Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "Achieve horizontal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

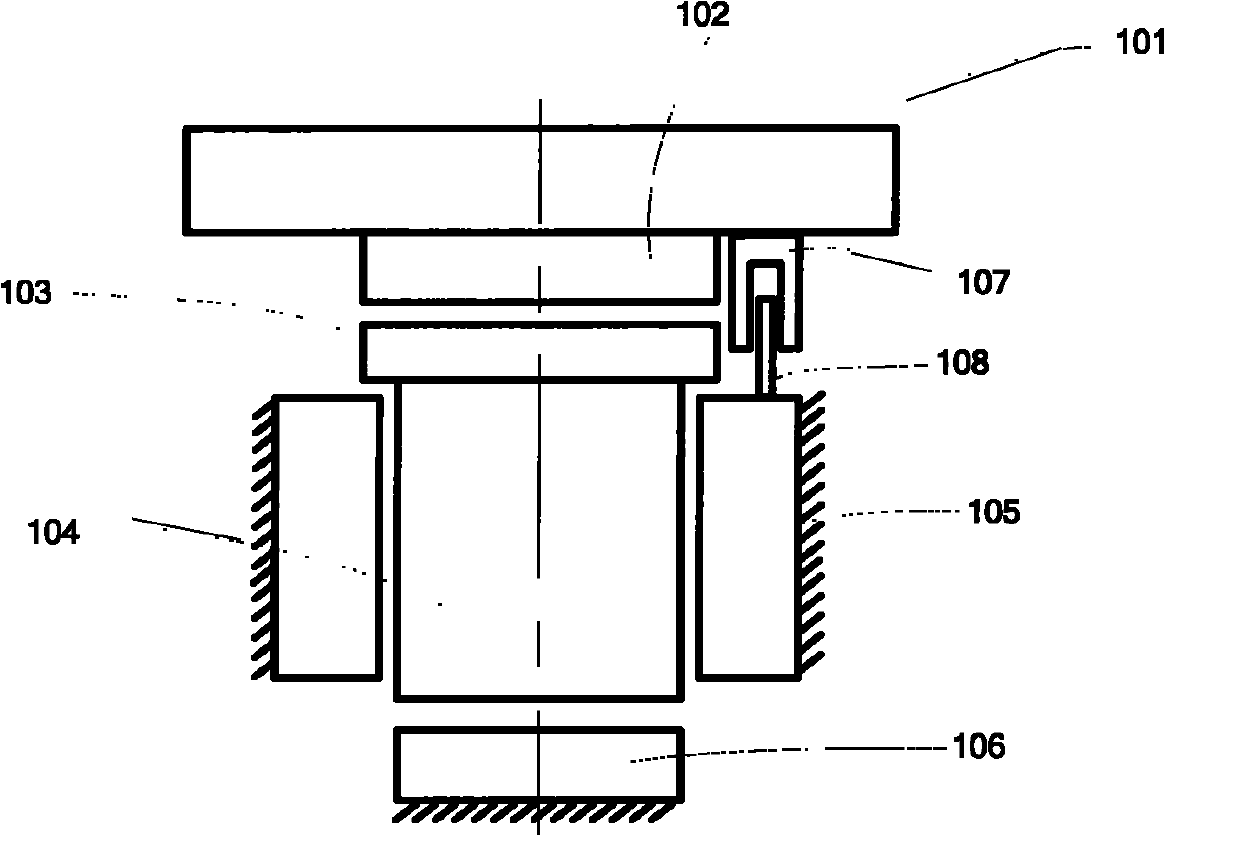

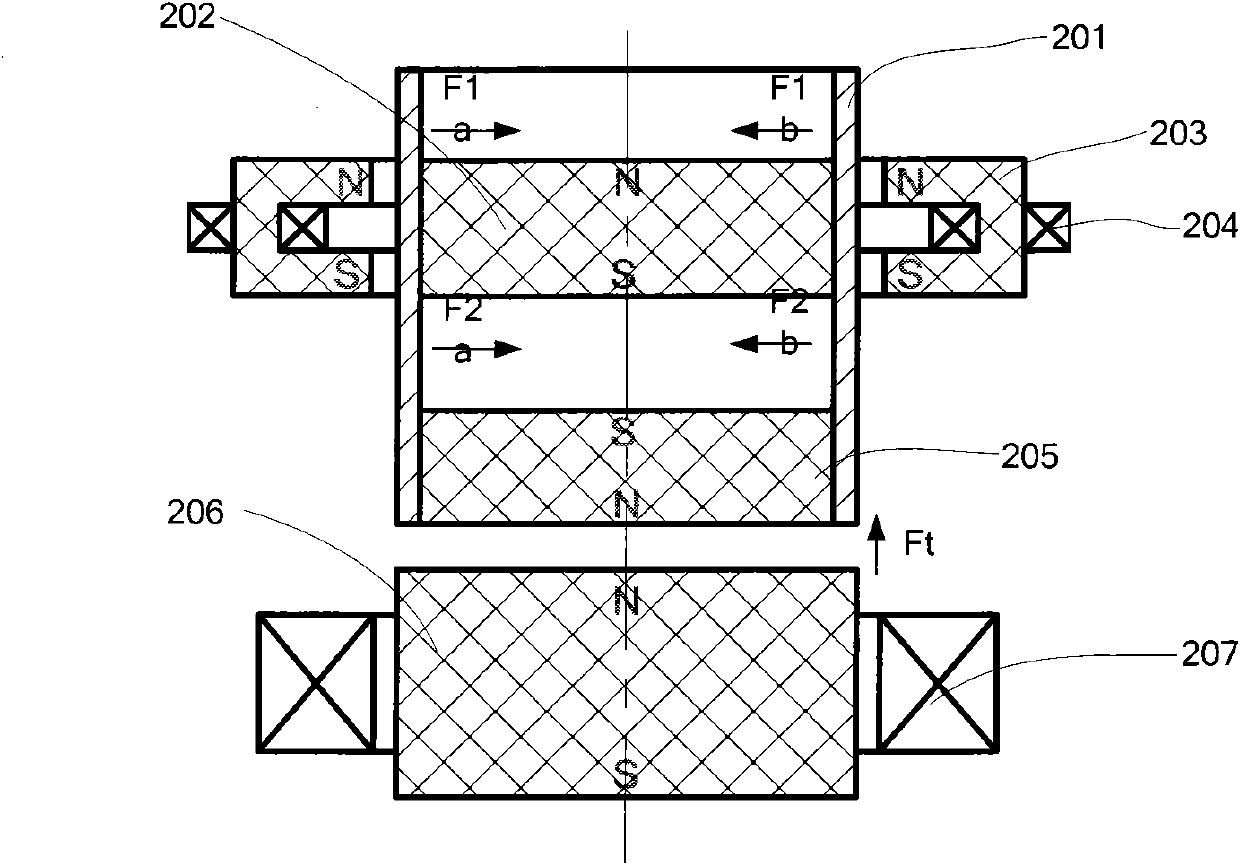

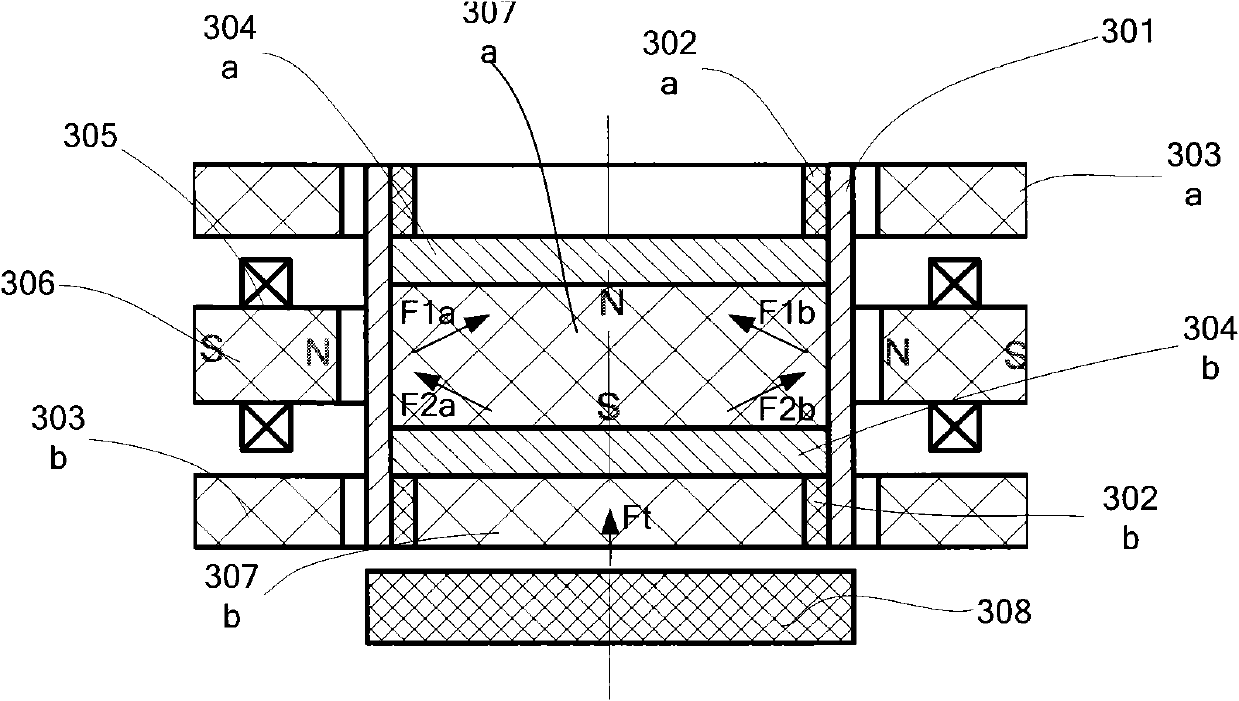

Hybrid maglev gravity compensation apparatus

ActiveCN102200689AImplement static gravity compensationAchieve horizontalPhotomechanical exposure apparatusMicrolithography exposure apparatusComputer moduleHorizontal and vertical

The invention discloses a hybrid maglev gravity compensation apparatus comprising a static gravity compensation module. The static gravity compensation module comprises: an intermediate moving component, an exterior fixed component arranged around the intermediate moving component, and a bottom fixed component arranged below the intermediate moving component. The intermediate moving component is in a radially suspended state with the magnetic forces between the exterior fixed component and the intermediate moving component, such that a vertical guiding to the intermediate moving component is carried out. Static gravity compensating between the exterior fixed component and the intermediate moving component can be carried out with adjustable magnetic forces. According to the invention, non-contact displacement between relatively moving objects can be achieved with maglev forces. Meanwhile, gravity compensation, horizontal and vertical decoupling of a wafer supporting stage can be achieved.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD +1

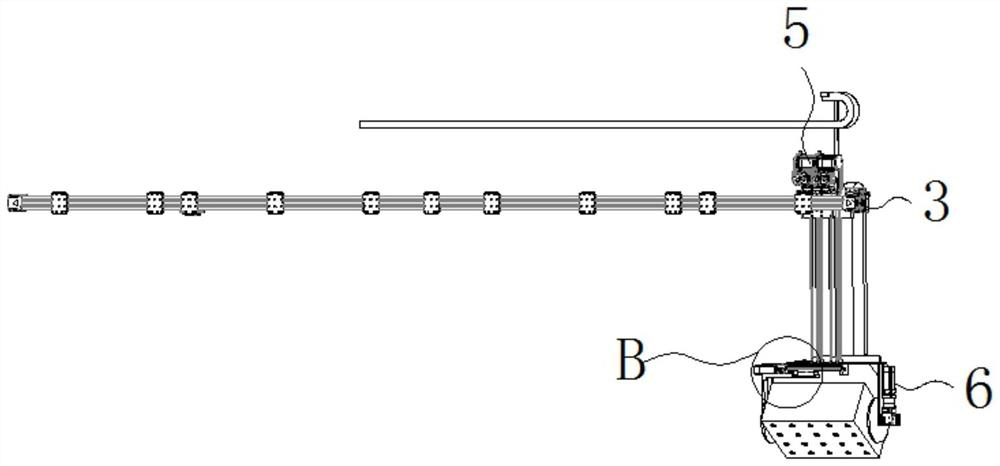

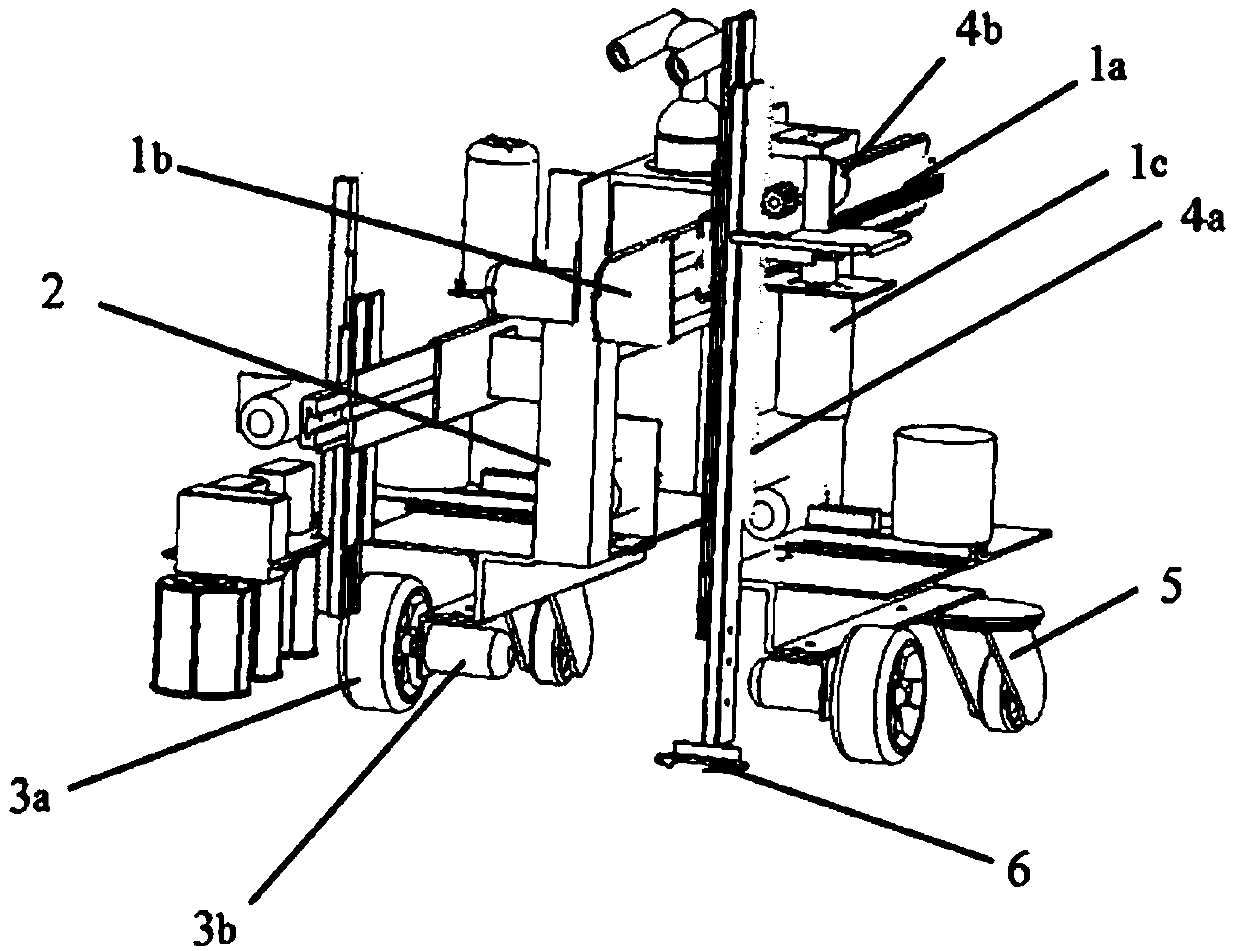

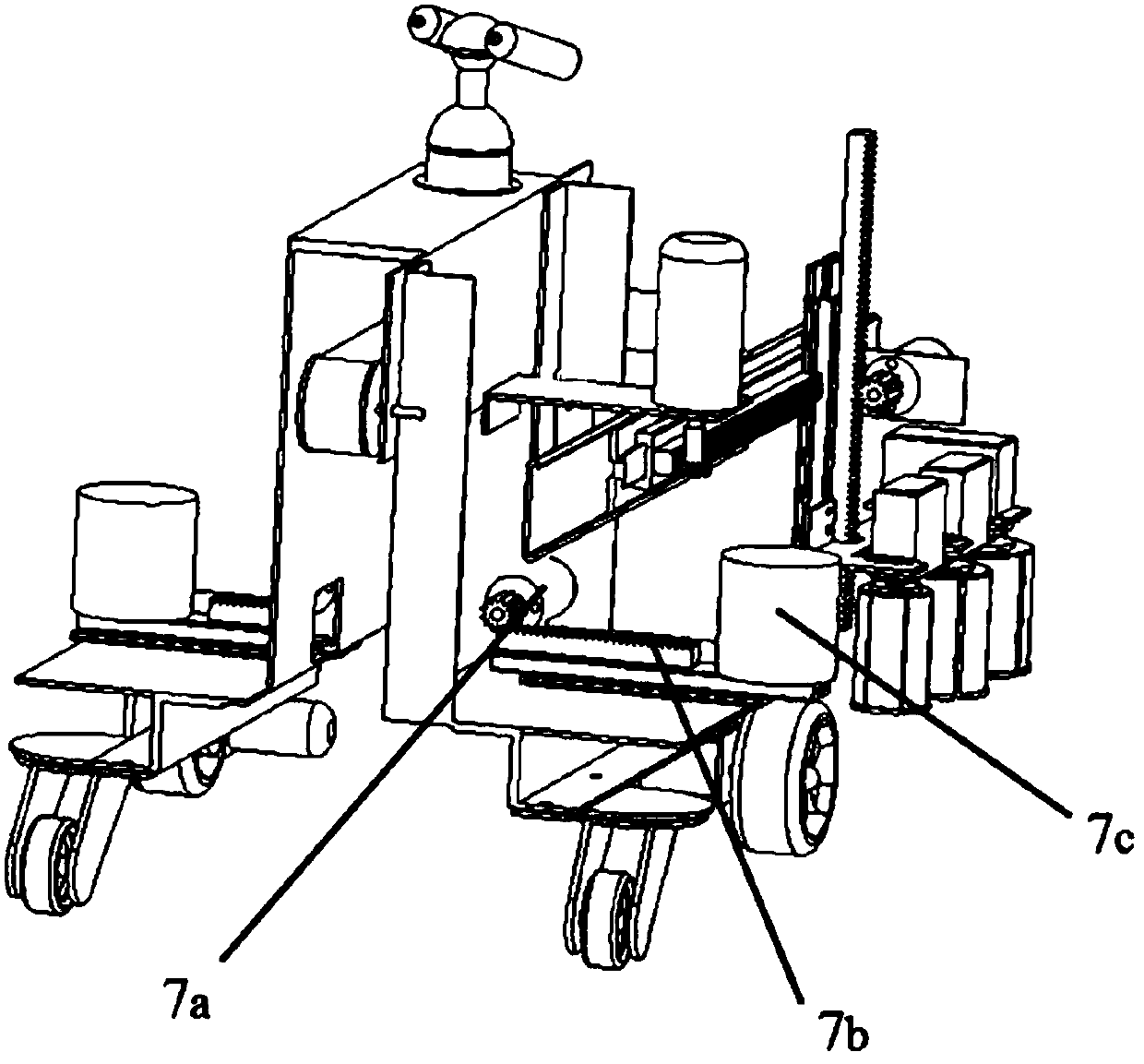

Grain harvesting and transporting integrated loading device and method based on image recognition

PendingCN111201879AAchieve horizontalChieve vertical controlMowersImage feed-backKinematic controllerAgricultural science

The invention discloses a grain harvesting and transporting integrated loading device and method based on image recognition, and relates to the technical fields of depth vision, image recognition, agricultural harvesting and internet of vehicle (IOV). Farm implements and agriculture are improved by a stereoscopic vision technology, the automation and agricultural informatization level of a harvester and a grain unloading vehicle is enhanced, and grain or equipment waste caused by human misoperation is avoided while the harvesting efficiency is improved. A self-adaptive operation manner of an existing combine harvester and a following skip car is effectively improved, a skip car human driver (driving robot) can be guided to make more accurately and effectively operation response for the current working condition, and advantageous improvement is made to avoid leakage waste, filling insufficiency and low efficiency in the operation process; and environmental information or decision instructions can be directly imported into a vehicle movement controller to realize transverse or longitudinal control on unmanned farming machinery so as to realize unmanned agricultural operation in the whole process.

