Quick response twisted nematic liquid crystal display and method

A liquid crystal display, twisted nematic technology, applied in static indicators, instruments, nonlinear optics, etc., to achieve the effects of improving color saturation and viewing angle range, increasing switching speed, and improving response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

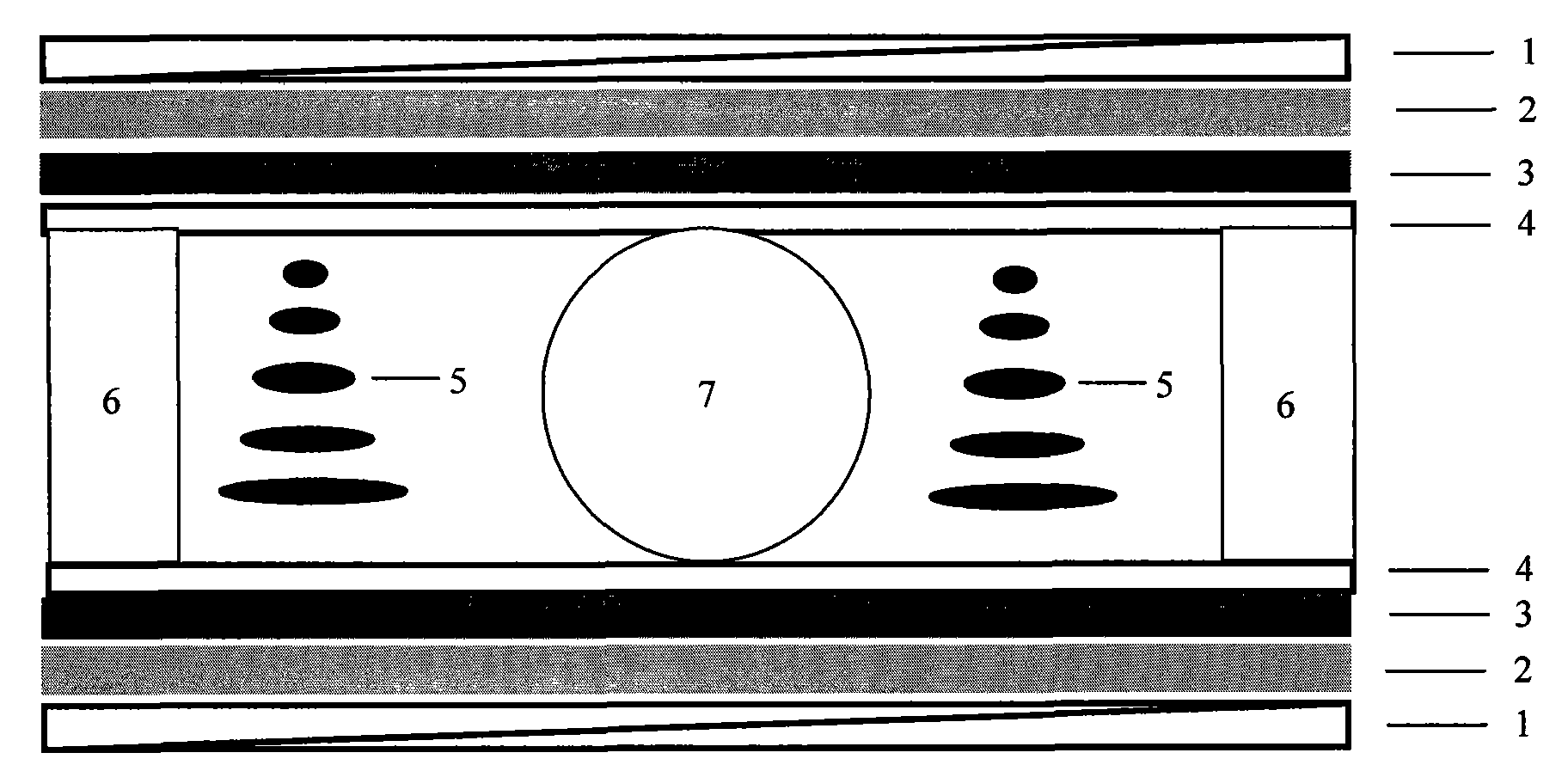

[0030] figure 1 Fast Response Twisted Nematic Liquid Crystal Display Structure

[0031] The structure of the fast-response twisted nematic liquid crystal display includes a polarizer 1, a glass substrate 2, an ITO electrode 3, an alignment layer 4, a liquid crystal material 5, a sealing frame 6, and a spacer 7; a polarizer 1, a glass substrate 2, an ITO The electrodes 3 and the alignment layer 4 are arranged up and down, with the liquid crystal material 5 and the spacer 7 in the middle.

[0032] Two polarizers 1 are attached to the outer surface of the glass substrate 2, and the inside of the glass substrate 2 has an ITO electrode 3 and an alignment layer 4; The liquid crystal material 5 is arranged along the rubbed direction of the alignment layer in advance, the two glass substrates 2 are bonded together by the bezel glue 6, and a spacer 7 with a certain diameter is placed in the liquid crystal to control the thickness of the liquid crystal layer.

[0033] The rubbing dire...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com