Method for preparing high-luster vacuum aluminum-plated paper, and vacuum aluminum-plated paper prepared by same

A vacuum aluminized paper and vacuum aluminized technology, which is applied in papermaking, paper coating, textiles and papermaking, can solve the problems of high production cost, low work efficiency, and the inability of aluminized paper to meet the requirements of high-end anti-counterfeiting packaging, and achieve flatness Good, high gloss, overcome the effect of long production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

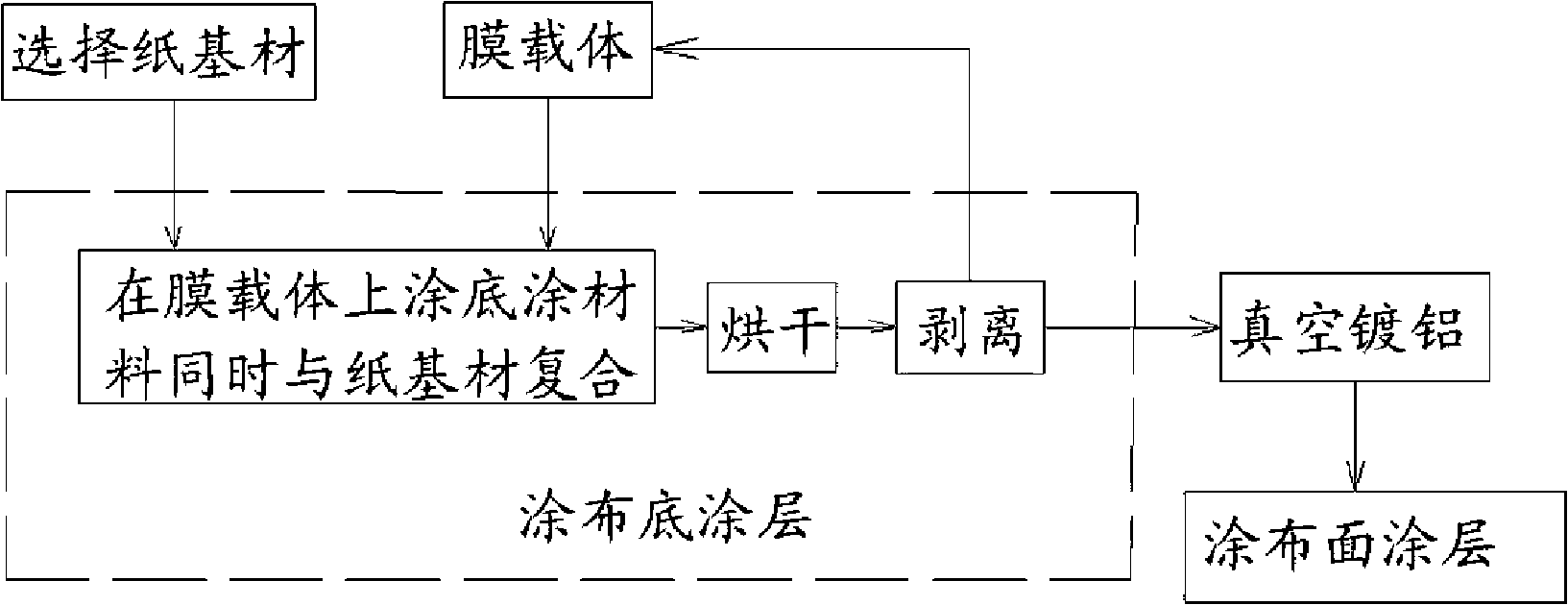

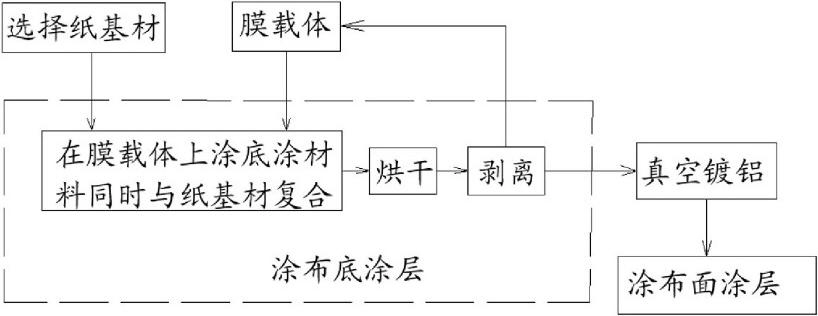

[0029] The preparation method of the high-gloss vacuum aluminum-coated paper, figure 1 shown, including the following steps:

[0030] A. Select paper substrate 1: select 60g / m 2 Coated paper is used as paper substrate 1.

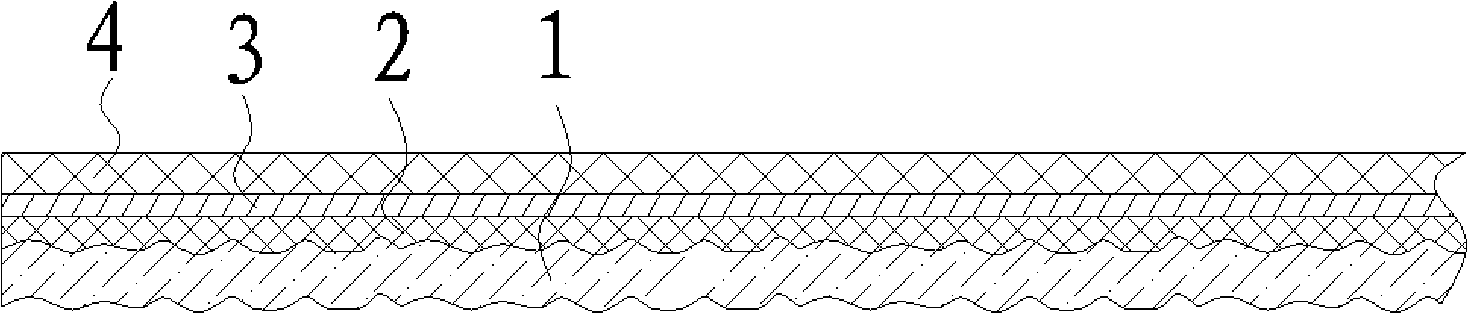

[0031] B. Forming the primer layer 2: BOPP or PET is used as the film carrier, and in the compound machine, the primer material is coated on the film carrier, and the film carrier and the paper substrate 1 are sent to the pressure roller of the compound machine Composite under a pressure of 4KG; the primer material is made of water-based materials with high solidity, low viscosity, high gloss, easy separation from the film carrier BOPP film or PET film, and good bonding force with the paper substrate 1 and the aluminum plating layer. The composition of the glue. Due to the adhesive effect of the primer material, the prime...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com