Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44results about How to "Improve finishing performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Environment-friendly flame-retardant single-component silane-modified polyether sealant and preparation method thereof

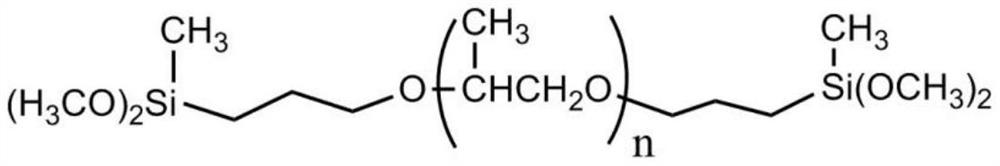

InactiveCN106367005ATaking into account performance requirementsTaking into account environmental protection requirementsNon-macromolecular adhesive additivesOther chemical processesPolypropylene glycolPlasticizer

The invention provides an environment-friendly flame-retardant single-component silane-modified polyether sealant and a preparation method thereof. The sealant is prepared from the following components in parts by mass: 10-40 parts of silane-modified esserbetol, 10-25 parts of a plasticizer, 30-70 parts of flame-retardant filler, 0-20 parts of reinforced filler, 0.1-1 part of a functional accessory ingredient, 0.5-1.5 parts of a dewatering agent and 1-3 parts of a cementation accelerant, wherein the plasticizer is at least one of hexamoll DINCH and polypropylene glycol. The environment-friendly flame-retardant single-component silane-modified polyether sealant provided by the invention does not need addition of a phthalic ester plasticizer, furthermore does not contain heavy metals such as organic tin, is environmentally friendly, and is good in product performance.

Owner:GUANGZHOU GLORYSTAR CHEM

Single-component epoxy modified silicone sealant and preparation method thereof

ActiveCN106590501AGood compatibilityHigh strengthNon-macromolecular adhesive additivesMacromolecular adhesive additivesAviationCross-link

The invention discloses a single-component epoxy modified silicone sealant and a preparation method thereof. the sealant is composed of, by mass, 100 parts of silane modified polyether resin, 10-50 parts of epoxy resin, 80-150 parts of plasticizers, 150-300 parts of nano calcium carbonate, 1-6 parts of first cross-linking agents, 3-10 parts of second cross-linking agents and 2-7 parts of catalysts. The advantages of the epoxy resin and the silane modified polyether resin are combined, the bonding powder, the tensile strength, the elasticity and the weather resistance of the sealant can be improved, and the sealant can be used for the different fields such as constructional engineering, electronics, the automobile industry and space flight and aviation. The sealant has the characteristics that the performance advantages of silicone and the epoxy resin are combined, the silicone and the epoxy resin are subjected to a cross-linking reaction with water molecules and the cross-linking agents under the action of the catalysts, and a three-dimensional spatial netty structure is formed. A cured system is high in binding performance and excellent in mechanical performance and weather resistance.

Owner:广东长鹿新材料科技有限公司

Halogen-free flame retardant new-energy wire and cable material for charging piles

ActiveCN106065175AEasy to processReduce hardnessPlastic/resin/waxes insulatorsInsulated cablesNew energyEngineering

