Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

92results about How to "Improve smearing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composition with makeup maintaining and oil controlling effects and cosmetic

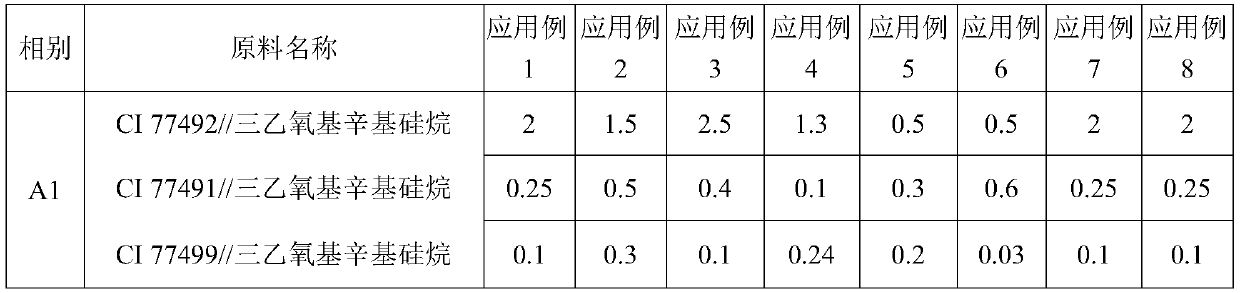

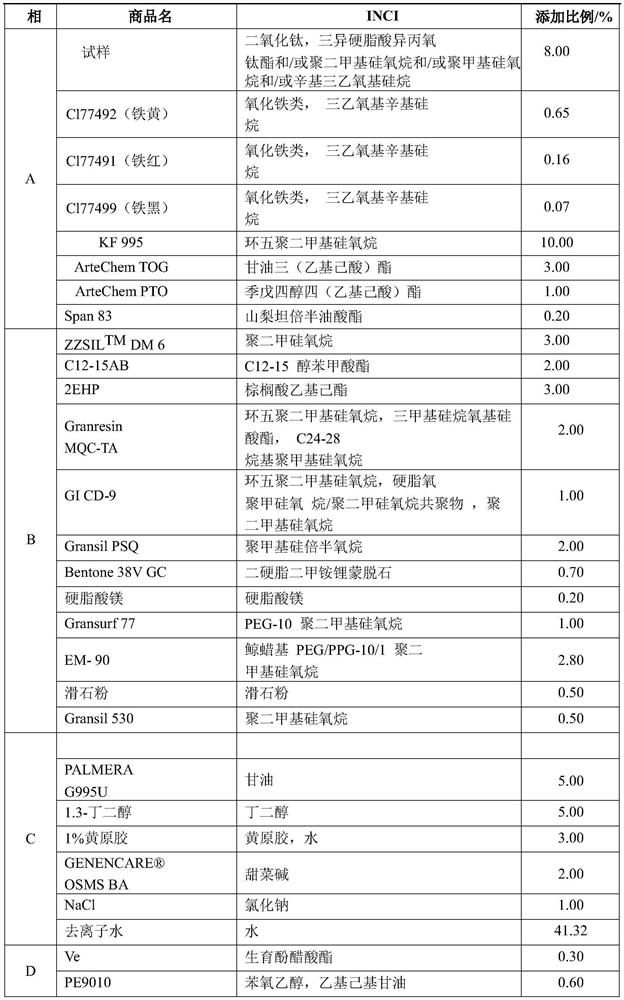

The invention discloses a composition with makeup maintaining and oil controlling effects and a cosmetic. The composition can effectively improve the migration resistance of foundation products, directionally absorb, flocculate and solidify sebum, has a good oil controlling effect, can effectively reduce the influence of sebum secreted by skin on makeup, and enables the skin to keep natural and lasting makeup. The composition with the makeup maintaining and oil controlling effects is prepared from, by weight, 0.8-2.5 parts of polydimethylsiloxane and polyol copolymer, 4-11 parts of film forming agent, 1-8 parts of functional powder and 14-33 parts of volatile silicone oil, wherein the functional powder is a mixture of synthetic fluorophlogopite, hydroxyapatite and zinc oxide; and the filmforming agent is a combination of polymethylsilsesquioxane and trimethylsiloxysilicate. The invention belongs to the technical field of cosmetics.

Owner:GUANGDONG BAWEI BIOLOGICAL TECH CO LTD

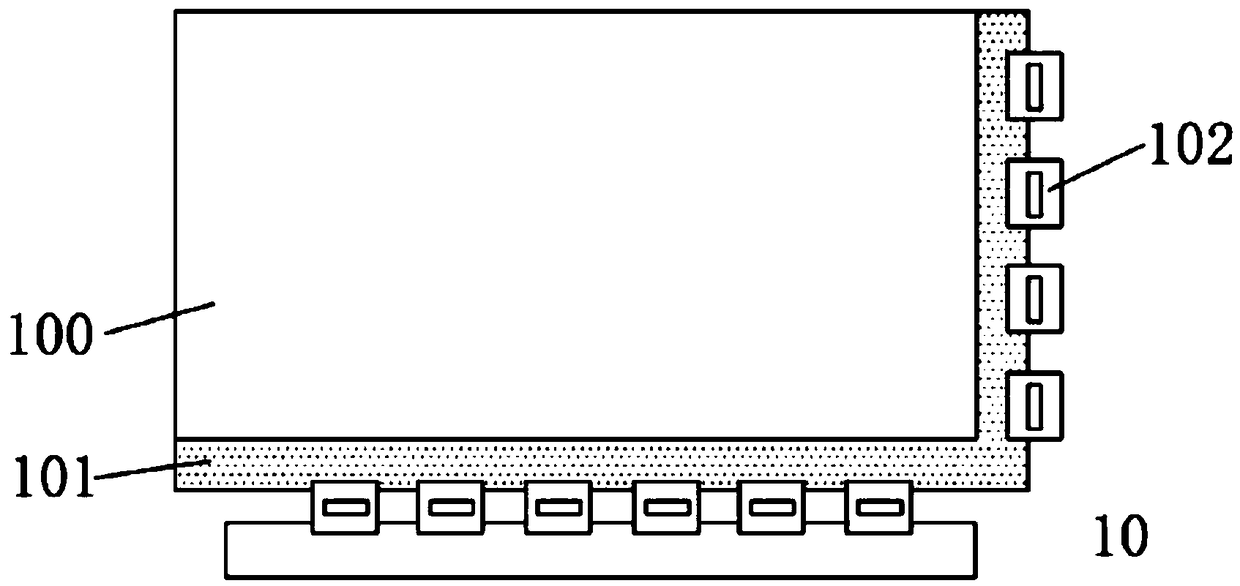

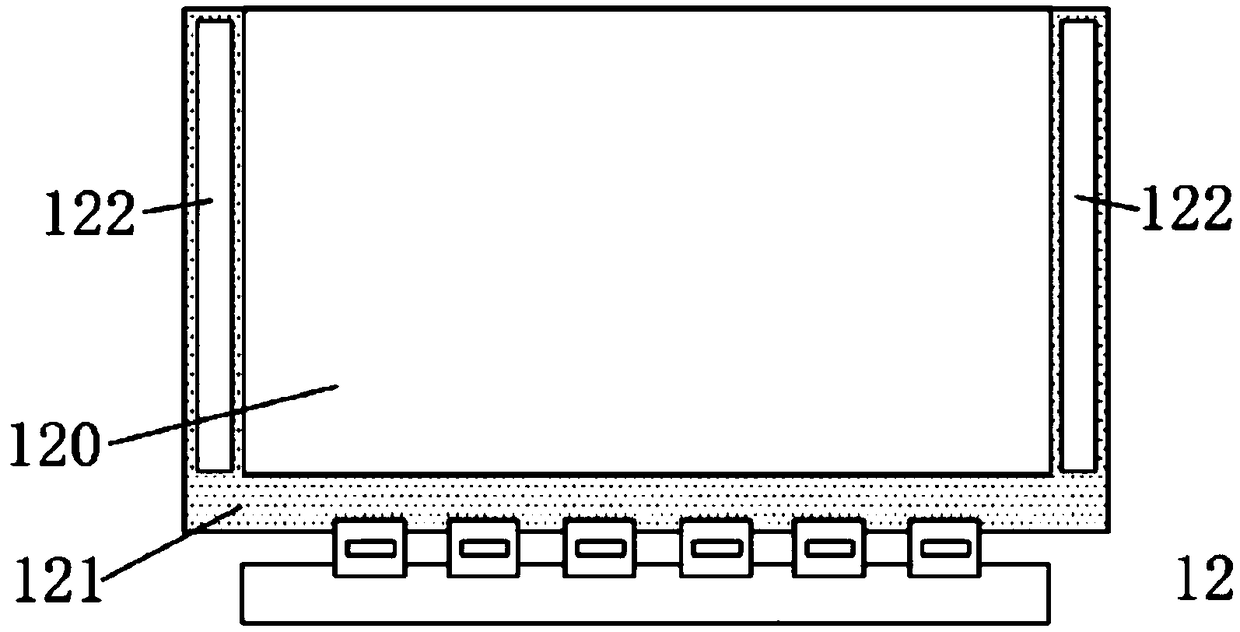

Backlight control method and apparatus, and liquid crystal display apparatus

ActiveCN106205497AImprove brightness uniformityImprove display qualityStatic indicating devicesLiquid-crystal displayBrightness perception

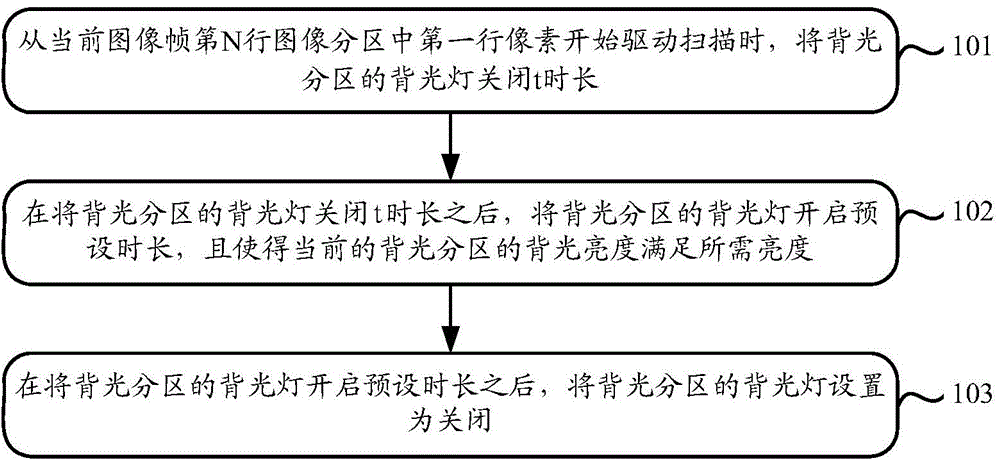

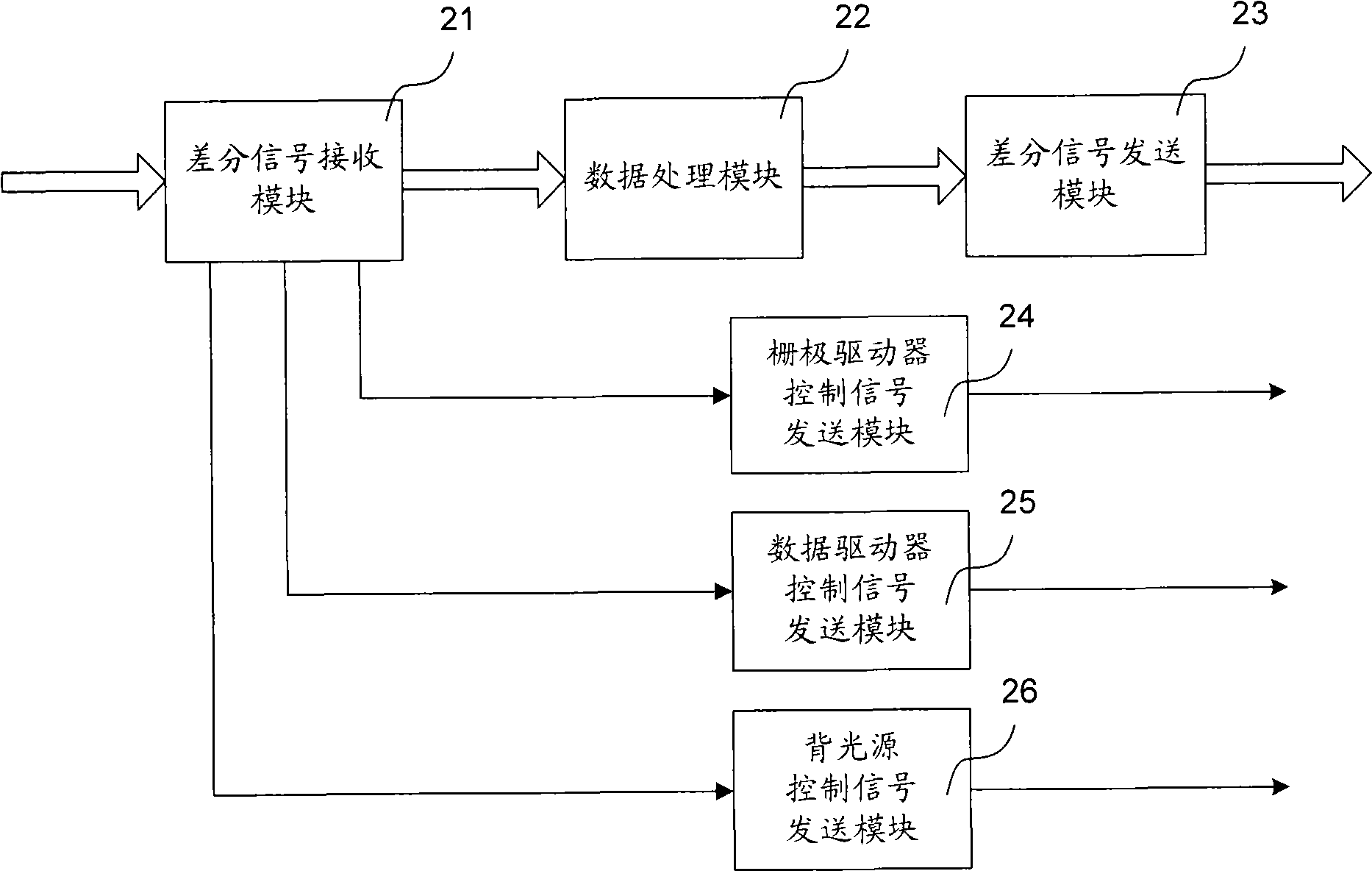

The invention discloses a backlight control method and apparatus, and a liquid crystal display apparatus. The main content of the method comprises the following steps: from the time when it is monitored that a first row of pixels in an N-th row image subarea of a current image frame starts driving scanning, switching off a backlight lamp of a backlight subarea for a time length of t, wherein t is scanning black frame insertion time; after the backlight lamp of the backlight subarea is switched off for the time length of t, switching on the backlight lamp of the backlight subarea for a preset time length, and enabling backlight brightness of the current backlight subarea to satisfy needed brightness; and after the backlight lamp of the backlight subarea is switched on for the preset time length, setting the backlight lamp of the backlight subarea to be closed. In such a way, a tailing phenomenon generated due to a visual persistence effect is effectively improved, at the same time, it is ensured that the backlight brightness of each backlight subarea is the same, the brightness uniformity of the backlight subarea is improved, and the display quality of a liquid crystal display apparatus is effectively improved.

Owner:HISENSE VISUAL TECH CO LTD

Drive device and drive method for liquid crystal display

InactiveCN101533617AReduce power consumptionImprove qualityStatic indicating devicesNon-linear opticsPersistence of visionLiquid-crystal display

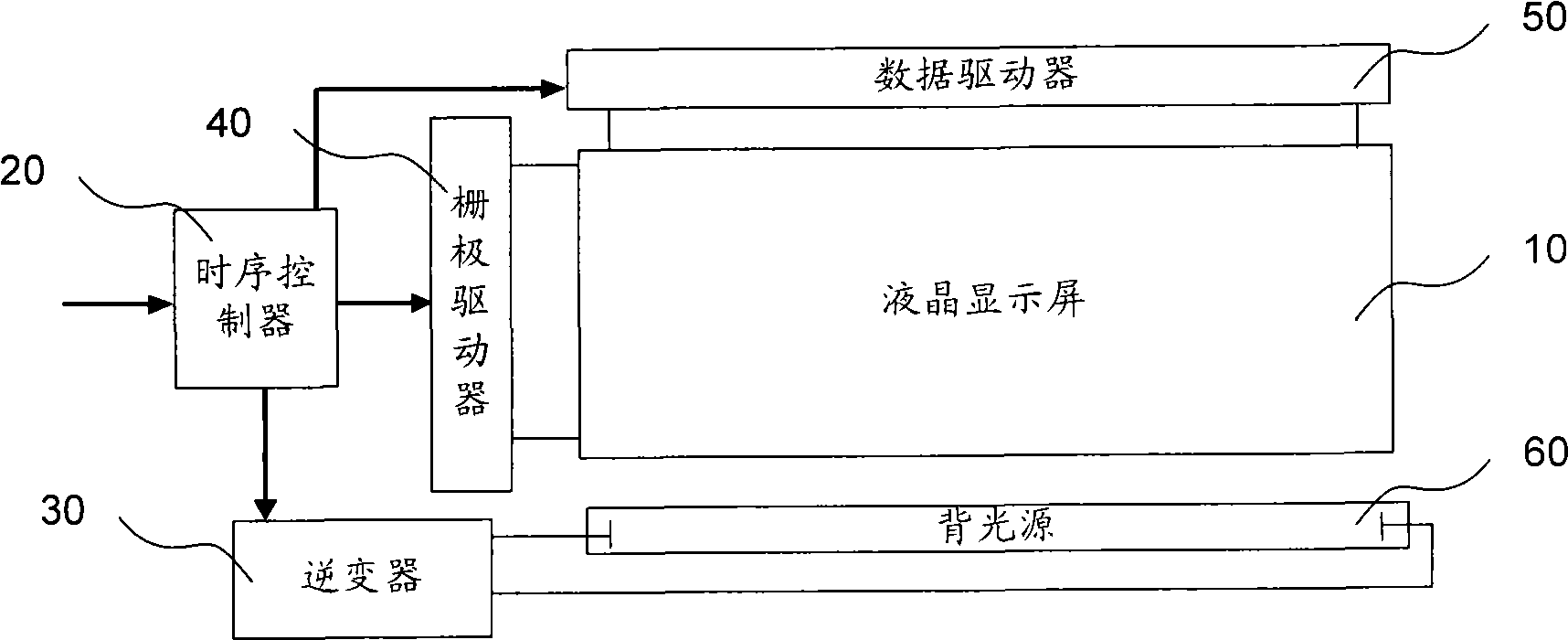

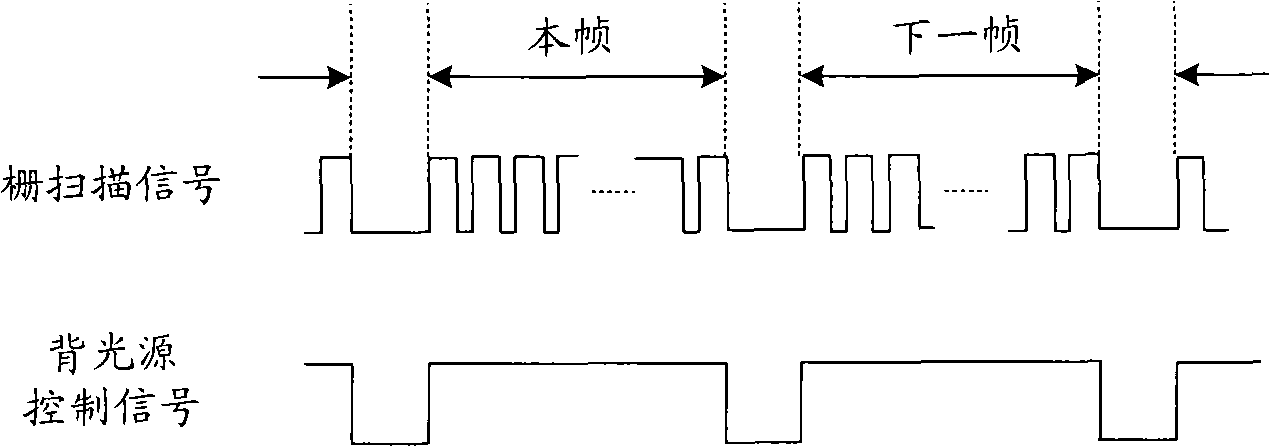

The invention relates to a drive device and a drive method for a liquid crystal display. The drive device comprises a liquid crystal display, a grid drive, a data drive and a time sequence controller, wherein the time sequence controller is connected with the grid drive, the data drive and a backlight source, and is used for generating a gray scale level data signal and an internal logic synchronous signal according to an input signal, and generating a grid scanning control signal, a data input control signal and a backlight source control signal according to the internal logic synchronous signal and the time sequence of a data transmission channel to make the backlight source closed between the end moment of a last row of grid scanning control signal of the frame and the start moment of a first row of grid scanning control signal of next frame. The invention controls the on-off of the backlight source between two frames, makes the liquid crystal display screen generate periodic black frame, effectively improves the trailing phenomenon of moving images caused by persistence of vision, improves the frame quality, and simultaneously reduces the power consumption of the backlight source as the backlight source is closed between the two frames.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD

Multi-frame image fusion method and device

ActiveCN110189285AThe denoising effect is normalNo additional time consumption for image acquisitionImage enhancementImage analysisImaging processingMultiple frame

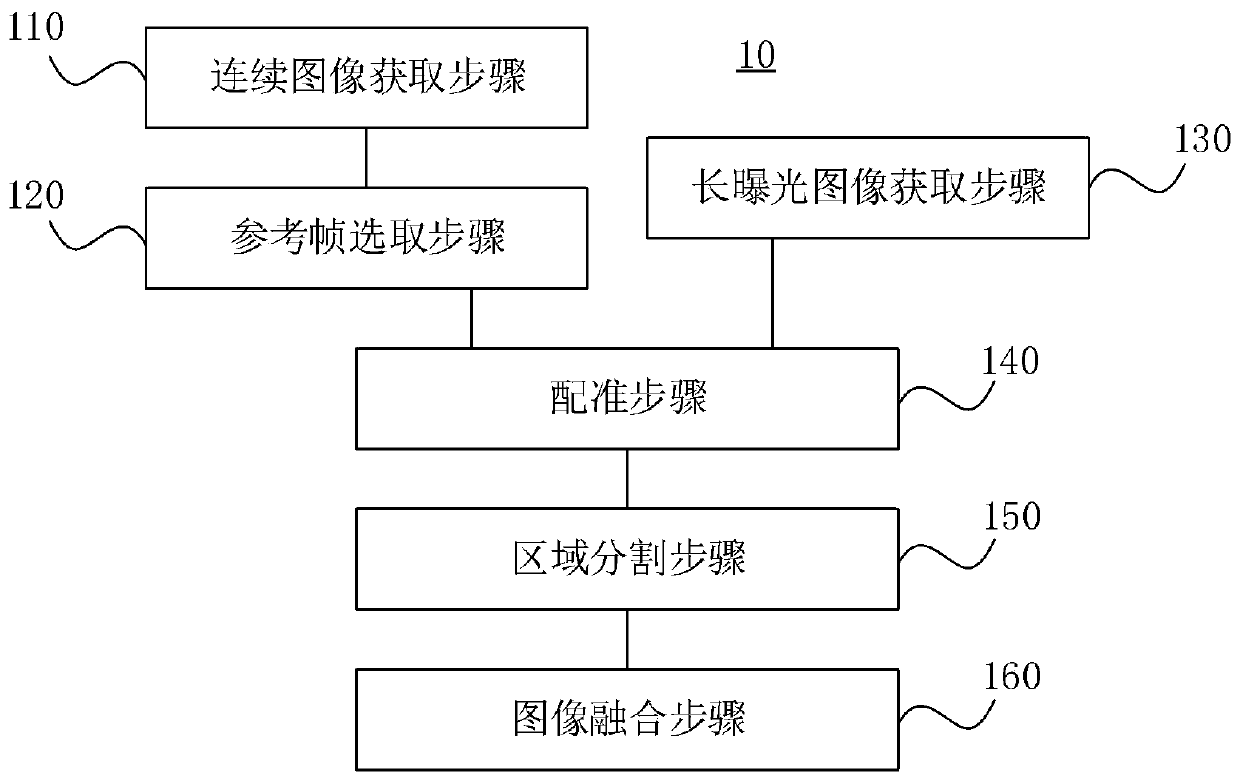

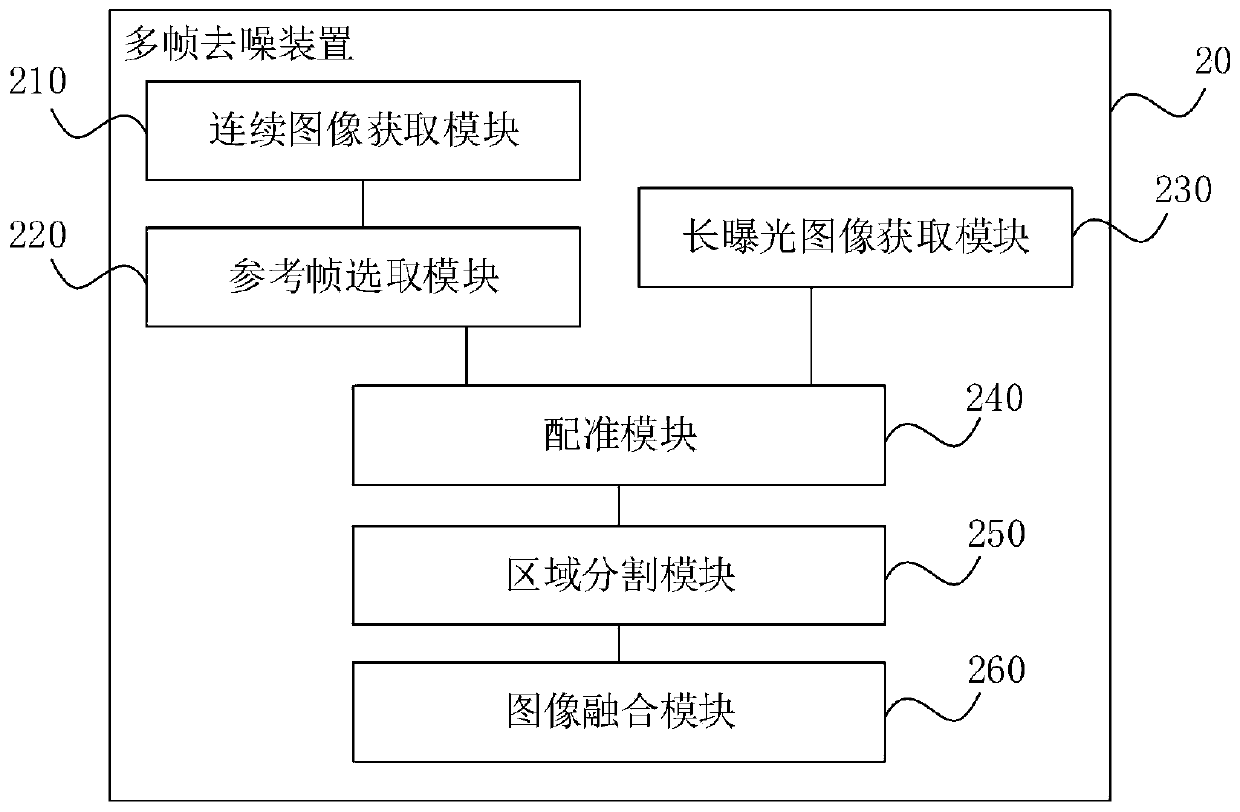

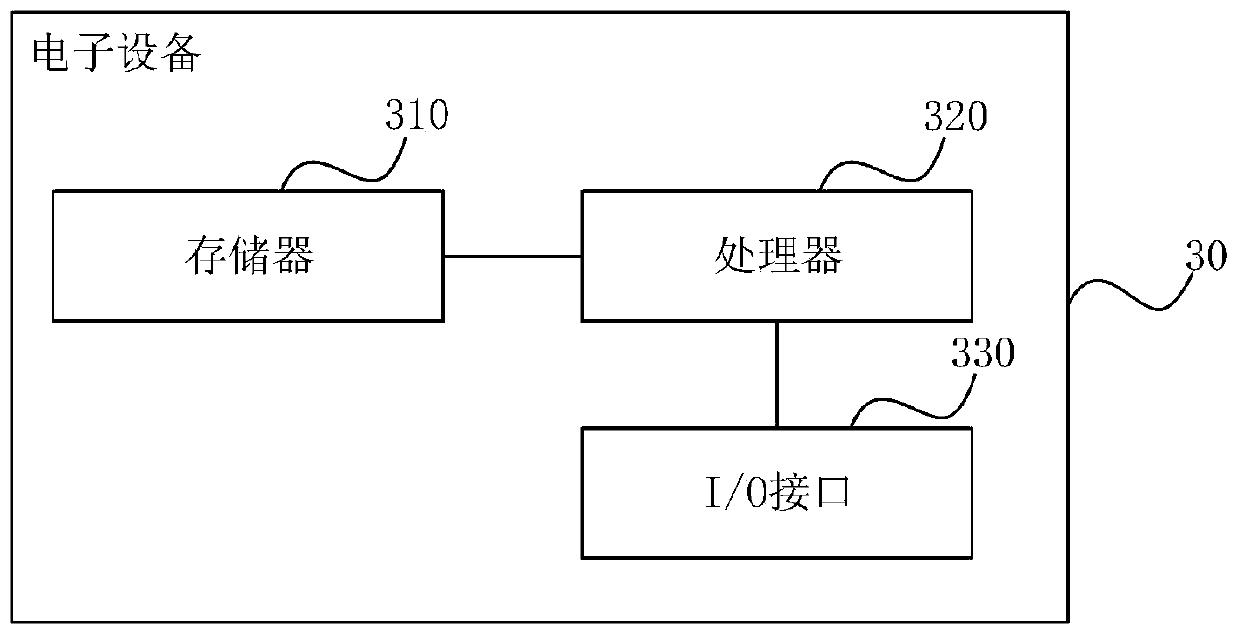

The invention relates to the technical field of image processing, and provides a multi-frame image fusion method and device. The multi-frame image fusion method comprises the following steps: a continuous image acquisition step: acquiring a plurality of continuously shot images; a reference frame selection step: selecting one reference frame image from the plurality of continuously shot images, and taking the rest as auxiliary images; a long exposure image obtaining step: obtaining a long exposure image through long exposure shooting; a registration step: respectively registering the long exposure image and the auxiliary image with the reference frame image; a region segmentation step: carrying out region segmentation on the registered long exposure image, and segmenting the long exposureimage into a texture region and a flat region; and an image fusion step: fusing the registered auxiliary images and the reference frame images according to the texture area and the flat area to obtaina result image. By using the infrared and visible light image fusion method, the image regions which may have the streaking phenomenon and do not have the streaking phenomenon are segmented and fused, so that the noise and the streaking phenomenon can be reasonably removed, and an image with high definition can be obtained.

Owner:MEGVII BEIJINGTECH CO LTD

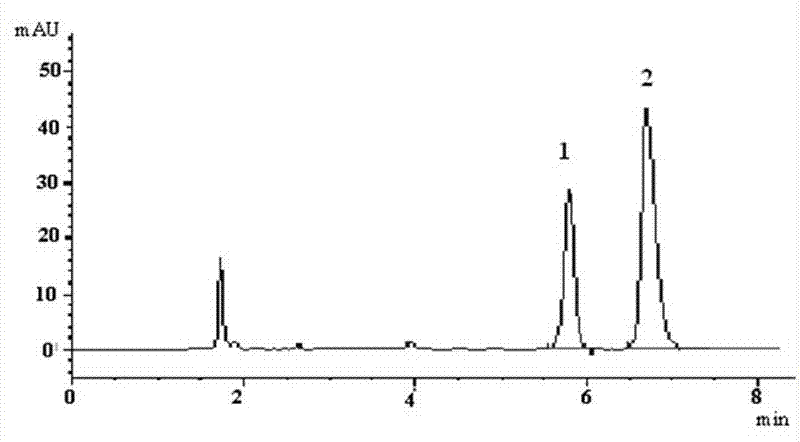

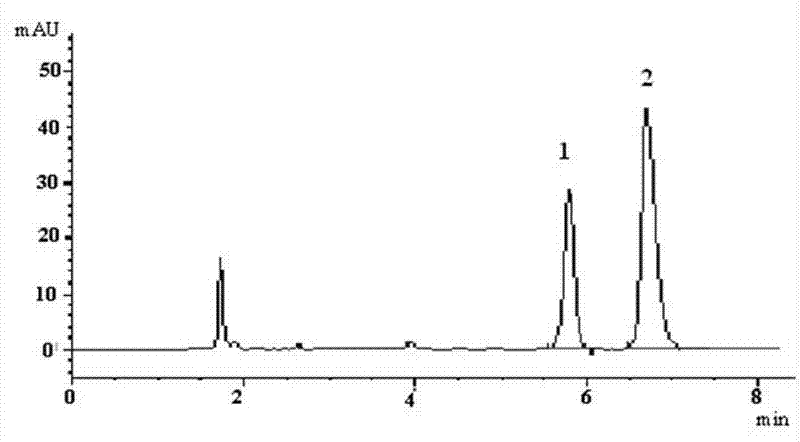

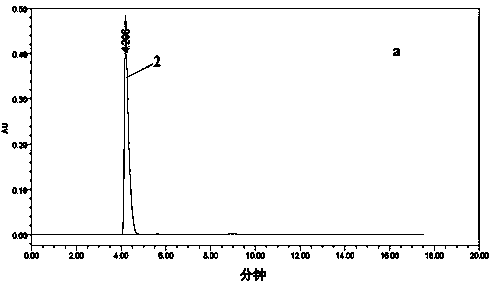

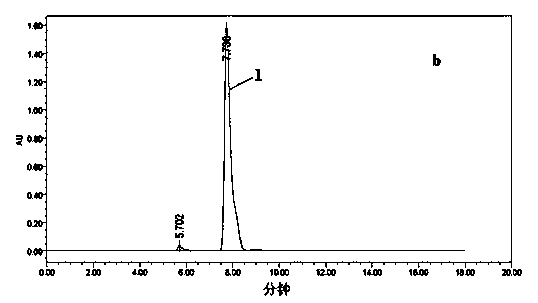

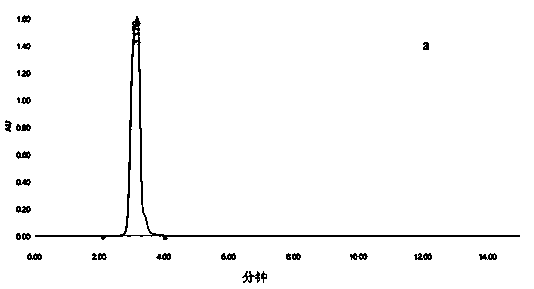

A kind of method for measuring paraquat blood concentration

InactiveCN102288696AEasy pretreatmentThe pre-processing process is simpleComponent separationParaquatBlood plasma

The invention discloses a method for measuring blood concentration of paraquat. The method comprises the following steps of: (1) pretreating a sample, namely adding aqueous solution of an internal standard substance and a protein precipitation agent acetonitrile into a plasma sample, performing whirl mixing, centrifuging and sampling supernatant; (2) separating the sample, namely adopting a universal C18 liquid chromatographic column, and using an ion pairing agent in an acid mobile phase, wherein the acid mobile phase is mixed solution of 3mmol.L<-1> aqueous solution of sodium dodecyl sulfate, 0.2 percent of aqueous solution of trifluoroacetic acid, acetonitrile and water; and (3) detecting by using a diode array detector, namely detecting by using the diode array detector at a detectionwavelength of 250 to 260nm, measuring peak areas of the internal standard substance and the paraquat, and calculating the blood concentration of the paraquat through least square method linear regression. The plasma sample is easy and convenient to pretreat, the detection process is sensitive and rapid, toxic substances and the blood concentration thereof can be rapidly determined in actual application, and the method is high in clinical application value.

