Integrated ring foot fine blank cup preparation process

A preparation process and an integrated technology, which is applied in the direction of manufacturing tools, auxiliary molding equipment, ceramic molding machines, etc., can solve the problems of ring feet falling, long operation time, and more cutting materials for ring feet, so as to avoid gap defects and reduce Efforts to improve accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below through specific embodiments.

[0023] In order to make the technical means, creative features, achievement goals and effects realized by the present invention easy to understand, the present invention will be further described below with reference to the specific embodiments.

[0024] As shown in the figure, the preparation process of the integrated ring Ashikaga blank cup of the present invention includes the following steps:

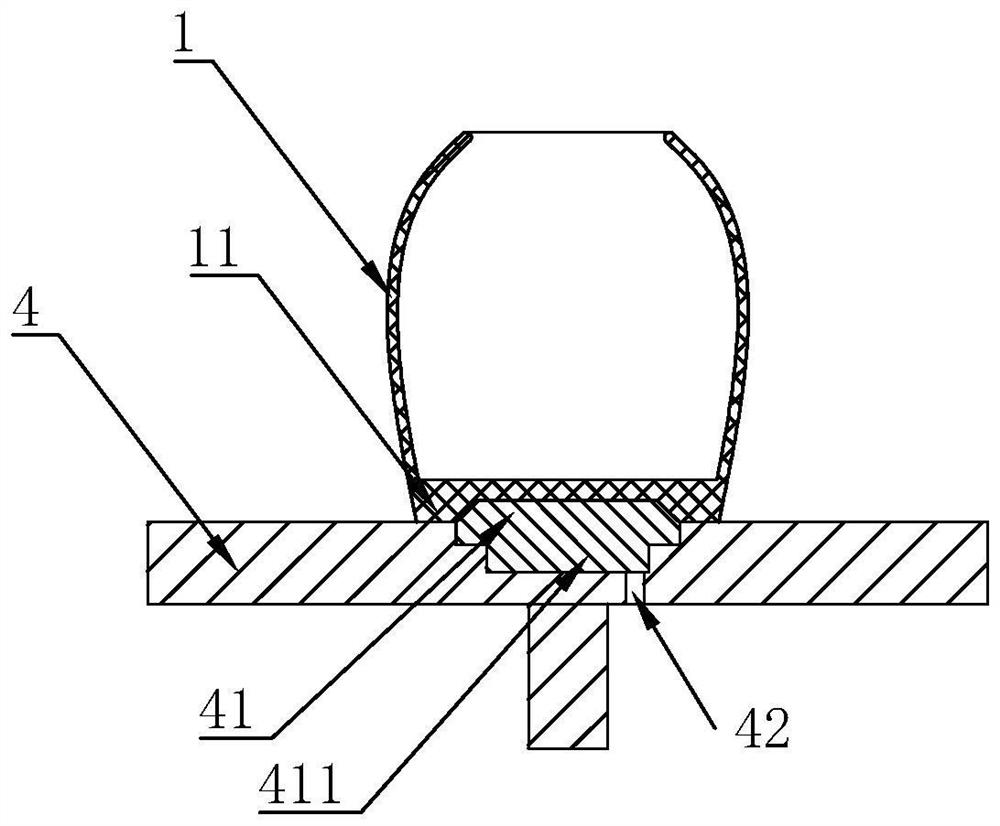

[0025] Step a, such as figure 1 , the mud material is placed on the drawing turntable 4 of the drawing machine, and the drawing is formed;

[0026] Step b, the blank 1 formed by drawing the blank is dried;

