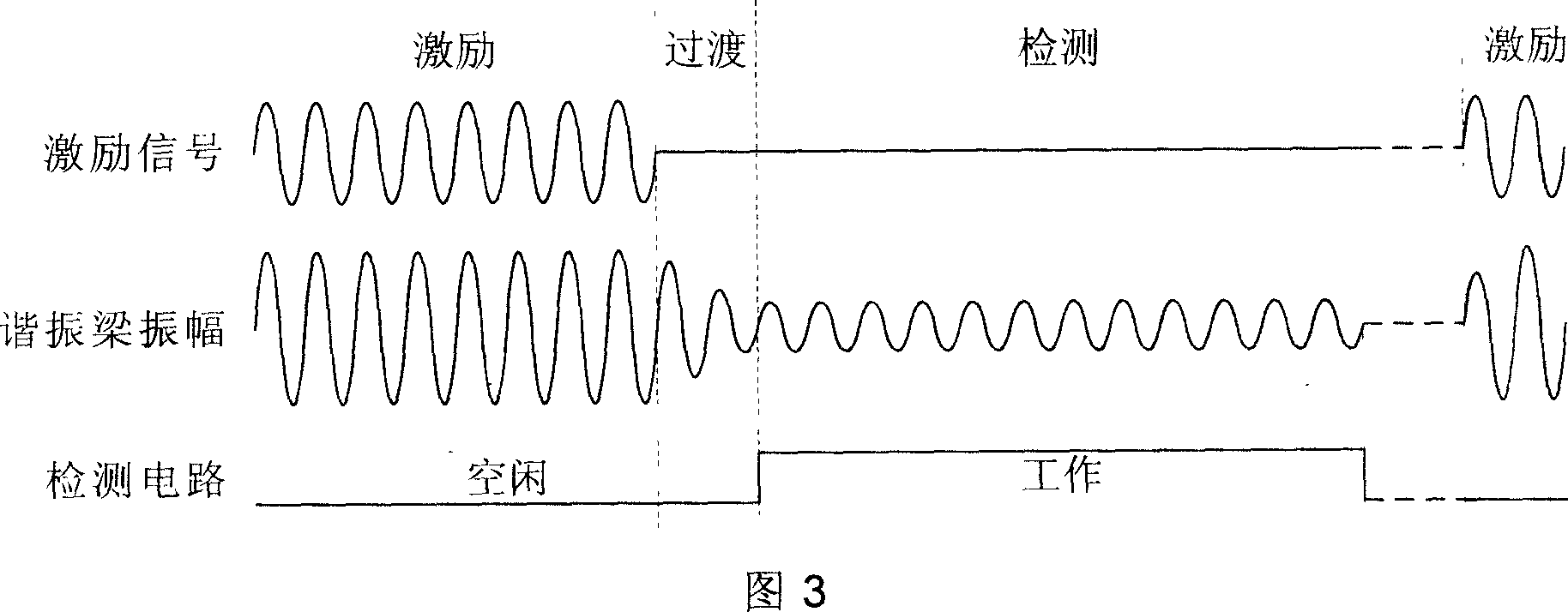

[0030] As shown in Figure 1, the present invention consists of a substrate 1 and a magnetic field The resonant beam 2 is composed of the resonant beam 2, and the base 1 is an elastic diaphragm that deforms elastically with the change of the measured physical quantity. Resonant measurement; the substrate 1 and the resonant beam 2 are made of SOI wafers, which are processed by epitaxy and etching; the two ends of the resonant beam 2 have electrodes, which are connected to the magnetic field The direction is orthogonal to each other. When the current passes through, the ampere force in the thickness direction is generated, and the induced voltage is generated at both ends when the vibration occurs. The intermittent principle is used to form a closed-loop system to completely solve the problem of coupling interference.

[0031] As shown in Fig. 4, the SOI wafer used in the substrate 1 and the resonant beam 2 consists of a single crystal silicon layer 13, SiO 2 The buried layer 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com