Owner:HENAN UNIV OF SCI & TECH

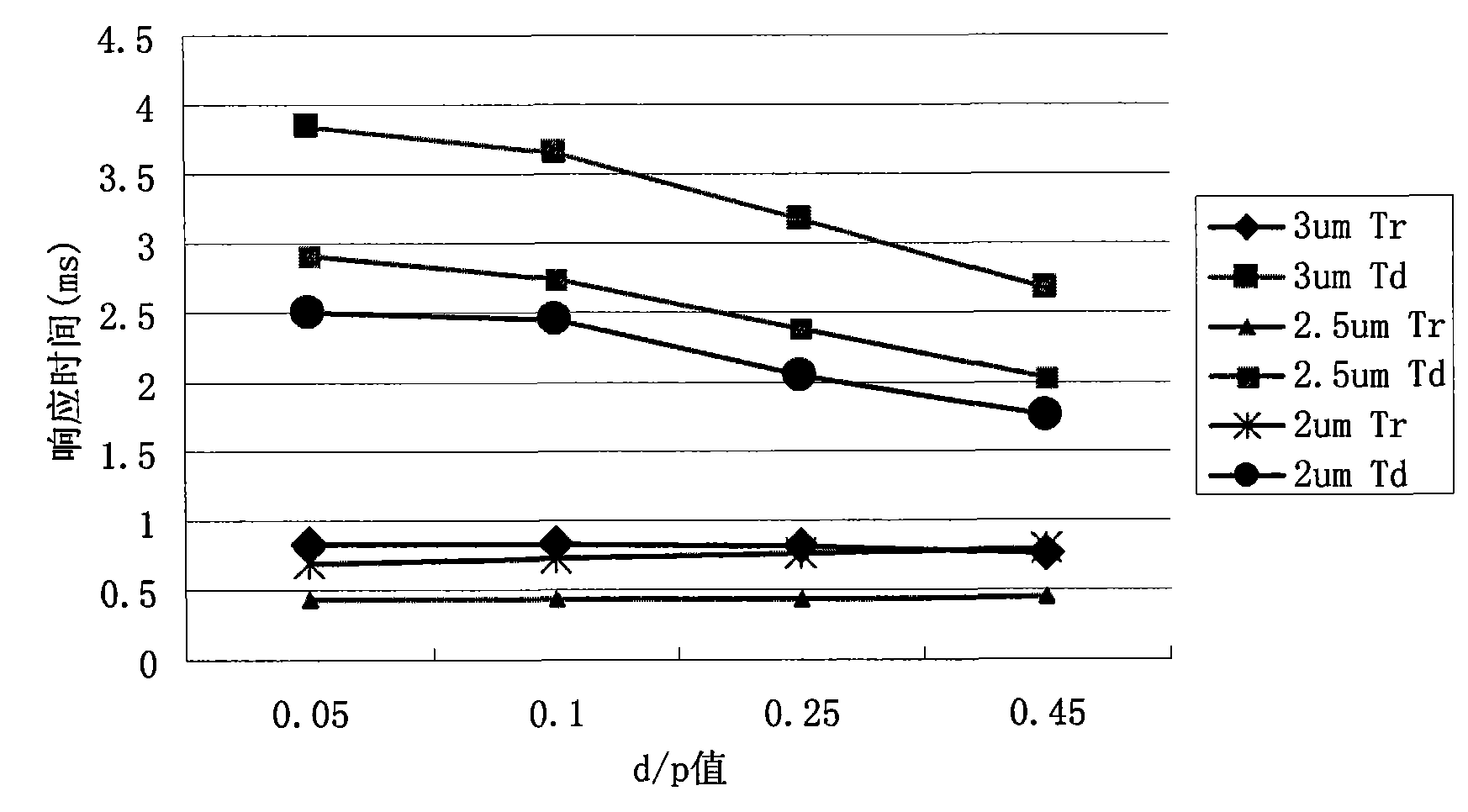

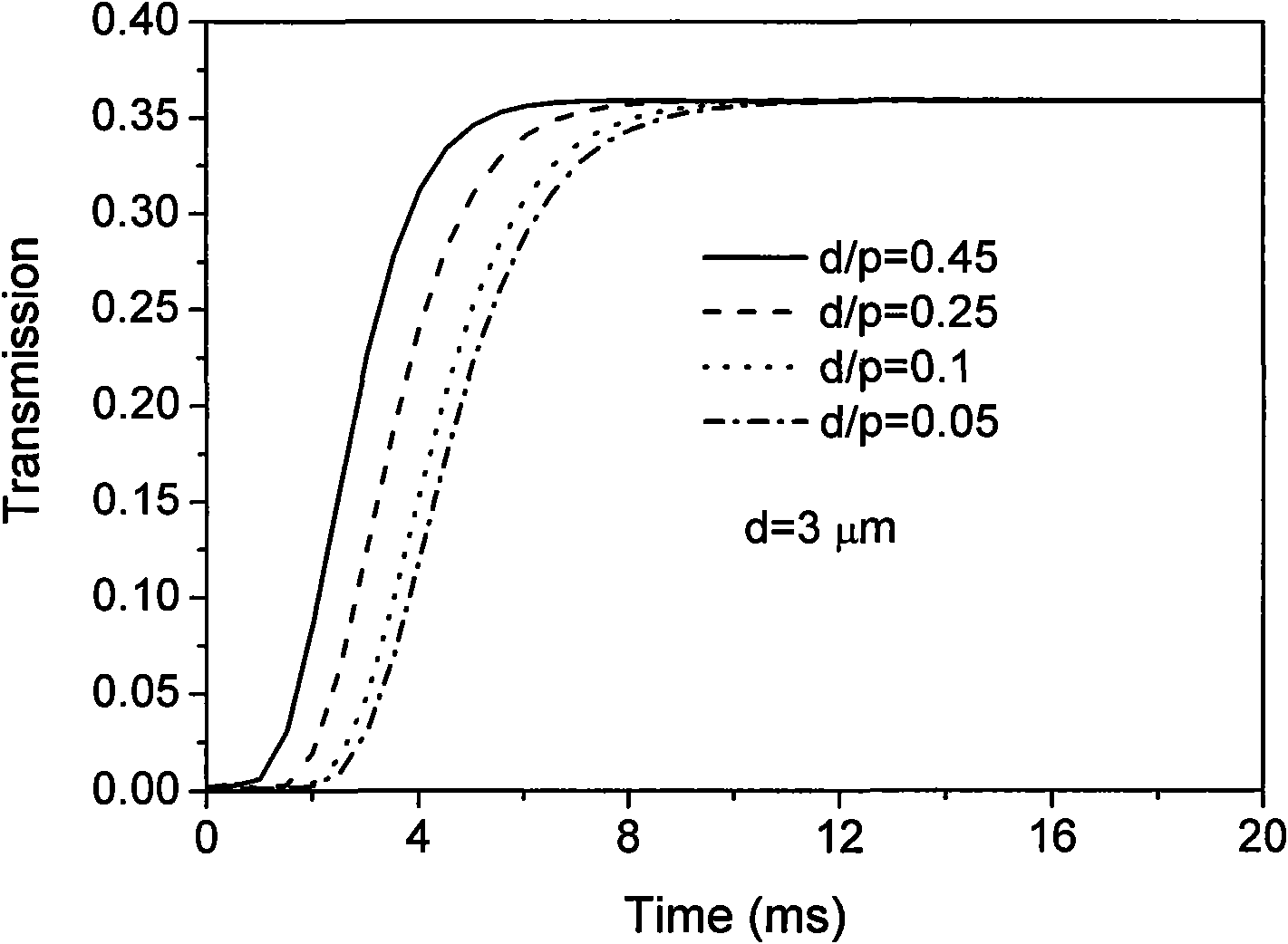

Quick response twisted nematic liquid crystal display and method

ActiveCN101644843AQuick responseAdapt to the requirements of field sequential color displayStatic indicating devicesNon-linear opticsLiquid-crystal displayDisplay device

Owner:SHENZHEN AV DISPLAY

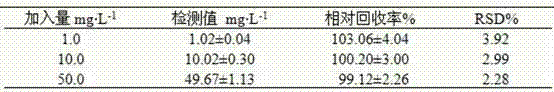

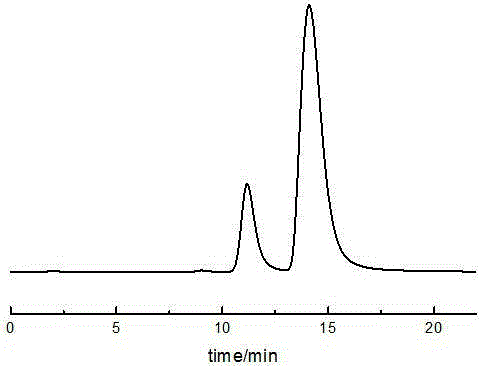

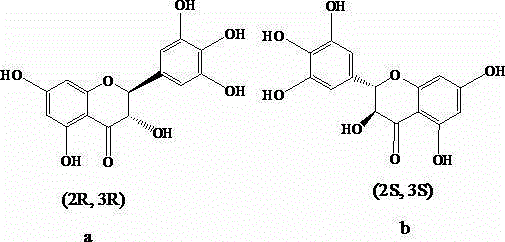

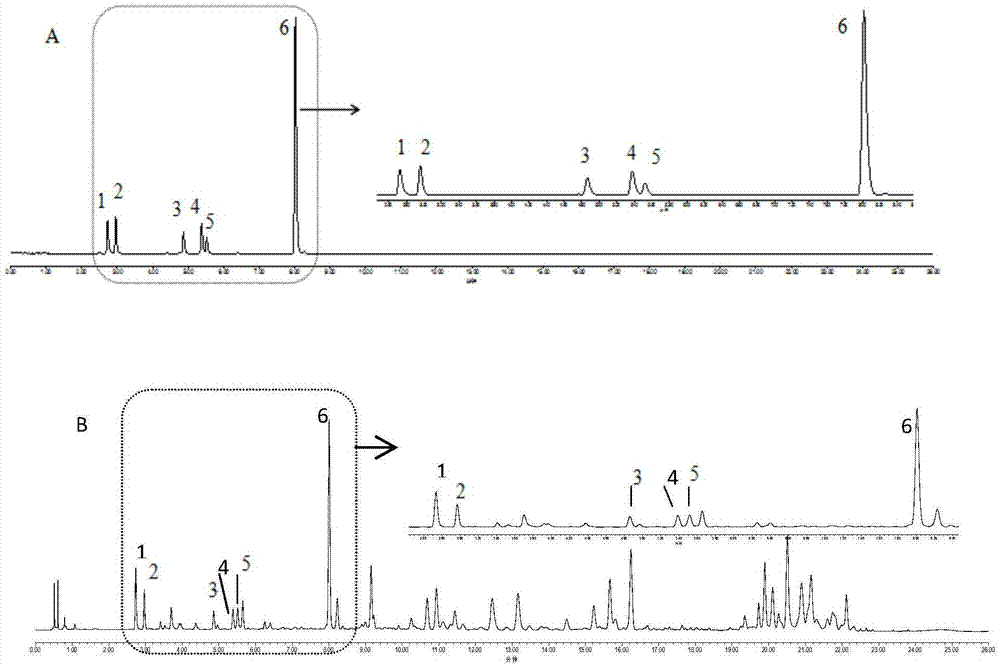

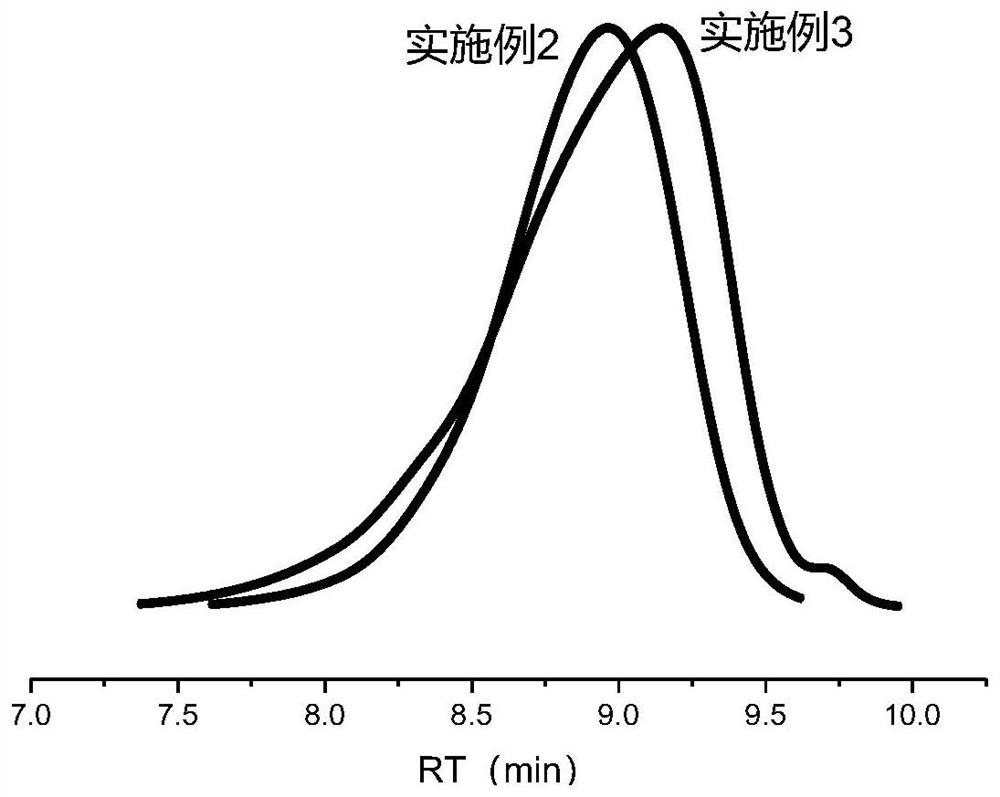

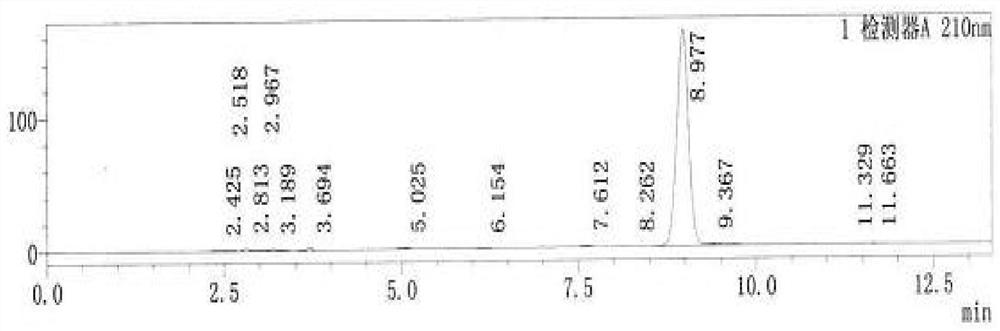

Chiral chromatographic separation and analysis method of dihydromyricetin enantiomer

ActiveCN105241982AGood chiral separationRapid Analysis DetectionComponent separationCelluloseChromatographic separation

The invention provides a chiral chromatographic separation and analysis method of dihydromyricetin enantiomer. The method comprises the following steps: dissolving a dihydromyricetin sample into the mobile phase, taking polysaccharide derivatives as the chiral stationary phase, and carrying out liquid chromatogram (LC) separation and analysis; wherein the mobile phase is a mixed solution of n-hexane and lower alcohols, and the polysaccharide derivative chiral stationary phase is one of stationary phases, which are individually covered by tri(3,5-dimethylphenylcarbamyl) straight-chain starch, tri((S)-(alpha)- phenylethylcarbamyl) straight-chain starch, tri(3,5- dimethylphenylcarbamyl)cellulose and tri(4- methylphenylcarbamyl)cellulose. According to the provided chiral separation and analysis method, the maximal separation degree of dihydromyricetin enantiomer is 1.95, and the maximal selection factor is 1.36.

Owner:GUANGDONG YANJIE PHARMA TECH CO LTD

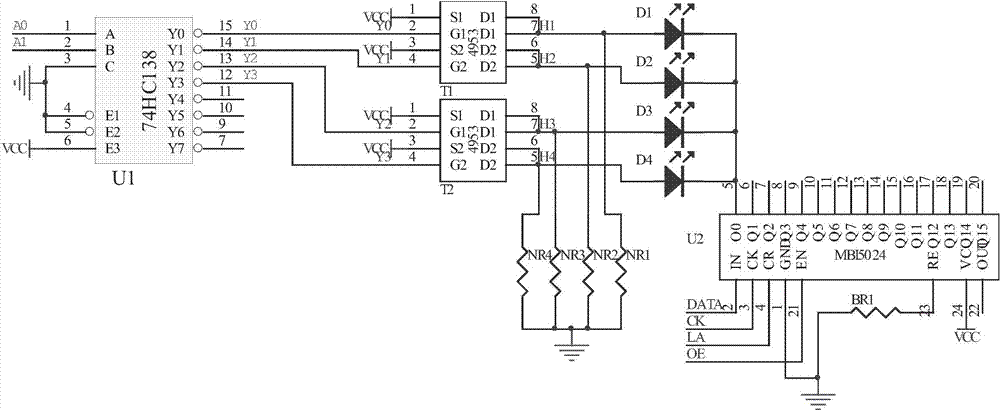

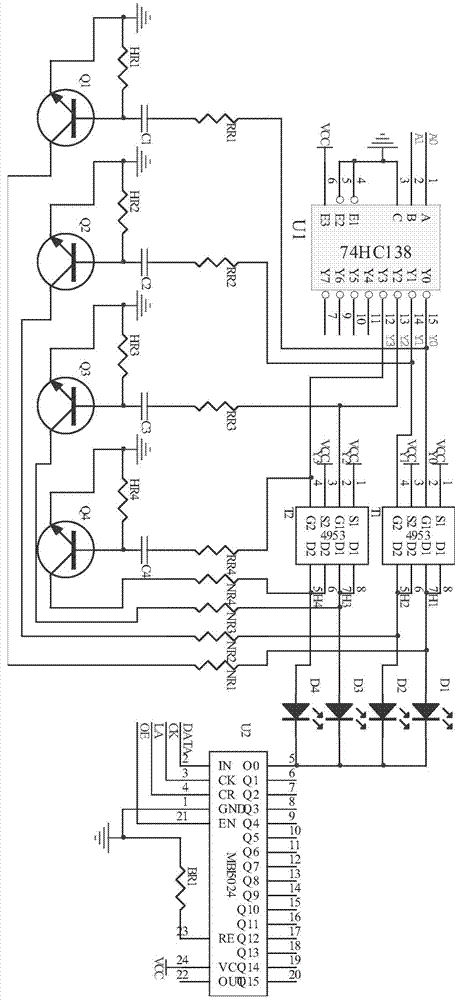

Non-control-lightening-free shadow elimination circuit for LED (Light Emitting Diode) display screen

The invention discloses a non-control-lightening-free shadow elimination circuit for an LED (Light Emitting Diode) display screen, which is arranged in a row driving circuit of the LED display screen arranged on a 1 / 4 scanning rank branch console. The non-control-lightening-free shadow elimination circuit is characterized in that a triode switching circuit is arranged among a row control line output end of a corresponding decoding chip, a row line output end of a field-effect tube and a public ground; when a level of the row control line output end is changed into a high level from an output low level, the row line output end is used for rapidly pulling a row power supply down; an isolation capacitor is charged and the connection with the public ground is switched off; device parameters are selected so that overlapping time of about 30ns exists between the front row and the next row in one frame of an image and the overlapping time is similar to the descending time of the row power supply. The circuit is simple and low in cost; the non-control lightening of LEDs on the other rows of the same line under the driving of the row power supply can be eliminated effectively; even if the non-control lightening of LEDs, caused by the electric leakage of the LEDs, happens, the trailing phenomenon of the LED display screen can be improved obviously so that human eyes cannot identify the effect that the front rows of the LEDs are slightly bright.

