Three-dimensional ordered porous lead dioxide membrane electrode and preparation method thereof

A lead dioxide, three-dimensional ordered technology, applied in circuits, fuel cells, electrical components, etc., can solve the problems of low electrode electrocatalytic efficiency, high energy consumption, low energy consumption, etc., and achieve reduced energy consumption and high specific surface area. , the effect of large water flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

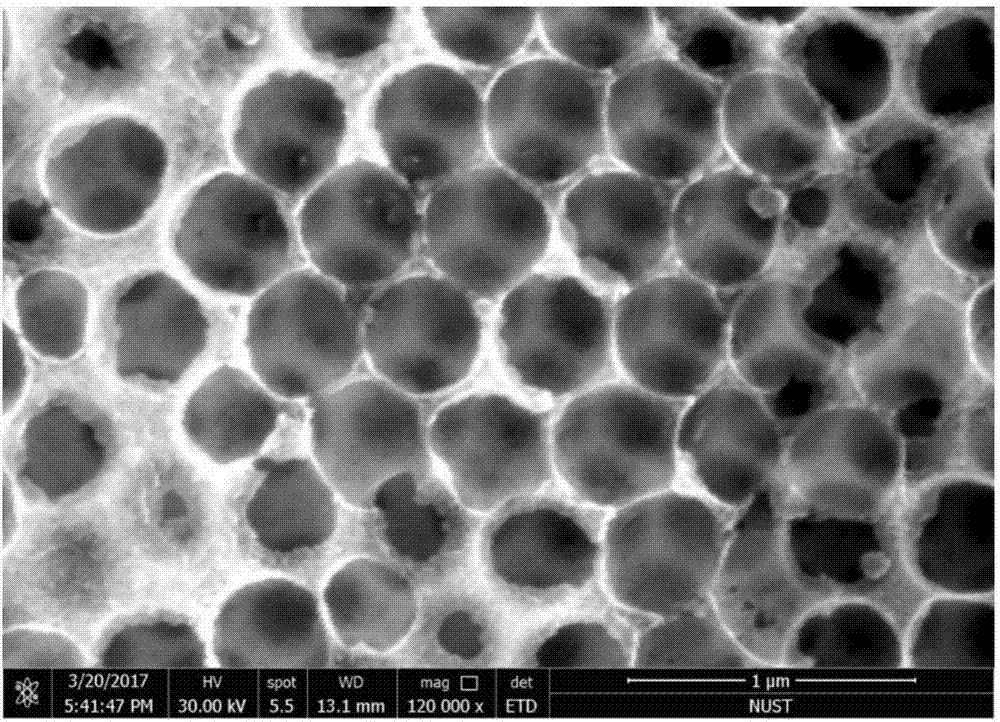

Embodiment 1

[0028] Cut a porous titanium plate with a pore size of 5 μm into a size of Φ6.0 cm, and polish the titanium surface with sandpaper until it is smooth; ultrasonically clean the surface to remove oil; then heat to 80°C in a mixed solution of 18% hydrochloric acid and 20% oxalic acid for 20 minutes Remove the oxide layer; finally put it in deionized water for later use. The treated porous titanium substrate is dipped and brushed in a mixed solution of citric acid, ethylene glycol, tin tetrachloride pentahydrate and antimony trichloride, dried, and this step is repeated. The molar ratio of citric acid, ethylene glycol, tin tetrachloride pentahydrate and antimony trichloride is 120:25:7:1. A porous electrode with an interlayer of antimony-doped tin dioxide is obtained by roasting at 450°C, and the heating rate is 1°C / min, the roasting time is 1h. The porous electrode with antimony-doped tin dioxide interlayer is placed in 50ml polystyrene bead monodisperse liquid, and the diameter...

Embodiment 2

[0034] Cut a porous titanium plate with a pore size of 5 μm into a size of Φ6.0 cm, and polish the titanium surface with sandpaper until it is smooth; ultrasonically clean the surface to remove oil; then heat to 80°C in a mixed solution of 18% hydrochloric acid and 20% oxalic acid for 20 minutes Remove the oxide layer; finally put it in deionized water for later use. The treated porous titanium substrate is dipped and brushed in a mixed solution of citric acid, ethylene glycol, tin tetrachloride pentahydrate and antimony trichloride, dried, and this step is repeated. The molar ratio of citric acid, ethylene glycol, tin tetrachloride pentahydrate and antimony trichloride is 120:25:7:1. A porous electrode with an interlayer of antimony-doped tin dioxide is obtained by roasting at 450°C, and the heating rate is 1°C / min, the roasting time is 1h. Place the porous electrode with the interlayer of antimony-doped tin dioxide in 50ml polystyrene bead monodisperse liquid, the diameter ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com