Clamping equipment for composite mechanical material processing

A clamping equipment and material processing technology, which is applied in the direction of manipulators, chucks, manufacturing tools, etc., can solve the problems of leaving marks on the plate and lack of processing methods, and achieve the effect of plate protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

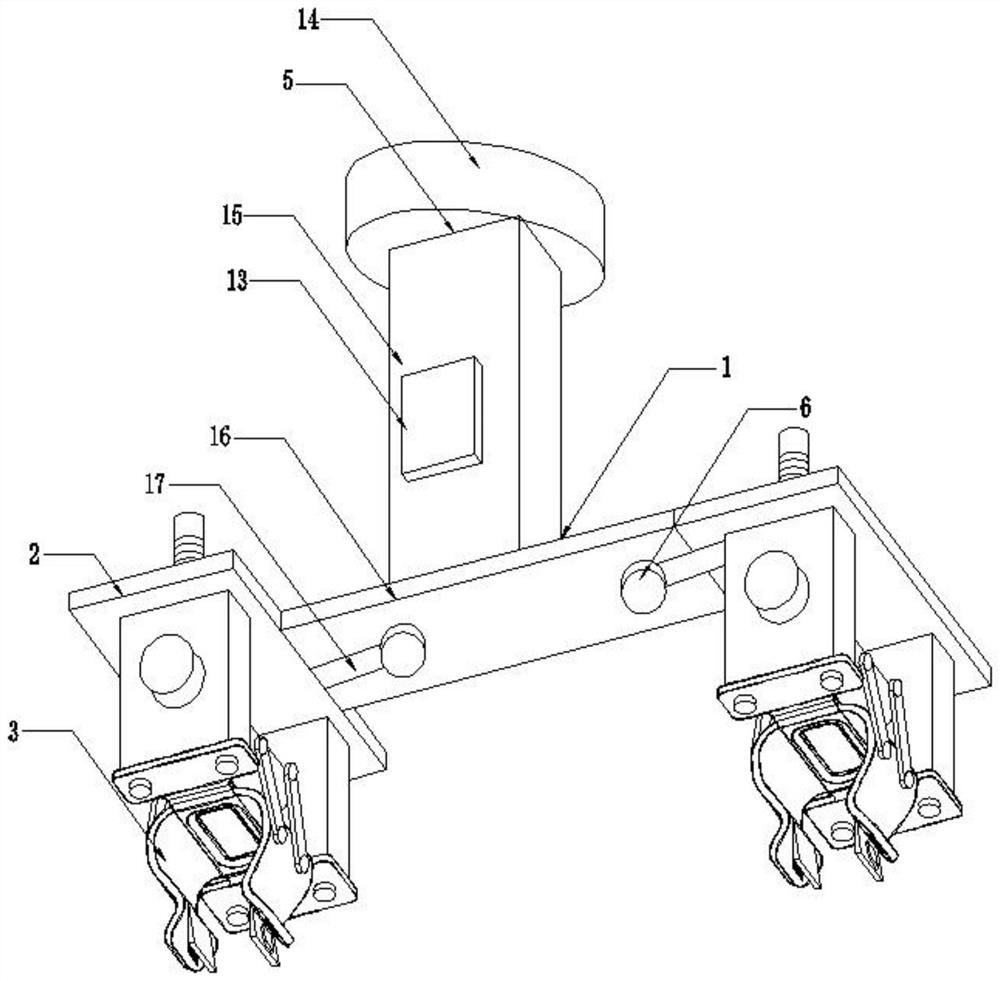

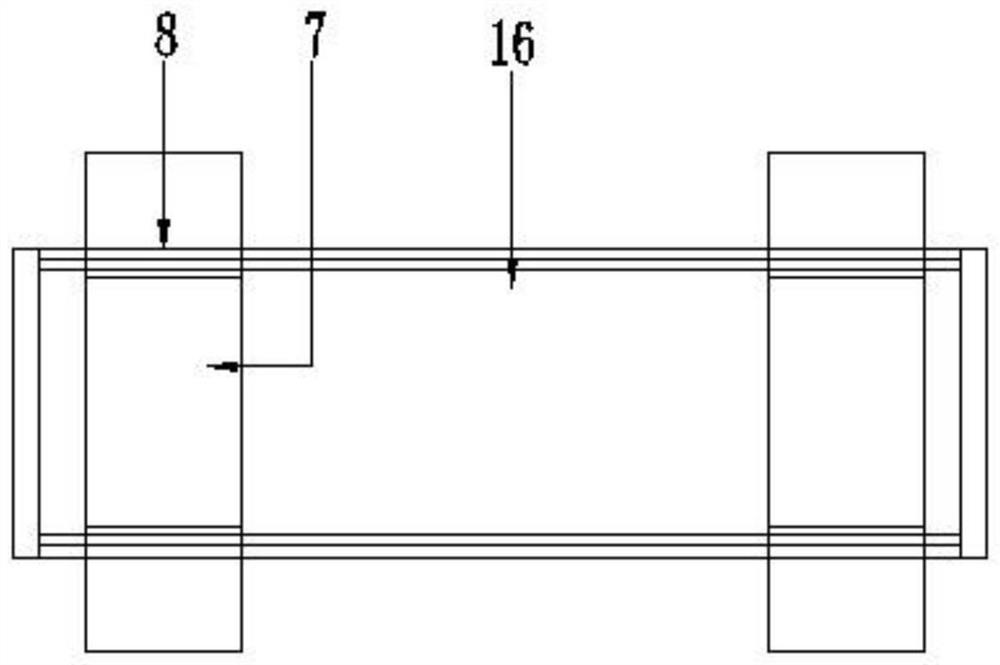

[0022] Example 1: See Figure 1-5 , the present invention provides a technical solution: a clamping device for processing composite mechanical materials, including a plate clamping device, the plate clamping device includes a bidirectional drive mechanism 1, an installation base 2, a clamping driver 3 and a clamping piece 4, The two-way driving mechanism 1 is composed of a longitudinal driver 5 and a transverse driver 6. The lower end of the longitudinal driver 5 is connected to the transverse driver 6. The installation base 2 is divided into two groups and is symmetrically installed on the two ends of the transverse driver 6. The installation base 2 includes a central opening. The main board 8 with guide port 7 and two groups of side plates 9 symmetrically installed on the lower end of the main board 8, the clamping driver is installed between the two groups of side plates 9, the power output end of the clamping drive is connected with the clamping piece 4, and the clamping T...

Embodiment 2

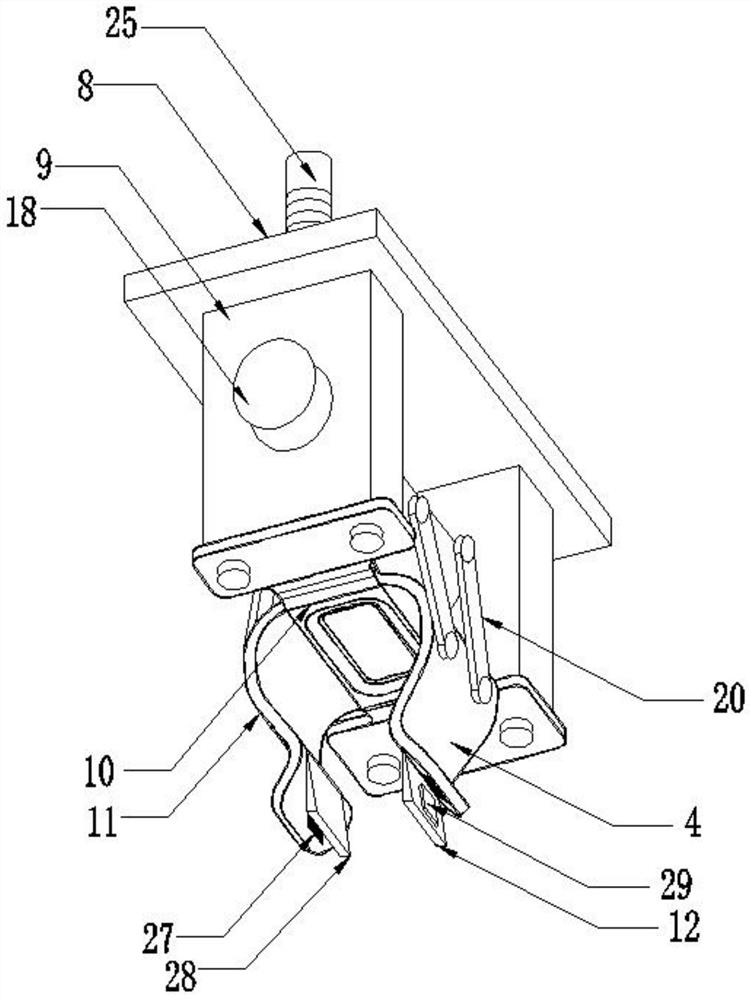