Owner:YAHAM OPTOELECTRONICS CO LTD

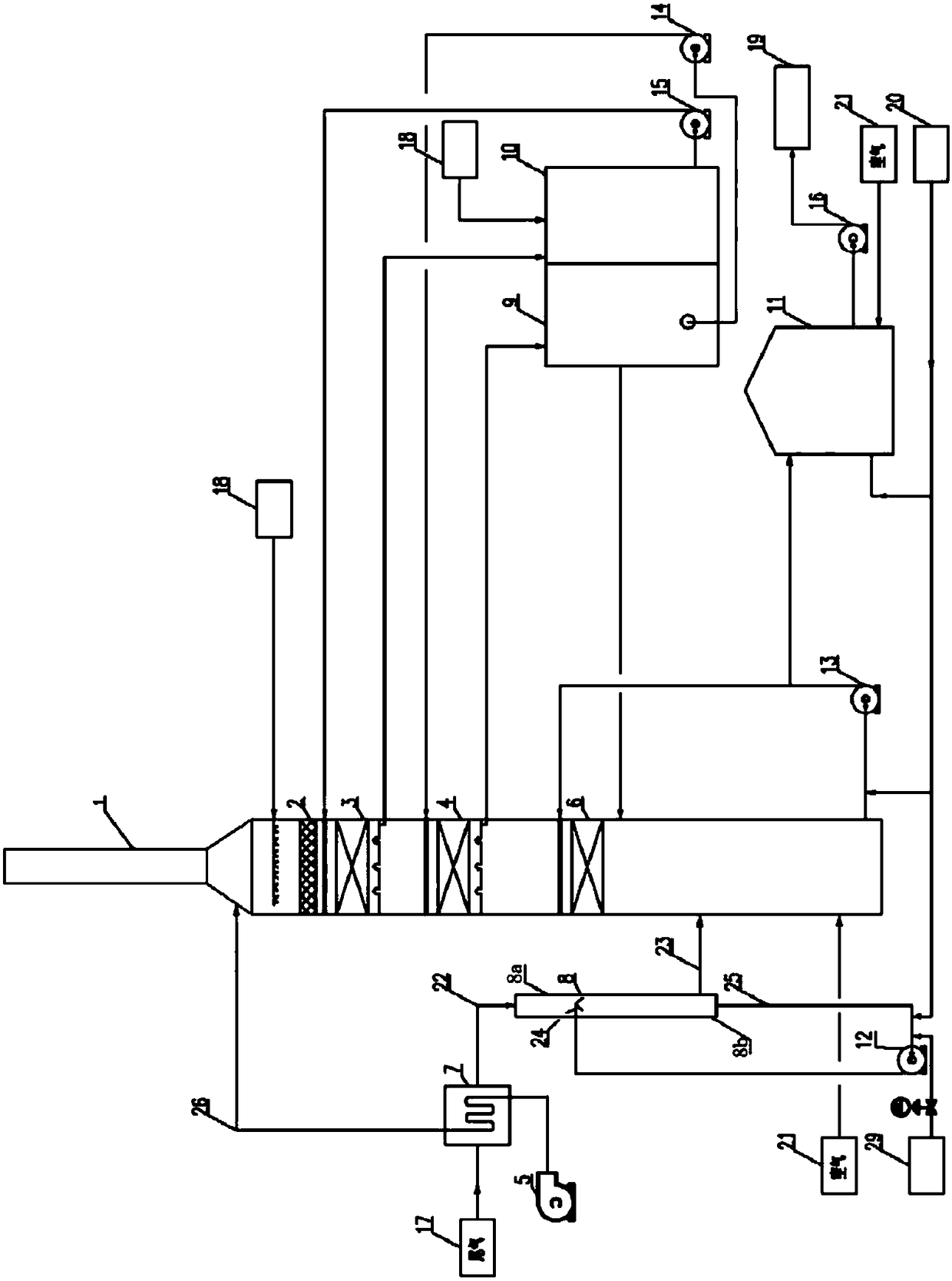

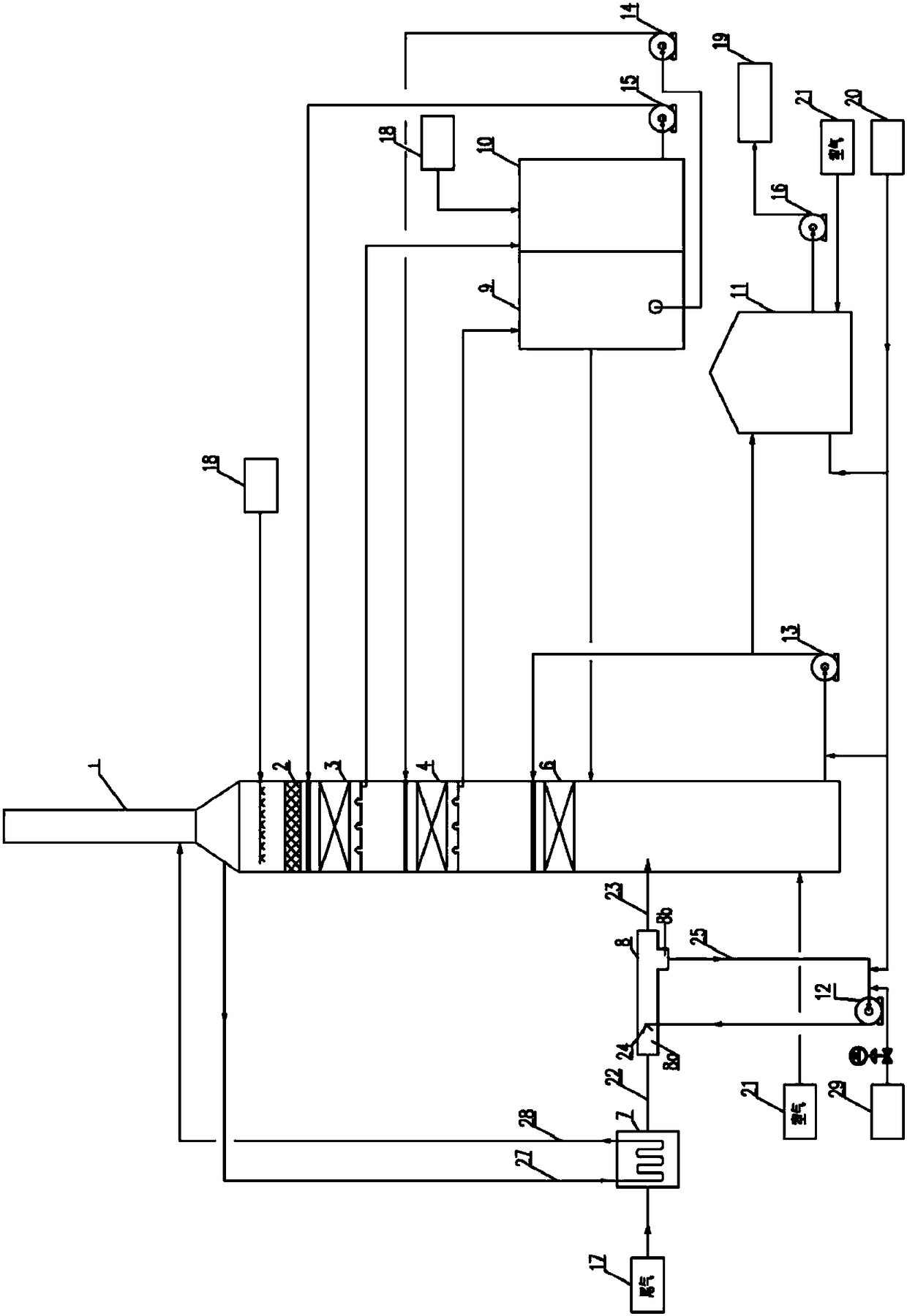

Flue gas desulfurizing system and method using flue gas desulfurizing system to desulfurize flue gas

ActiveCN108079762AImprove smearingHigh sodium salt solubilityGas treatmentLighting and heating apparatusParticulatesHigh concentration

The invention discloses a flue gas desulfurizing system. The flue gas desulfurizing system comprises a chilling section and an absorbing section which are mutually communicated by a connecting pipe, wherein the chilling section comprises a spraying area and a liquid storage tank which are mutually communicated; the spraying area is provided with a spraying layer, the liquid storage tank is positioned under the spraying area, and the spraying layer and the bottom part of the liquid storage tank are connected by a pipeline and a chilling circulation pump to form a chilling loop; a pipeline for connecting the chilling circulation pump and the liquid storage tank is provided with an alkaline liquid inlet, and the alkaline liquid inlet is connected with an alkaline liquid storage tank through aswitch valve. The invention also provides a method using flue gas desulfurizing system to desulfurize flue gas. The flue gas desulfurizing system has the advantages that the high-temperature tail gaswith higher concentration of SO2 (silicon dioxide) can be treated, the investment is low, the energy consumption is low, and the clean and environment-friendly effects are realized. A method has theadvantages that the operation is simple, the absorbing ability is strong, and the scaling and blockage of equipment can be avoided; the higher desulfurizing rate can be obtained with fewer circulationliquid, the exhausted flue gas is clean, any inorganic particulate matter is basically not contained, the trailing white smoke is avoided, and the haze weather is not formed.

Owner:SINOPEC NANJING ENG & CONSTR +1

Chlorate oxygen column as ignitor and production thereof

ActiveCN1817824AIncrease oxygen contentMature and stable manufacturing processExplosivesOxygenPotassium perchlorate

An ignition medicine with chlorate oxygen column and its production are disclosed. The ignition medicine consists of sodium chlorate 30~50% with grain size 60~300 meshes, lithium hyperchlorate or sodium perchlorate 10~30% with grain size 60~300 meshes, barium dioxide 0.1~6% with grain size 80~200 meshes, metal oxide ironic oxide or cuprous oxide 5~9% with grain size 20~200 meshes, metal powders 15~25% with grain size 100~300 meshes and cobalt salt 5~15% with grain size 40~200 meshes. It has shorter gas-take time and higher starting success probability of engine.

Owner:中国航天科技集团公司第四研究院第四十二所

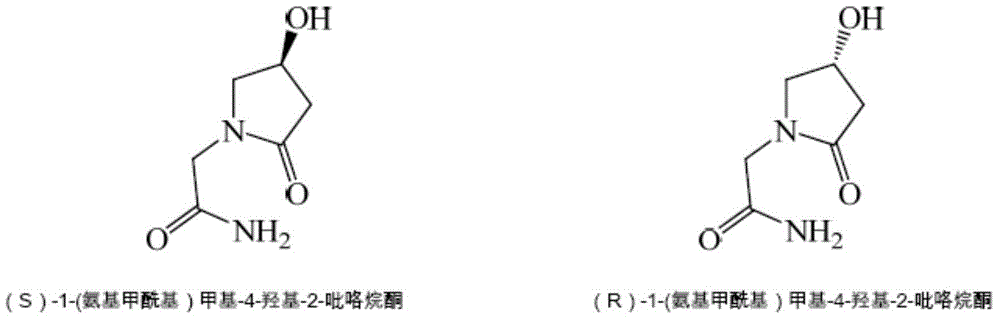

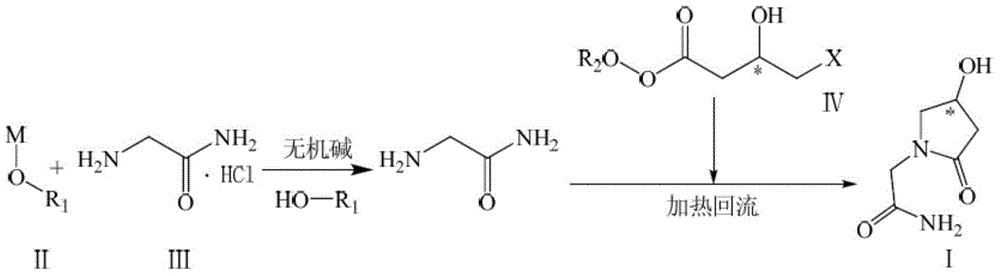

Preparation method of optically active pure 1-(carbamoyl)methyl-4-hydroxy-2-pyrrolidone

ActiveCN105820101AImprove the efficiency of dissociation reactionAvoid destructionOrganic chemistry4-hydroxy-2-pyrrolidoneGradient elution

The invention relates to a preparation method of optically active pure 1-(carbamoyl)methyl-4-hydroxy-2-pyrrolidone. According to the method, optically active pure 4-halo-3-hydroxybutyrate and glycinamide hydrochloride are used as raw materials to synthesize optically active pure 1-(carbamoyl)methyl-4-hydroxy-2-pyrrolidone. By mixed bases feeding improved synthetic reaction, preparative silica gel packed column chromatography and gradient elution improved refining technology, the optically active pure 1-(carbamoyl)methyl-4-hydroxy-2-pyrrolidone product with its purity being greater than or equal to 99.5% can be obtained without recrystallization. In addition, yield is high, technological conditions are stable and controllable, operation is safe, simple and convenient, and three industrial wastes hardly exist. The preparation method is suitable for industrial large-scale production.

Owner:HARBIN SANLIAN PHARMA CO LTD

Skin care products for neck and preparation technique thereof

InactiveCN101259095AIncrease firmnessIncrease elasticityCosmetic preparationsToilet preparationsElastomerWrinkle skin

The invention relates to a neck skin care product and a preparation technique thereof. The proportioning for the components of neck skin care product is scientific and reasonable; the neck skin care product comprises active ingredients of Limnanthes Alba seed oil (meadowfoam seed oil), palmitoyl pentapeptide, soliquoid of organosilicone elastomers, etc., and the preparation of the neck skin care product aims at caring the neck skin of pregnant women and lying-in women that is characterized by hydropenia and easy aging caused by escalatory secretion of thyrotropin and corticotrophin; the neck skin care product has prominent anti-oxidation and free radical capturing properties, and is not greasy with strong permeability, obviously reinforcing the synthesis of elastin and collagen protein of the skin, smoothening the wrinkles and promoting skin elasticity; meanwhile, the neck skin care product ensures the skin moist and silken texture and covers the fine wrinkles of the neck; through the synergistic effect on the skin from endothecium to surface, the neck skin care product is capable of promoting the elasticity of the skin, preventing the loss of moisture, supplying moisture and nutrition inside the skin simultaneously, and ensuring the skin of the neck to be healthier and more lustrous.

Owner:天津盛世永业科技发展有限公司

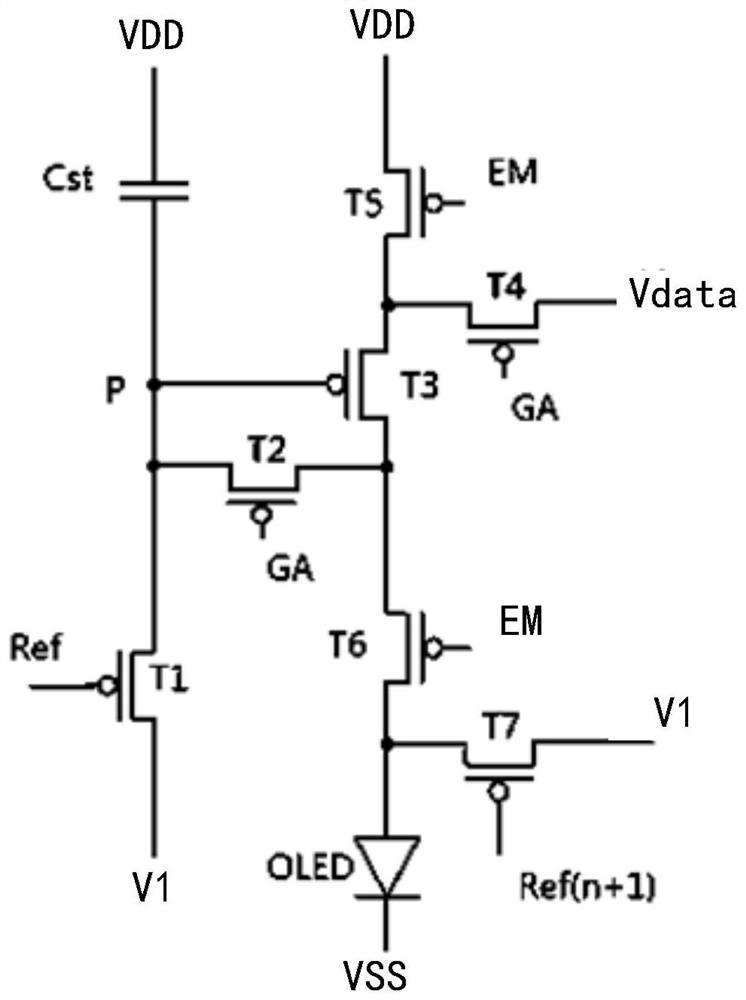

Display device and driving method and driving device thereof

ActiveCN113450711AIncrease the ratio of display brightnessGuaranteed Brightness RatioStatic indicating devicesComputer hardwareComputer graphics (images)

The invention provides a display device and a driving method and a driving device thereof, relates to the technical field of display, and aims to solve the problem that the brightness of a high-gray-scale display picture in a first frame is lower than normal brightness when the display picture of the display device is switched from a low gray scale to a high gray scale. The driving method of the display device comprises the following steps of switching the display device from an mth gray-scale picture to an nth gray-scale picture, wherein m is more than or equal to 0 and less than or equal to 255; the step specifically comprises the following steps: under the condition of a target brightness display mode, obtaining a data difference value between a data voltage corresponding to an mth gray-scale picture and a data voltage corresponding to an nth gray-scale picture of a sub-pixel; judging whether the data difference value is larger than a preset difference value or not, and if the data difference value is larger than the preset difference value, when the display device is switched from the mth gray-scale picture to the nth gray-scale picture, controlling the sub-pixels to display a non-first-frame display picture in the nth gray-scale picture. The driving method provided by the invention is used for driving the display device to display.

Owner:BOE TECH GRP CO LTD +1

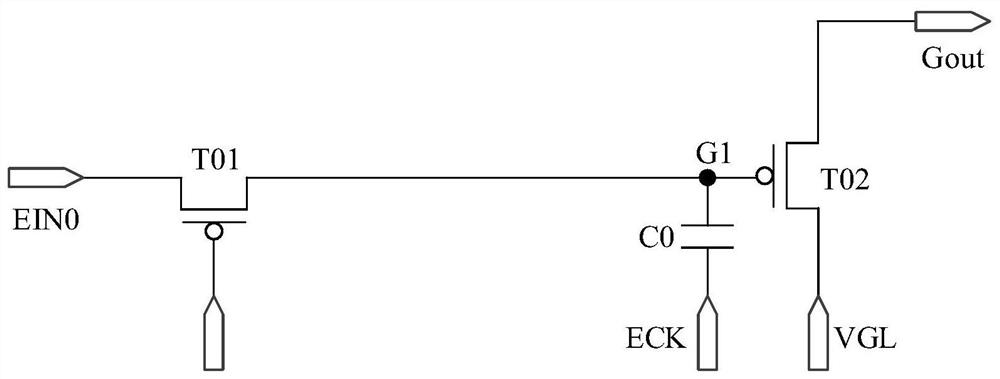

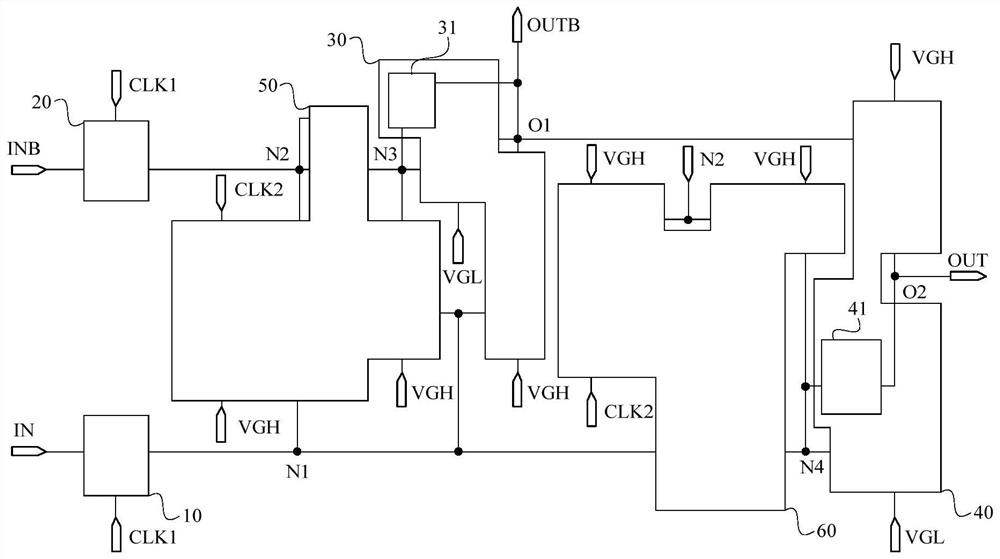

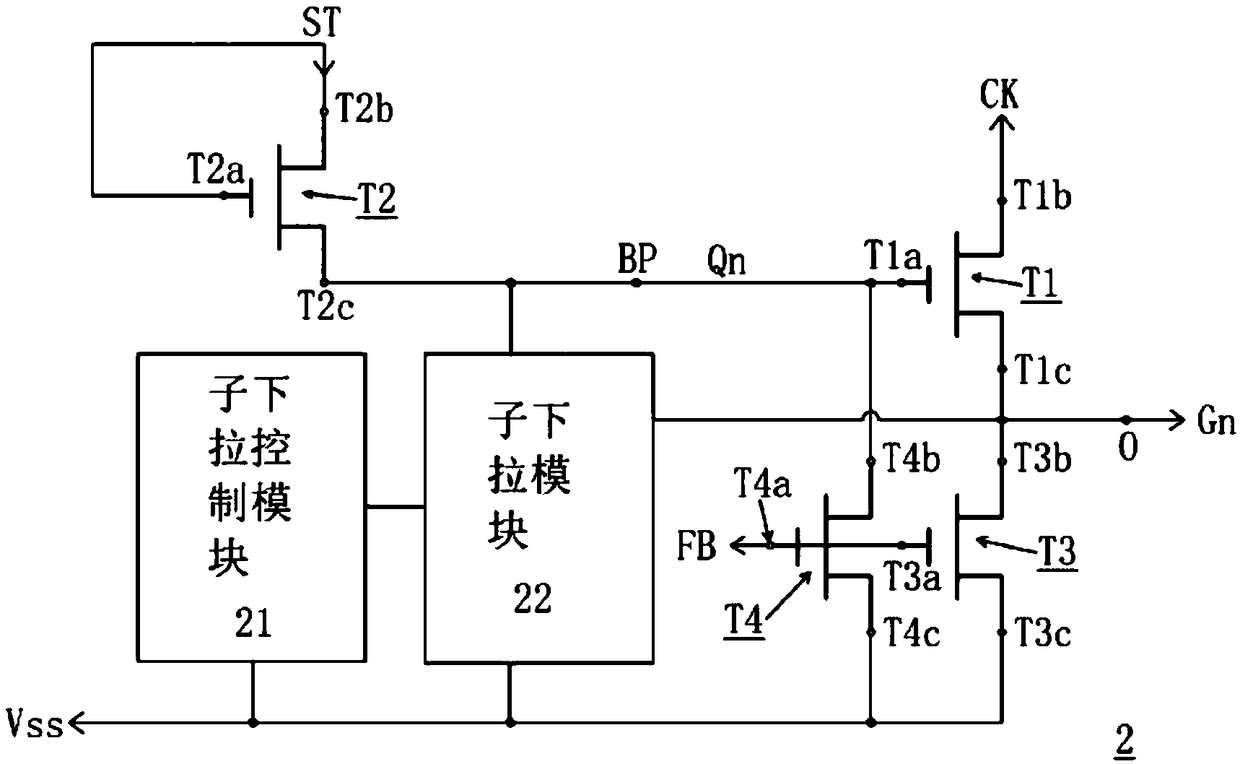

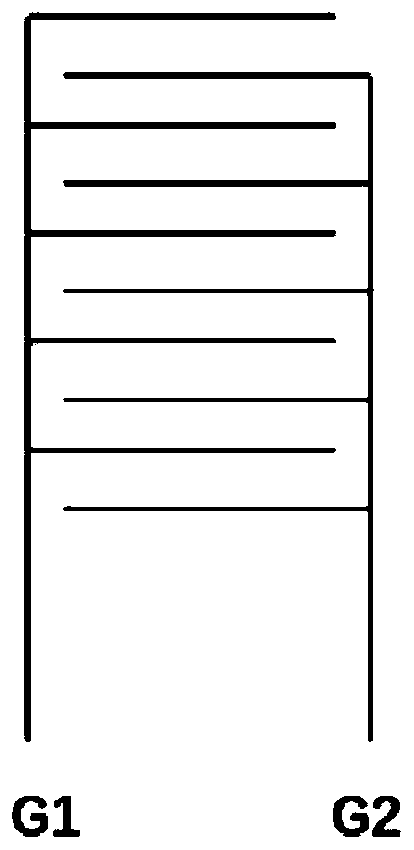

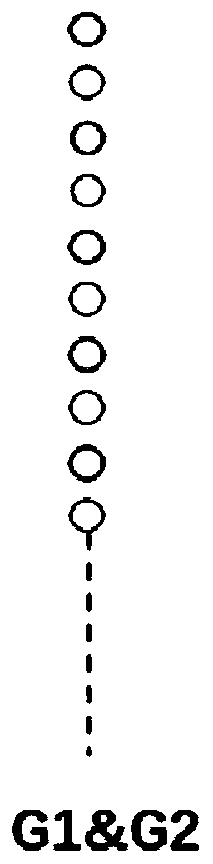

Shift register, gate drive circuit and display panel

ActiveCN112687230AReduce level lossReduce smearingStatic indicating devicesDigital storageShift registerDriver circuit

The embodiment of the invention discloses a shift register, a gate drive circuit and a display panel. The shift register comprises a first input module, a second input module, a first output module, a second output module, a first output control module and a second output control module. The first input module controls the potential of the first node according to the first starting signal and the first clock signal; the second input module controls the potential of a second node according to a second starting signal and the first clock signal, wherein the potential of the second starting signal is opposite to that of the first starting signal; the first output module comprises a first coupling unit, and the first coupling unit couples the potential of the third node according to the potential of the first output end when the potential of the first output end jumps; and the second output module comprises a second coupling unit, and the second coupling unit couples the potential of the fourth node according to the potential of the second output end when the potential of the second output end jumps.