Owner:金华中科艾特智能科技研究所有限公司

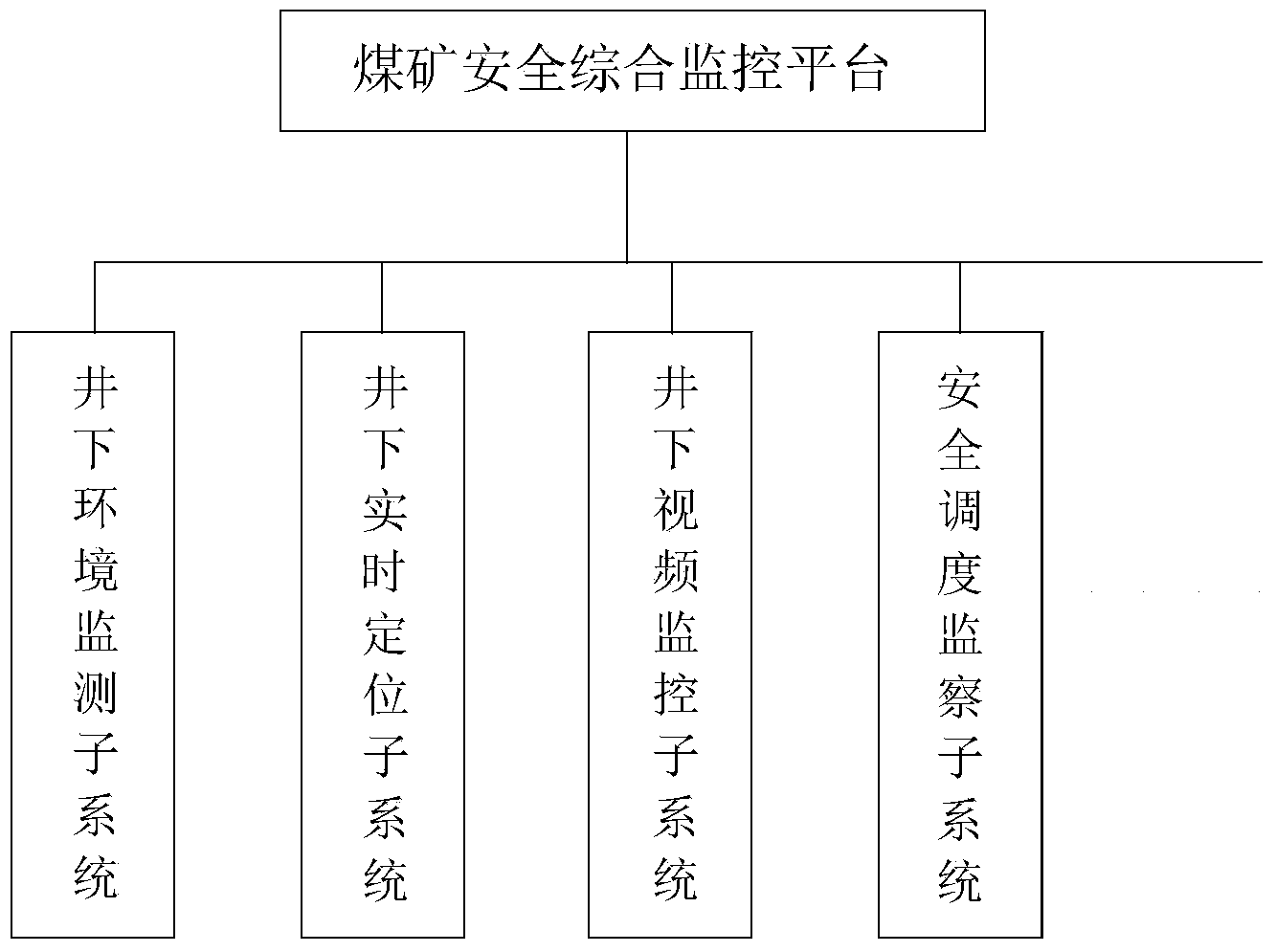

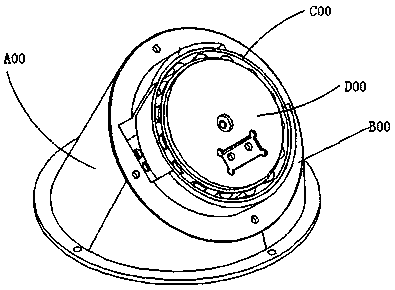

Coal mine safety comprehensive monitoring platform

InactiveCN103916638ARealize linkage monitoringAchieve horizontalClosed circuit television systemsAlarmsInformation processingVideo monitoring

The invention discloses a coal mine safety comprehensive monitoring platform. The coal mine safety comprehensive monitoring platform comprises a monitoring center, an underground environment monitoring subsystem, a worker underground real-time positioning subsystem, an underground video monitoring subsystem and a safety dispatching monitoring subsystem, wherein alarm information sent by the underground environment monitoring subsystem and worker position condition abnormal information sent by the worker underground real-time positioning subsystem are uploaded to the monitoring center; after the underground video monitoring subsystem receives an alarm information processing instruction or a worker position condition abnormal information processing instruction sent by the monitoring center, a cradle head or a camera set at the alarm information occurrence point or in the worker position condition abnormal area is automatically switched, and real-time video recording is carried out; in addition, the safety dispatching monitoring subsystem and the worker underground real-time positioning subsystem work cooperatively, and the safety dispatching monitoring subsystem accurately and completely records inspection tour in-place conditions of workers. By means of the real-time, effective and cooperative management and control among the subsystems, safe and intelligent monitoring and management of a coal mine are achieved.

Owner:SHANDONG UNIV OF SCI & TECH +1

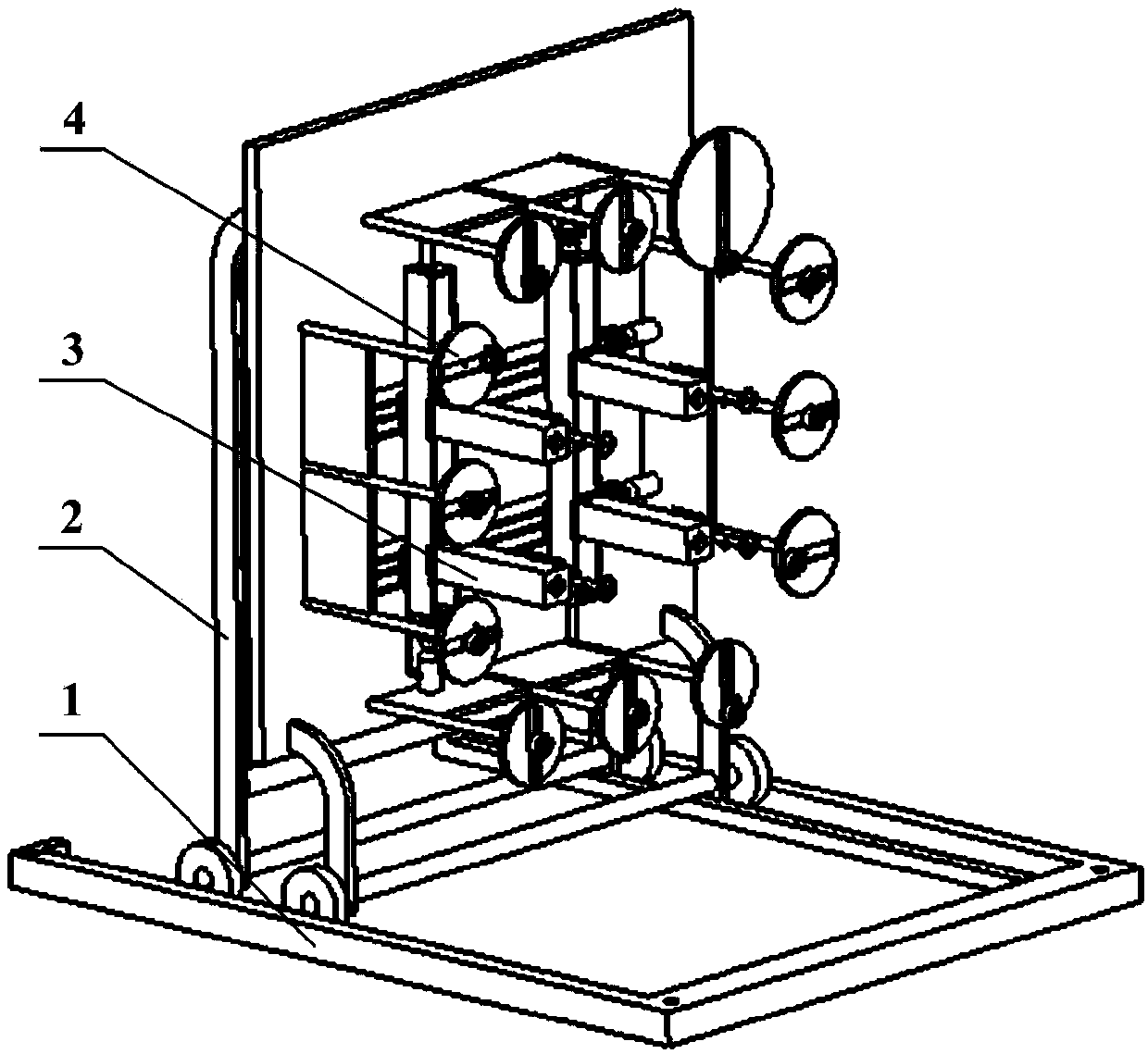

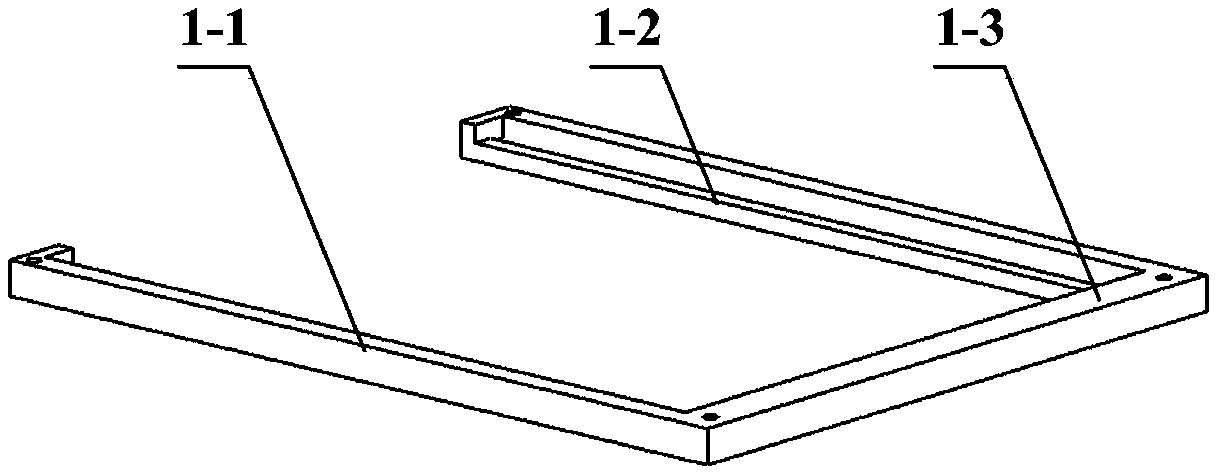

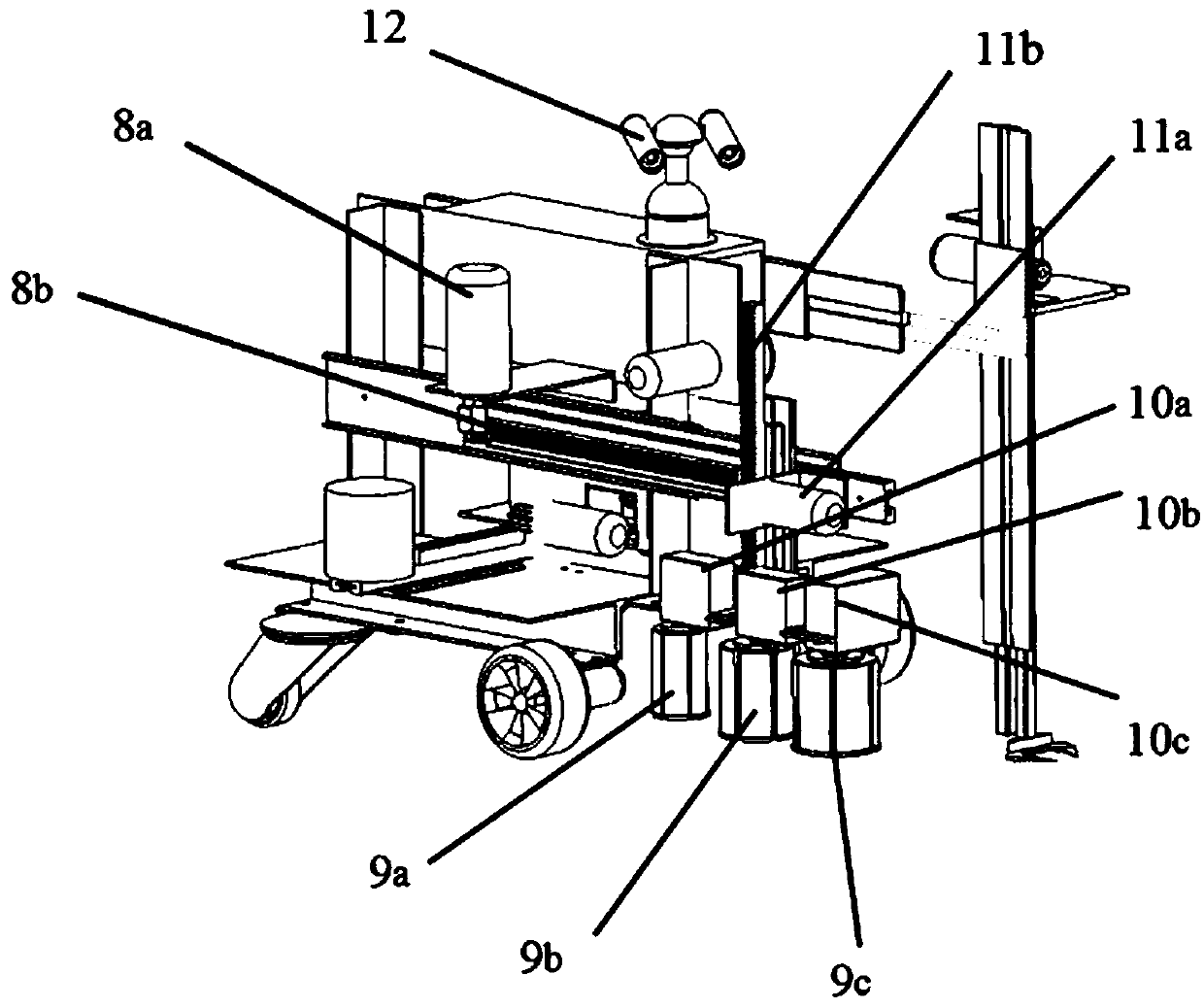

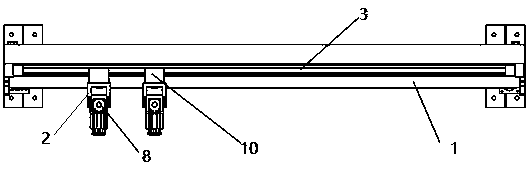

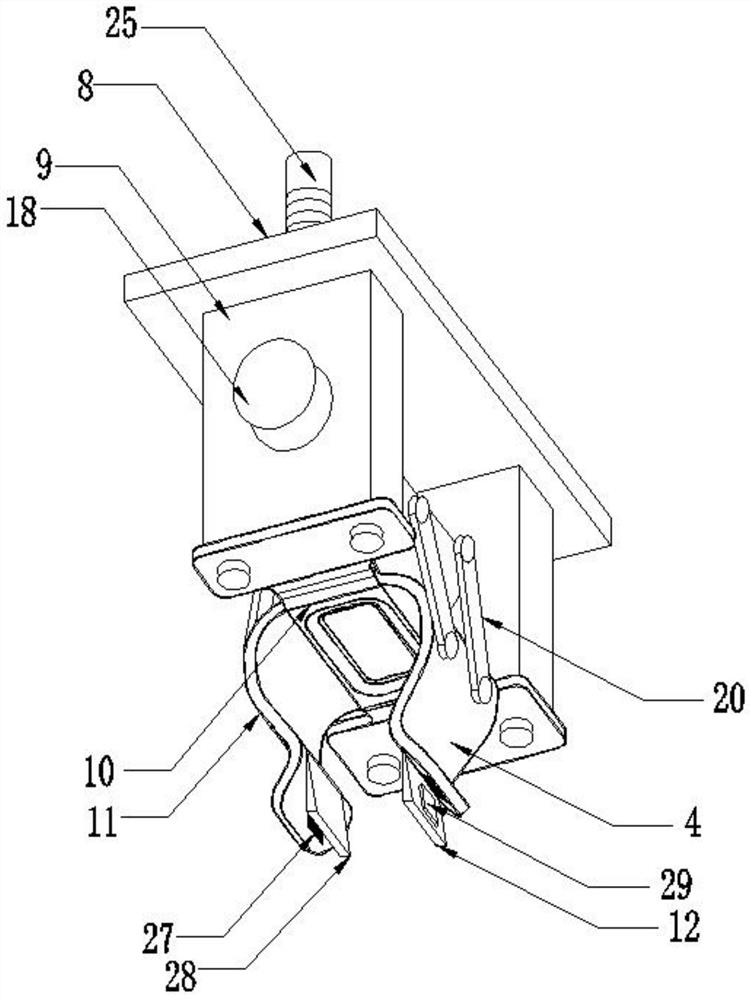

Automobile door adjusting mounting device and working method thereof

PendingCN108674526ARealize adaptive adjustmentGuaranteed uniformityMetal working apparatusVehiclesMechanical engineering technologyManufacturing quality

The invention relates to an automobile door adjusting mounting device and a working method thereof, and belongs to the technical field of mechanical engineering. The automobile door adjusting mountingdevice comprises a bottom plate guide rail, a travelling mechanism, an automobile door adjusting mechanism and a measuring mechanism. The travelling mechanism is arranged on the bottom plate guide rail; the automobile door adjusting mechanism and the measuring mechanism are arranged on the travelling mechanism; the automobile door adjusting mechanism comprises a transverse moving mechanism; a longitudinal moving mechanism is arranged on the transverse moving mechanism; a vertical moving mechanism is arranged on the longitudinal moving mechanism; the automobile door adjusting mechanism is usedfor driving an automobile door to conduct transverse, longitudinal and vertical moving adjustment; and the measuring mechanism comprises an optical sensor and is used for measuring the periphery gapand the magnitude of the face difference of the automobile door and an automobile body door frame. Through the automobile door adjusting mounting device, intelligent and accurate automobile door mounting can be achieved, the current experience adjustment situation is changed, the automobile door adjusting mounting device is suitable for mounting of the automobile doors of different automobile models and different sizes, adaptive adjustment of the manufacturing quality of the different automobile doors and the automobile body door frame can be achieved, and thus the optimal mounting quality isobtained.

