Surface treatment method of high-hydrophobicity and high-dispersity titanium dioxide pigment for cosmetics

A titanium dioxide, high-dispersibility technology, applied in the direction of dyeing low-molecular organic compound treatment, fibrous fillers, etc., can solve the problems of poor skin feeling, poor hydrophobicity, insufficient compatibility and dispersibility of ester components, etc., to achieve Excellent water repellency, reduced oil absorption, and excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

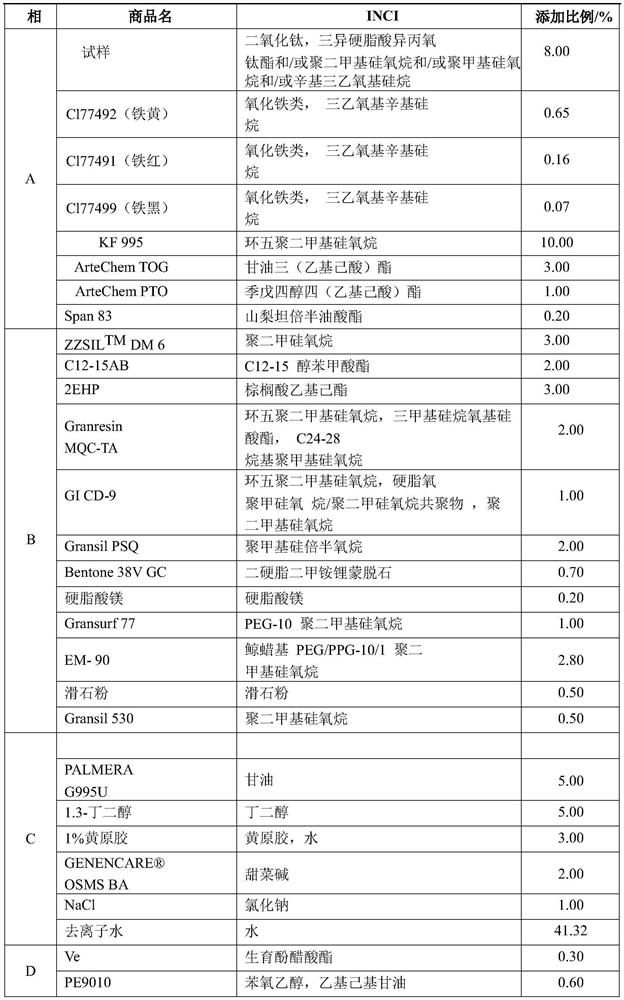

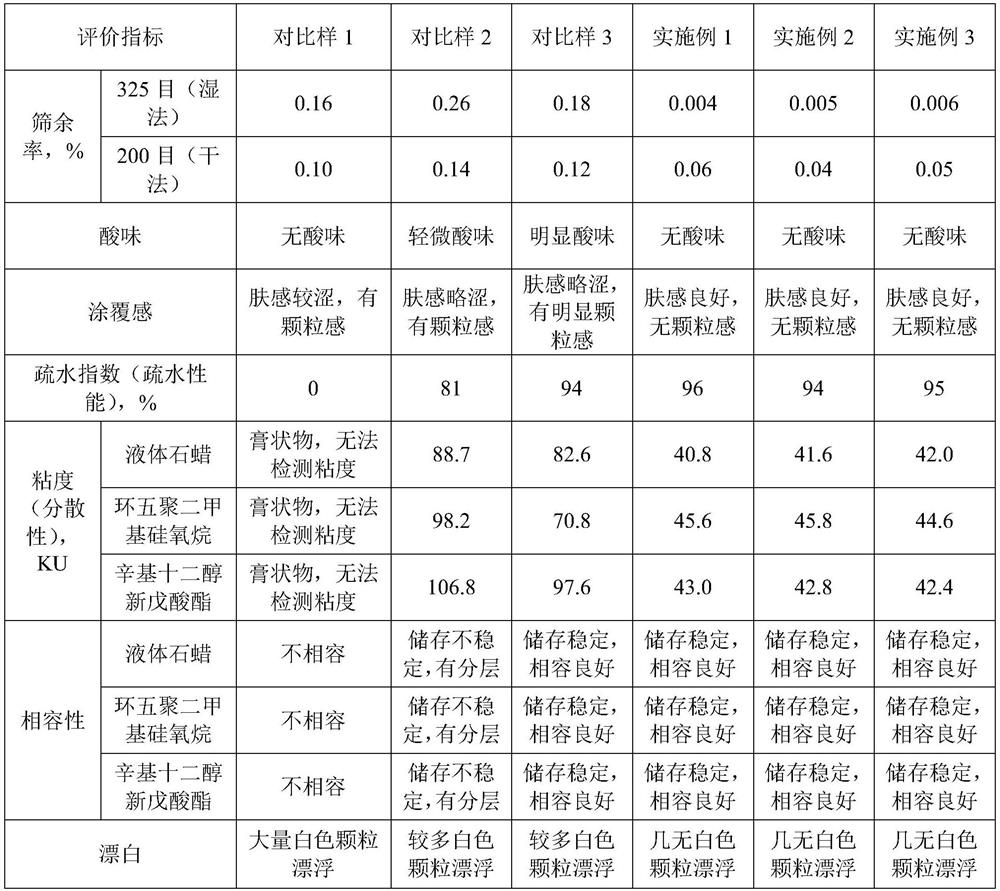

Embodiment 1

[0061] The rutile titanium dioxide pigment that meets the aforementioned technical requirements is used as a raw material, and is sent to the airflow mill equipped with an airflow classifier through a metering conveyor belt, and at the feed port of the airflow mill, titanium dioxide is added dropwise through a metering pump with a mass ratio of 0.5 ‰ sodium polyacrylate dispersant solution. The agglomerated particles in the titanium dioxide raw material are removed by adjusting the parameters such as the speed of the airflow mill and the airflow classifier, supplementary air, and rotor clearance. The 325 mesh sieve yield of the obtained titanium dioxide pigment was measured to be 0.004% by wet sieving, and the 200 mesh sieve yield was 0.06% by dry sieve. In this embodiment, the mass concentration of the sodium polyacrylate dispersant solution is 45%.

[0062] The titanium dioxide pigment obtained in step (1) is configured into a paste material with a mass concentration of 40%...

Embodiment 2

