Large-area high-quality nitrogen-doped graphene as well as preparation method and application thereof

A nitrogen-doped graphene, large-area technology, applied in the field of graphene, can solve problems such as unfavorable C-N bonds, and achieve the effect of simple process, good structural quality, and high photoelectric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

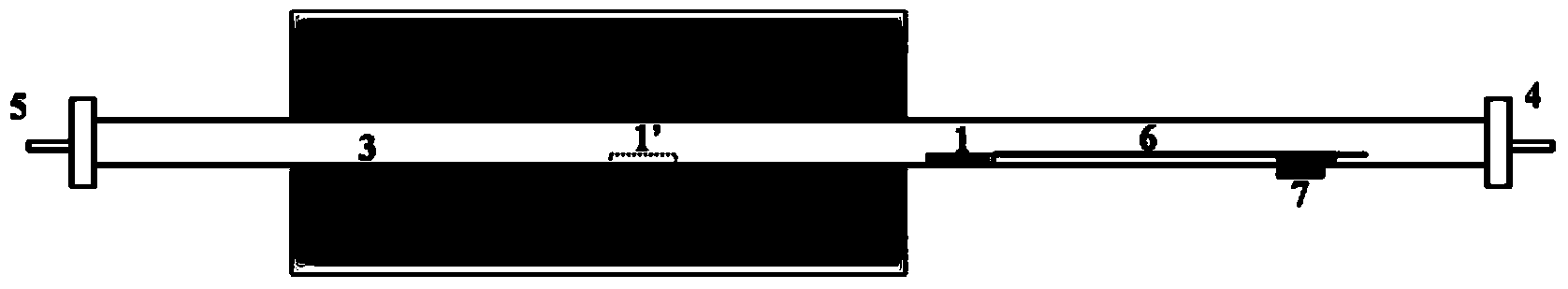

[0043] The general preparation process is as follows:

[0044] The first step, the preparation of catalyst:

[0045] If copper foil, copper block, copper alloy, etc. are used, it can be used directly; if copper plating is used as a catalyst, copper can be evaporated on the substrate by electron beam evaporation and other methods; if a copper-containing compound is used as a catalyst, the compound can be dissolved In a certain solvent, it is attached to the substrate by spin coating or direct drop method, and it is used after being dried.

[0046] The second step: Spin-coat P4VP (polytetravinylpyridine) on the copper catalyst used as a carbon and nitrogen source and dry it in an oven

[0047] The third step: the reaction device such as figure 1 As shown, the copper catalyst with P4VP is placed in the low-temperature zone of the clean quartz tube, and then the air in the quartz tube is removed by repeated vacuuming three times, or 10-3000 sccm non-oxidizing gas (such as hydrog...

Embodiment 1

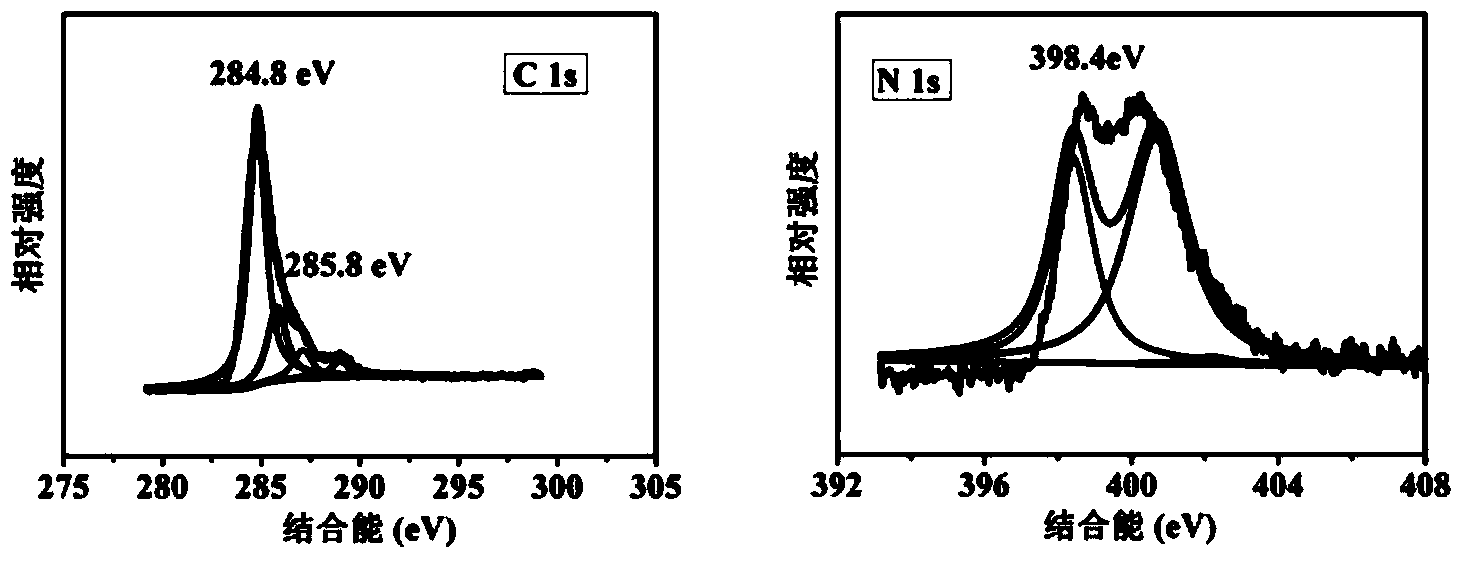

[0051] Example 1. Preparation of nitrogen-doped graphene with a high-quality crystal structure on a copper-based substrate

[0052] The first step: ultrasonically clean the copper foil with deionized water, ethanol, and acetone in sequence, then dry it in an oven, then spin-coat P4VP (polytetravinylpyridine, molecular weight 60,000) on its surface as a carbon and nitrogen source, and then dry it in an oven Internal drying, the average thickness of the film after drying is 100nm. The specific coating process is as follows: Take 40 μL of P4VP solution with a molar concentration of 0.1 mg / mL dissolved in chloroform solvent, and spin-coat evenly on a surface with a size of 1 cm. 2 ×1cm 2 copper foil surface. Place the P4VP-coated and dried copper foil in the low-temperature area of a clean quartz tube, and then completely remove the air in the furnace by repeated vacuuming. Through 150sccm H 2 And 30sccm Ar mixed gas as carrier gas, start heating.

[0053] Step 2: When the ...

Embodiment 2

[0056] Embodiment 2, prepare nitrogen-doped graphene on copper-based substrate

[0057] The preparation method is basically the same as in Example 1, except that: when the temperature in the central area of the furnace reaches 600° C., an iron bar is used to push the copper foil to the high temperature area. The Raman spectrum of the product is as Figure 7 As shown, it is proved that the product is graphene with 5-10 layer structure, and the nitrogen content is 8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com