[0025] Embodiment 2: as Figure 4 As shown: the clamping driver is composed of a main shaft 18, a movable half ring 19, a driving rod 20 and a driving mechanism. The two ends of the main shaft 18 are fixedly connected with two groups of side plates 9. Pulley 21, two groups of movable semi-rings 19 are symmetrically installed on the outside of main shaft 18, pulley 21 is slidably embedded on the main shaft 18, the lower end of driving rod 20 is connected with clamping piece 4 and the upper end is connected with movable semi-ring 19, two Also be provided with connecting rod 22 between group drive rod 20, the outer end of connecting rod 22 is connected with driving mechanism, and driving mechanism is installed on the mainboard 8, and movable half ring 19 carries out activity regulation along main shaft 18.

Embodiment 3

[0026] Embodiment 3: as Figure 4 As shown: the driving mechanism is composed of a driving motor 23, a driving wheel 24, a screw 25 and a movable disc 26, the power output end of the driving motor 23 is connected to the driving wheel 24, the driving wheel 24 is meshed with the screw 25, and the screw 25 is inserted into the main board 8 and the outer end is connected with the movable disk 26, the movable disk 26 is connected with the drive rod 20 in rotation, the driving motor 23 drives the driving wheel 24 to rotate, the driving wheel 24 promotes the rotation of the screw rod 25, the screw rod 25 moves longitudinally and drives the movable disk to rotate, and the During the up-and-down adjustment of the disc, the connecting rod 22 is used to push the movable half-ring 19 to adjust, and the movable half-ring 19 is used to push the driving rod 20 to be displaced, and the purpose of adjusting the splint 11 is achieved by using the displacement.

[0027] further improved, such as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com