Owner:SHANDONG UNIV

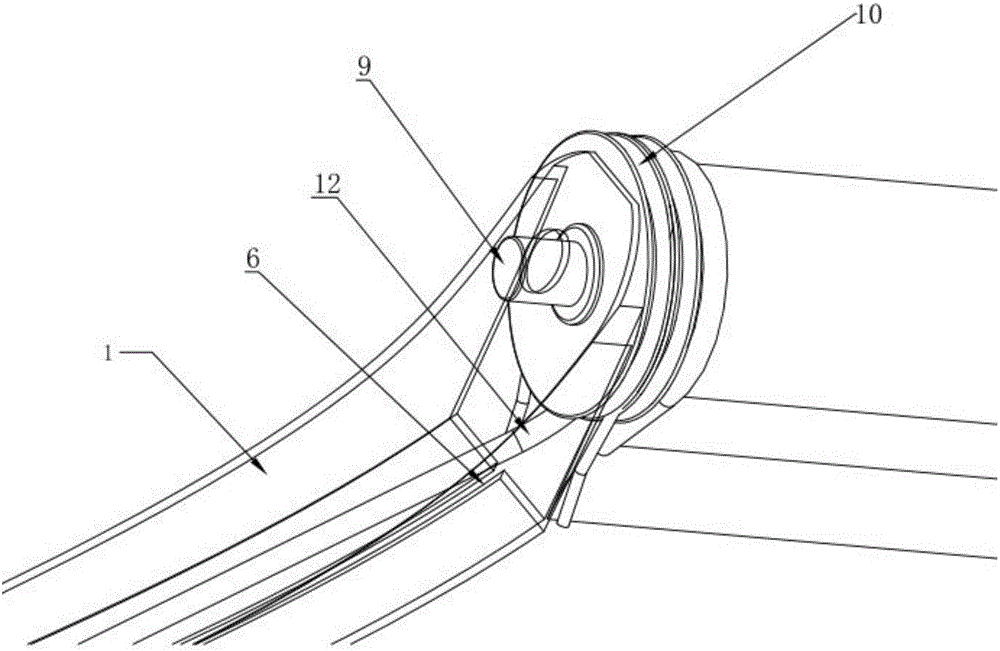

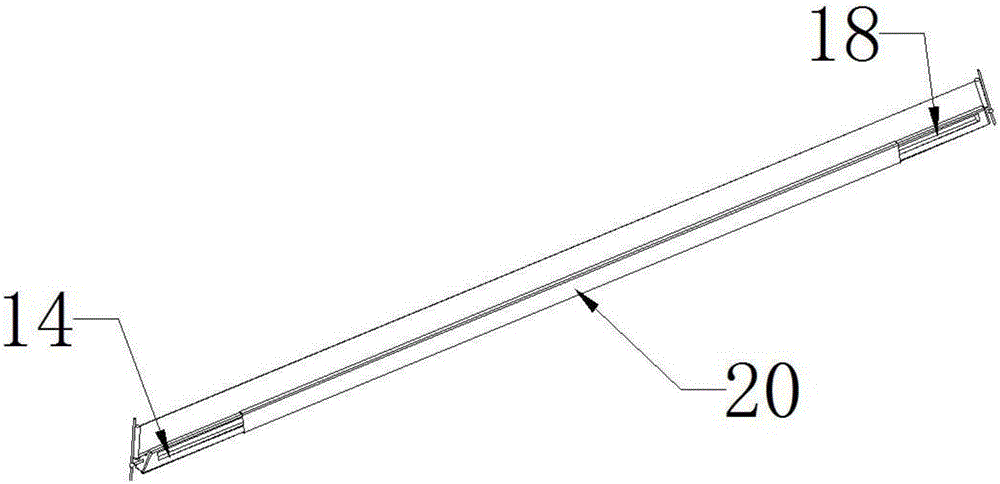

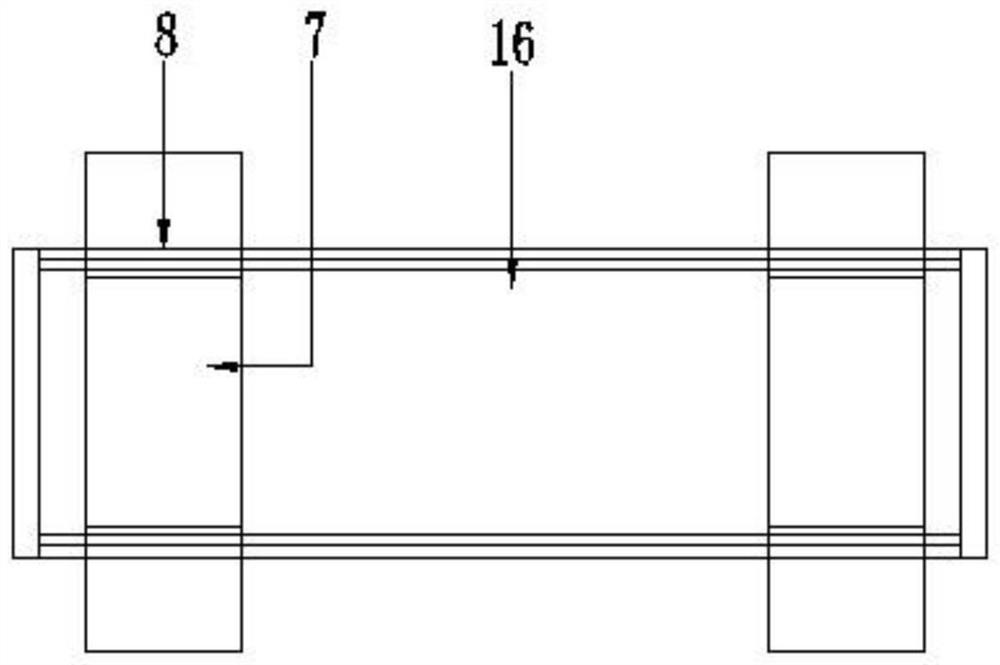

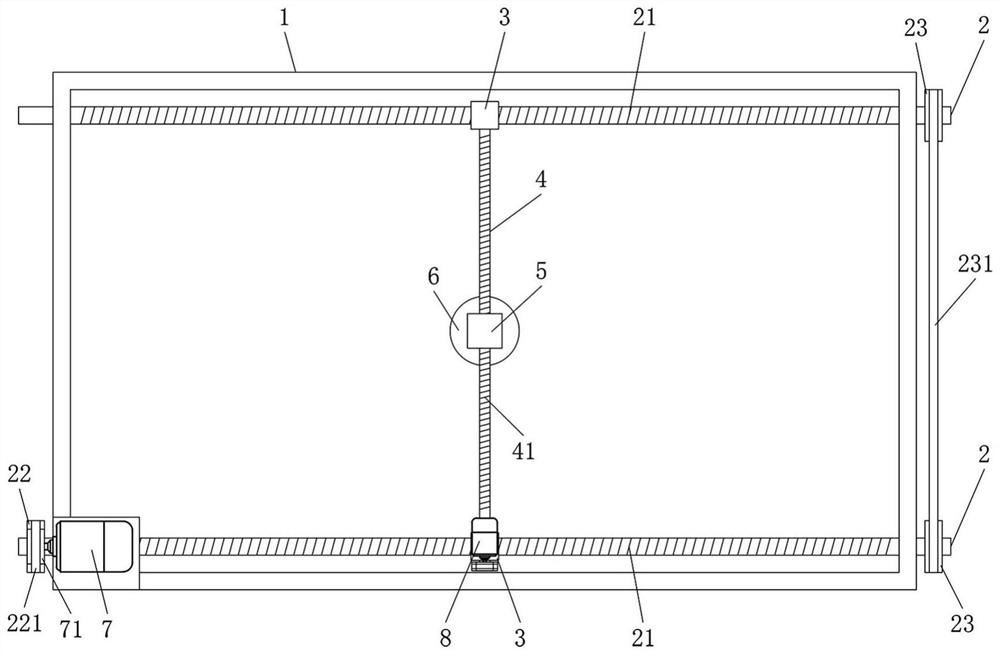

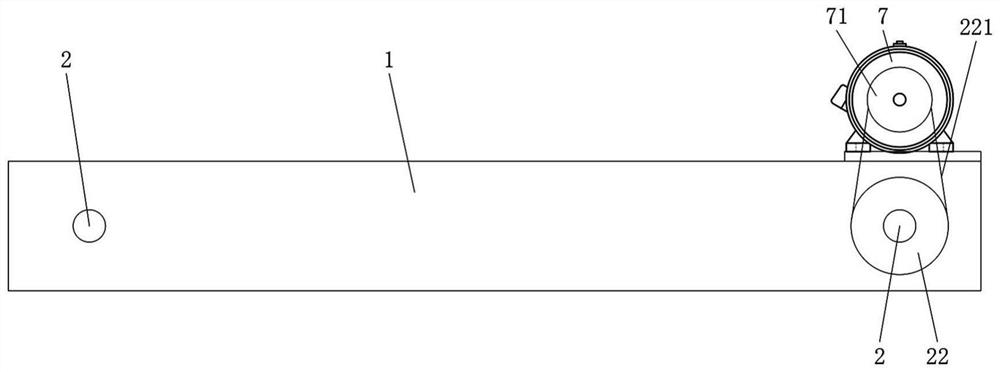

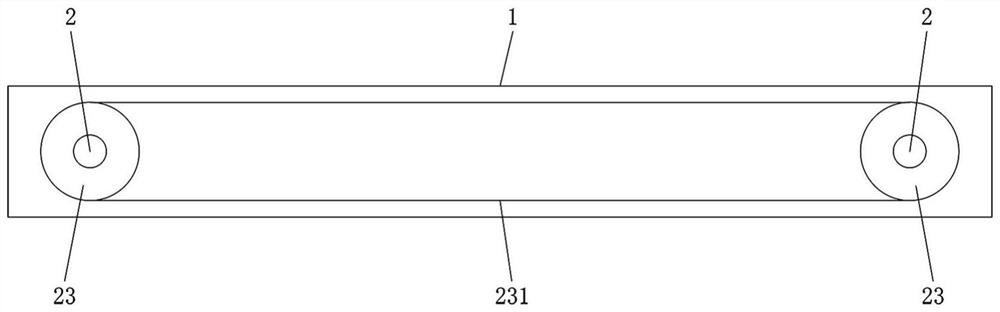

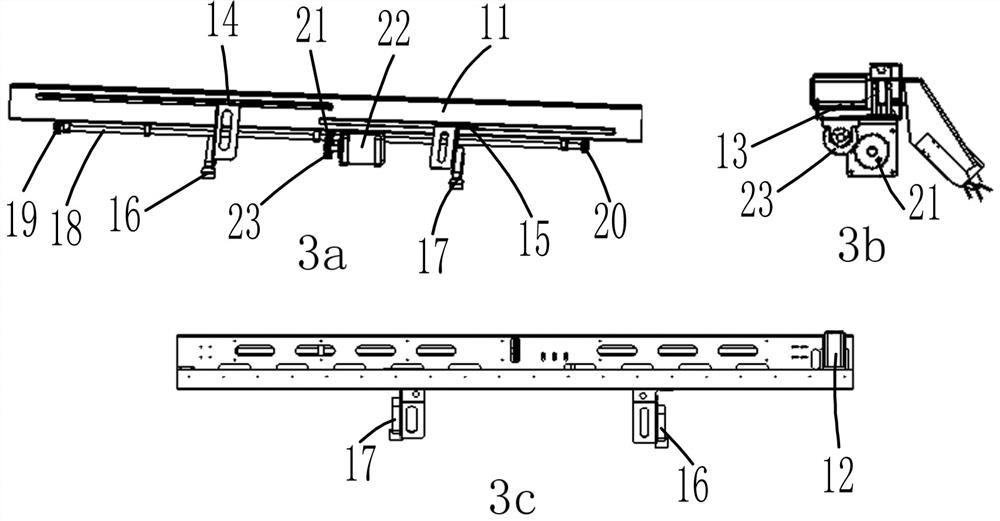

Novel curtain device

ActiveCN106437473AAvoid wrinklesAchieve horizontalLight protection screensMechanical engineeringTextile

The invention provides a novel curtain device which comprises a first slide rail, a second slide rail, a curtain fabric, bottom extension devices and a roller shutter device, wherein a slide chute is formed inside the first slide rail; a first guide wheel is arranged at the bottom of the first slide rail; another slide chute is formed inside the second slide rail; a second guide wheel is arranged at the bottom of the second slide rail; the roller shutter device is connected between tops of the first slide rail and the second slide rail; the bottom extension devices are movably arranged in the slide chutes inside the first slide rail and the second slide rail; the upper end of the curtain fabric is fixedly connected with the roller shutter device and can be wound on the roller shutter device; the lower end of the curtain fabric is fixedly connected with both ends of the bottom extension devices and are connected with the middle position in a floating manner; the roller shutter device comprises a roller shutter shaft, a first double-groove wheel and a second double-groove wheel. The novel curtain device provided by the invention is simple in structure, convenient to operate, and suitable for various doors and windows of buildings, automobiles, trains, ships and the like.

Owner:SHENZHEN FULONG INTELLIGENT TECH DEV CO LTD

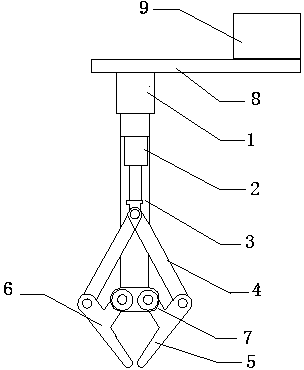

Automatic manipulator

The invention discloses an automatic manipulator comprising a first hydraulic lever, a second hydraulic lever, a support arm, connecting rods, a left clamp arm, a right clamp arm, a guide rail and a control cabinet. The first hydraulic lever is fixed at the upper end of the support arm; the second hydraulic lever is fixed at the lower end of the support arm; the front ends of the hydraulic levers are hinged with one ends of the connecting rods; the other ends of the connecting rods are hinged with the left clamp arm and the right clamp arm; the middle portion of each of the left clamp arm and the right clamp arm is hinged with the support arm, the tail portion of the first hydraulic lever is movably connected on the guide rail; the control cabinet is mounted at the upper end of the guide rail; the control cabinet is electrically connected with the first hydraulic lever and the second hydraulic lever. The automatic manipulator is simple in structure and capable of realizing horizontal and longitudinal adjustment; good handling effect can be achieved by the cooperation of the first hydraulic lever, the second hydraulic lever and the guide rail.

Owner:TAICANG ZIWU ELECTRICAL

Adjustable auxiliary device for tumor clinical treatment

InactiveCN107928947AMeet regulatory requirementsStable structureOperating tablesTherapeutic DevicesEngineering

The invention discloses an adjustable auxiliary device for tumor clinical treatment. The adjustable auxiliary device comprises a base; roller wheels are arranged at the lower end of the base; a fixedbox body is installed on the base; a lifting box body is installed at the upper end of the fixed box body; a reversing gearbox is arranged on the base at the inner side of the fixed box body and is provided with threaded columns; each threaded column is connected with the interior of a threaded sleeve seat; the threaded sleeve seats are fixedly connected with the lifting box body; a limiting groove is formed in the upper end of the lifting box body and is internally provided with a rotary column; a fluted disc is arranged on the rotary column and is in mesh connection with a worm and gear gearbox; a lifting seat is internally provided with a first sliding seat; the upper end of a first threaded sliding block is connected with a movable seat; a second threaded sliding block is connected with a bed board. The adjustable auxiliary device for tumor clinical treatment is stable in structure and running, convenient to move and use and easy to operate, and can be matched with tumor treatmentequipment for use; the adjustable auxiliary device is convenient to adjust, the height and rotation of the adjustable auxiliary device can be adjusted, and the horizontal and vertical adjustment of the adjustable auxiliary device can be realized along the horizontal direction, so that the adjustment requirements of different treatment devices can be met, and the existing operating requirements canbe met.

Owner:THE AFFILIATED HOSPITAL OF QINGDAO UNIV

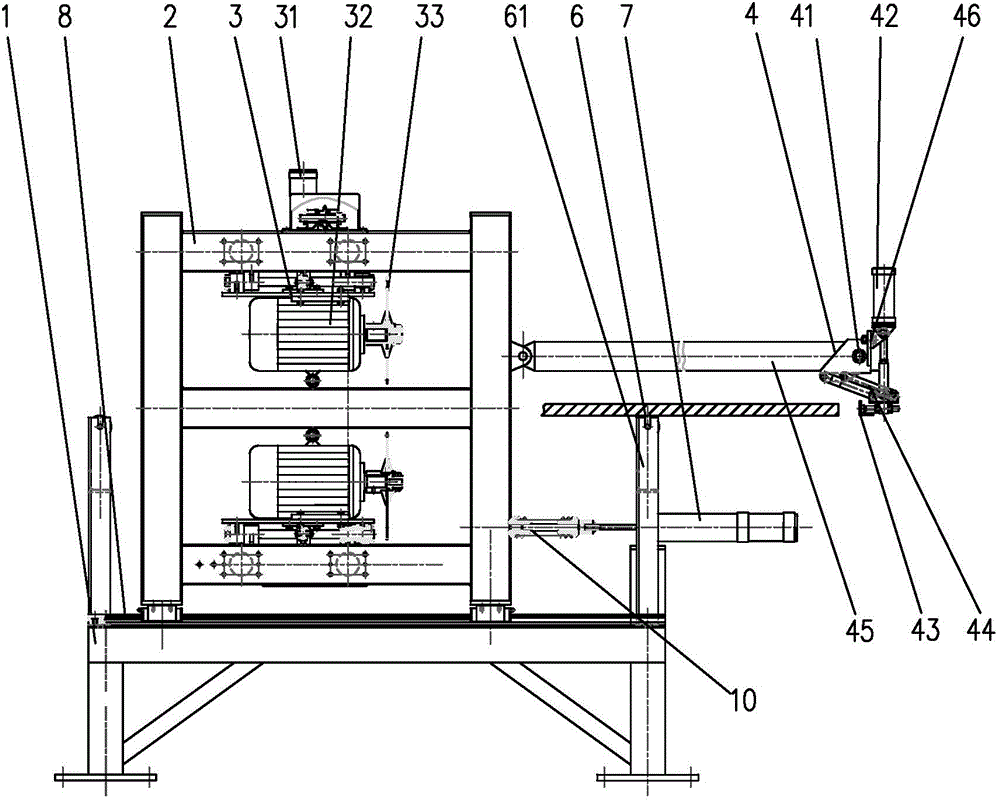

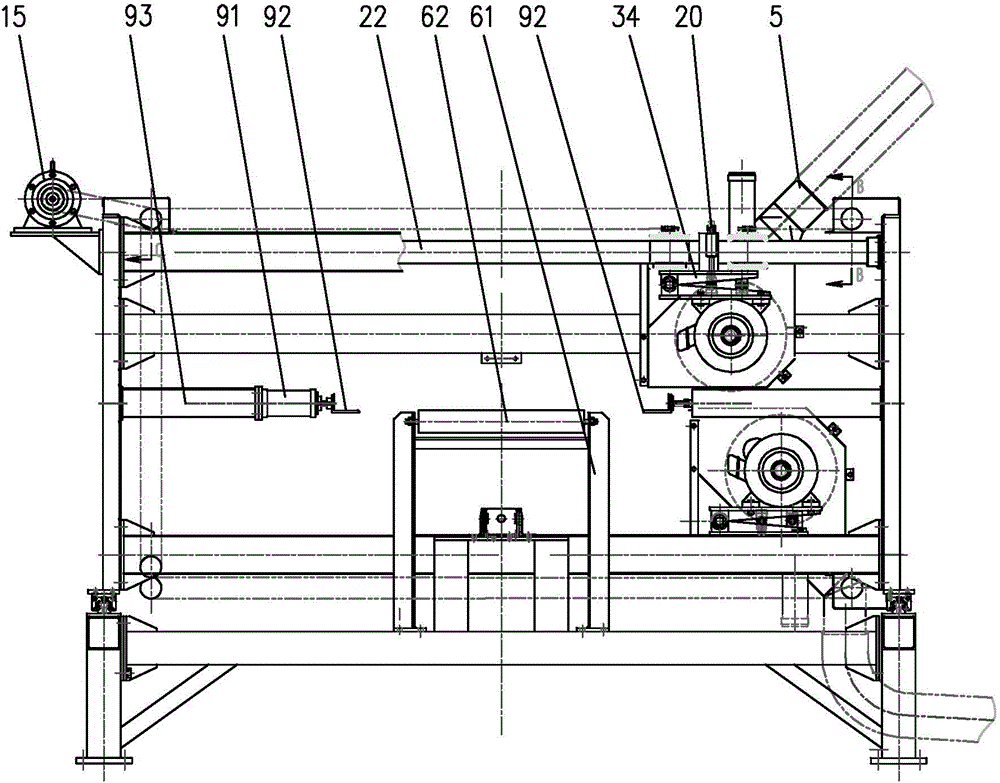

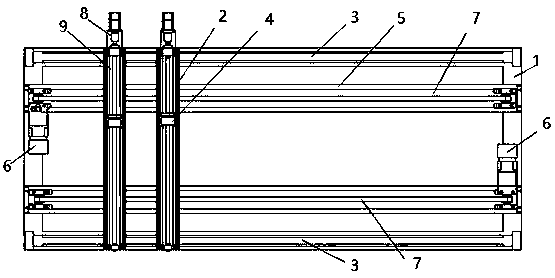

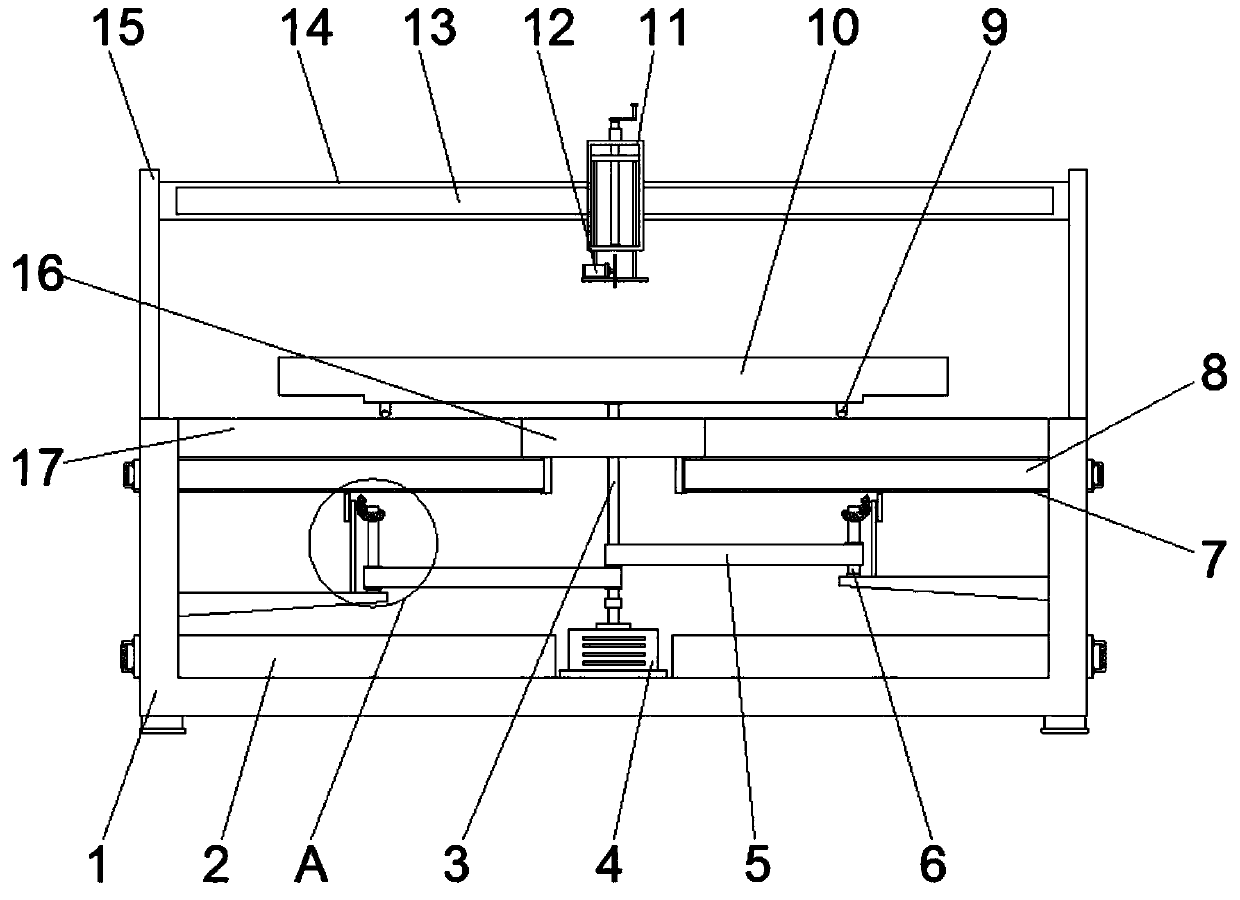

Paper surface straw plate cutting device

ActiveCN104608165AAchieve horizontalRealize vertical linkageMetal working apparatusAutomationPulp and paper industry

The invention relates to a paper surface straw plate cutting device, and belongs to the technical field of paper surface straw plate manufacturing. The paper surface straw plate cutting device aims at solving the problems that in the paper surface straw plate cutting procedure, the automation degree is low, the cutting efficiency is low, manual participation is needed in the operation process, potential safety hazards exist, and the flatness of a cut straw plate cross section is poor. The paper surface straw plate cutting device comprises a rack, a servo clamping frame, a cutting device, a length measuring device and a dust collection device. The rack is fixedly installed on a foundation, the two sides of the rack are provided with carrier roller devices, a horizontal pushing air cylinder is installed on each carrier roller device and fixedly connected with the servo clamping frame, the servo clamping frame is installed on the rack through two linear sliding rails, the cutting device is installed on a linear guide rail of the servo clamping frame through a linear bearing, and a straw plate clamping device, the length measuring device and the dust collection device are installed on the servo clamping frame. The paper surface straw plate cutting device can automatically cut paper surface straw plates.