[0067]The rutile titanium dioxide pigment that meets the aforementioned technical requirements is used as the raw material, and is delivered to the hammer mill equipped with an air classifier through a metering conveyor belt, and the titanium dioxide feeding amount is added dropwise through a metering pump at the feeding port of the air hammer mill. A mass ratio of 0.5‰ is a composite dispersion of sodium polyacrylate: sodium hexametaphosphate = 1:1. The agglomerated particles in the titanium dioxide raw material are removed by adjusting the parameters such as the speed of the hammer mill and the air classifier, the supplementary air, and the rotor clearance. The obtained titanium dioxide pigment has a wet sieving rate of 0.005% at 325 mesh and a dry sieving rate of 0.04% at 200 mesh. In this embodiment, the mass concentration of the composite dispersion liquid is 15%.

[0068] The titanium dioxide pigment obtained in step (1) is configured into a paste material with a mass c...

Embodiment 3

[0073] The rutile titanium dioxide pigment that meets the aforementioned technical requirements is used as the raw material, and is sent to the turbine pulverizer equipped with an air classifier through a metering conveyor belt. At the feeding port of the turbo pulverizer, titanium dioxide is added dropwise through a metering pump. Sodium polyacrylate with a ratio of 2.0‰: sodium silicate = 1:1 composite dispersion. The agglomerated particles in the titanium dioxide raw material are removed by adjusting the parameters such as the speed of the turbo crusher and the air classifier, the supplementary air, and the rotor clearance. The 325-mesh sieve yield of the obtained titanium dioxide pigment was measured to be 0.006% by wet sieving, and the 200-mesh sieve yield was 0.05% by dry sieve. In this embodiment, the mass concentration of the composite dispersion liquid is 15%.

[0074] The titanium dioxide pigment obtained in step (1) is configured into a paste material with a mass c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com