Shaft end grinding and polishing device and method

A shaft end and equipment technology, which is applied in the field of shaft end grinding and polishing equipment, can solve the problems of low work efficiency, high labor intensity of operators, and inability to meet the processing needs of large batches, and achieve the effect of ensuring the grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

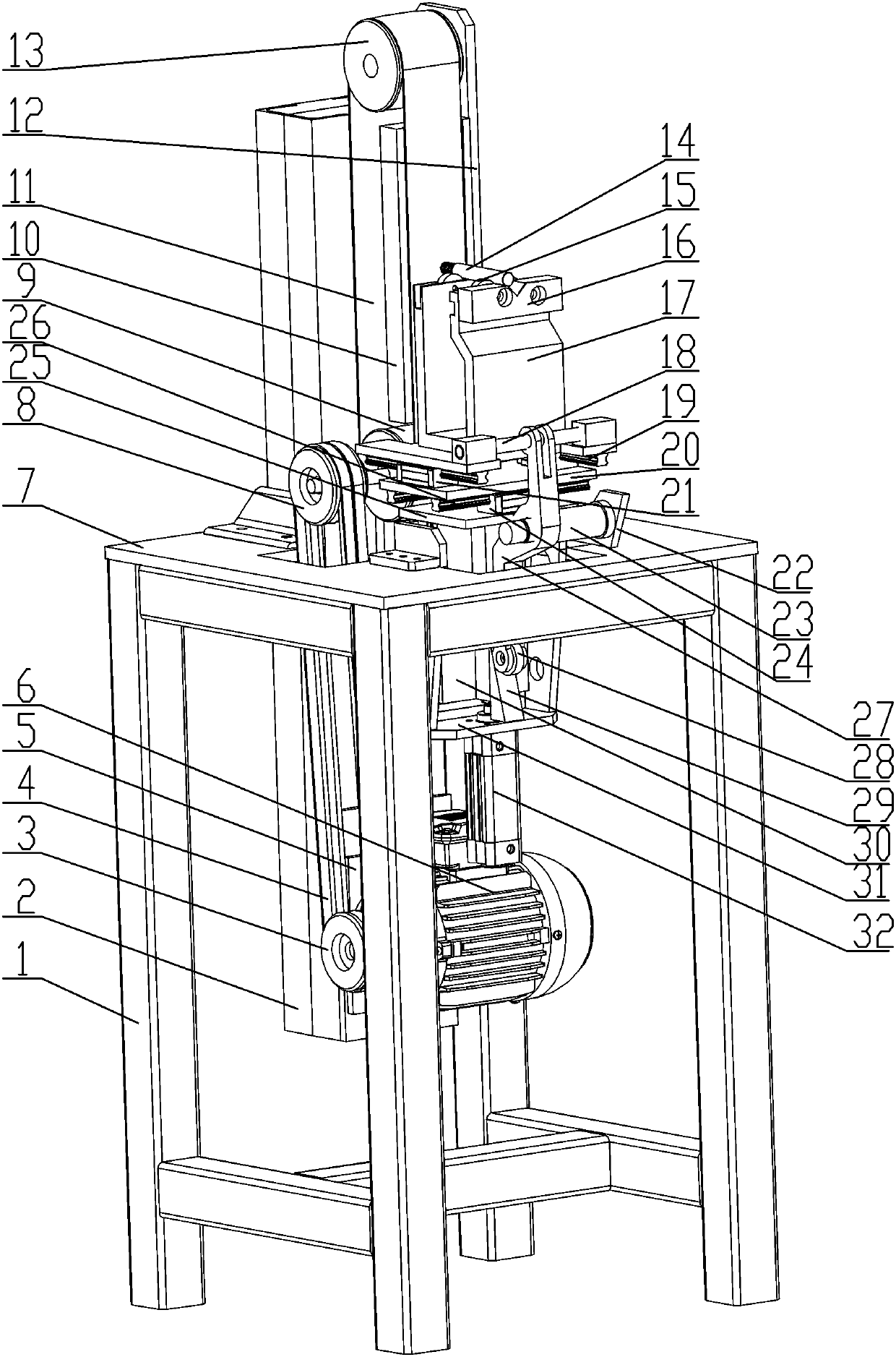

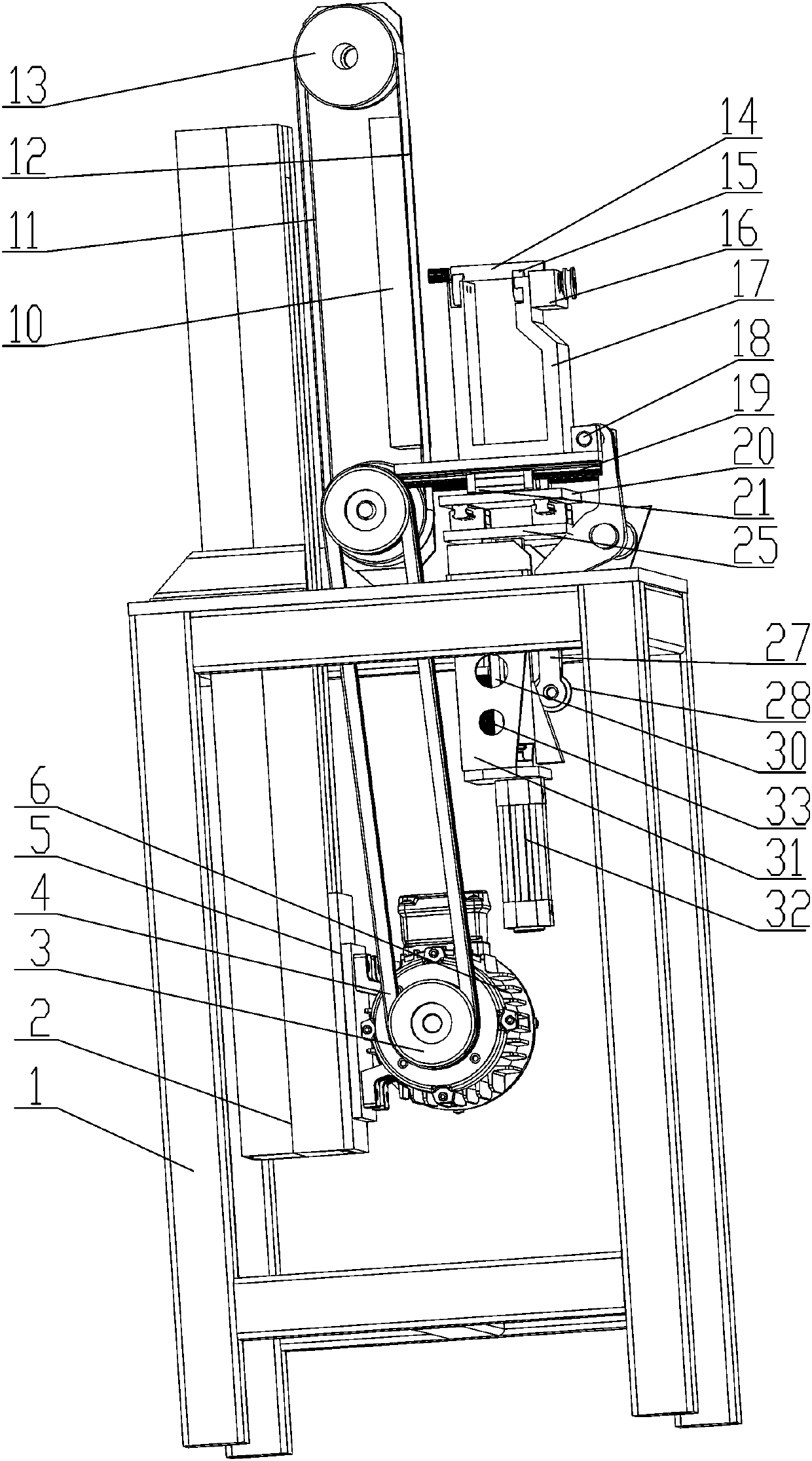

[0031] see Figure 1-2 , shaft end grinding and polishing equipment, which includes a frame 1, a column 2 is fixedly installed on the frame 1, a polishing belt mounting plate 12 is fixedly installed on the upper part of the column 2, and a useful The grinding belt device is used for grinding, and the grinding belt device is connected with the grinding power device for driving it to rotate. The top plate 7 is fixedly installed on the top of the frame 1, and the lifting box 31 is fixedly installed on the bottom end of the top plate 7. , the lifting box 31 is equipped with a lifting mechanism, the top of the lifting mechanism is fixedly equipped with a lifting top plate 25, and the top of the lifting top plate 25 is fixedly installed with a two-axis slide mechanism for horizontal and vertical movement. The top of the shaft slide mechanism is fixedly equipped with a clamping seat 17 for fixing shaft parts, and a cam type grinding feed mechanism for driving it close to the grinding...

Embodiment 2

[0040] The method for grinding the shaft end by the shaft end grinding and polishing equipment comprises the following steps:

[0041] Step1: Fix the shaft part 14 to be polished on the top of the clamping seat 17 through the top clamp, and fix it through the V-shaped positioning plate 16;

[0042] Step2: Start the grinding power device, drive the driving pulley 3 through the motor 6, drive the belt 4 through the driving pulley 3, drive the driven pulley 8 through the belt 4, and drive the grinding belt device through the driven pulley 8;

[0043] Step3: Drive the grinding belt 11 through the second roller 9 of the grinding belt device;

[0044] Step4: Restart the lifting mechanism, drive the vertical lifting plate 30 to lift along the vertical guide rail 33 through the lifting cylinder 32, and then drive the lifting top plate 25 to rise through the vertical lifting plate 30, and then drive the two shafts on the top through the lifting top plate 25 The sliding table mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com