Owner:南京金道普禾机械装备有限公司

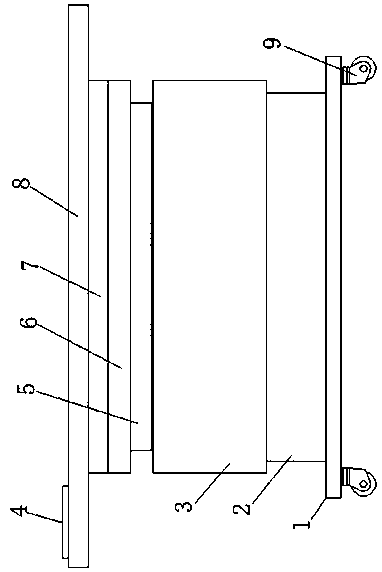

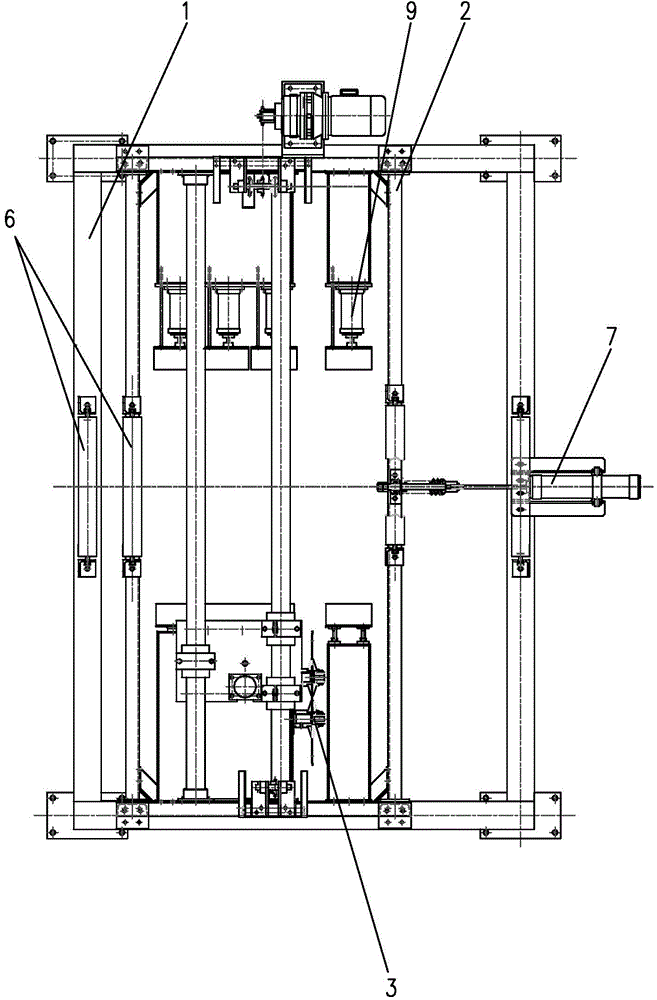

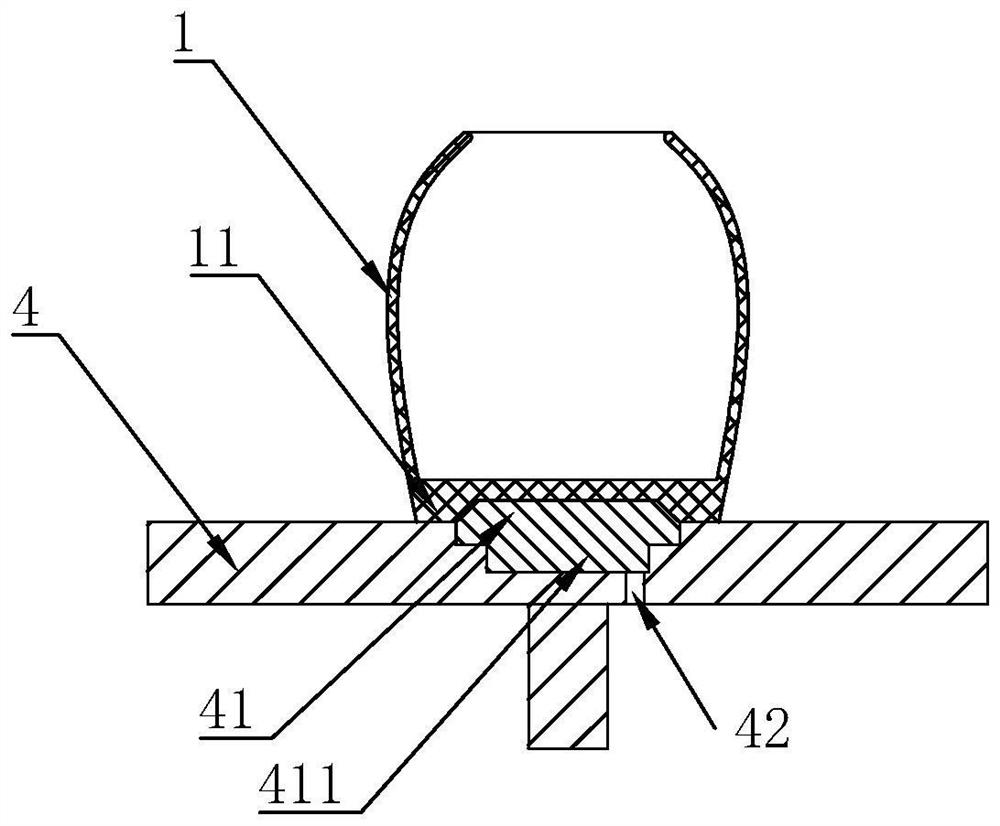

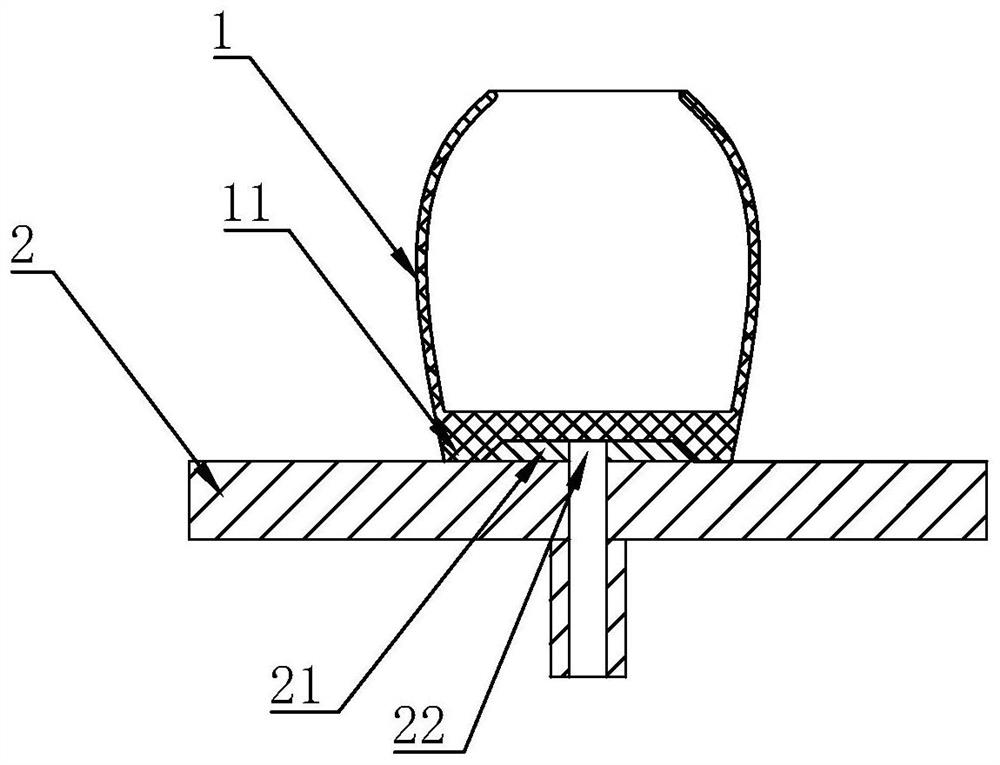

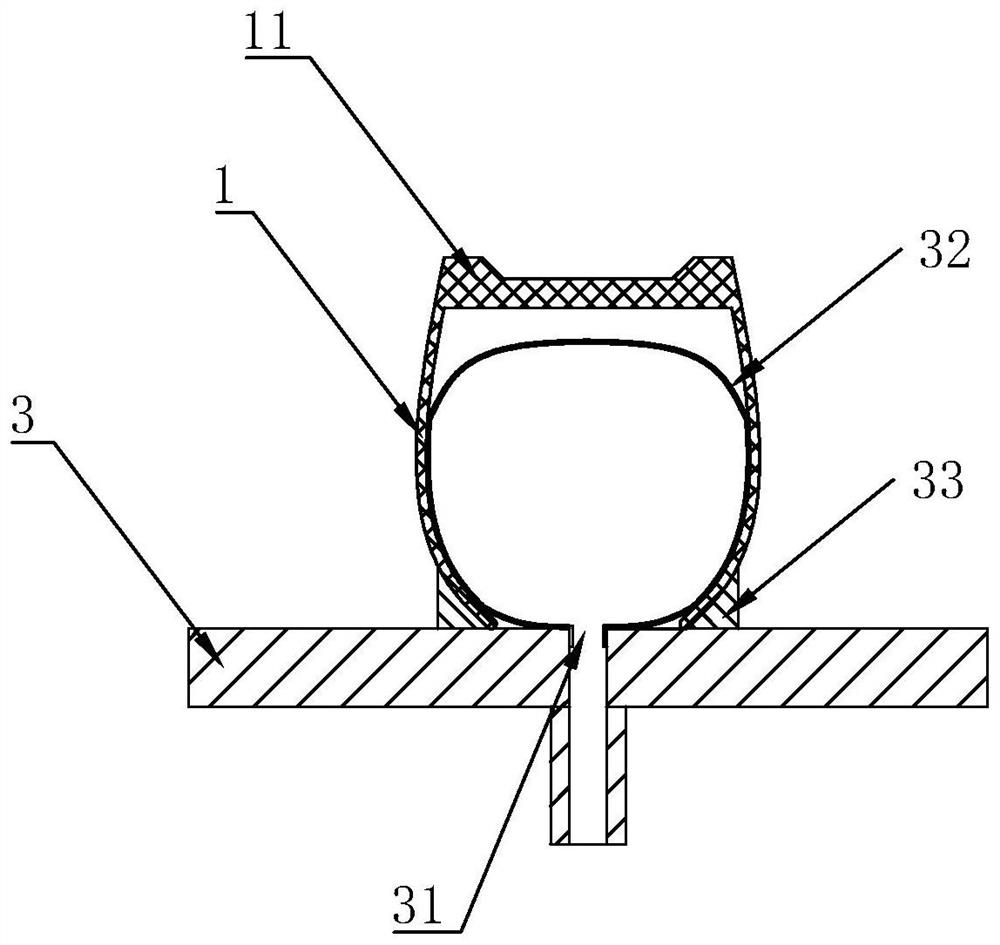

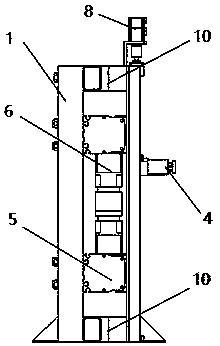

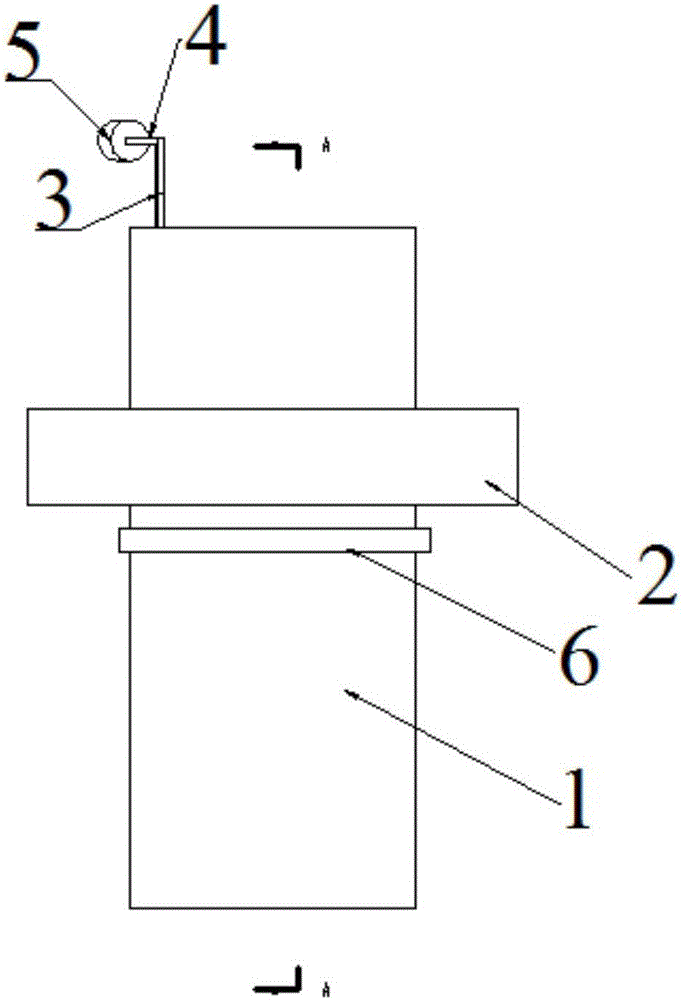

Bearing press-fitting device

InactiveCN105856158AAchieve horizontalRealize regulationMetal-working hand toolsFixed bearingEngineering

The invention provides a bearing press-fitting device, belongs to the technical field of machinery, and aims to solve the problem that the bearings are dismounted and changed due to bearing noise generated in the assembling as the conventional bearing press-fitting devices are low in press-fitting precision. The bearing press-fitting device comprises a base, a lower die on the base and an upper die above the lower die, wherein a vertical concave cavity which is used for containing a rotor body is arranged in the lower die; a through hole I which is coaxial with the concave cavity and is used for containing a rotor lower rotation shaft is formed in the concave cavity; a containing cavity which is coaxial with the concave cavity and is used for containing a bearing is arranged in the upper die; a through hole II which is coaxial with the containing cavity and is used for containing a rotor upper rotation shaft is formed in the containing cavity; a fixing structure which is used for fixing the bearing is arranged in the containing cavity. The bearing press-fitting device has the advantages of being high in press-fitting precision and good in press-fitting effect.

Owner:LEO GRP ZHEJIANG PUMP CO LTD

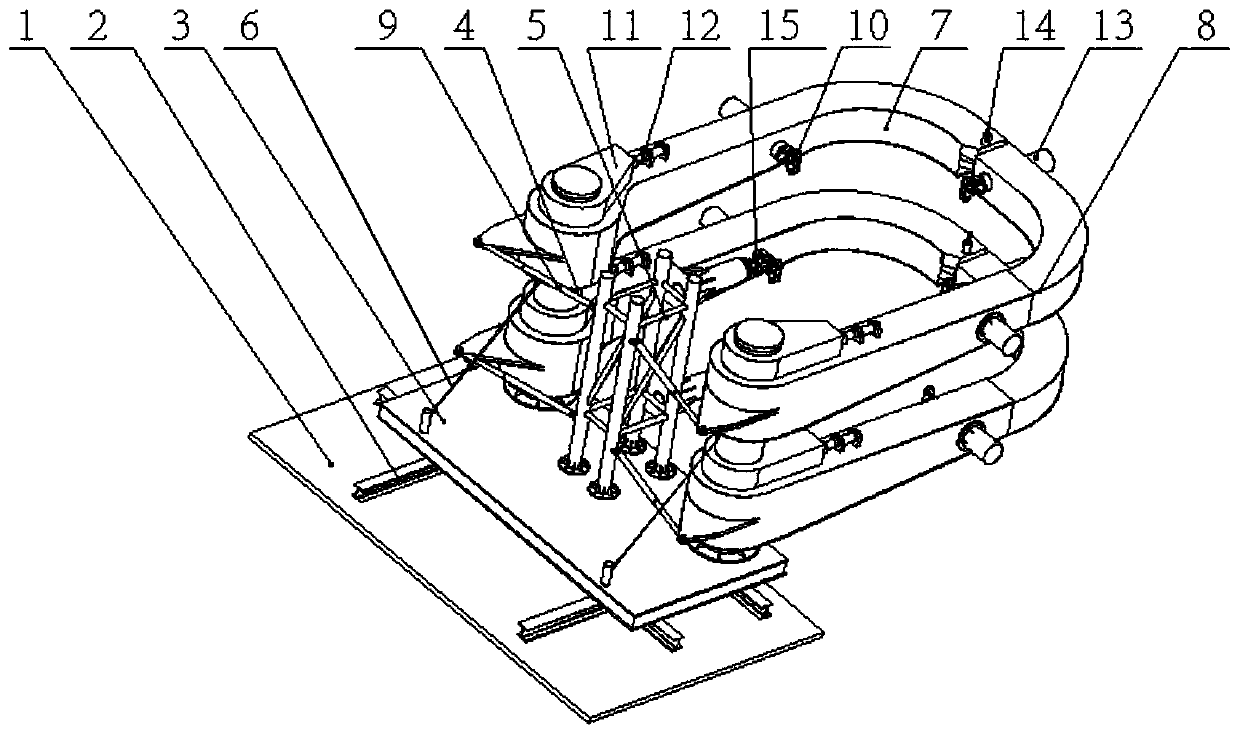

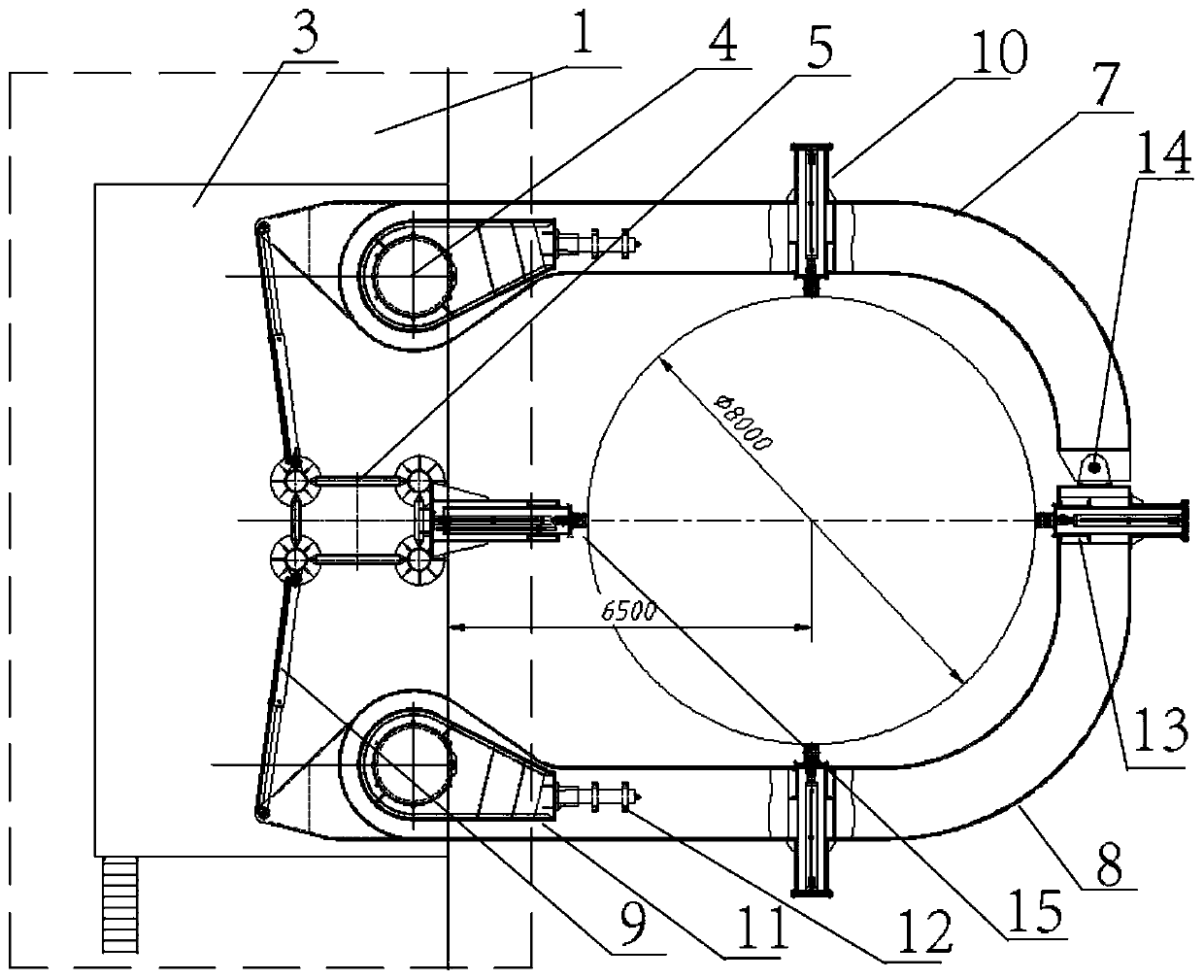

Large-deviation-rectifying-force pile holding machine and operation process thereof

The invention discloses a large-deviation-rectifying-force pile holding machine and an operation process thereof. The machine comprises a ship deck, double H-shaped steel rails, an upper platform, round stand columns, a stand column assembly, a pull cable, left pile claw arms, right pile claw arms, a pile claw tail oil cylinder, middle contacts, a stand column stretching-out box body, a locking device, end contacts, end plug pin mechanisms and tail positioning contacts. The double H-shaped steel rails are fixedly mounted on the upper surface of the ship deck; the upper platform is fixedly mounted at the top ends of the double-H-shaped steel rails; two round stand columns and the stand column assembly are fixedly installed on the upper surface of the upper platform; the number of the left pile claw arms and the number of the right pile claw arms are both two; the middle contacts, the end contacts and the tail positioning contacts are mounted on the inner sides of the left pile claw armsand the right pile claw arms; and one end, away from the connecting round stand column, of the stand column stretching-out box body is flexibly connected with a locking device, and one end, away fromthe connected round stand column, of each left pile claw arm is equipped with the end plug pin mechanism. According to the invention, the structure and the operation process are reasonable, deviationrectification can be conducted in time, the working efficiency is greatly improved, the applicability is high, and the overall service life is greatly prolonged.