Owner:YUNGU GUAN TECH CO LTD

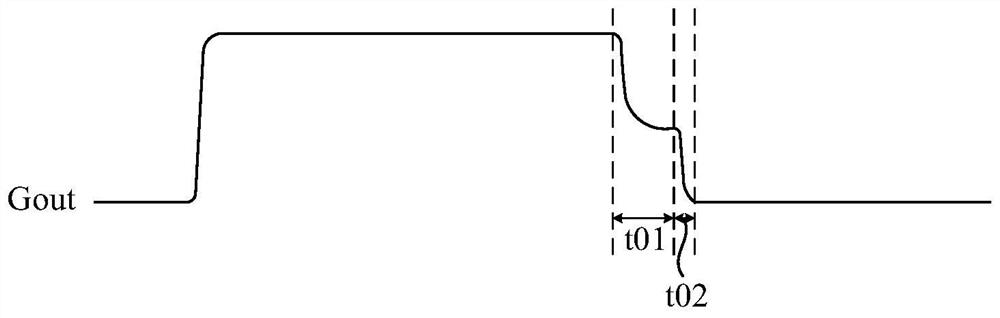

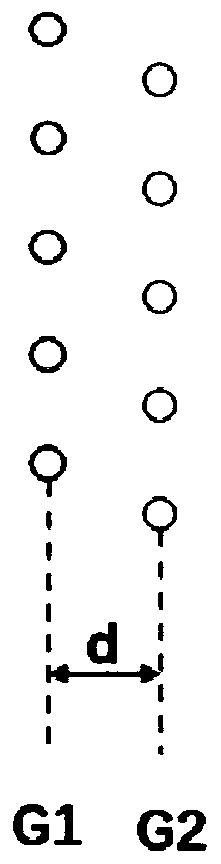

Display device and shift temporary storage circuit

ActiveCN108877713AAccurate and smooth outputImprove smearingStatic indicating devicesDigital storageCouplingDisplay device

The invention proposes a display device and a shift temporary storage circuit therefor. The shift temporary storage circuit comprises a multistage shift temporary storage unit, wherein one shift temporary storage unit at any stage comprises the following modules: an input module, wherein an input stage transmits a signal to a boost node; a coupling pull-up module which generates a first pull-up signal and pulls the level of the voltage signal to a second level from the first level; an output module which performs the coupling and pulling-up of the level of the voltage signal to the third levelfrom the second level according to a clock signal, and outputs a grid scanning signal through an output end, wherein the coupling pull-up module generates a second pull-up signal when the pulse of the clock signal is finished, and the second pull-up signal acts on the boost node in a coupling manner, so as to enable the voltage signal to remain at the second level; a feedback module which receives a feedback signal, and pulls the level of the voltage signal and the level of the grid scanning signal to a preset low level.

Owner:HKC CORP LTD

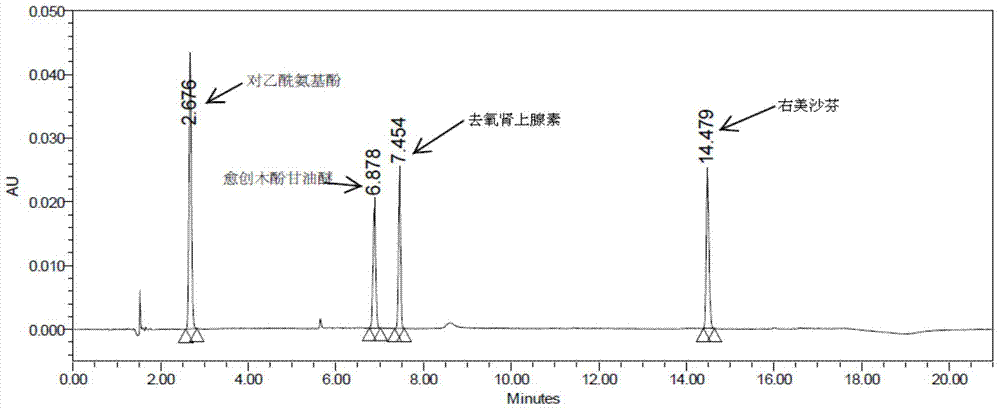

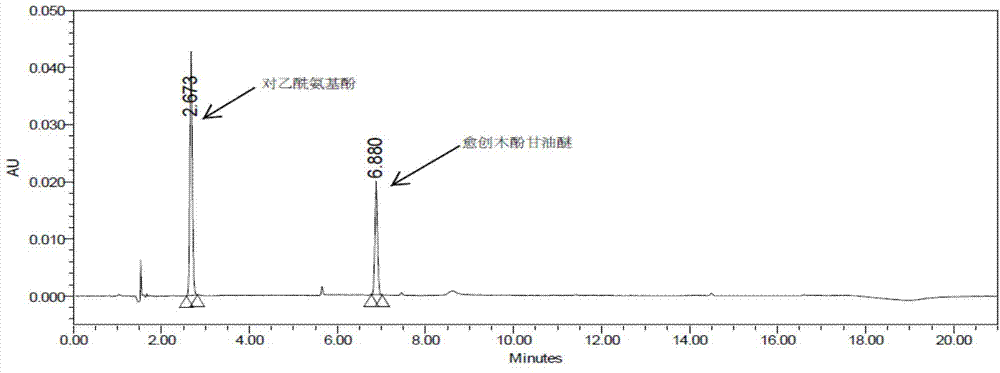

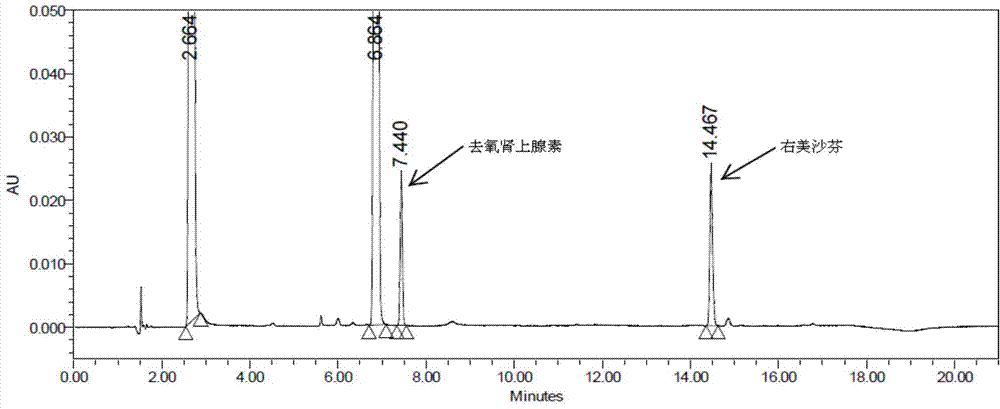

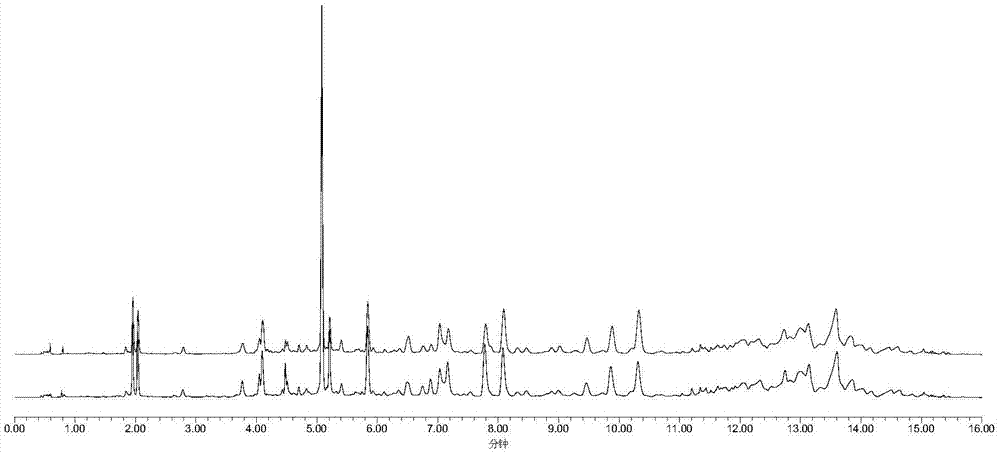

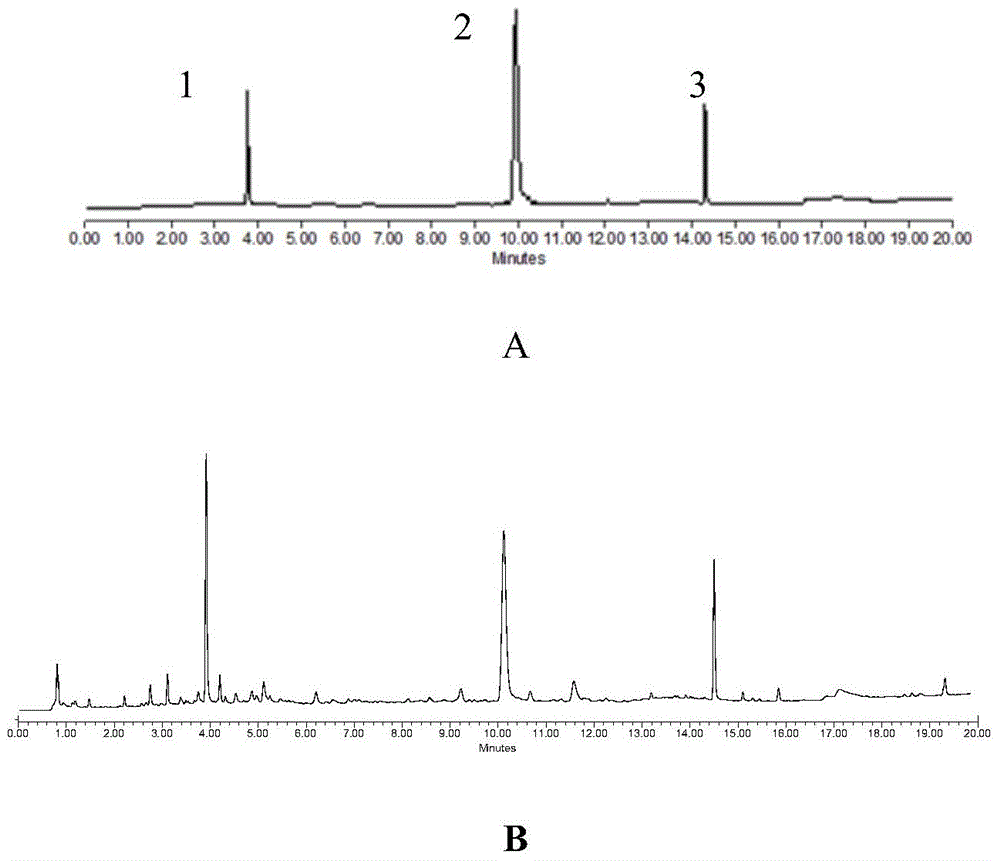

Method for analyzing daytime severe cold and flu capsules by high performance liquid chromatography

The invention discloses a method for analyzing daytime severe cold and flu capsules by high performance liquid chromatography. The daytime severe cold and flu capsules contain acetaminophen, phenylephrine hydrochloride, dextromethorphan hydrobromide and guaifenesin; high performance liquid chromatography analysis conditions are as follows: a chromatographic column adopts an octadecyl silane bonded silica gel column, a sodium octanesulfonate containing 0.1v% triethylamine is used as a mobile phase A, and acetonitrile is used as a mobile phase B. The method can efficiently and simultaneously detect four effective components in the daytime severe cold and flu capsules; furthermore, the method is easy to operate, high in analysis speed, high in repetitiveness and extremely high in specificity; the product quality of a daytime severe cold and flu capsule preparation can be relatively efficiently and comprehensively controlled.

Owner:HUMANWELL PURACAP PHARM WUHAN CO LTD

Method for determining contents of rhynchophylline and isorhynchophylline in Xiao'er Qixingcha granules

The invention discloses a method for determining contents of rhynchophylline and isorhynchophylline in Xiao'er Qixingcha granules. The method comprises the following steps: (1) preparing a mixed reference: weighing an appropriate amount of rhynchophylline and isorhynchophylline, accurately weighing, and adding methanol to prepare the mixed control of the rhynchophylline and the isorhynchophylline;(2) preparing a test: accurately weigh the Xiao'er Qixingcha granules, adding hot water for dissolving, carrying out ultrasonic treatment, standing for cooling, adjusting the pH value with ammonia water, then shaking and extracting with ethyl acetate, recovering the ethyl acetate liquid, and adding the methanol for dissolving residues; (3) determining by using a high performance liquid chromatography: using octadecyl silane bonded silica gel as a chromatographic column of a filling agent; mobile phase: acetonitrile (A): 0.02-0.07% diethylamine-(7-10) mM ammonium acetate (B) = (40-60) to (60-40) V / V; flow rate: 0.8-1.2mL / min; elution time: 35-60 minutes; column temperature: 25-35 DEG C; detection wavelength: 240-250nm. The content determination method is simple to operate, and can accurately reflect the real content of a product, thus being suitable for industrial daily production inspection.

Owner:GUANGZHOU WANGLAOJI PHARM CO LTD

UPLC determination method for polygala root

ActiveCN106918655AAdvantages of high-throughput analysisShort analysis timeComponent separationSucroseHplc mass spectrometry

The invention relates to an UPLC determination method for a polygala root. The method comprises the following steps: step 1, preparation of a control solution: weighing sibiricose A5, sibiricose A6, sibiricaxanthone B, glomeratose A, polygalaxanthone III and 3,6'-disinapoyl sucrose, and fixing a volume by using methanol so as to prepare the mixed control solution; step 2, preparation of a test solution: extracting the medicinal material polygala root with water-containing lower alcohol and carrying out filtering so as to obtain the test solution; and step 3, determination: separately injecting the mixed control solution and the test solution into an ultra-high performance liquid chromatograph so as to obtain chromatograms and calculating the contents of active components in a test substance according to the chromatograms.

