Production system for low-radiation coated energy-saving glass

A low-radiation coating and energy-saving glass technology, which is applied in glass manufacturing equipment, glass transportation equipment, manufacturing tools, etc., can solve the problems of glass quality deterioration, difficult operation, and quality failure, so as to improve production quality and mold plastic Neat and easy to discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

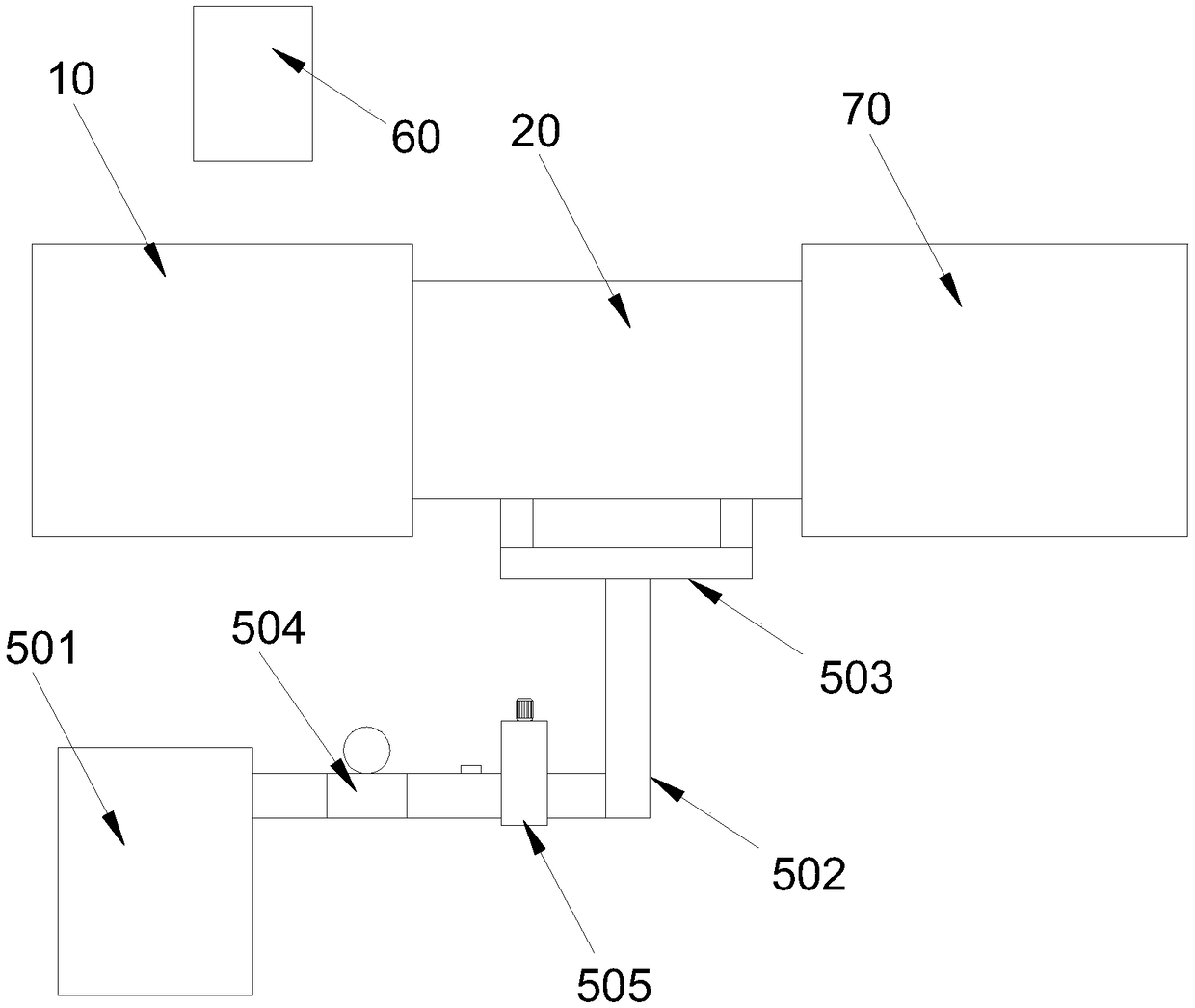

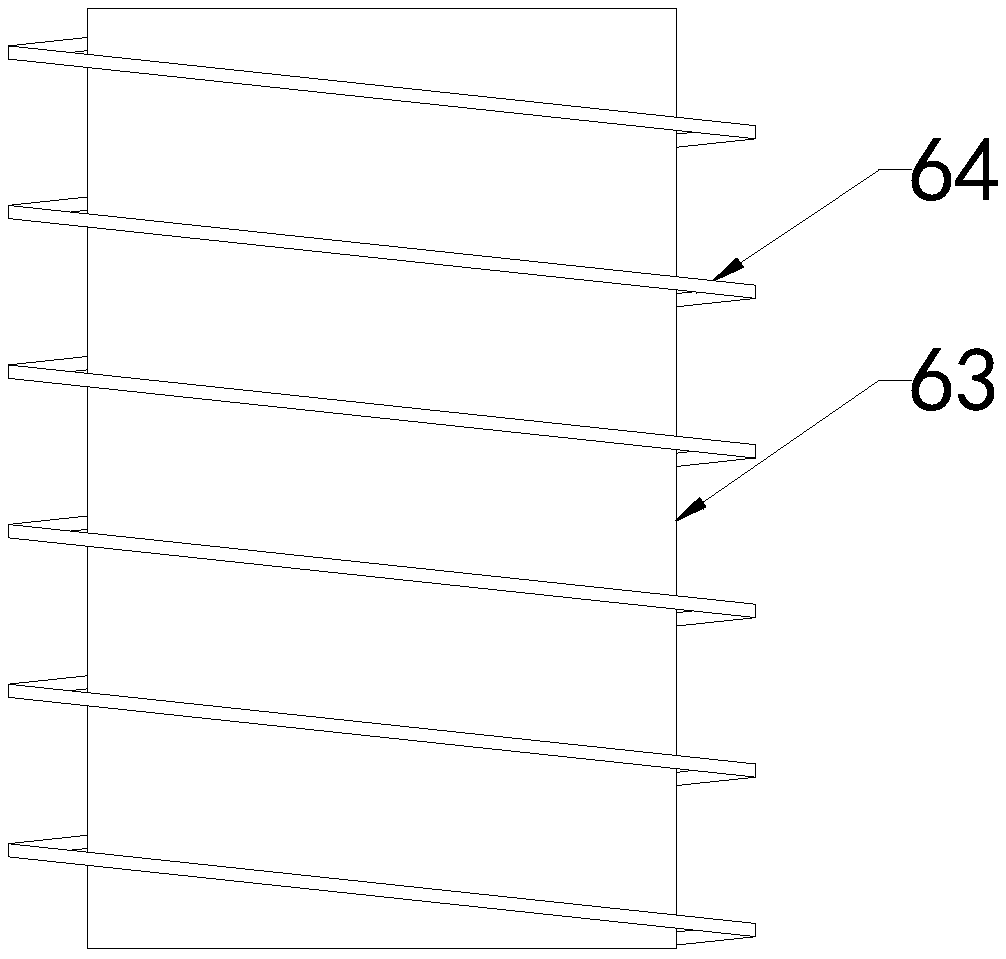

[0047] Such as Figures 1 to 19 As shown, a low-emissivity coated energy-saving glass production system includes a glass liquid mixing device 60, a glass forming processing table 10, a transition roller table 20 for conveying after forming, a flattening device 30 for controlling the surface during forming, and a glass forming table before forming. The slag removal device 40 of the processing table 10, the gas delivery device 50 for conveying the protective gas during the transmission process, and the finished product cutting device 70, the mixing device 60 is fixedly installed above the processing table 10, and the top surface of the processing table 10 There is a rectangular tin bath 11 in the center, the discharge end of the processing table 10 is horizontally and fixedly connected with the feed end of the transition roller table 20, and the flattening device 30 is arranged on the top surface of the processing table 10 and connected Slidingly connected, the slag removal devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com