Owner:JIANGSU LONGYUAN ZHENHUA MARINE ENG

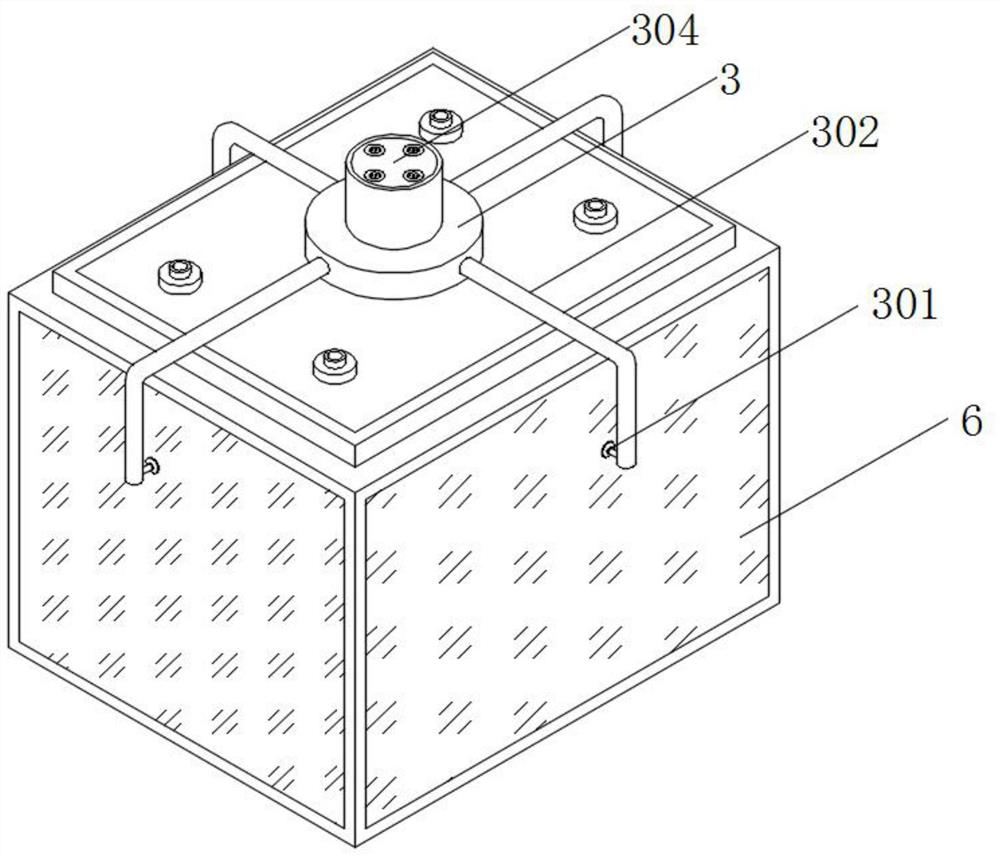

Constant temperature system for lithium battery of electric vehicle

ActiveCN113437390APlay a thermal insulation effectReduce the cost of maintaining a constant temperature stateSecondary cellsCell component detailsEngineeringHeat conservation

A constant temperature system for a lithium battery of electric vehicle disclosed by the present invention comprises a mounting bottom plate and a safety box, the top of the mounting bottom plate is provided with a heat preservation box body, the inner bottom wall of the heat preservation box body is provided with a rectangular insulation bottom plate, the top of the insulation bottom plate is provided with a lithium battery body, and the top of the lithium battery body is provided with a detection disc. The inner walls of the two sides of the heat preservation box body are both provided with heat preservation counterweight boxes, the inner bottom wall of the heat preservation box body is provided with an embedding groove, the embedding groove is internally provided with a heat preservation door frame, the inner bottom wall of the heat preservation box body is provided with a safety box, and the top of the lithium battery body is provided with a detection disc. By arranging the heat preservation door frame, after embedded installation, a space exists between the heat preservation door frame and the top of the heat preservation box body, heat dissipation operation in the heat preservation box body is facilitated, meanwhile, a space for blocking operation is provided for subsequent heat preservation and heating operation, and then a constant-temperature environment is provided for the lithium battery body.

Owner:南通明诺新能源应用科技有限公司

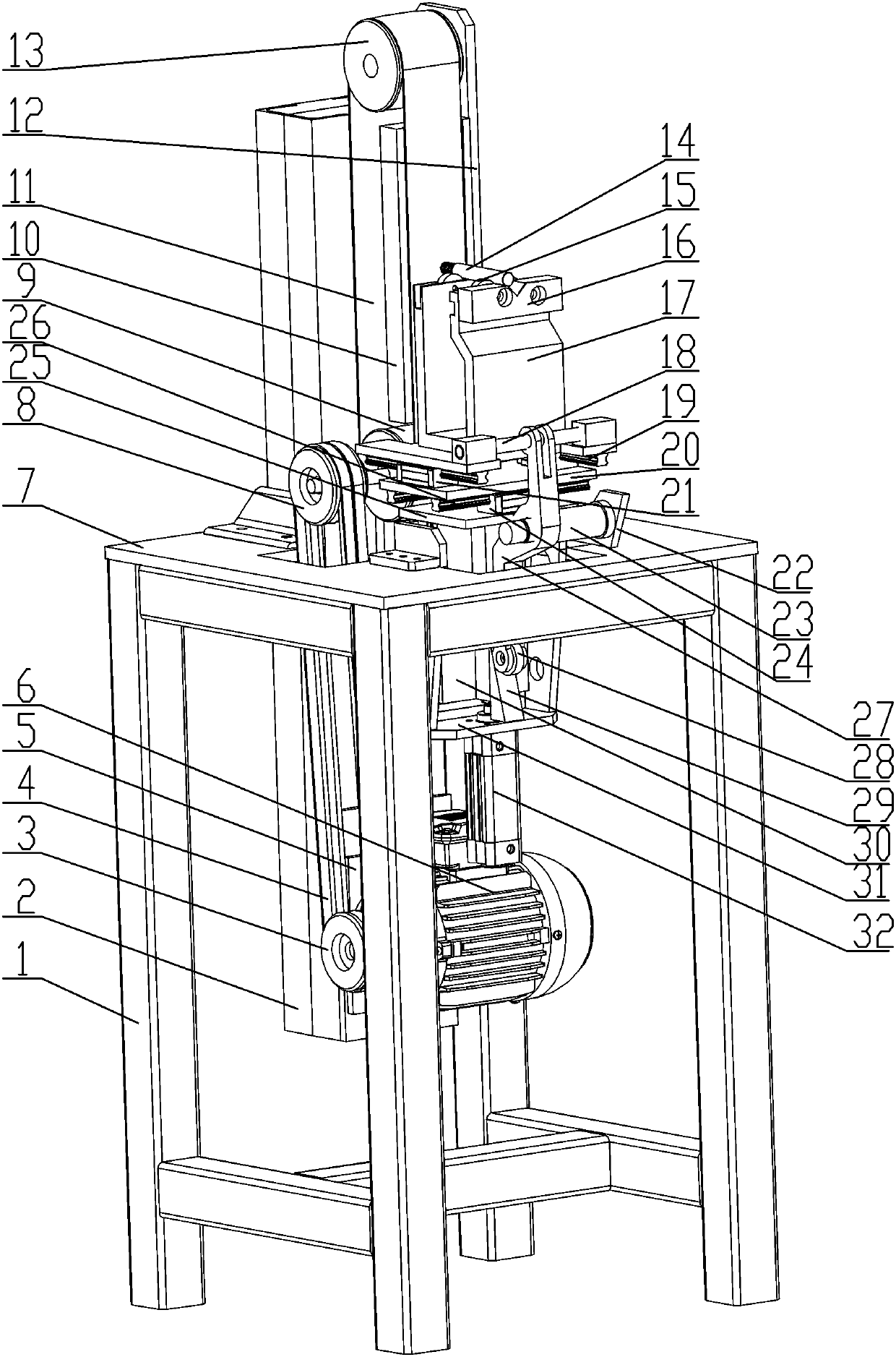

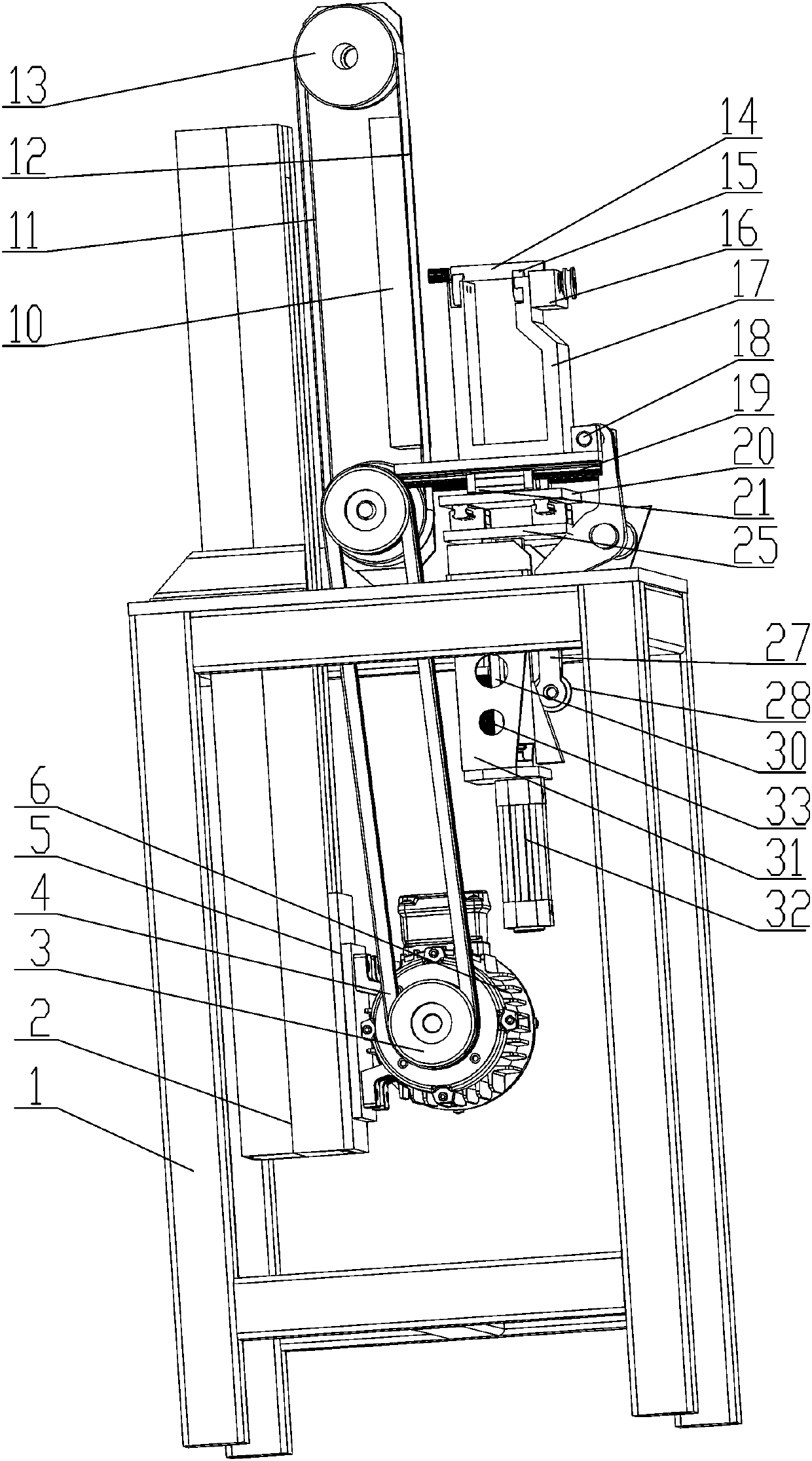

Shaft end grinding and polishing device and method

ActiveCN111360654AFit tightlyGuaranteed grinding effectGrinding carriagesGrinding drivesPolishingCam

The invention provides a shaft end grinding and polishing device and method. A stand column is fixedly installed on a rack, a grinding belt installing plate is fixedly installed on the upper portion of the stand column, a grinding belt device used for conducting grinding is installed on the grinding belt installing plate, and the grinding belt device is connected with a grinding power device usedfor driving the grinding belt device to rotate; and a top plate is fixedly installed on the top of the rack, a lifting box body is fixedly installed on the end face of the bottom of the top plate, a lifting mechanism is installed on the lifting box body, a lifting top plate is fixedly installed on the top of the lifting mechanism, a biaxial sliding platform mechanism for achieving transverse and longitudinal moving is fixedly installed on the top of the lifting top plate, a clamping base used for fixing shaft type parts is fixedly installed on the top of the biaxial sliding platform mechanism,and a cam type grinding feeding mechanism used for driving the clamping base to be close to the grinding belt device is installed between the clamping base and the lifting mechanism. The polishing equipment can be used for grinding and polishing the shaft ends of the shaft type parts, and then a traditional manual grinding mode is replaced.

Owner:CHINA THREE GORGES UNIV

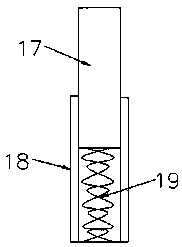

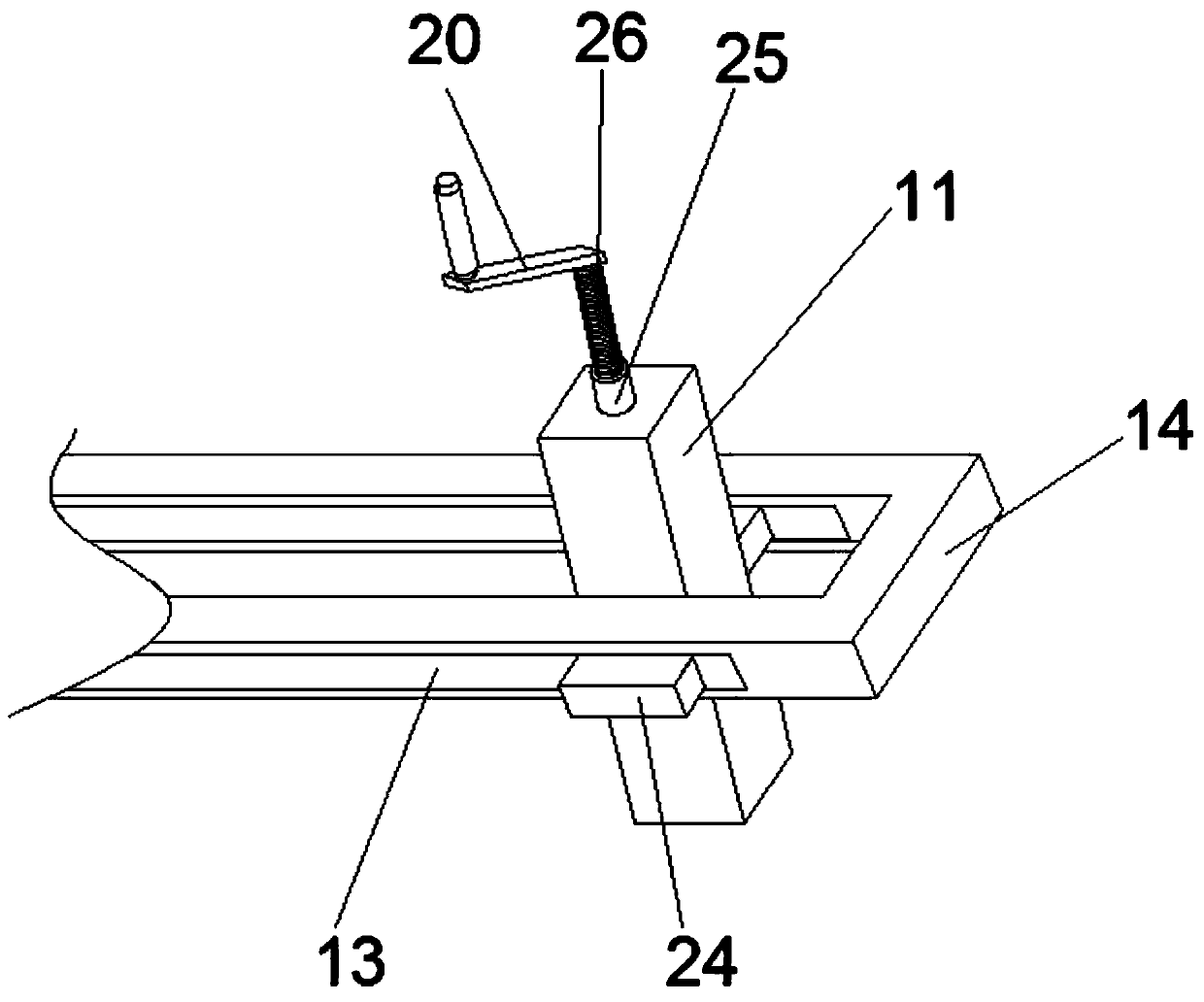

Efficiency workpiece point welding machine

InactiveCN109551093APlay a buffer rolePlay a guiding roleResistance welding apparatusEngineeringMechanical engineering

The invention discloses an efficiency workpiece point welding machine. The efficiency workpiece point welding machine comprises a u-shaped bracket. A transverse sliding rail is fixedly mounted on theinner side of the upper end of the u-shaped bracket. A first sliding block is mounted in the transverse sliding rail. The first sliding block is mounted at the upper end of a longitudinal sliding rail. A second sliding block is mounted in the longitudinal sliding rail. A welding head mounting seat is mounted on the second sliding block. A welding head is mounted below the welding head mounting seat. Two sets of buffer springs are arranged between the upper end of the welding head and the lower end of the welding head mounting seat. A guide assembly is mounted between the two sets of buffer springs. A workpiece placing mechanism is mounted on the inner side of the u-shaped bracket. The physical design is novel. A workpiece can be welded transversely and longitudinally. The workpiece placingmechanism is arranged to clamp workpieces of different sizes. It is unnecessary to replace the whole placing mechanism, and therefore the point welding efficiency can be improved.

Owner:马鞍山迪斯福工业设计有限公司

Production system for low-radiation coated energy-saving glass

The invention discloses a production system for low-radiation coated energy-saving glass. The production system comprises a batch mixing device, a processing table, a transition roller table, a spreading device, a slag removing device, a gas conveying device and a finished product cutting device, wherein the batch mixing device is fixedly mounted above the processing table; the center of the top surface of the processing table is provided with a rectangular tin bath; the discharging end of the processing table is horizontally and fixedly connected with the feeding end of the transition rollertable; the spreading device is arranged on the top surface of the processing table and is slidably connected with the processing table; the slag removing device is also arranged on the top surface ofthe processing table and is slidably connected with the processing table; the gas conveying device is in communication with the transition roller table; and the feeding end of the finished product cutting device is fixedly connected with the discharging end of the gas conveying device. The apparatus of the invention improves the quality of the glass by means of uniform batch mixing, flat spreadingof materials, removal of impurities and control of the flow of shielding gas.

Owner:TG ANHUI GLASS

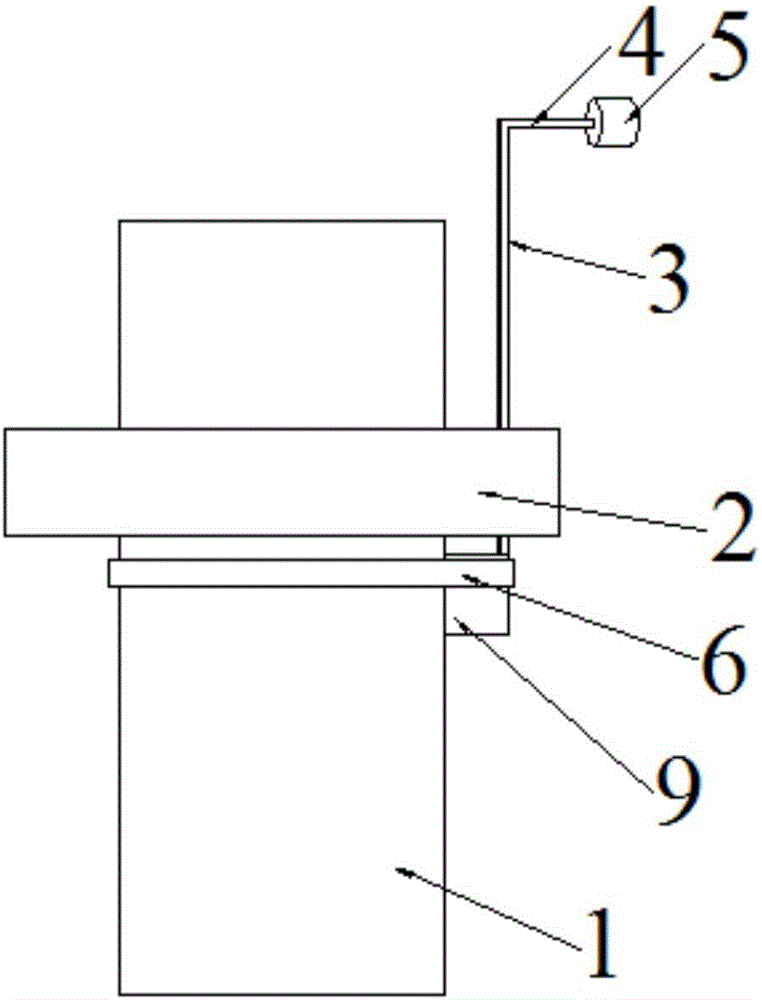

Energy-saving and environment-friendly comprehensive treatment device for flue gas of coking plant

InactiveCN112985092AImprove stabilityAchieve horizontalChimneysWaste heat treatmentFlue gasProcess engineering

The invention discloses an energy-saving and environment-friendly comprehensive treatment device for the flue gas of a coking plant. The device comprises a flue gas pipeline and a treatment device, wherein a mounting sleeve is arranged at the flue gas outlet end of the flue gas pipeline, the treatment device is connected with a dismounting head, and the mounting sleeve and the dismounting head are arranged in a mounting and dismounting manner; mounting bayonets are formed in the two ends of the mounting sleeve, dismounting assemblies are arranged on the two sides of the dismounting head, the mounting sleeve is communicated with the mounting pipe, and the mounting pipe is matched with a dismounting opening in the dismounting head. A positioning buckle is connected with a positioning clamping groove in the dismounting head in a clamped mode, the mounting pipe is matched with the dismounting opening in the dismounting head, and through rotation of an external shaft, rotation of a dismounting rotating wheel and angle change of a dismounting inclined rod, a fixed sleeve block is driven to move, and through movement of a fixed moving column.

