Hybrid maglev gravity compensation apparatus

A gravity compensation and magnetic levitation technology, which is applied in the field of gravity compensation devices, can solve problems such as high motor heat generation, affecting the thermal performance of the wafer holder, and air flow disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In the following, preferred embodiments according to the present invention will be described in detail with reference to the accompanying drawings.

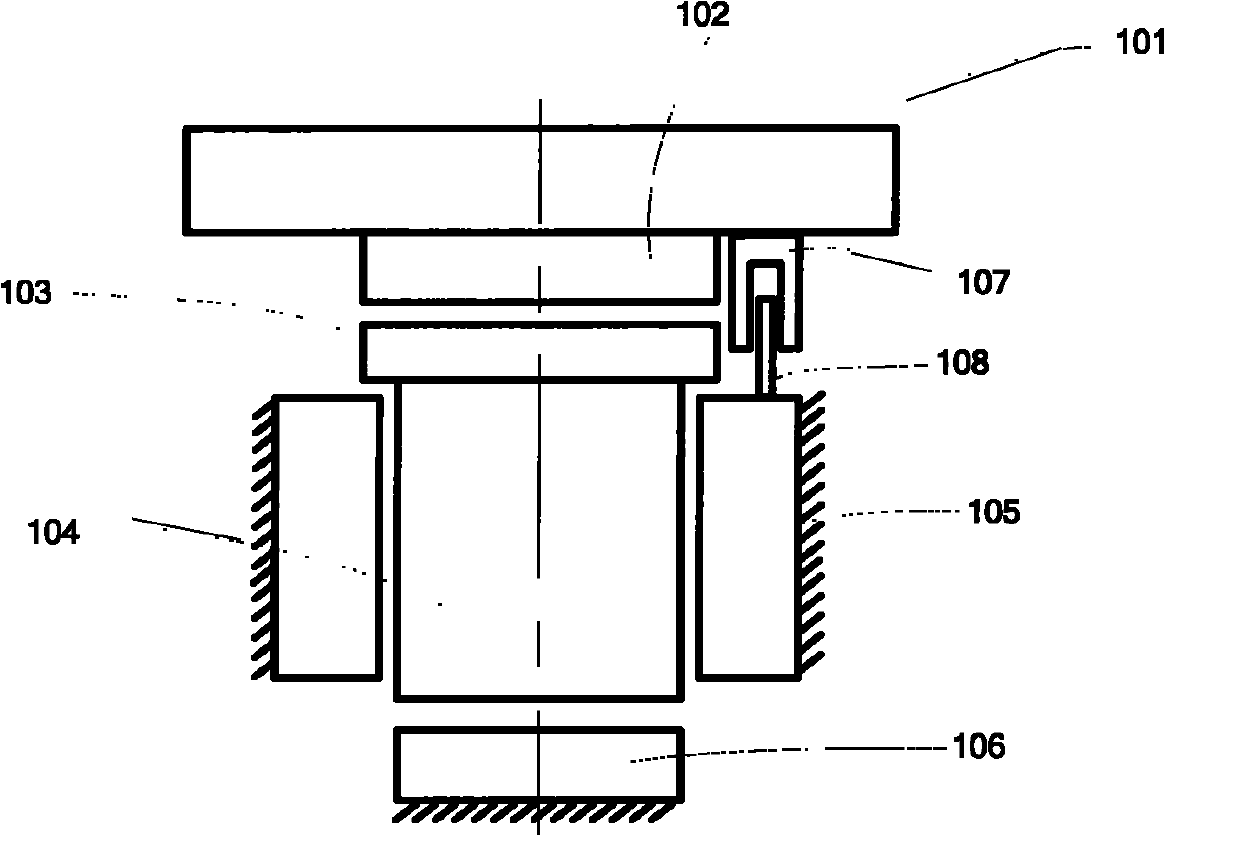

[0025] Such as figure 1 As shown, the connecting part 102 is placed under the micro-moving wafer stage part 101, and the connecting part 102 and the top part 103 below it together form a horizontal (X / Y direction) decoupling part; the middle moving part 104 and the external fixed part 105 The vertical guide part; the middle moving part 104 and the bottom fixed part 106 form a static vertical gravity compensation part. The decoupling part and the guide part together form a moving part, and the outer fixing part 105 and the bottom fixing part 106 are stationary parts. When it is necessary to measure the vertical displacement of the gravity compensation device, a differential sensor can be used—the stator part 108 of the sensor is installed on the bottom fixed part 106 or the external fixed part 105, and the mover part 107 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com