Owner:TIANJIN TASLY MORDEN TCM RESOURCES

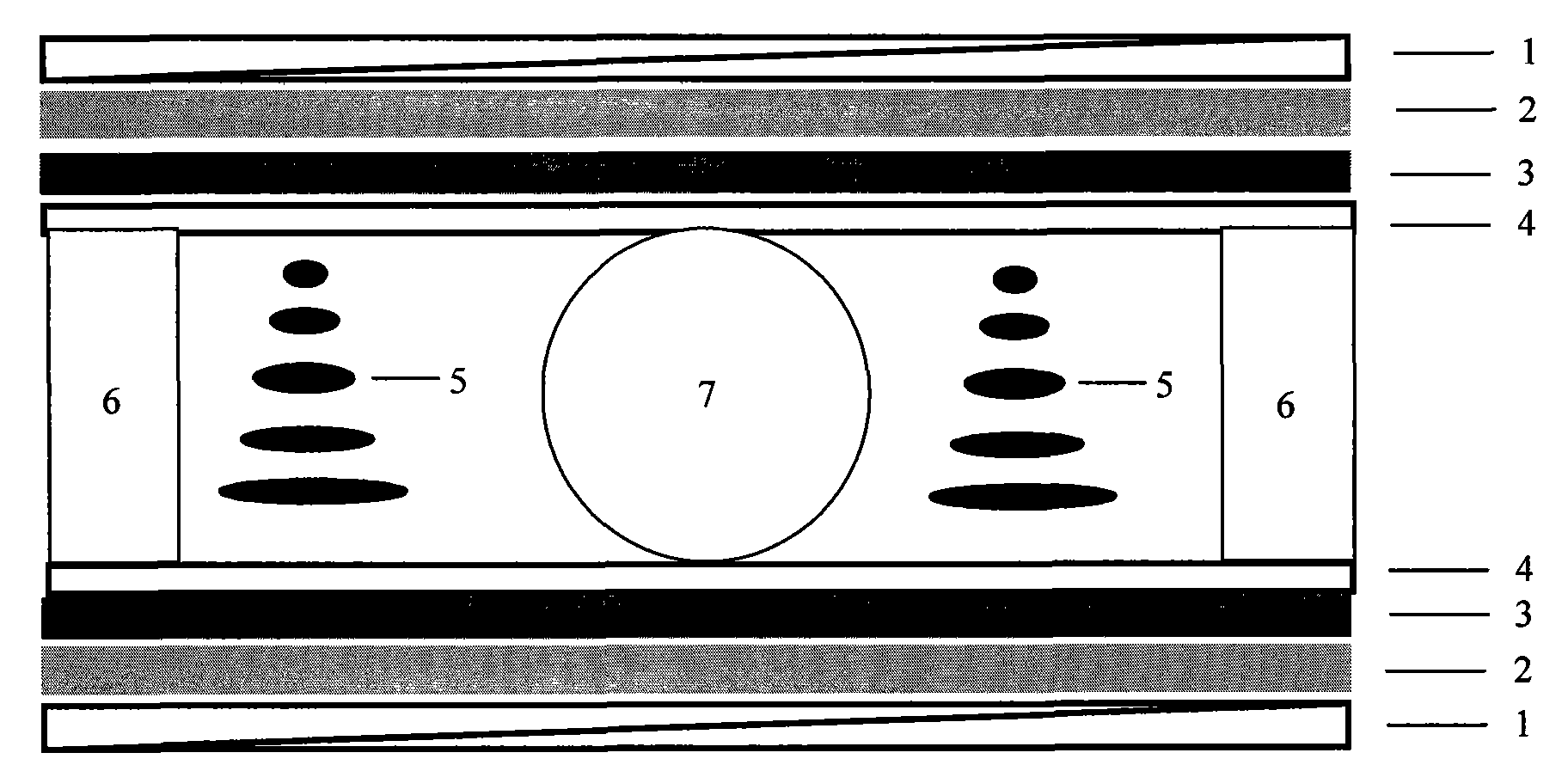

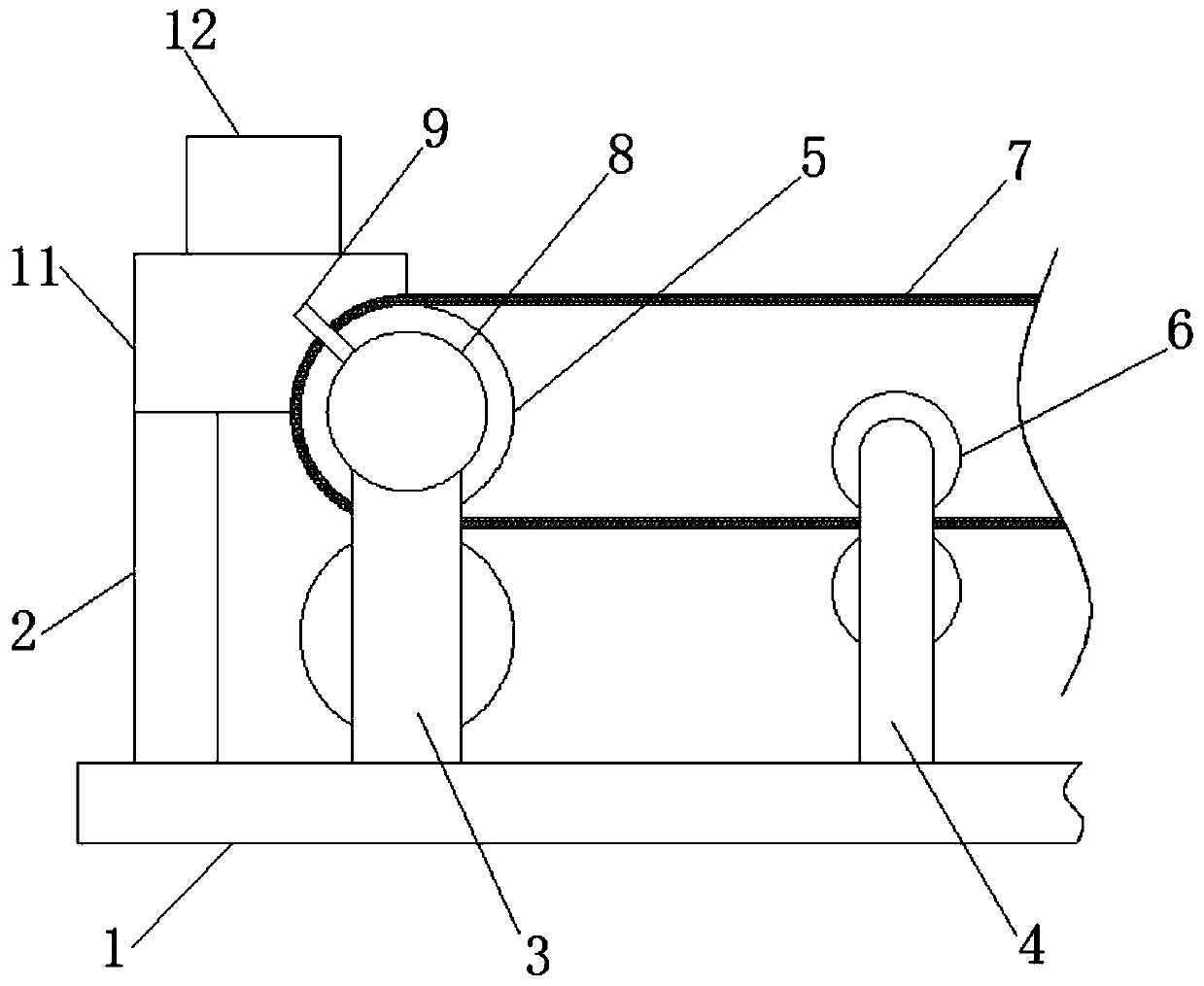

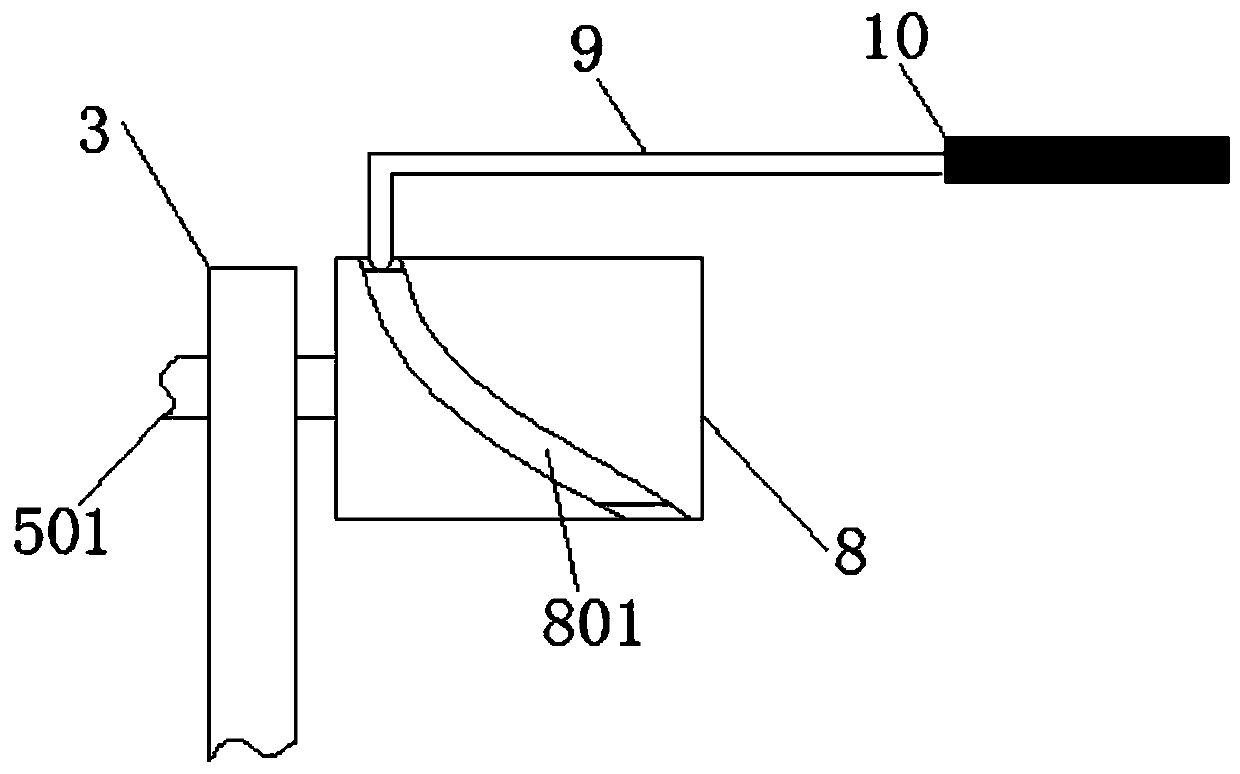

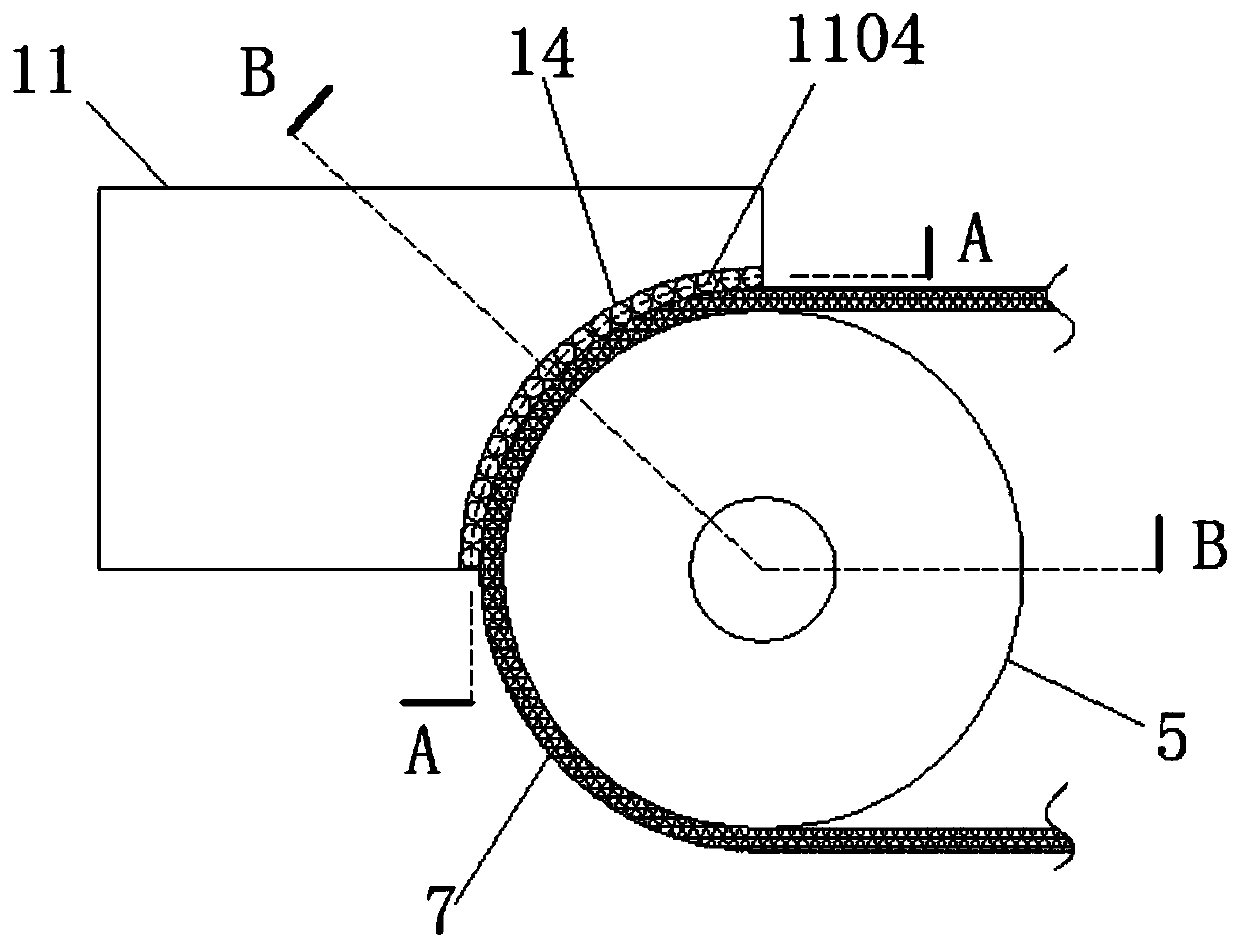

High precision smearing and quantitative sizing device for textile fabric

InactiveCN111020910ASolve complexitySmudge range can be adjustedTextile treatment machine arrangementsLiquid/gas/vapor textile treatmentReciprocating motionEngineering

The invention relates to the technical field of textile fabric, and discloses a high precision smearing and quantitative sizing device for textile fabric. The device includes a pedestal, wherein an arc-shaped pathway is formed on the outer side of a drum, a sliding rod is connected to the outer side of the drum; a magnetic plate is connected to the rear end of the sliding rod; steel balls are arranged in a feeding device; rubber balls are connected to the interior of the feeding device; and spherical magnets are arranged in the rubber balls. A feed roller and the drum are driven to rotate viaa drive shaft in the feed roller, and a sliding rod in the arc-shaped pathway is driven to intermittently move forwards and backwards via the drum, so that slurry in a slurry storage slot is uniformlyextruded into a round slot via through holes; the spherical magnets and the rubber balls are driven to move left and right via the magnetic plate, the steel balls are extruded by the rubber balls, and the slurry in the round slot falls onto the fabric and uniformly and flatly smeared on the fabric via reciprocating motion of the steel balls; via such a structure, the problem that the existing textile fabric smearing device cannot smear quantitatively and is nonuniform in smearing is solved.

Owner:郑丽丽

Method for analyzing content of A beta plaque developer precursor AV45

The invention relates to a method for analyzing the content of an A beta plaque developer precursor AV45, belonging to the technical field of apparatus analysis. An 18F-AV45 is capable of identifying an A beta plaque pathological state in the brain of an AD (Alzheimer Disease) patient in vivo, is used for visualized and quantitative research of an amyloid protein deposition process of a human body, and moves towards the clinical. A high-purity precursor AV45 needs to be obtained if a higher radiochemical purity PET (Positron Emission Tomography) developer 18F-AV45 is obtained. According to the method, the chromatography condition is as follows: a WATERS 600 type high performance liquid chromatograph, a 2487 ultraviolet detector, a chromatographic column Inertsil C18 column, 5 micrometers and 4.6*250mm; a flowing phase is as follows: a ratio v / v of 50mM disodium hydrogen phosphate to acetonitrile is 15-85, and 0.01 percent triethylamine is added; the flowing speed is 0.8mL / min; the AV45 sample feeding volume is 10mu L; the column temperature is the room temperature; and the detection wavelength is 325nm. According to the method, phosphate is used as a buffering agent, and the triethylamine is added, so that the trailing phenomenon is improved, and the peak symmetry is better. Compared with a literature method, the method has the advantages that the number of theoretical plates and the separation degree are greatly improved, and all impurities are separated well. Various impurities can be effectively detected by using 325nm detection.

Owner:JIANGSU INST OF NUCLEAR MEDICINE

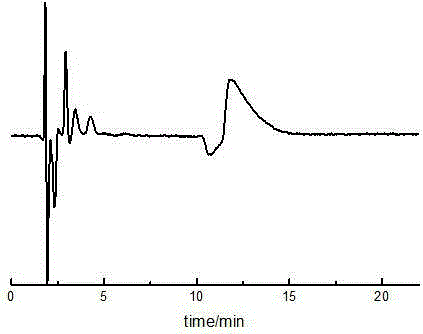

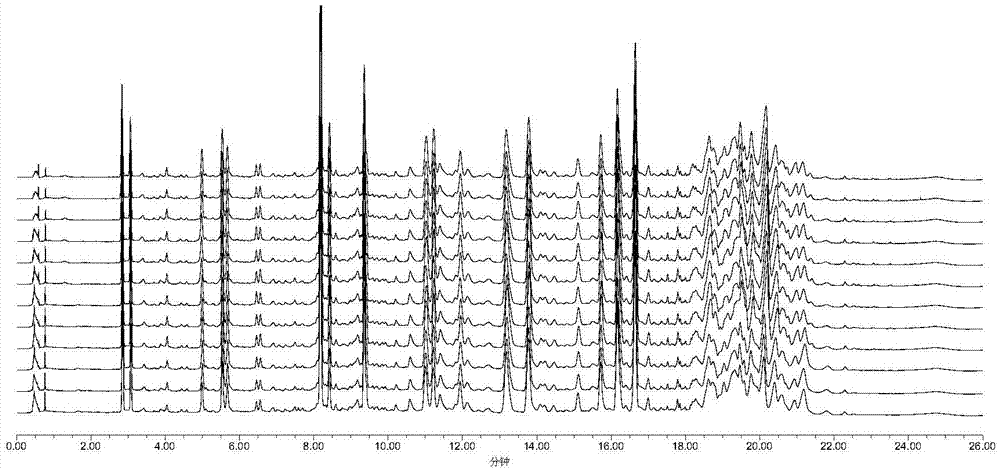

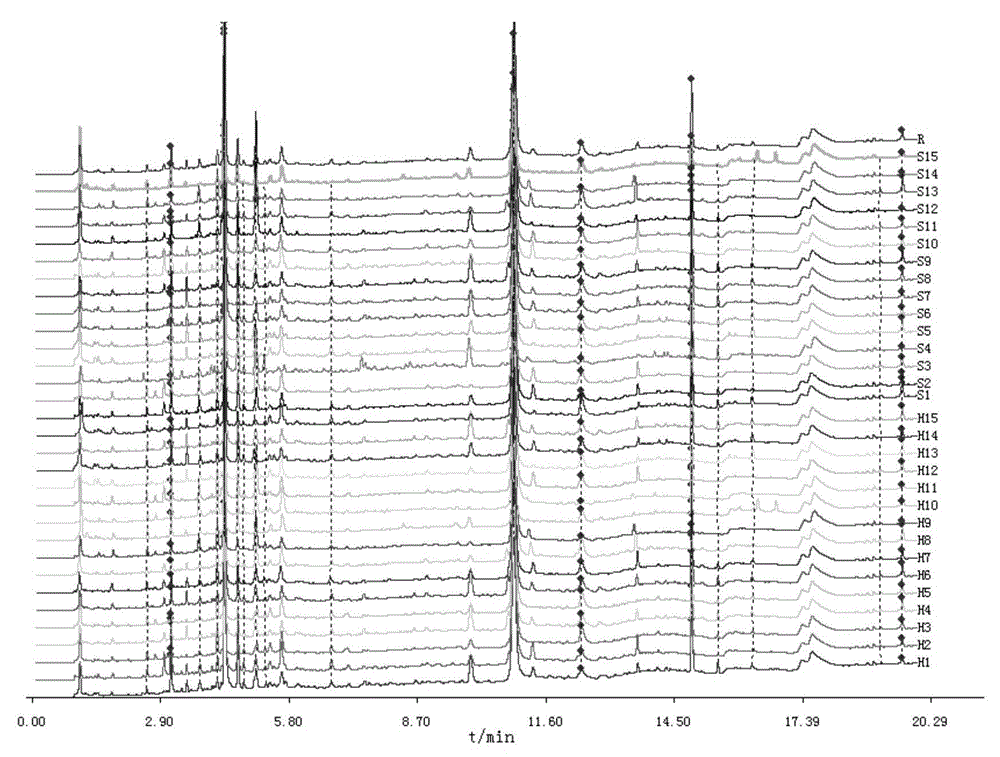

Fingerprint of Cortex Periplocae and quality detection method for Cortex Periplocae

ActiveCN106153792AImprove smearingThe number of peaks increasesComponent separationChlorogenic acidCentrifugation

The invention relates to a determination method for effective components of Cortex Periplocae. The method is characterized by comprising the following steps: (1) preparation of a control solution: weighing control substances consisting of chlorogenic acid, 4-methoxysalicylaldehyde and periplocin and adding methanol to prepare the mixed control solution; (2) preparation of a test solution: drying and crushing Cortex Periplocae, then sieving the crushed Cortex Periplocae, carrying out precise weighing, adding a methanol solution, then carrying out extraction for 20 to 50 min, carrying out standing for cooling, then carrying out centrifugation and taking supernatant so as to obtain the test solution; and (3) determination: sucking up the mixed control solution and the test solution, injecting the mixed control solution and the test solution into a liquid chromatograph so as to obtain chromatograms and calculating the contents of corresponding components in a test substance according to the chromatogram.