Owner:山西光大焦化气源有限公司

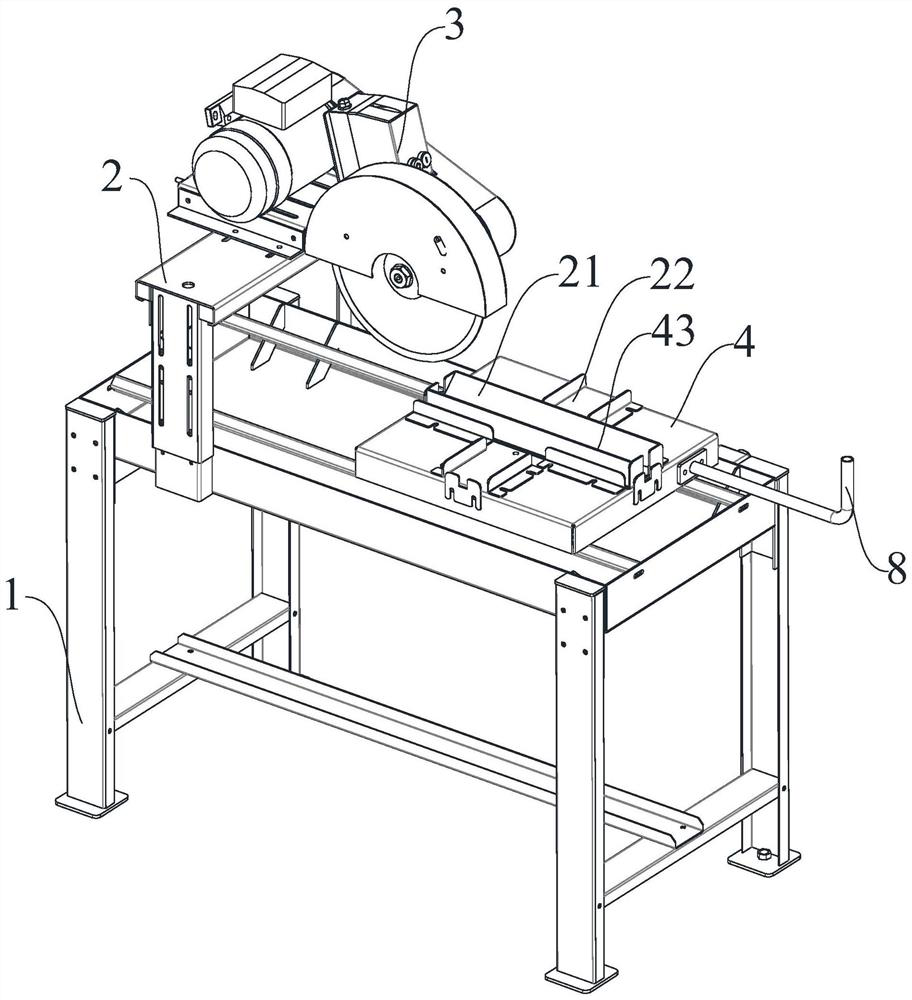

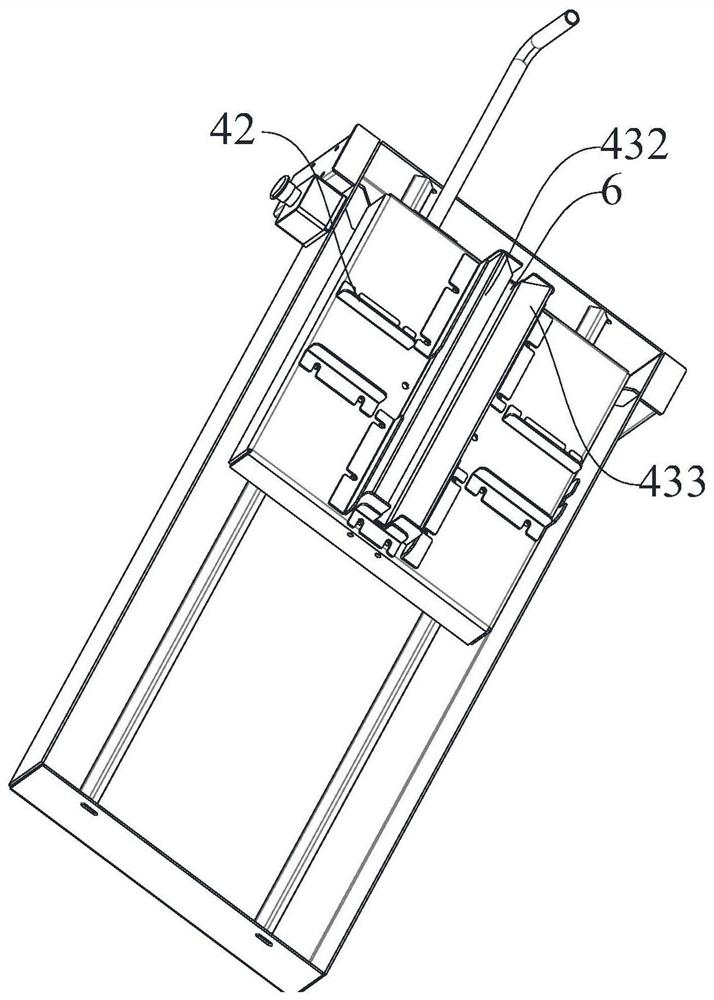

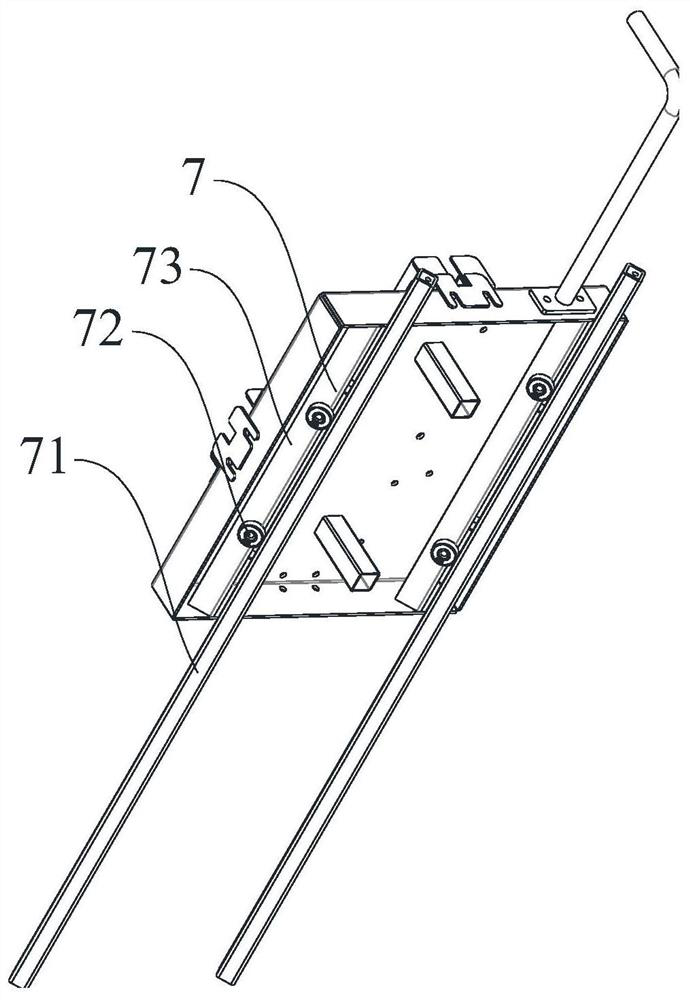

Multidirectional cutting machine

PendingCN112743142AAchieve horizontalAchieving longitudinal cutsShearing machinesShearing machine accessoriesEngineeringMachine

The invention discloses a multidirectional cutting machine which comprises a workbench, a connecting assembly, a cutting mechanism and a carrying assembly. The cutting mechanism is arranged above the workbench and connected with the workbench through the connecting assembly. The carrying assembly is arranged below the cutting mechanism and comprises a carrying table, a limiting assembly and a carrying supporting part, the carrying table is arranged on the workbench, the limiting assembly is arranged above the carrying table and connected with the workbench to form a first containing groove and a second containing groove which are communicated with each other, and the first containing groove and the second containing groove both can clamp the carrying supporting part. The multidirectional cutting machine can conduct multidirectional cutting, so that the working efficiency is improved.

Owner:YANCHENG CITY HAITONG MACHINERY MFG PLANT

Integrated ring foot fine blank cup preparation process

PendingCN114683374AReduce workloadAvoid stickingAuxillary shaping apparatusEngineeringMechanical engineering

The invention relates to the field of ceramic preparation processes, in particular to a preparation process of an integrated ring foot sharp blank cup, a blank drawing circular truncated cone is used for drawing and positioning a blank, and due to the fact that the blank drawing circular truncated cone occupies the space in a ring foot, the workload of a ring foot sharp blank in the later period can be reduced; the throwing circular truncated cone made of the gypsum material is beneficial to separation of the throwing circular truncated cone and the green body after being dried, the phenomenon of adhesion of the green body is avoided, and the cone-shaped throwing circular truncated cone is also beneficial to separation of the green body and the throwing circular truncated cone; the throwing circular truncated cone and the blank body can be conveniently separated from the throwing rotary table through the blank lifting opening; vacuum adsorption is carried out on a fine trimming body round table, positioning during fine trimming is facilitated, the centers of fine trimming are consistent, vertical jumping is avoided, and the notch defect caused by jumping is avoided; the opening of the green body is not necked down and is smaller than other parts of the inner cavity of the green body, downward pressure and tensile force are generated on the green body through the expanded air bag, and the green body can be transversely and vertically positioned in cooperation with the positioning ring, so that the precision of the fine trimming is improved, and the notch defect caused by vertical or horizontal jumping is avoided.

Owner:德化县如瓷生活文化有限公司

Torque table capable of being converted transversely and longitudinally

InactiveCN109812659AAchieve horizontalAchieving a vertical transformationStands/trestlesStructural engineeringEngineering

The invention provides a torque table capable of being converted transversely and longitudinally. The torque table is characterized in that a positioning supporting cover is arranged on a vertical plate, a rotating sleeve is deviated from the wall surface of a motor and keeps a radian of pi / 3 with a vertical surface; the rotating sleeve is in parallel with the wall surface deviated from the motorand the wall surface of a sleeve hoop of the positioning supporting cover, and the positioning supporting cover is arranged on the vertical plate, and the sleeve hoop of the positioning supporting cover also keeps the radian of pi / 3 with the vertical surface. According to the torque table, the defects that in the prior art, the structure is not standardized, and transverse and longitudinal conversion cannot be realized are effectively avoided.

