Automatic loading mechanism for self-service store

An automatic, shop-based technology, applied in the direction of coin-free or similar appliances, coin-operated equipment for distributing discrete items, instruments, etc., can solve the problems of inconvenient delivery of goods to other institutions, cumbersome problems, etc., to reduce work steps and improve Work efficiency, easy transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

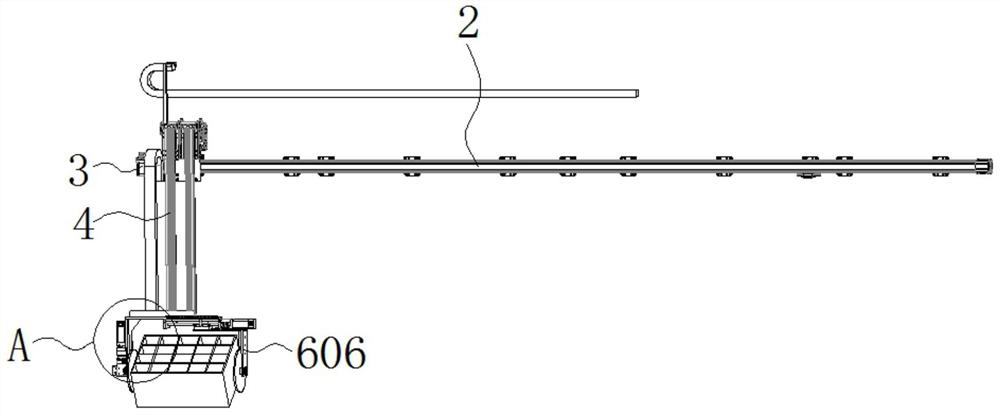

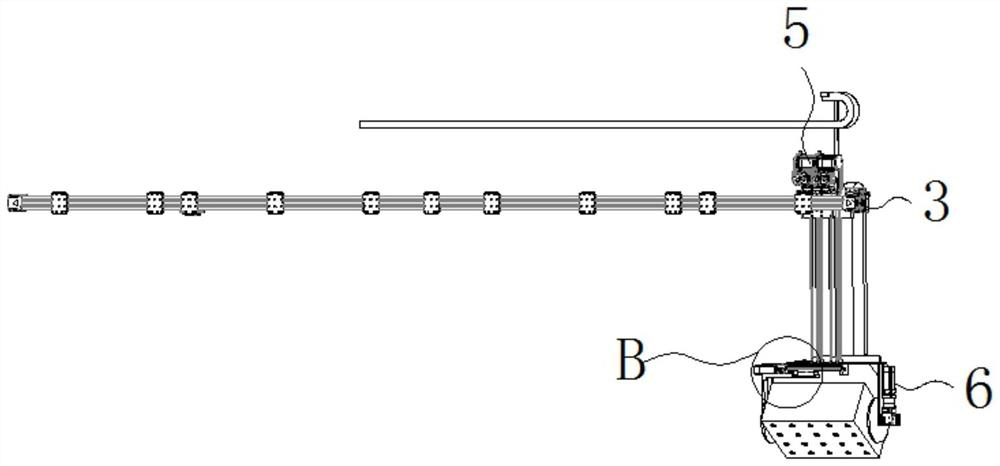

[0021] Such as Figure 1 to Figure 5 As shown, the present invention provides a technical solution: an automatic loading mechanism for an unmanned store, including a main body frame 1 and a warehouse clamping and turning mechanism 6, the front end of the main body frame 1 is provided with a transverse belt 2, and one side of the transverse belt 2 A transverse drive motor 3 is connected, and the longitudinal belt 4 forms a translation structure through the transverse drive motor 3 and the transverse belt 2 and the main body frame 1, and the transverse belt 2 is parallel to the ground, and the front end of the transverse belt 2 is provided with a longitudinal belt 4, and The upper end of the longitudinal belt 4 is provided with a longitudinal drive motor 5, and the warehouse holding and turning mechanism 6 forms a lifting structure through the longitudinal drive motor 5, the longitudinal belt 4 and the main frame 1, and the longitudinal belt 4 is perpendicular to the ground, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com