Owner:TIANJIN TASLY PHARMA CO LTD

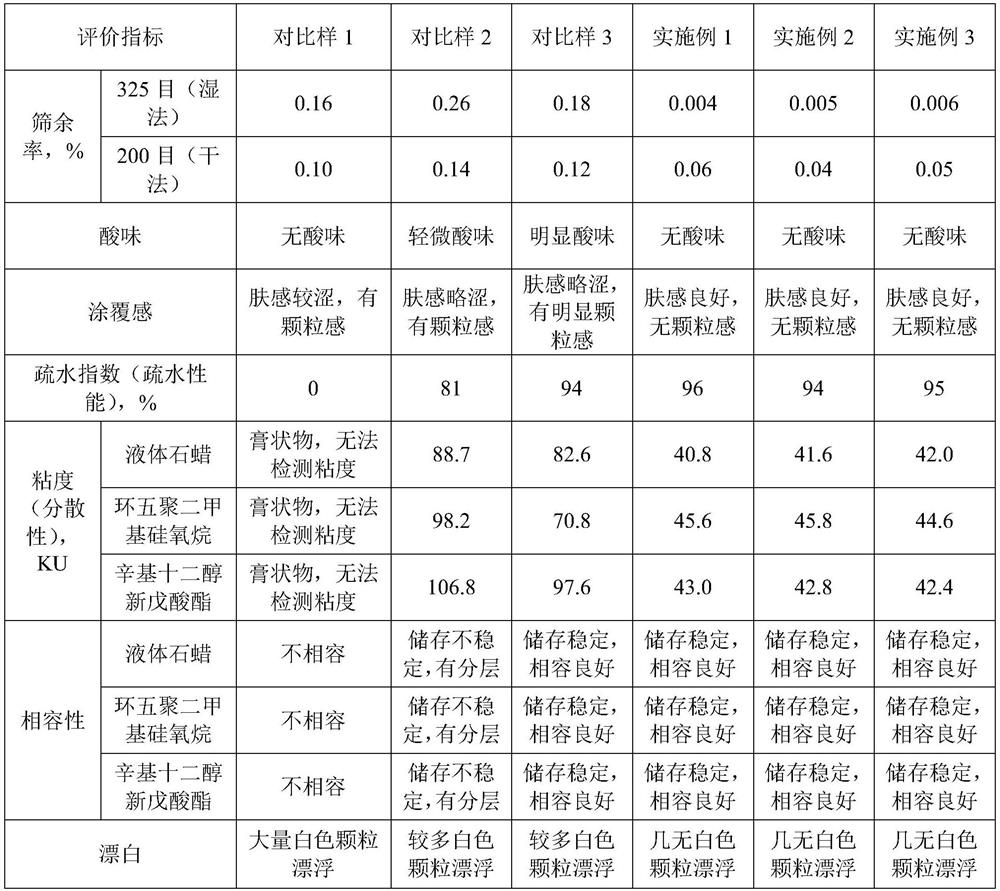

Surface treatment method of high-hydrophobicity and high-dispersity titanium dioxide pigment for cosmetics

ActiveCN112552710AActiveEasy to wetPigment treatment with non-polymer organic compoundsPhysical chemistryHydrophobe

The invention provides a surface treatment method of a high-hydrophobicity and high-dispersity titanium dioxide pigment for cosmetics. The method comprises the following steps: firstly, grinding and grading a rutile titanium dioxide pigment raw material under the action of a grinding aid to remove agglomerated particles in the titanium dioxide pigment raw material; preparing the treated titanium dioxide pigment into paste, transferring the paste into reaction equipment, starting stirring, adjusting the pH value to be weakly alkaline, and heating to 50-100 DEG C for reaction bonding; heating and drying to obtain a titanium dioxide pigment cake; and finally, crushing and removing impurities to obtain the high-hydrophobicity and high-dispersity titanium dioxide pigment product for cosmetics.According to the preparation process disclosed by the invention, the coating feeling of the titanium dioxide pigment can be effectively improved, the titanium dioxide pigment is endowed with excellenthydrophobicity and good compatibility and dispersity with oil ester components in a cosmetic formula, so that the use requirements of cosmetics are met, and the use effect of the cosmetics is guaranteed.

Owner:安徽格锐新材料科技有限公司

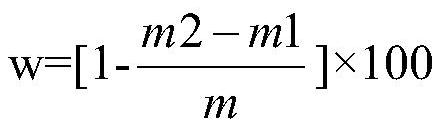

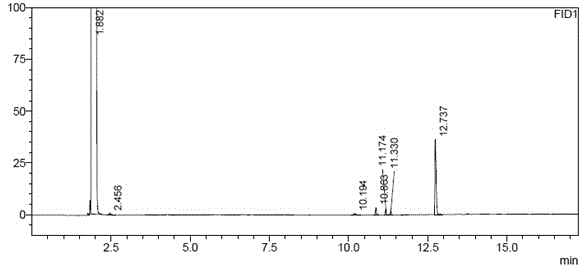

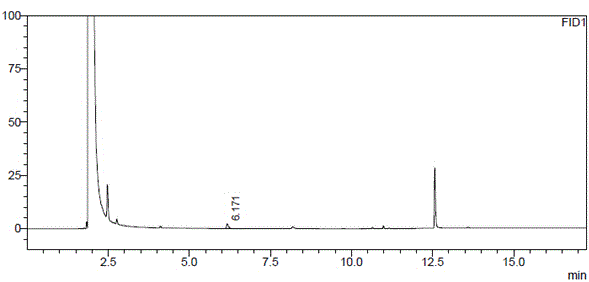

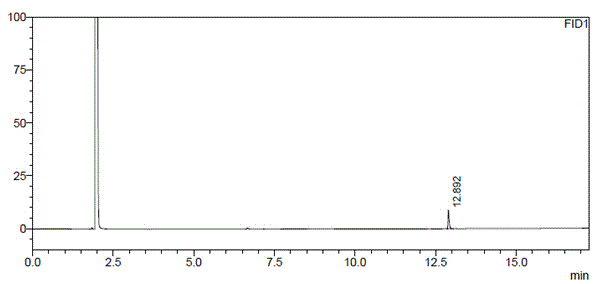

Method for separating and determining 1,2-propylene glycol enantiomers by using gas chromatography

The invention discloses a method for separating and determining 1,2-propylene glycol, bulk drugs containing 1,2-propylene glycol and 1,2-propylene glycol enantiomer impurities in preparations of the bulk drugs by using precolumn derivatization gas chromatography. The method employs an aldehyde ketone compound as a derivative reagent, carries out precolumn derivatization on the aldehyde ketone compound and 1,2-propylene glycol in the presence of a catalyst and a water reducer and determines trace enantiomer impurities by using gas chromatography. The method provided by the invention overcomes the defect of incapability of accurate quantification of 1,2-propylene glycol enantiomer impurities due to serious trailing of peaks during frequently-used chiral gas chromatographic column separation and guarantees that the quality of 1,2-propylene glycol, the bulk drugs containing 1,2-propylene glycol and the preparations thereof is controllable.

Owner:CHONGQING PHARMA RES INST

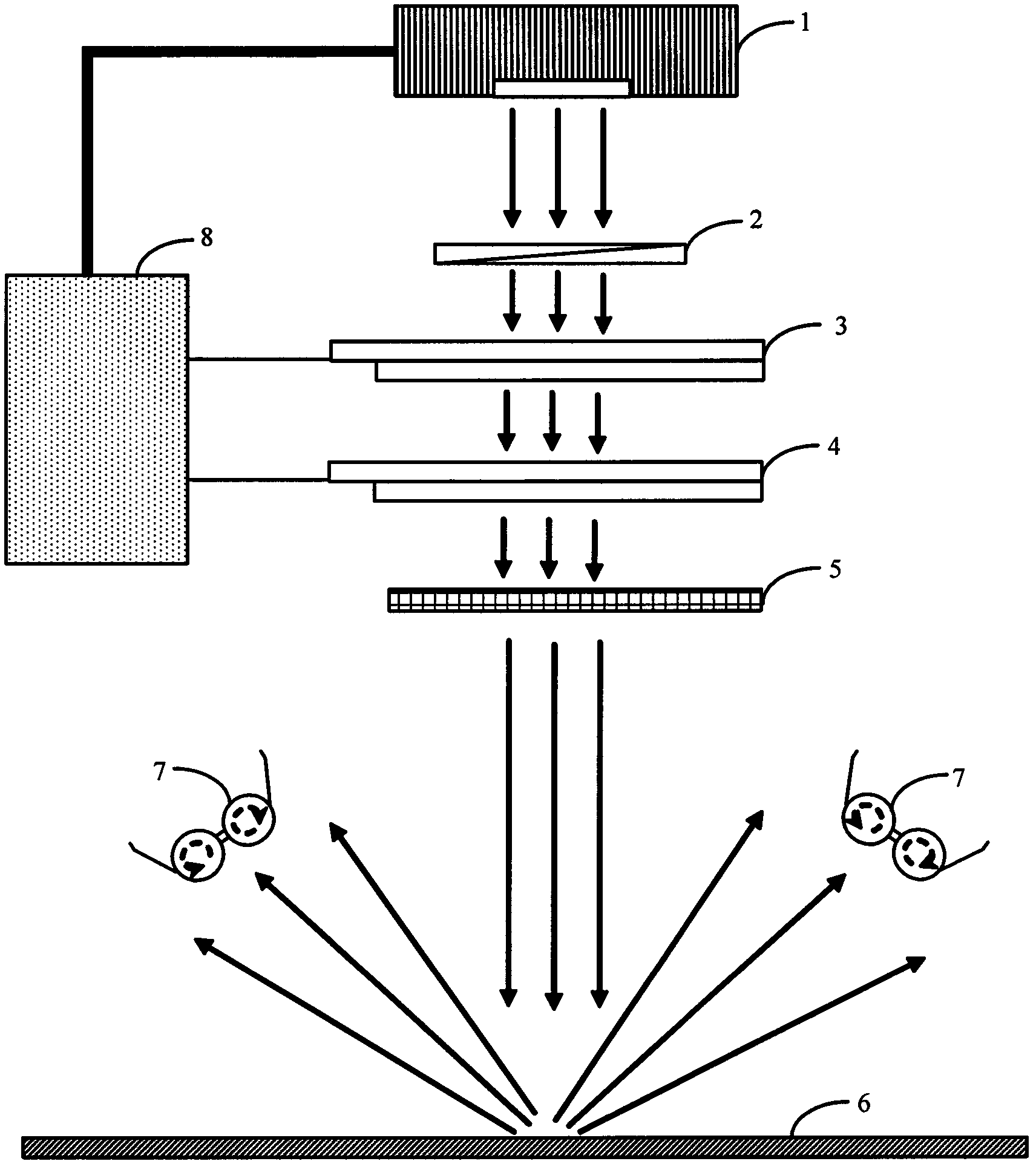

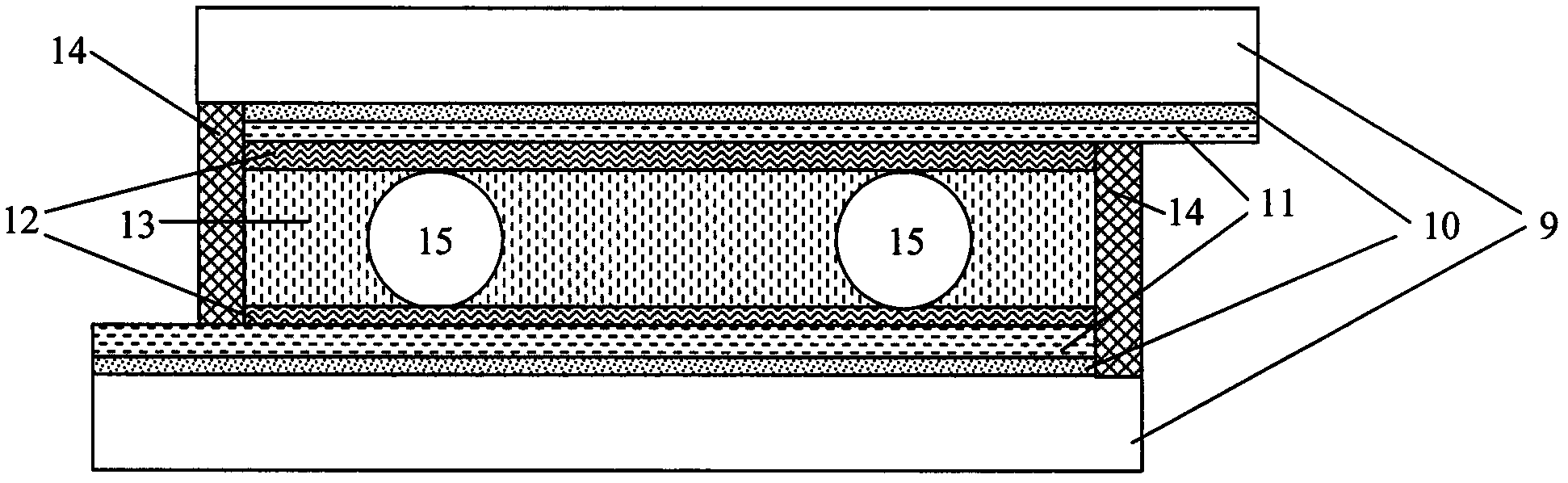

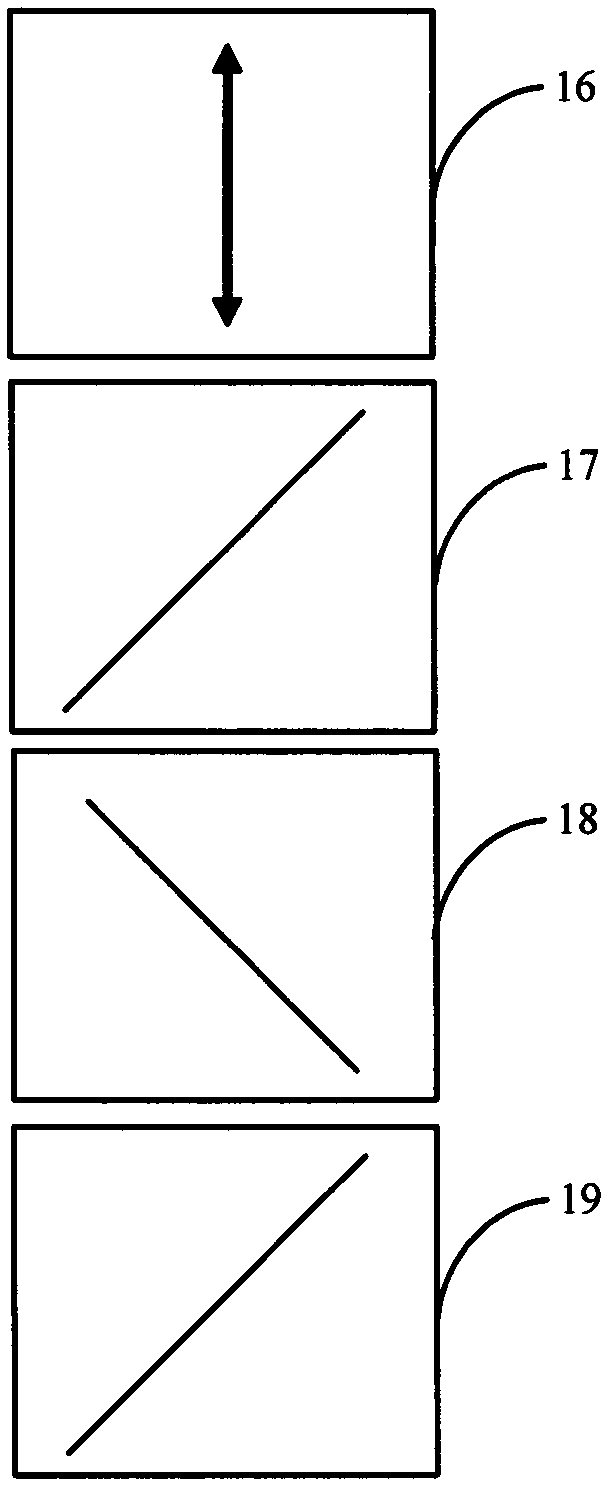

Stereo projection system with single projector and dual liquid crystal light valves, projector and driving method

ActiveCN102566249AIncrease frame rateQuick responseProjectorsStereoscopic photographyHigh frame rateLiquid crystal light valve

The invention belongs to the technical field of stereo projection and provides a stereo projection system with a single projector and dual liquid crystal light valves. Along the direction of light path, the stereo projection system sequentially comprises a projector, a linear polarizer, a first optical self-compensated bend (OCB) mode liquid crystal light valve, a second OCB mode liquid crystal light valve, a polarization state converter, a projector screen, circular polarized glasses and a synchronous circuit. Stereo projection at higher frame rates is achieved by means of the stereo projection system with the single projector and the dual OCB mode liquid crystal light valves, the dynamic compensation driving technology and the dual OCB mode liquid crystal light valves capable of adjusting the polarization state of light at a high speed. Besides, the structure is simple, the cost is low, and by using one projector to match with the dual liquid crystal light valves and a mating driving circuit, audiences can watch stereo projection through wearing pairs of circular polarized glasses.

Owner:SHENZHEN AV DISPLAY

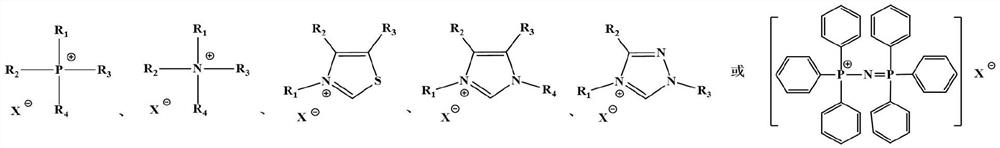

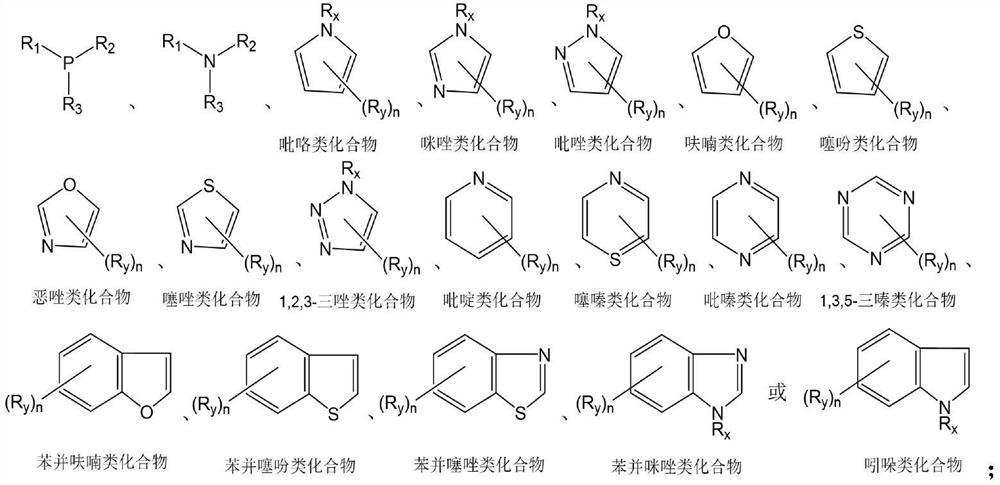

Bi-component catalytic system for high-activity preparation of polyether polyol or polyether ester polyol, and application of bi-component catalytic system

The invention relates to a bi-component catalytic system for high-activity preparation of polyether polyol or polyether ester polyol and application of the bi-component catalytic system. The catalyticsystem comprises a double-metal cyanide catalyst and a promoter, wherein a mass ratio of the activity promoter to the double-metal cyanide catalyst is (0.01-100): 1; and the promoter is one or more selected from quaternary ammonium salt, quaternary phosphonium salt, metal salt and Lewis base. By using the catalytic system, an epoxy compound can be efficiently catalyzed to be undergo ring-openinghomopolymerization or copolymerization with one or two selected from carbon dioxide and anhydride to prepare polyether ester polyol, and activity can reach 11 kg polymer / g DMC or above after a reaction is carried out for 6 h.