Owner:SHAANXI JOIN CREATE SCI & TECH

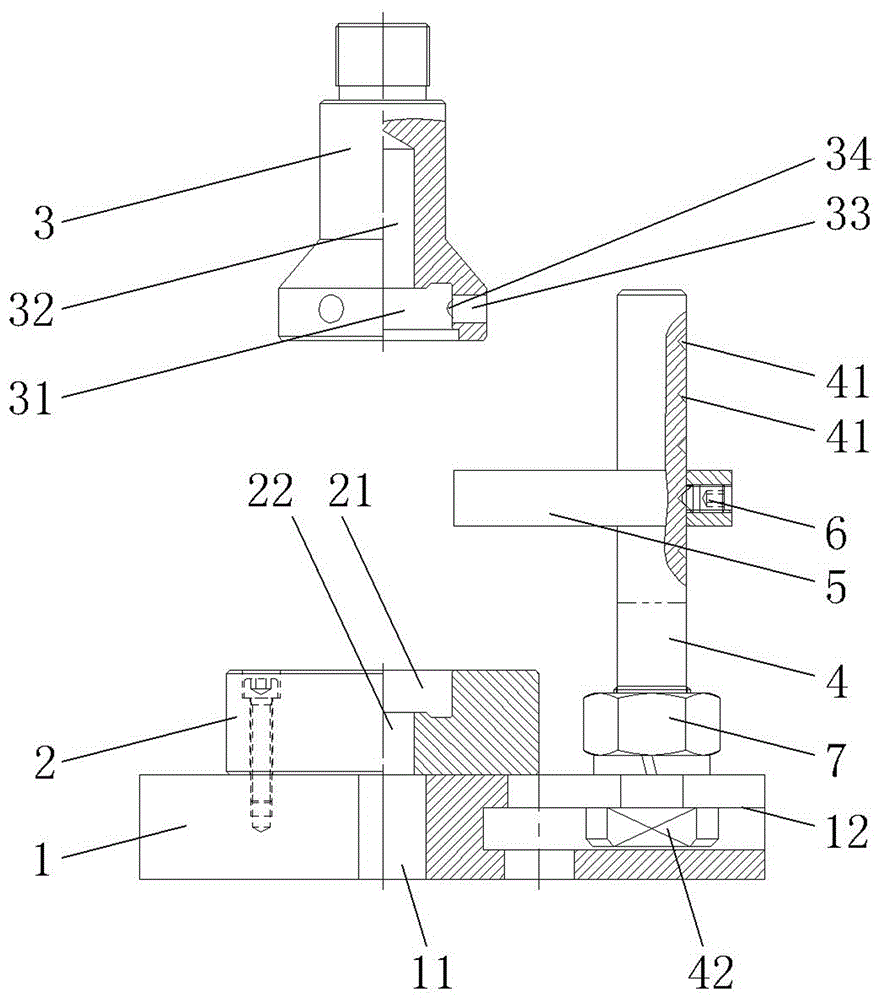

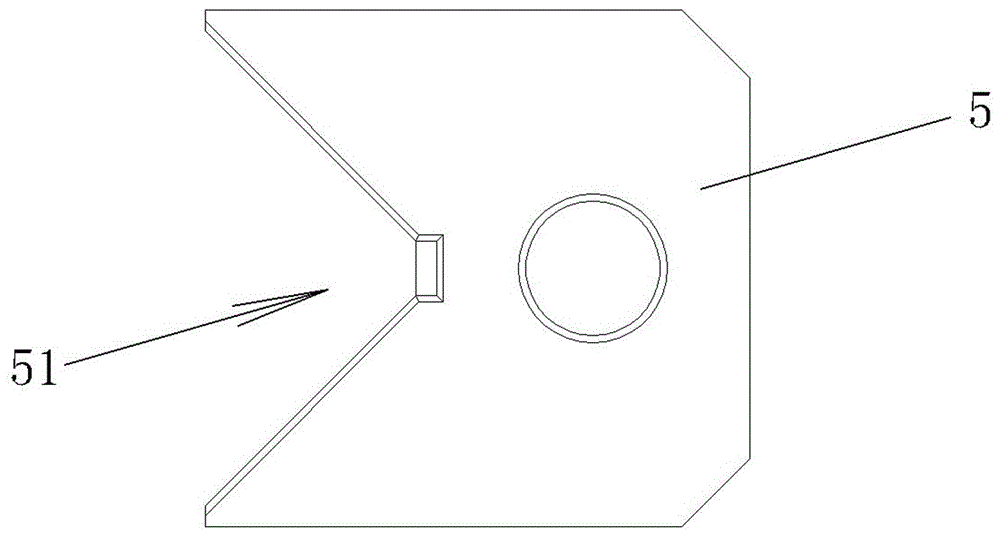

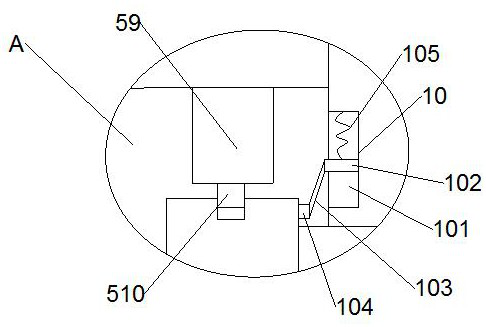

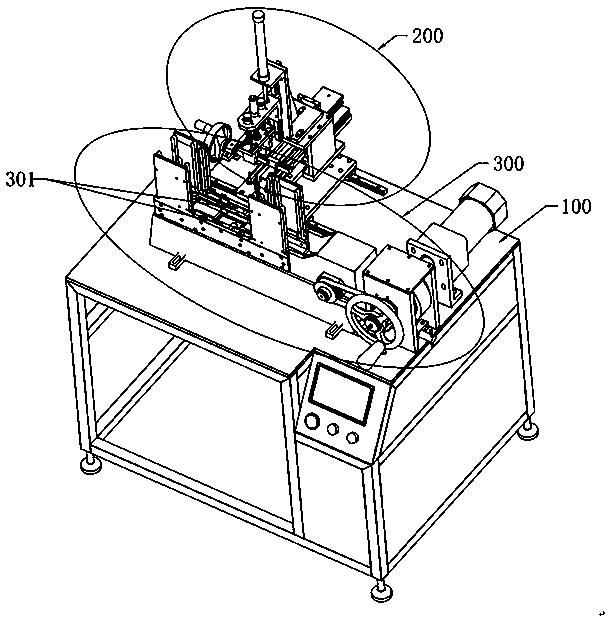

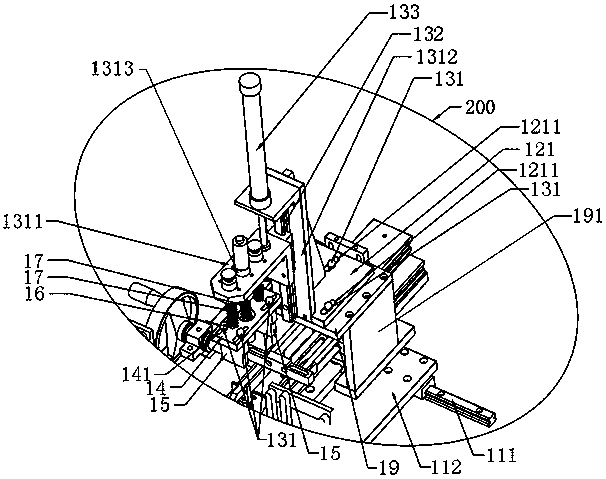

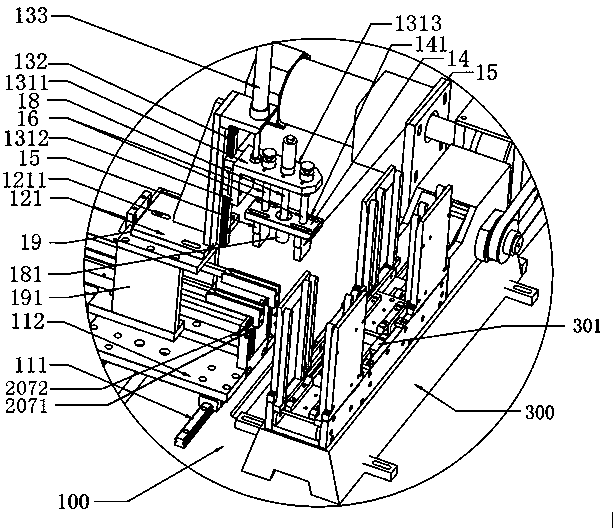

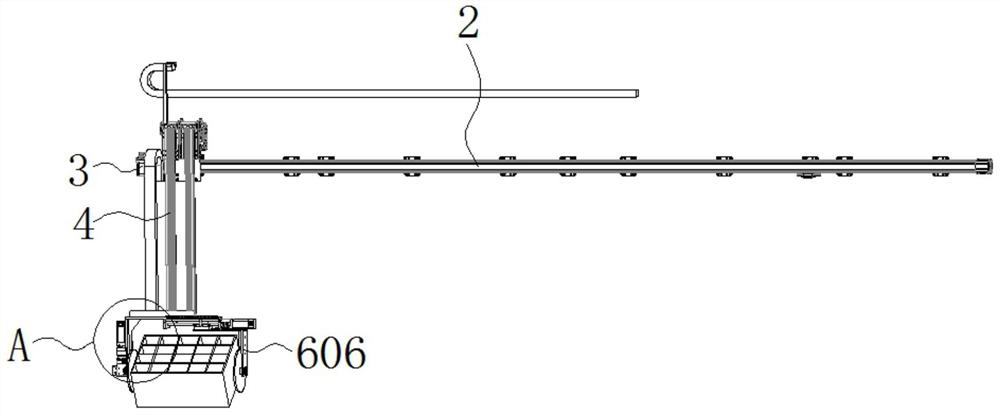

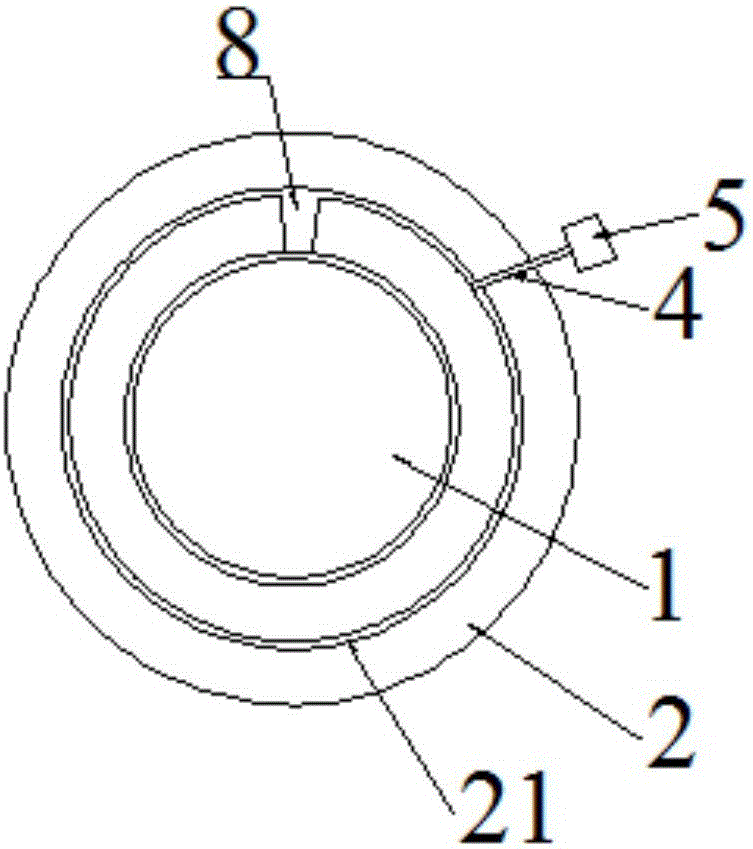

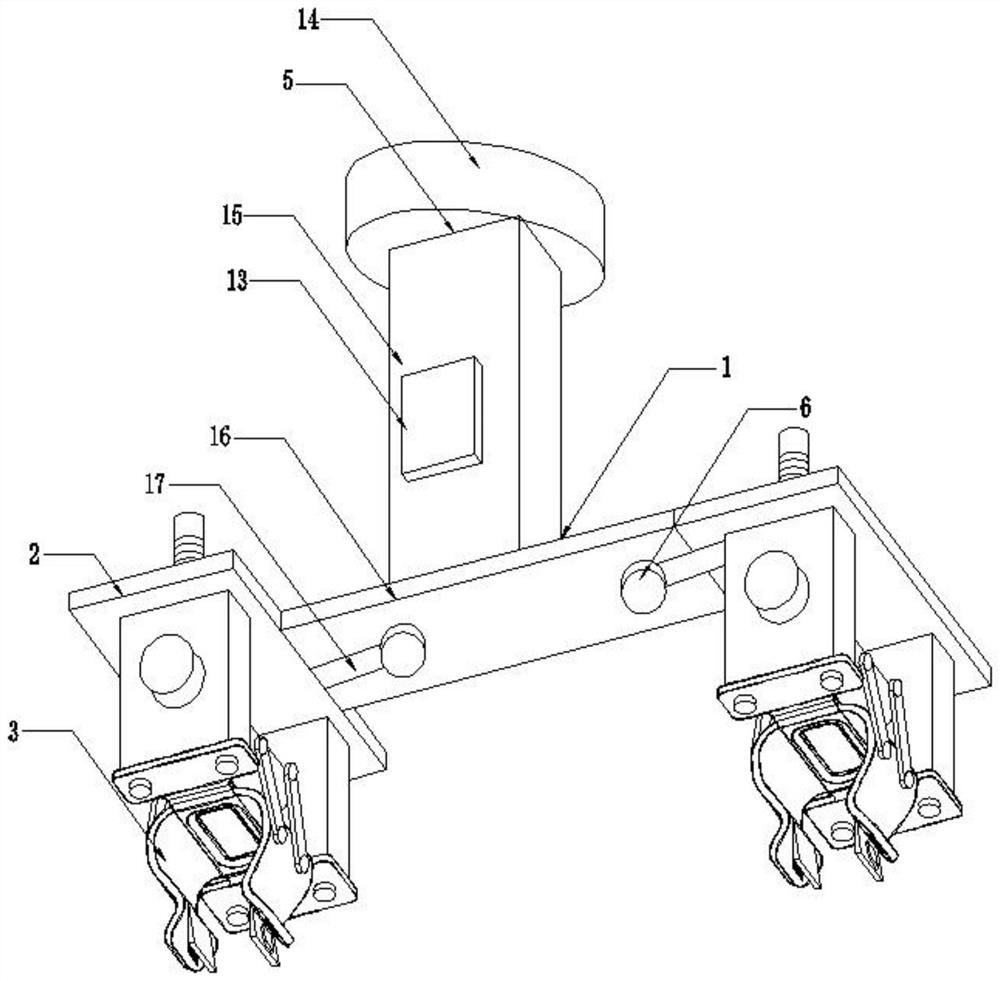

Pressing magnetic attraction device of transformer sheet inserting machine

PendingCN110491663AAchieve horizontalEnable mobilityInductances/transformers/magnets manufactureElectrical and Electronics engineeringTransformer

The utility model discloses a pressing magnetic attraction device of a transformer sheet inserting machine. The invention relates to the technical field of transformer inserting machines. The device structurally comprises a rack, and an E- sheet pressing device and an I sheet magnetic attraction device which are arranged on the rack; the E sheet pressing device comprises an adjusting mechanism, alifting device and a pressing head; the adjusting mechanism comprises a transverse adjusting mechanism and a longitudinal adjusting mechanism; the pressing head is arranged on the lifting device; theI sheet magnetic attraction device is fixed to the transverse adjusting mechanism; the I sheet magnetic attraction device comprises two magnetic attraction strips and a driving device for driving thetwo magnetic attraction strips to enter an I sheet placing area of the sheet inserting machine and exit from the I sheet placing area of the sheet inserting machine; the positions of the two magneticattraction strips correspond to the positions of two I sheets on the sheet inserting machine; and the two magnetic attraction strips can move. The pressing magnetic attraction device is suitable for various types of transformer sheet inserting machines, and can effectively press E sheets and attract away redundant I sheets.

Owner:GUANGDONG NRE TECH

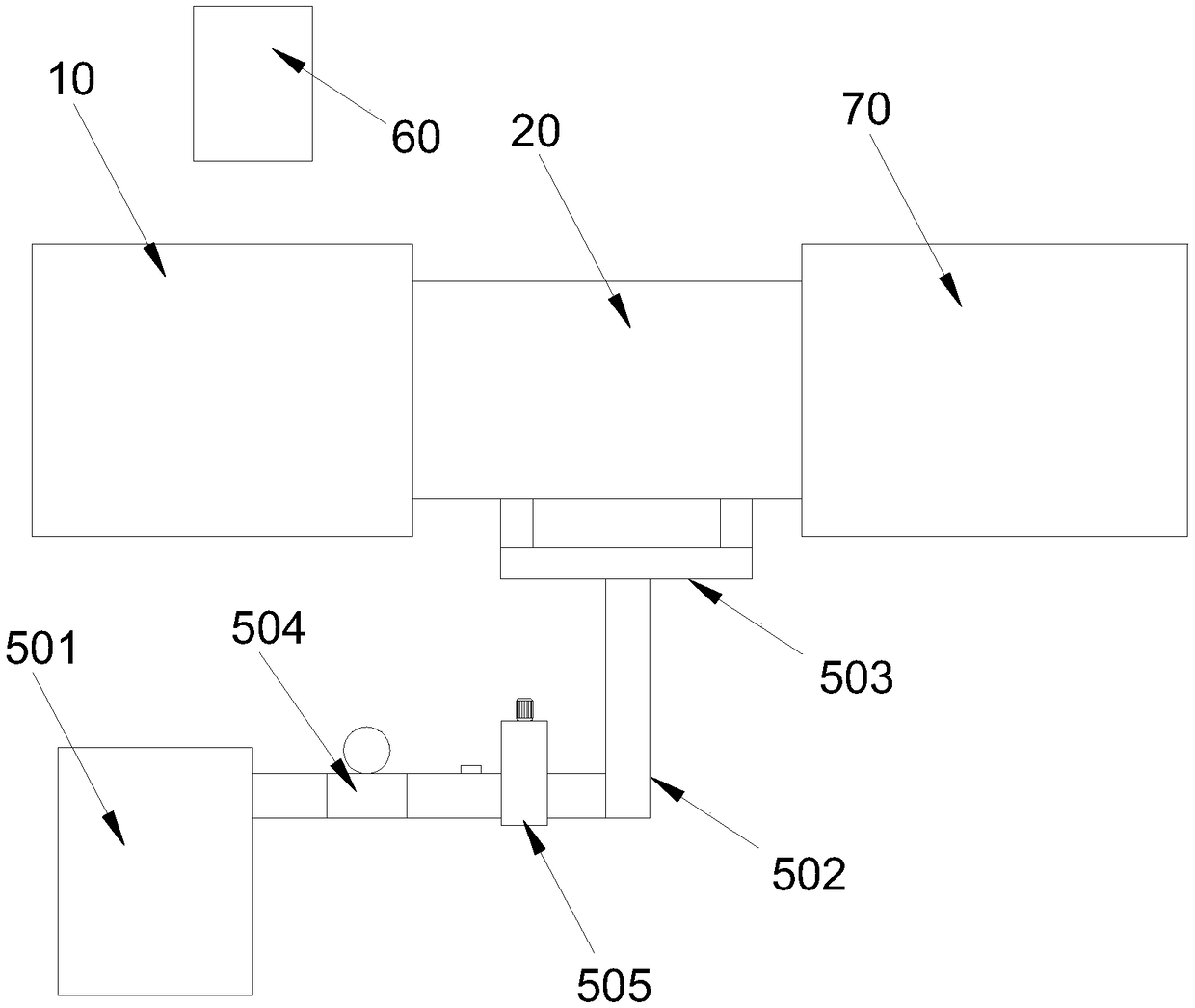

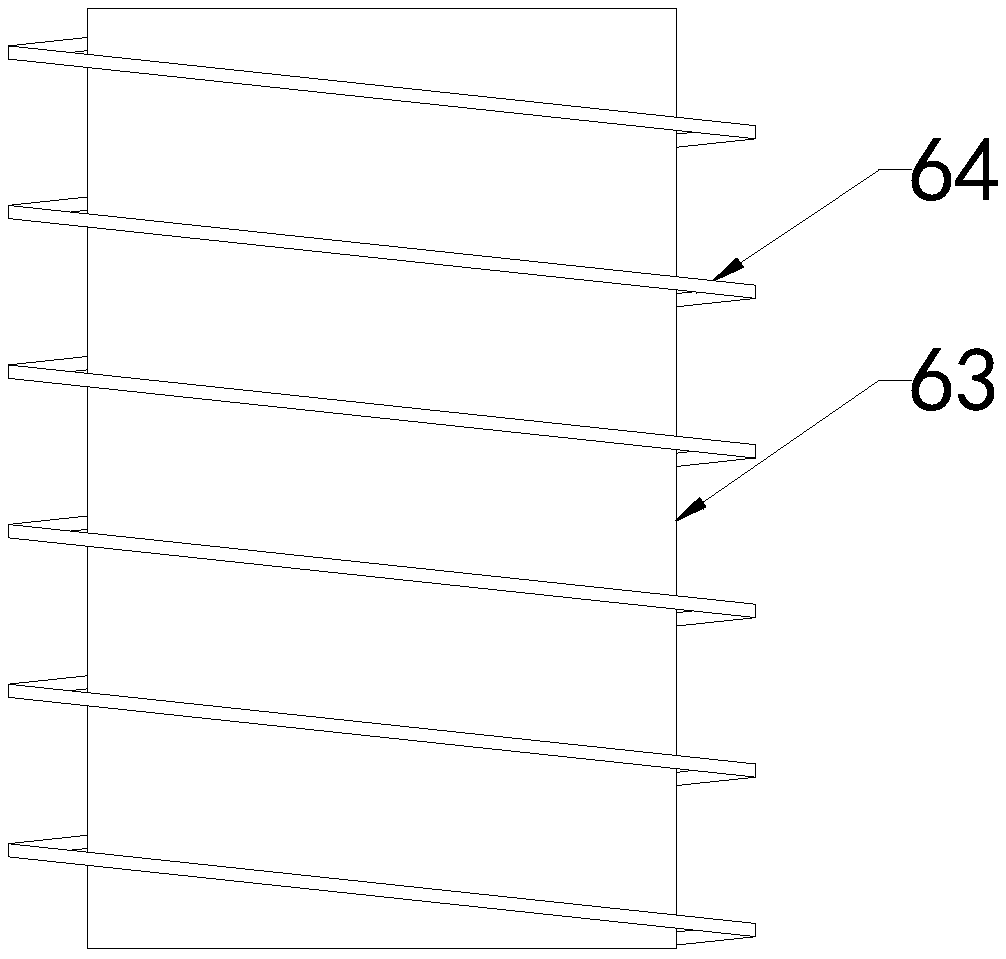

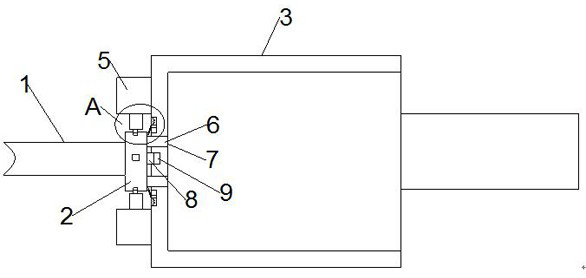

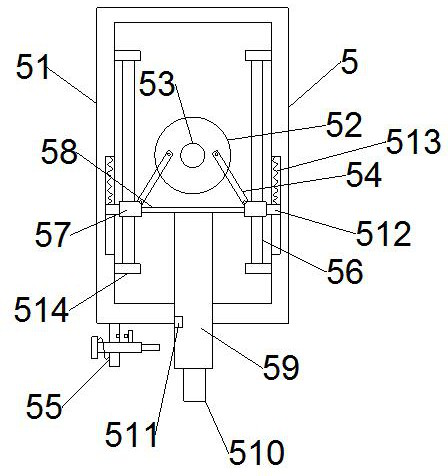

Automatic loading mechanism for self-service store

ActiveCN113421374AEasy to moveReduce work stepsCoin-freed apparatus detailsApparatus for dispensing discrete articlesElectric machineryIndustrial engineering

The present invention relates to an automatic loading mechanism fora self-service store. The mechanism comprises a main body frame and a warehouse clamping and overturning mechanism, a transverse belt is arranged at the front end of the main body frame, one side of the transverse belt is connected with a transverse driving motor, a longitudinal belt is arranged at the front end of the transverse belt, a longitudinal driving motor is arranged at the upper end of the longitudinal belt, a warehouse clamping and overturning mechanism is arranged at the front end of the longitudinal belt, a warehouse body is arranged on the inner side of the warehouse clamping and overturning mechanism, a power mechanism is arranged on the right side of the body frame, and a transmission mechanism is arranged above the power mechanism. The automatic loading mechanism for the self-service store has the beneficial effects that transverse and longitudinal omni-directional movement can be achieved, commodities are accurately clamped and then placed on the transferring device, then the next internal transferring link of the commodities is carried out, containers can be directly conveyed to the next step, other equipment is not needed for matched conveying, the working steps of the equipment are reduced, and the working efficiency of the equipment is improved.

Owner:SHENZHEN GUANQIAO PACKAGING PROD

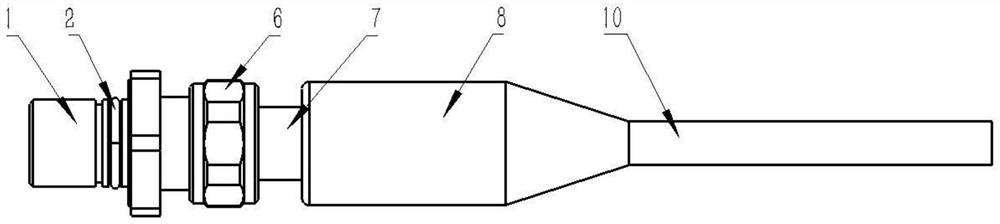

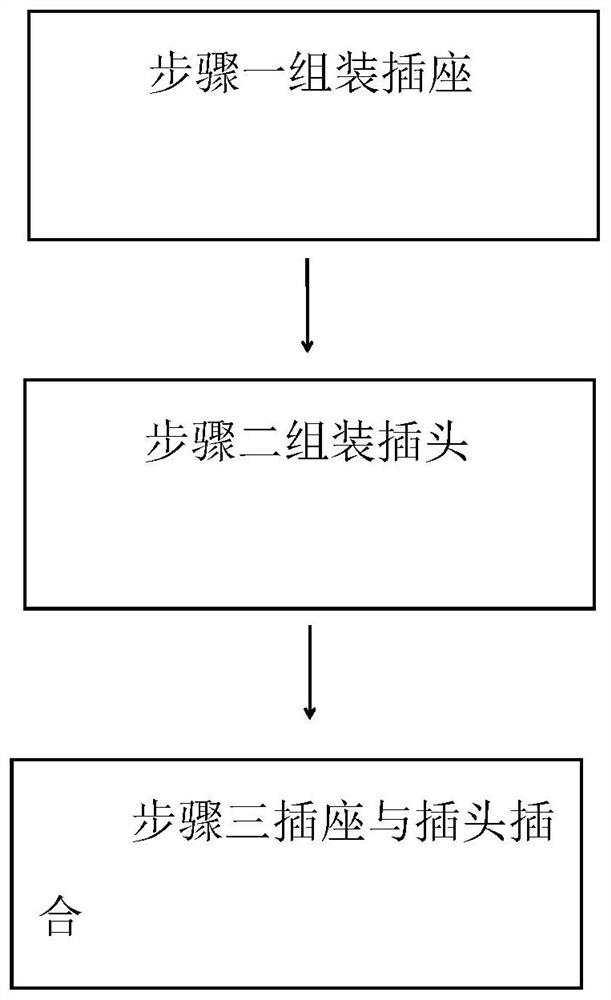

Small pouring forming longitudinal watertight transmission assembly and preparation process

PendingCN114221155ASimple structureReasonable designSecuring/insulating coupling contact membersCouplings bases/casesElastomerEngineering

The assembly comprises a plug shell and a socket shell, a screw sleeve is arranged at the left end of the outer side of the plug shell, an injection molding elastomer is arranged at the right end of the outer side of the plug shell, and a plug pouring electric assembly is arranged at the left end of the inner side of the plug shell. A glue pouring sleeve is arranged at the right end of the plug pouring electric assembly, a fifth sealing ring is arranged at the right end of the inner side of the socket shell, a socket pouring electric assembly is arranged at the left end of the inner side of the socket shell, and a silver-plated wire is arranged at the left end of the socket pouring electric assembly. The small-sized pouring-molded longitudinal watertight transmission assembly is simple in structure and reasonable in design, and the overall structure of the connector is optimized in design, so that the overall structure size of the connector is miniaturized, a sealing ring is additionally arranged, and the sealing reliability is high; meanwhile, the plug and the socket contact element are integrally formed by pouring, so that the electrical performance of the contact element is improved, and transverse and longitudinal double sealing is realized at the same time.

Owner:上海溪淇电子科技有限公司

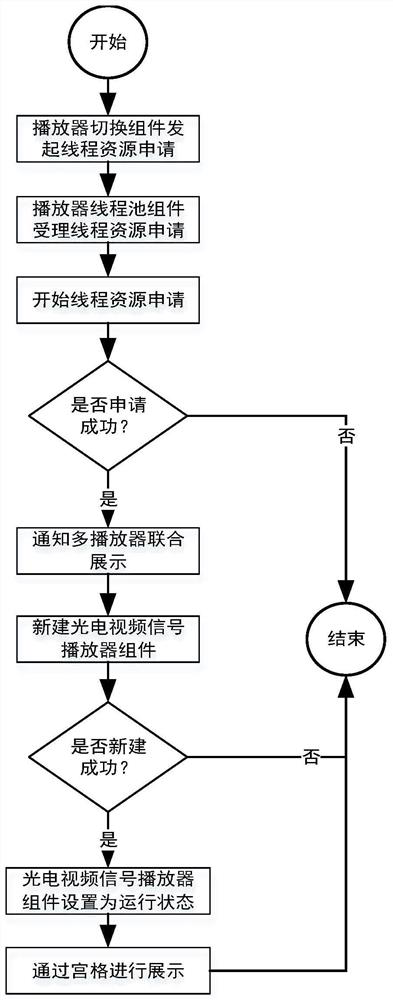

Multi-channel photoelectric video management device capable of realizing rapid and real-time switching and management method of multi-channel photoelectric video management device

PendingCN114286187AAchieve horizontalAchieve scalabilitySelective content distributionComputer hardwareEmbedded system

The invention discloses a multi-channel photoelectric video management device capable of realizing quick real-time switching and a management method thereof. The multi-channel photoelectric video management device comprises a player thread pool assembly, a plurality of photoelectric video signal player assemblies, a multi-player joint display assembly and a player switching assembly, the player thread pool assembly is respectively connected with the plurality of photoelectric video signal player assemblies, and the plurality of photoelectric video signal player assemblies are connected with the multi-player joint display assembly; the player switching assembly is respectively connected with the player thread pool assembly, the plurality of photoelectric video signal player assemblies and the multi-player joint display assembly. According to the method, transverse and longitudinal expansion of the system can be realized, the association processing performance is improved, and the expansibility of the system is enhanced; by using a unified protocol conversion template method, different monitoring source data can be self-introduced according to actual requirements under the condition of less change.

