Papermaking wastewater deep treatment apparatus

A technology for advanced treatment and papermaking wastewater, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. It can solve the problems of refractory macromolecules, wastewater difficult to meet standards, and large load , to achieve the effect of improving the degradation rate of pollutants, reducing energy consumption and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

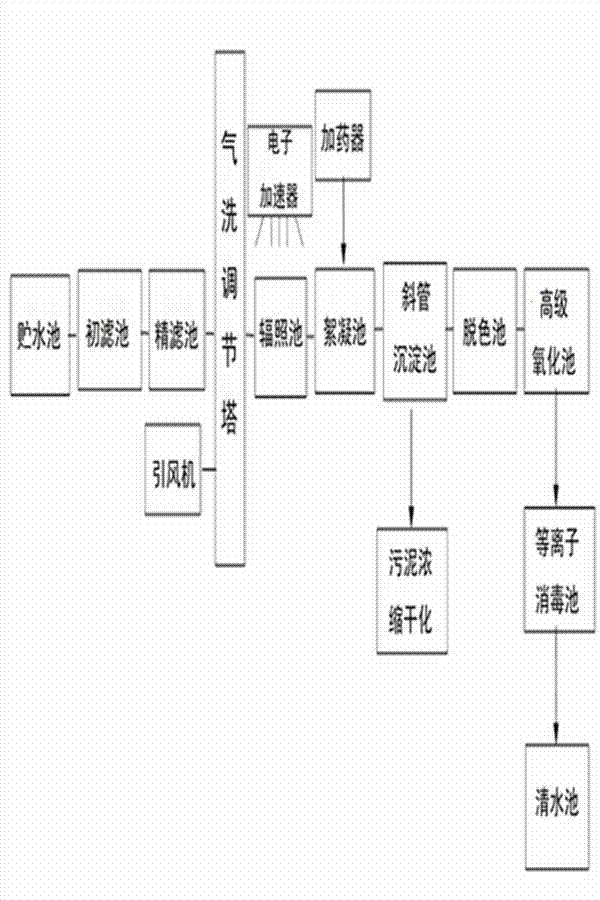

[0038] A treatment device for paper-making wastewater, including a water storage tank, a primary filter tank, a fine filter tank, an air washing adjustment tower, an irradiation tank, a flocculation tank, an inclined tube sedimentation tank, a decolorization tank, an advanced oxidation tank, and a plasma tank connected sequentially by water pipes. Disinfection pool and clean water pool; 70-mesh sieve is set in the primary filter, and 130-mesh sieve is set in the fine filter; the flue gas inlet is set at the lower part of the air washing regulating tower, which is used to introduce the coal-fired waste gas from the induced draft fan, and the bottom is set There is a filter; an electron accelerator is installed above the irradiation tank, and an aeration and tumbling device is installed at the bottom of the irradiation tank; Gas machine; RuO is installed in the advanced oxidation pool 2 -IrO 2 -Tio 2 / Ti-coated anode, graphite cathode, the distance between the power supply and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com