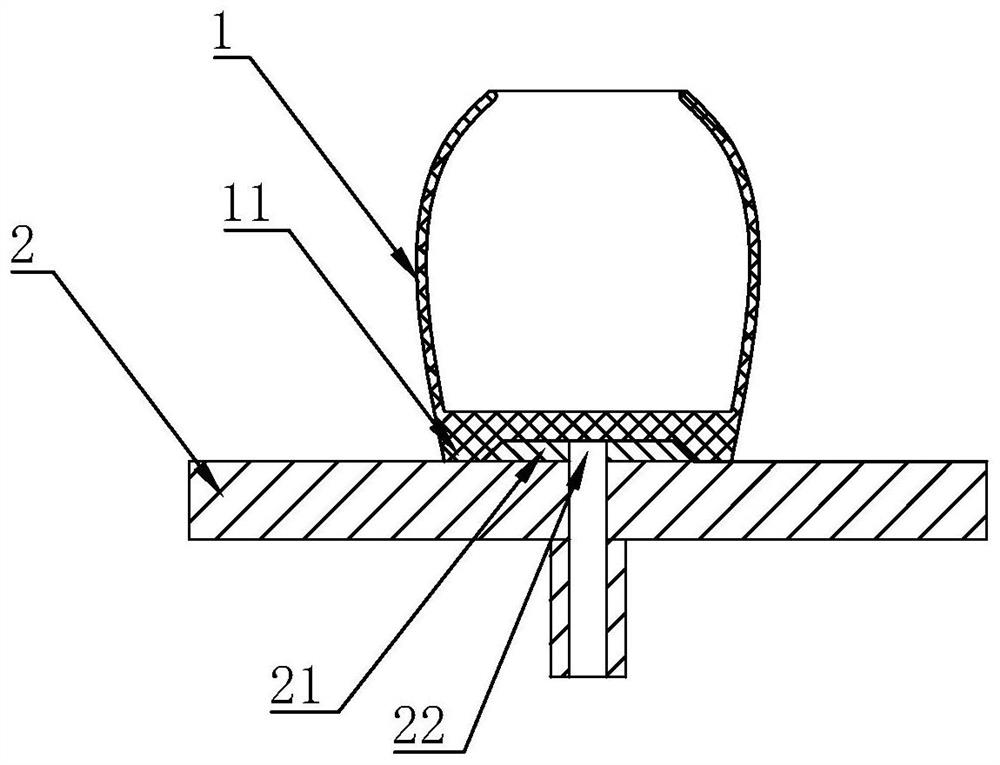

[0027] Step c, such as figure 2 , transfer the blank 1 to the blank turntable 2 of the blank blanking machine, and carry out blanking on the blank 1;

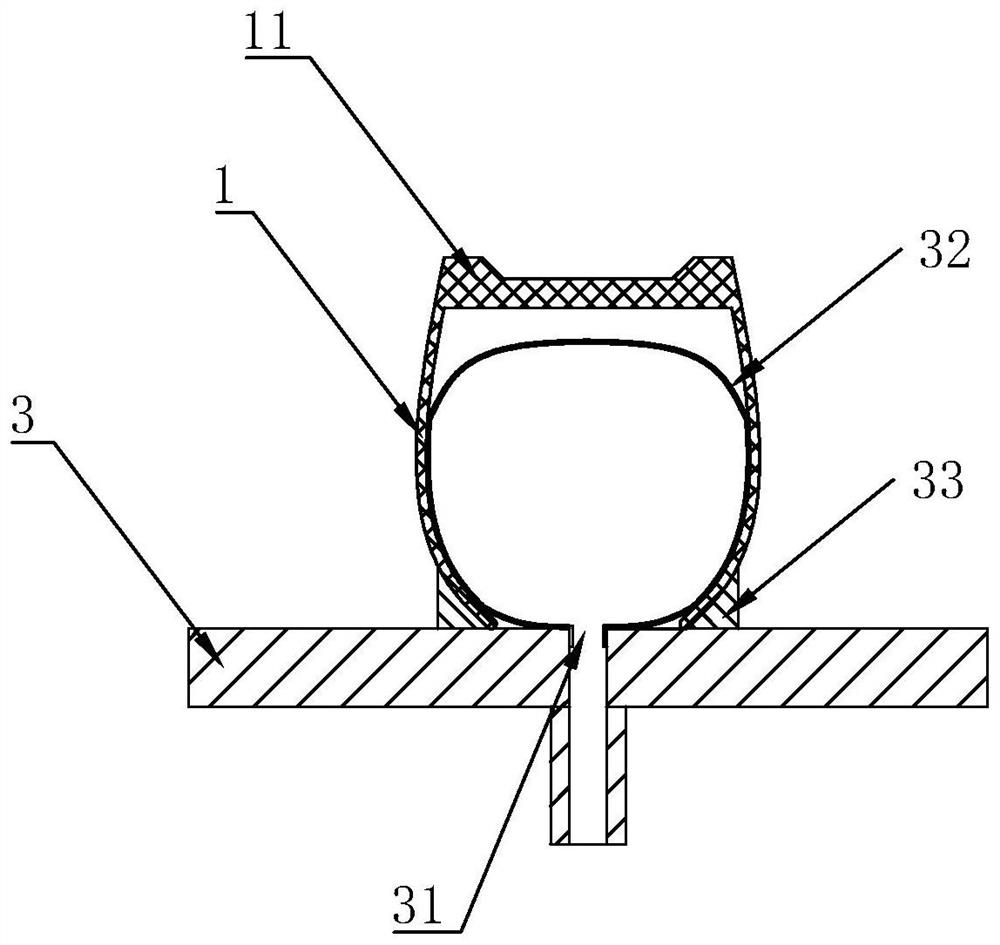

[0028] Step d, such as image 3 , the blank 1 is placed upside down on the ring foot turntable 3 on the ring foot profit blank mac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com