Owner:成都福瑞空天科技有限公司

Rescue machine

The invention provides a rescue machine, and belongs to the technical field of machinery. The rescue machine comprises a machine body, wherein the machine body is provided with driving wheels and universal wheels, the machine body is provided with a transverse sliding rail I and a vertical sliding rail I, the transverse sliding rail I is provided with a sliding strip I, the vertical sliding rail Iis fixed on the sliding strip I, the vertical sliding rail I is provided with a sliding strip II in a sliding mode, a rack II is vertically fixed on the sliding strip II, a fork shovel is fixed at the lower end of the rack II, the machine body is provided with a transverse sliding rail II and a vertical sliding rail II, the transverse sliding rail II is provided with a sliding strip III in a sliding mode, the vertical sliding rail II is fixed on the sliding strip III, a sliding strip IV is arranged on the vertical sliding rail II in a sliding mode, a rack IV is vertically fixed on the slidingstrip IV, a mounting plate is fixed at the lower end of the rack IV, and a mechanical arm I, a mechanical arm II and a mechanical arm III are fixed on the mounting plate. The rescue machine has the advantages of being capable of stably moving in a complex terrain, and capable of being involved in dangerous situations to explore for object sending or taking.

Owner:QUZHOU UNIV

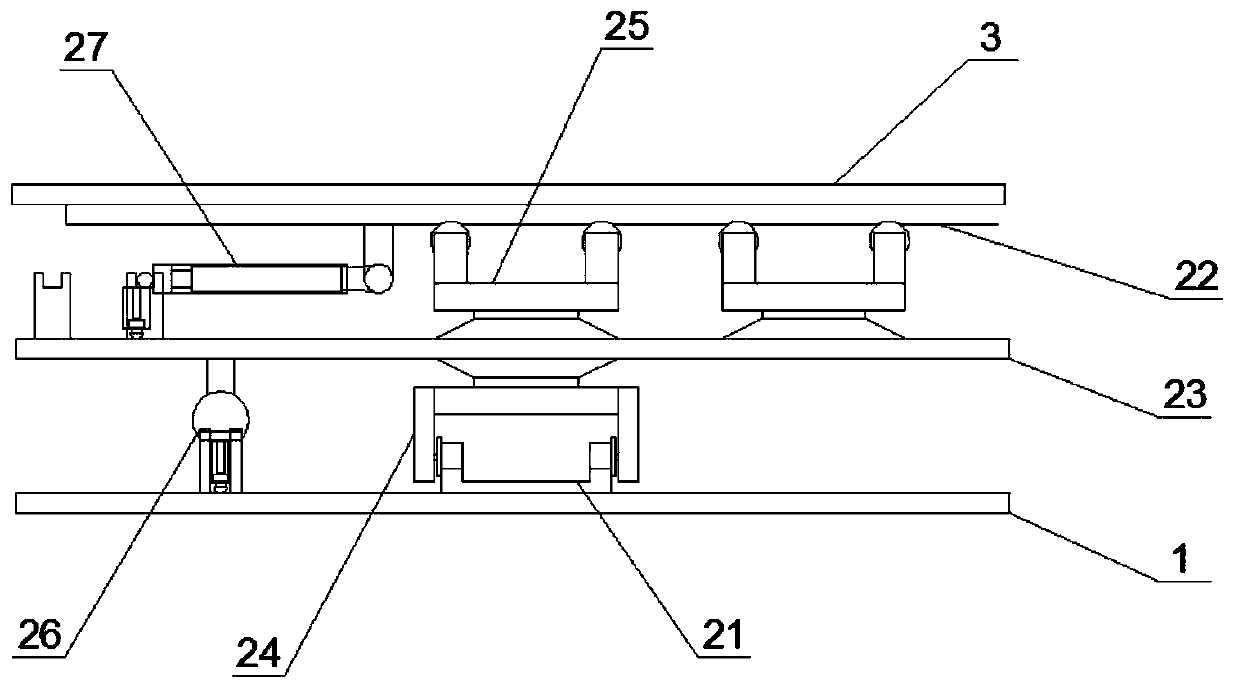

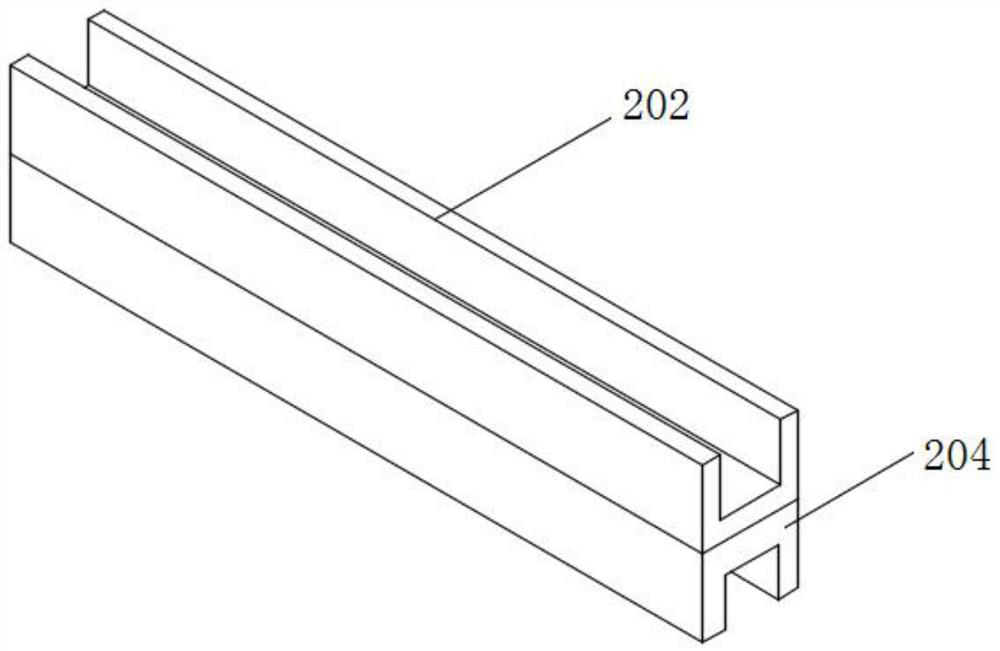

Manipulator moving mechanism and detection equipment installation system containing moving mechanism

ActiveCN107662093AFull range of mobilityControl precise positioningMetal working apparatusManipulatorBogieEngineering

The invention discloses a manipulator moving mechanism and a detection equipment installation system containing the moving mechanism and relates to the technical field of nondestructive testing of locomotive vehicles. The manipulator moving mechanism comprises a machine frame and a vertical arc frame, wherein two guide rails are arranged at the upper part and the lower part of the machine frame inparallel, a horizontal moving structure is arranged on the machine frame, the vertical arc frame can be driven by the horizontal moving structure to horizontally move along the guide rails, a longitudinal moving structure and a slide bench for installing manipulators are arranged on the vertical arm frame, and the slide bench can be driven by the longitudinal moving mechanism to move in the longitudinal direction of the vertical arm frame. By means of the manipulator moving mechanism disclosed by the invention, the manipulators can be arranged on the slide bench of the vertical arm frame; horizontal and longitudinal movement of the slide benches can be achieved by coordinated movement of the horizontal moving structure and the longitudinal moving structure, so that the manipulators can cover all the height and length directions on a bogie; by means of controlling accurate location of the two manipulators, accurate installation of detection equipment can be achieved; thus, an installation efficiency of the detection equipment is achieved, and labor intensity of operators is reduced.

Owner:SHIJIAZHUANG TIEDAO UNIV

Pulse eddy current testing equipment for marine pipeline

PendingCN106370721AAchieve horizontalEasy to detectMaterial magnetic variablesEngineeringEddy-current testing

The invention provides pulse eddy current testing equipment for a marine pipeline. During detection, people hold a straight rod by hand to drive a detecting probe to move vertically so as to detect the pipeline in the vertical direction or to drive the detecting probe to make a circle so as to achieve annular rotary detection. Through an annular limiting through hole, the pulse eddy current testing equipment can carry out annular detection on the pipeline conveniently, guarantee that the detecting probe and the outer wall of the pipeline are tangential, and improve the accuracy of detection.

Owner:TIANJIN YINKE XINCHUANG TECH CO LTD

Edge cutting device of furniture filler and using method of edge cutting device

PendingCN111015768AAchieve horizontalRealize vertical cuttingMetal working apparatusStructural engineeringKnife blades

The invention discloses an edge cutting device of a furniture filler and a using method of the edge cutting device, and relates to the technical field of furniture related equipment. The edge cuttingdevice specifically comprises a shell, wherein the shell is a cuboid with an opening in the top surface, a circular plate is arranged in the center of the opening of the shell, the circumferential surface of the circular plate is fixedly connected with one ends of a plurality of connecting rods, an annular groove is in rolling connection with balls, the balls are in rolling connection in rolling grooves formed in the bottom ends of fixing blocks, the top ends of the fixing blocks are fixedly connected with corresponding positions of the lower surface of the workbench, supporting plates are fixedly connected to the two sides of the upper surface of the shell, and fixing plates are fixedly connected between the opposite surfaces of the tops of the two supporting plates. According to the edgecutting device, a mounting plate can be lifted in a certain range, so that the distance between a blade and the workbench can be adjusted, the furniture filling with different thicknesses can be cutto a certain extent, the filler can be cut in the arc and the linear direction, and meanwhile, cut leftover materials can be recycled and reused.

Owner:海南科技职业大学

Clamping equipment for composite mechanical material processing

PendingCN113977620AAchieve the purpose of protectionAchieve horizontalGripping headsConveyor partsEngineeringEquipment use

The invention discloses clamping equipment for composite mechanical material processing. The clamping equipment comprises a plate clamping device, the plate clamping device comprises a bidirectional driving mechanism, mounting pedestals, clamping drivers and clamping sheets; the bidirectional driving mechanism is composed of a longitudinal driver and a transverse driver; the lower end of the longitudinal driver is connected with the transverse driver; the two sets of mounting pedestals are symmetrically mounted at the two ends of the transverse driver; each mounting pedestal comprises a main plate with a guide opening formed in the middle and two sets of side plates symmetrically mounted at the lower end of the main plate, and one clamping driver is mounted between the two sets of side plates; the power output end of each clamping driver is connected with the corresponding clamping sheet; and each clamping piece comprises a bottom plate located in the middle and two sets of clamping plates movably installed on the two sides of the bottom plate. According to the clamping equipment of the invention, an automatic driving mode is adopted, the purpose of soft contact with a plate can be achieved, and the use safety and the automation degree of the clamping equipment are improved.

Owner:YANCHENG INST OF TECH +1

Accurately-controlled illuminating lamp movement adjusting device

InactiveCN113007674AAchieve horizontalEnable mobilityLighting support devicesEngineeringMechanical engineering

The invention provides an accurately-controlled illuminating lamp movement adjusting device, and relates to the technical field of stage equipment. The accurately-controlled illuminating lamp movement adjusting device comprises a rectangular mounting rack, wherein parallel transverse driving rods are arranged on the inner sides of the two long side edges of the mounting rack respectively, and transverse moving blocks are arranged on the transverse driving rods respectively; a longitudinal driving rod is connected between the transverse moving blocks, and a longitudinal moving block is arranged on the longitudinal driving rod; a ceiling lamp is arranged below the longitudinal moving block; and the position of the ceiling lamp is adjusted under the driving action of the transverse driving rods and the longitudinal driving rod. According to the accurately-controlled illuminating lamp movement adjusting device, the transverse driving rods are adopted to drive the transverse moving blocks to transversely move so as to drive the longitudinal driving rod to transversely move, the longitudinal driving rod is adopted to drive the longitudinal moving block to longitudinally move, and therefore transverse and longitudinal movement of the ceiling lamp arranged on the longitudinal moving block is achieved. Thus, the irradiation position of an illuminating lamp can be flexibly and accurately changed.

Owner:WUCHANG UNIV OF TECH

Laser cutting device for metal cutting

InactiveCN109332881APrevent fallingAchieve horizontalLaser beam welding apparatusEngineeringLaser cutting

The invention relates to a laser cutting device for metal cutting. The laser cutting device comprises a support, transverse supports arranged on the support and a longitudinal support. The longitudinal support is arranged in slideways of the transverse supports. The bottom end of the longitudinal support is provided with a focusing field lens. The focusing field lens can move along the longitudinal support. The two ends of the longitudinal support are fixedly arranged on the transverse supports through fixed columns. A laser device is arranged on one side of the focusing field lens. A conveying device is arranged on the other side of the focusing field lens. The conveying device comprises conveying rollers and a conveyor belt arranged on the conveying rollers. The two sides of the conveyorbelt are provided with limiting plates for preventing parts to be cut from falling off. The longitudinal support moves along the transverse supports to drive the focusing field lens to move. The focusing field lens can move on the longitudinal support. The longitudinal support moves up and down along the fixed columns to drive the focusing field lens to move up and down. Accordingly, omni-directional movement of the focusing field lens in the height, longitudinal and transverse directions is realized so that an output laser beam can conduct cutting in multiple dimensionality directions of a material.

Owner:YANGZHOU HANGFEI PRECISION ELECTROMECHANICAL CO LTD

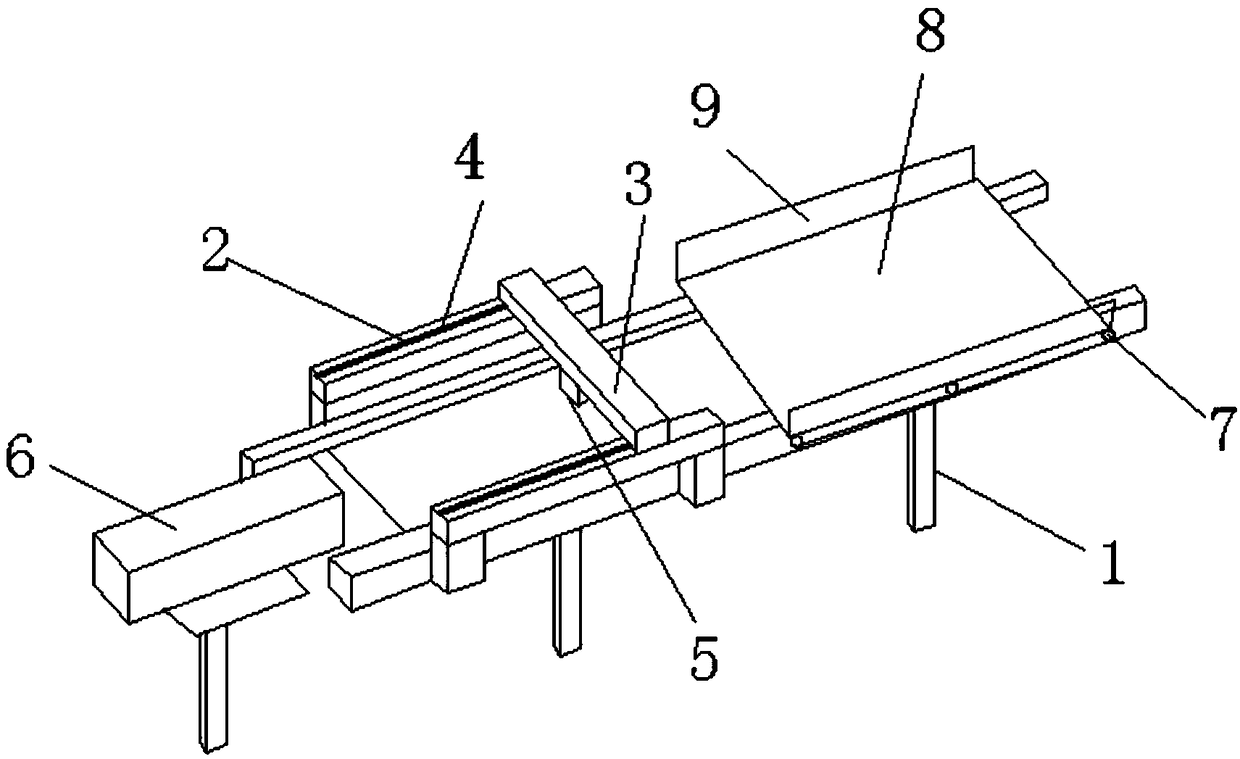

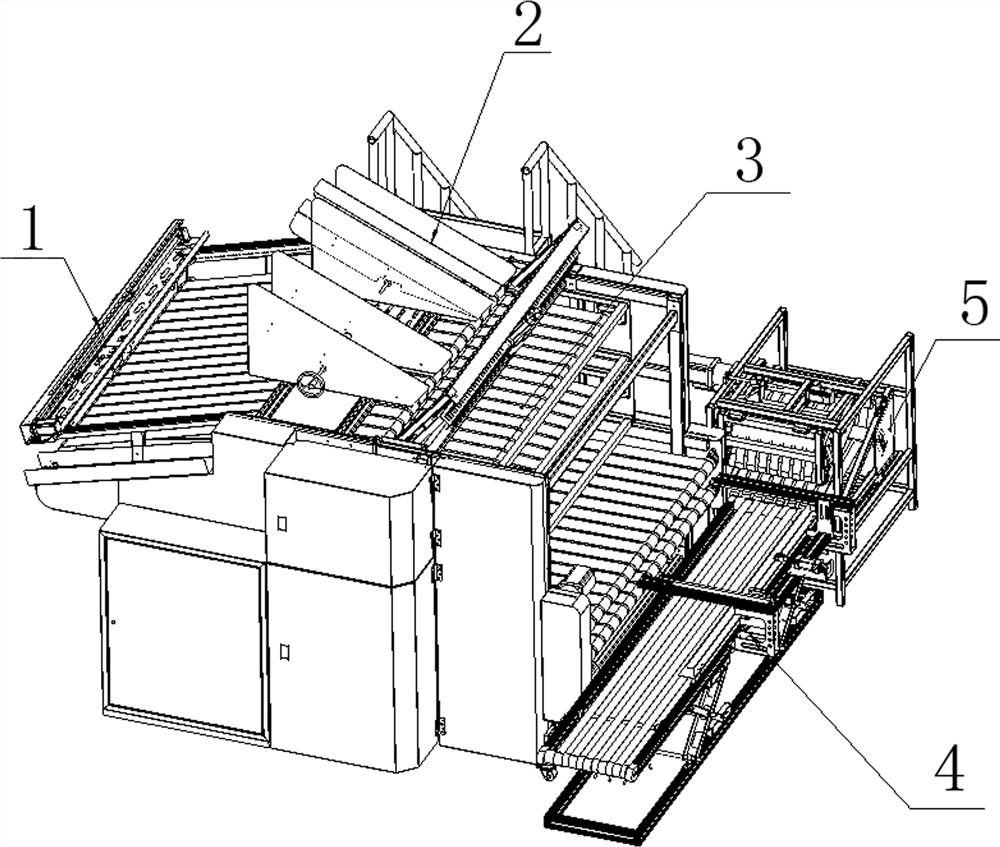

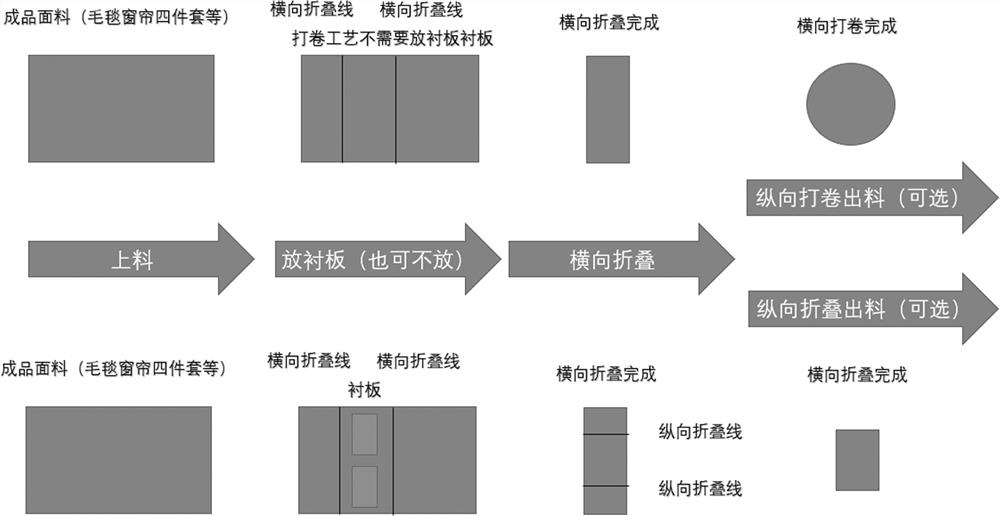

Full-automatic packaging machine

PendingCN114162413ARealize the requirements of lining boards in different positionsThe quantity of lining can be controlledPackagingEngineeringFully automated

The full-automatic packaging machine comprises a rack, a feeding unit is installed above the feeding end of a folding unit, a lining plate placing unit is arranged above the folding unit, and a discharging unit is arranged at the discharging end of the folding unit; the feeding unit opens cloth products towards the two sides to be flattened through a clamping and supporting mechanism and then conveys the cloth products to the folding unit, after the cloth products are conveyed in place through a first set of front belt conveying set and a first set of rear belt conveying set forming the folding unit, linings are taken through the feeding part forming the lining plate placing unit, and then the linings are placed between the front belt conveying set and the rear belt conveying set through the placing part. A large lining plate dragging plate forming the discharging part is driven by an oblique inserting power mechanism to be inserted and pushed into a front belt conveying group and a rear belt conveying group of the next folding unit to finish folding; after being folded, the cloth is conveyed and sucked between the upper belt group and the lower belt group by the discharging unit until the cloth advances and is rolled up. According to the device, single-person feeding is achieved, discharging is neat, the function of automatic lining plate placing can be achieved through the lining plate placing unit, and automatic rolling of folded cloth products is completed through the discharging unit.

Owner:浙江艾智智能设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com