Owner:HEBEI UNIV OF TECH

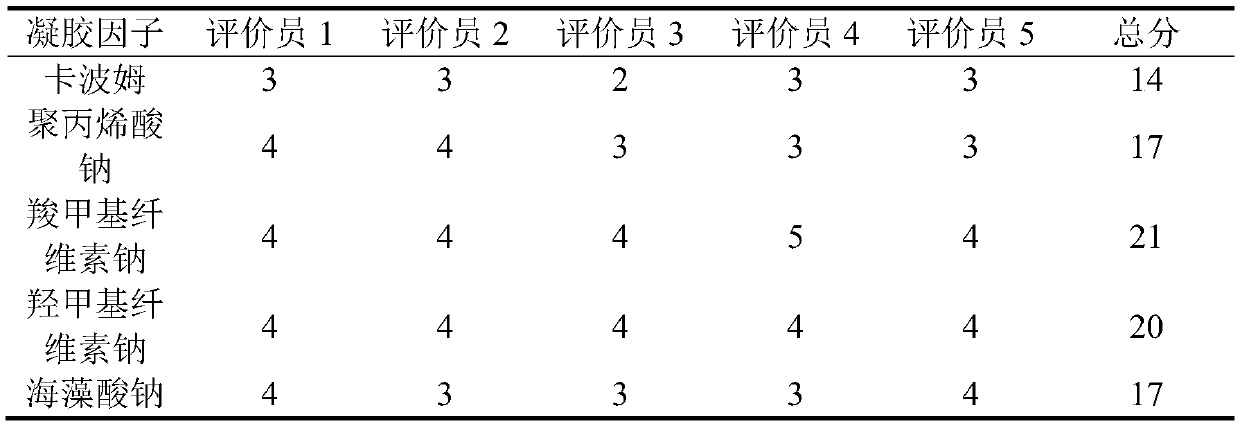

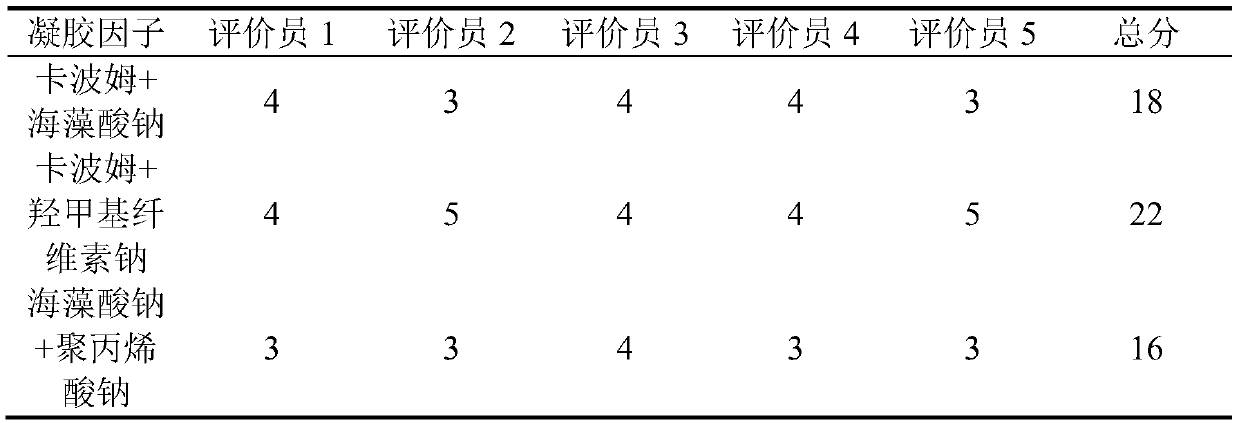

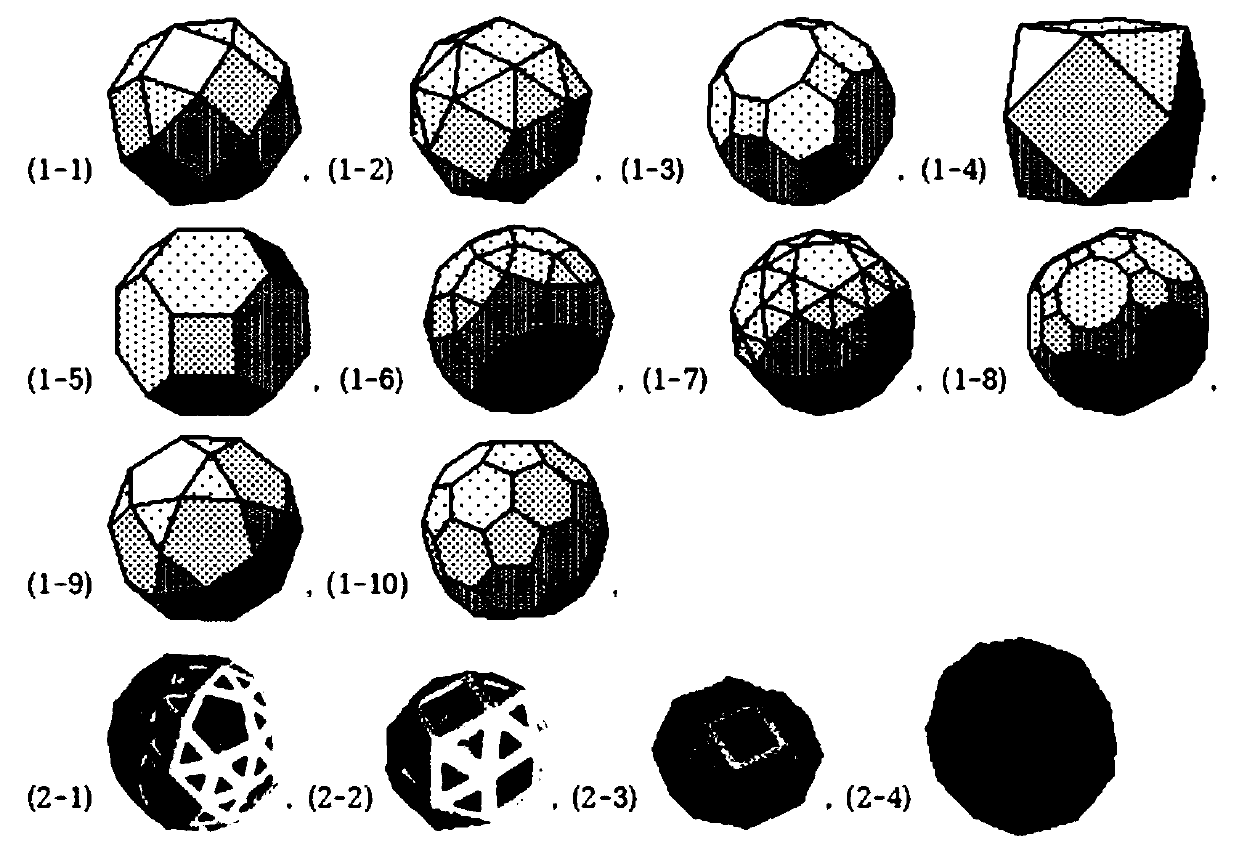

Powder-filled hydrogel and preparing method and application thereof

ActiveCN105496798AImprove stabilityEasy to storeCosmetic preparationsToilet preparationsSolventCopolymer

The invention discloses powder-filled hydrogel. The powder-filled hydrogel is prepared from, by mass, 0.5 part of powder, 0.05-0.5 part of gelator and 5-20 parts of solvent. The powder is prepared from plant powder for cosmetics, pearl powder and inorganic particles for cosmetics. The gelator is obtained by mixing one or more of sodium polyacrylate, sodium carboxymethylcellulose, carboxymethyl cellulose sodium, polyacrylic acid copolymer, sodium alga acid and Carbomer. The gelator is free of toxicity, safe, low in price and free of pollution and facilitates the application and popularization of the gel product. The powder-filled hydrogel is high in stability, free of delamination, easy to store, easy to absorb and good in smear feeing and can be widely applied to the field of cosmetics.

Owner:ZHEJIANG UNIV OF TECH

Wax-based stick cosmetic capable of outputting water and preparation method

ActiveCN110227040AHigh hardnessImprove stabilityCosmetic preparationsMake-upWaxBiochemical engineering

The invention discloses a wax-based stick cosmetic capable of outputting water, wherein the oil phase portion or the oil phase mixed portion of the wax-based stick cosmetic capable of outputting waterenvelops water to release the moisture to provide a combination component of an emulsifier, compounded combination component of the emulsifier of the sheet structure encapsulates the characteristicsof the moisture particles. The invention, based on the prior art, solves the problem that the wax-based stick cosmetic can output water during the application process, and a large amount of water candirectly provide the skin with a moist and cool skin feeling. The wax-based stick cosmetic capable of outputting water prepared by the invention can not only directly supply a large amount of water, but also has good hardness, excellent state stability, excellent smear feeling, excellent storage stability and excellent coloring features.

Owner:广州雅纯化妆品制造有限公司 +1

Method for determining content of clindamycin phosphate vaginal tablets

ActiveCN112684056AEasy to separateHigh measurement accuracyComponent separationFluid phaseClindamycin Phosphate

The invention provides a method for determining the content of clindamycin phosphate vaginal tablets. The method adopts high performance liquid chromatography for detection, selects mobile phase components, adopts scientific proportioning, adopts gradient elution and sets elution conditions, and can rapidly and accurately detect the content of clindamycin hydrochloride for injection so as to achieve the purpose of simply, conveniently, rapidly and accurately controlling the product quality.

Owner:HAINAN HAISHEN TONGZHOU PHARM CO LTD

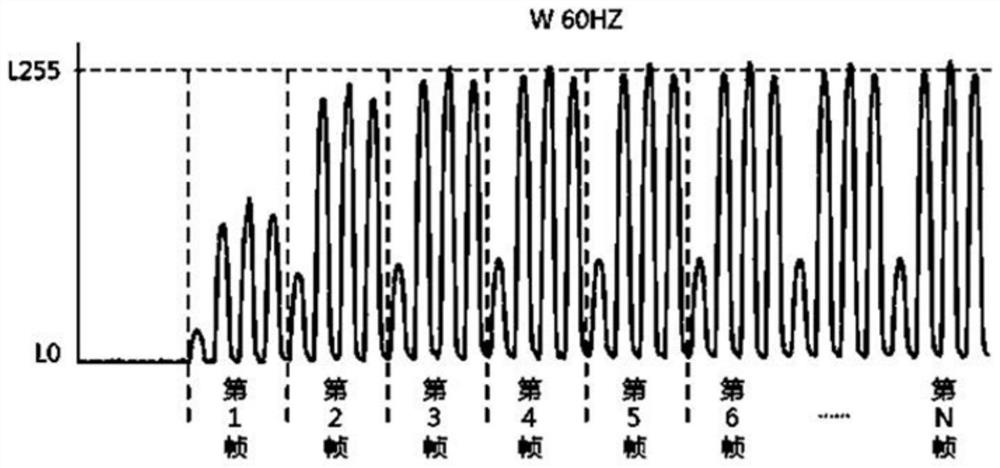

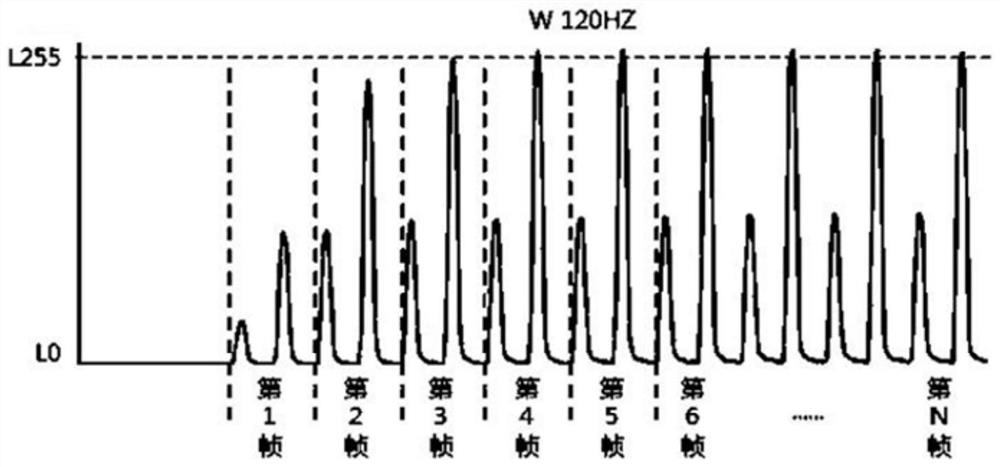

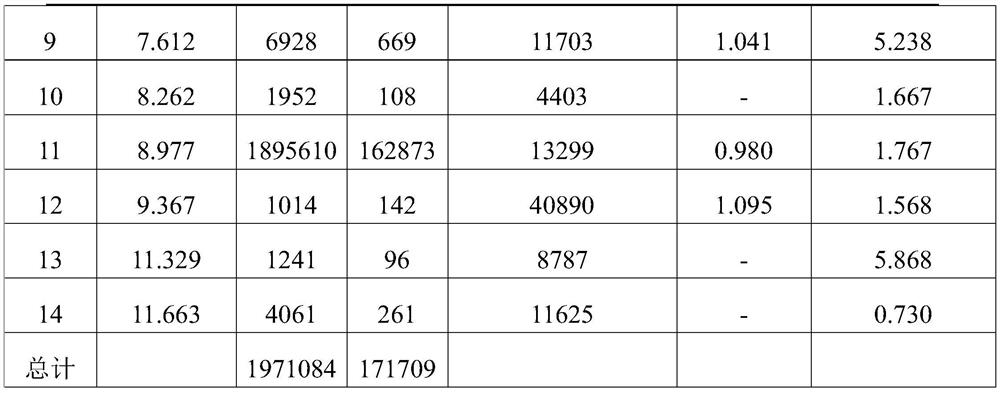

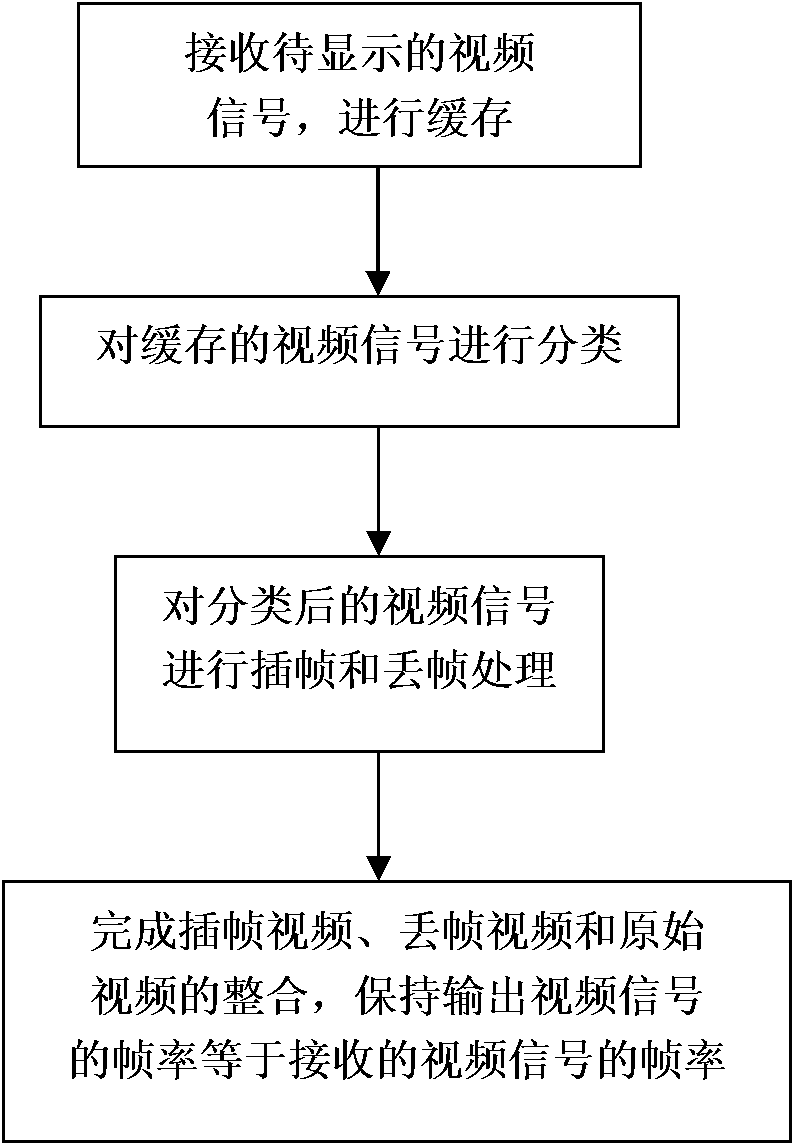

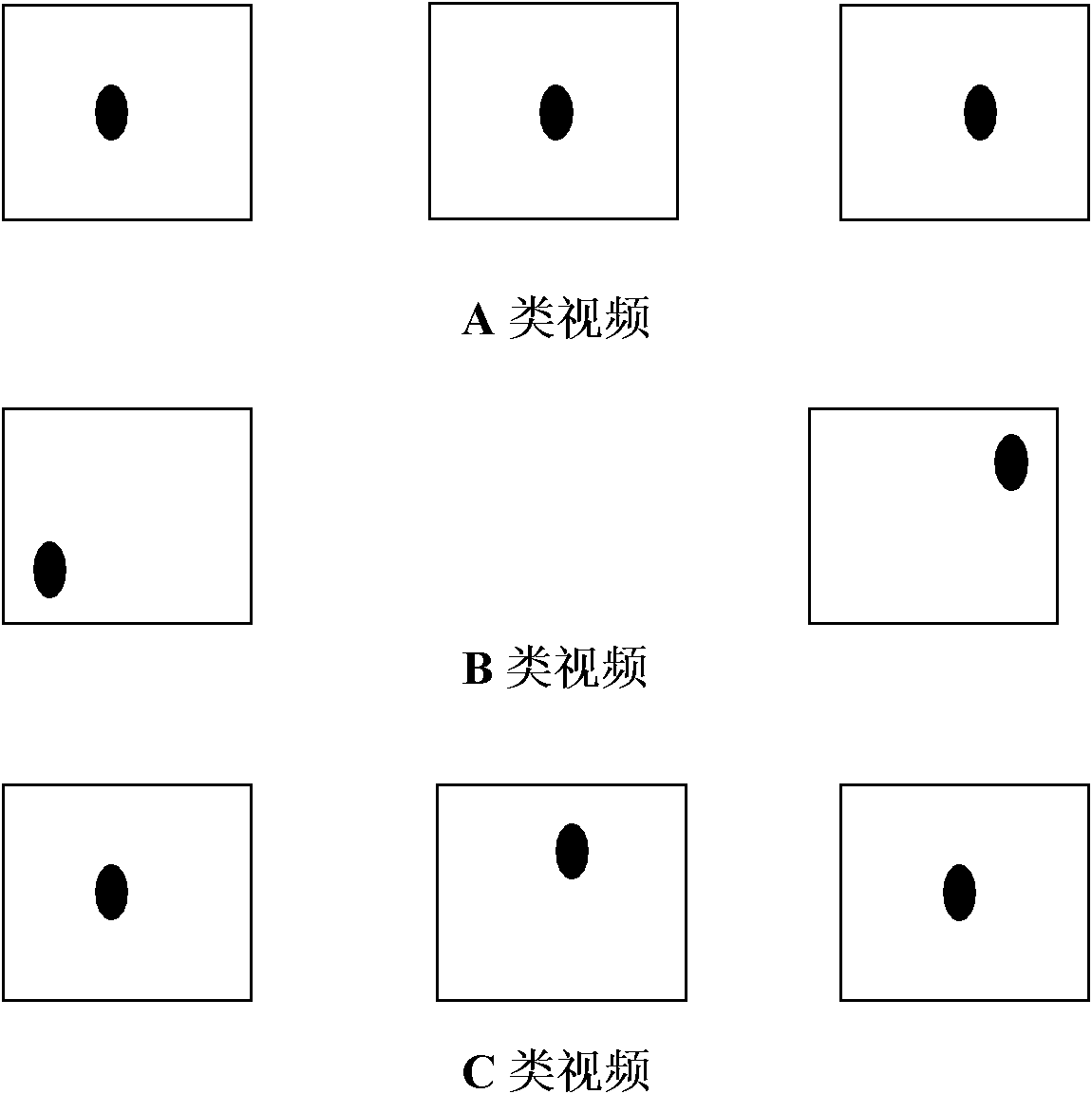

Method for treating video of liquid crystal display device

InactiveCN102082896BLess exerciseImprove smearingTelevision system detailsStatic indicating devicesLiquid-crystal displayComputer graphics (images)

The invention discloses a method for treating a video of a liquid crystal display device, and in the method, interleaving and frame erasure techniques are utilized to lower the video image moving velocity so as to efficiently reduce the streaking phenomenon of the liquid crystal display device. The method comprises the following steps: 1) receiving and caching a to-be-displayed video signal; 2) estimating the motion of a continuous two-frame video and dividing a continuous three-frame video into a video with a smaller motion frame, a video with a proper motion frame and a video with a bigger motion frame; 3) performing frame erasure treatment on the video with the smaller motion frame, eliminating the middle frame of the continuous three-frame video, performing no treatment on the video with the proper motion frame, and performing interleaving treatment on the video with the bigger motion frame by using the interleaving technique based on bidirectional motion estimation and the motion compensation; and 4) finishing integrating the interleaved video and the frame-erased video with the original video and keeping a frame rate of the output video signal equal to the frame rate of the received video signal. The method is suitable for the current mainstream 50Hz / 60Hz liquid crystal display device as well as high-class liquid crystal display devices, such as the 100Hz / 120Hz / 200Hz / 240Hz liquid crystal display devices, and the like.

Owner:SUN YAT SEN UNIV

Ion gate control method for ion mobility spectrometer

ActiveCN110571126AImprove smearingImprove resolutionElectron/ion optical arrangementsElectric fieldEngineering

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com