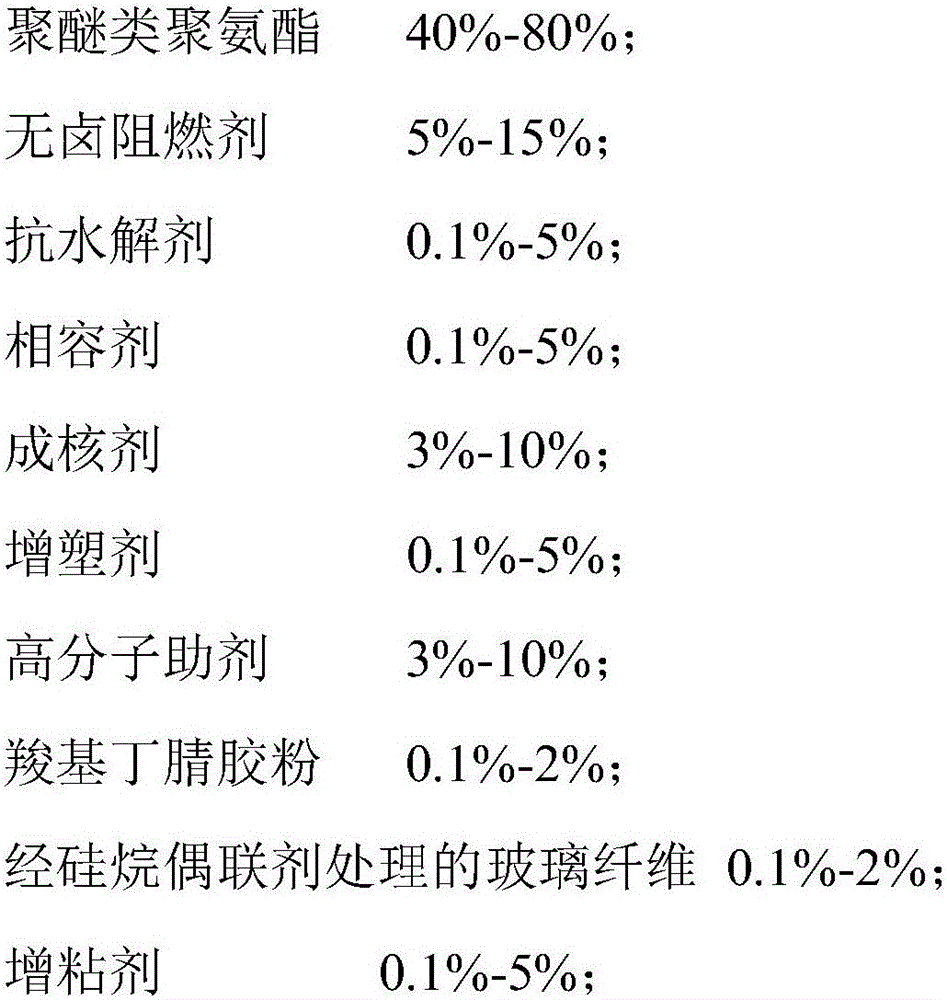

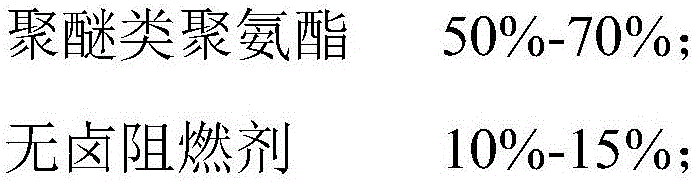

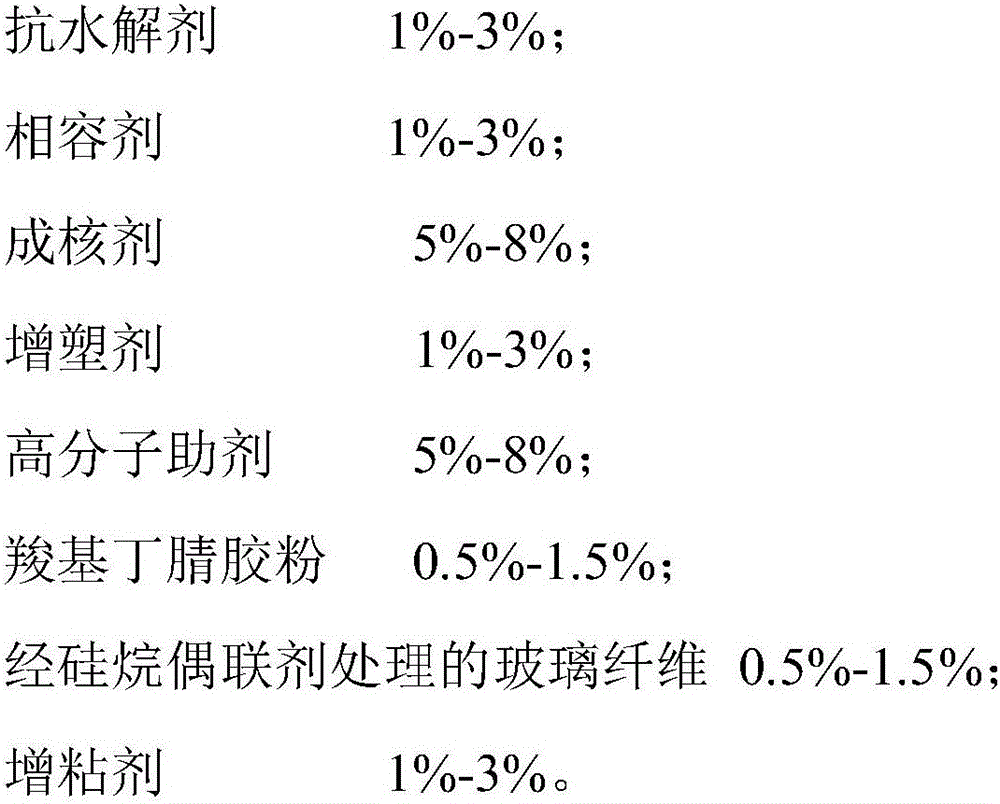

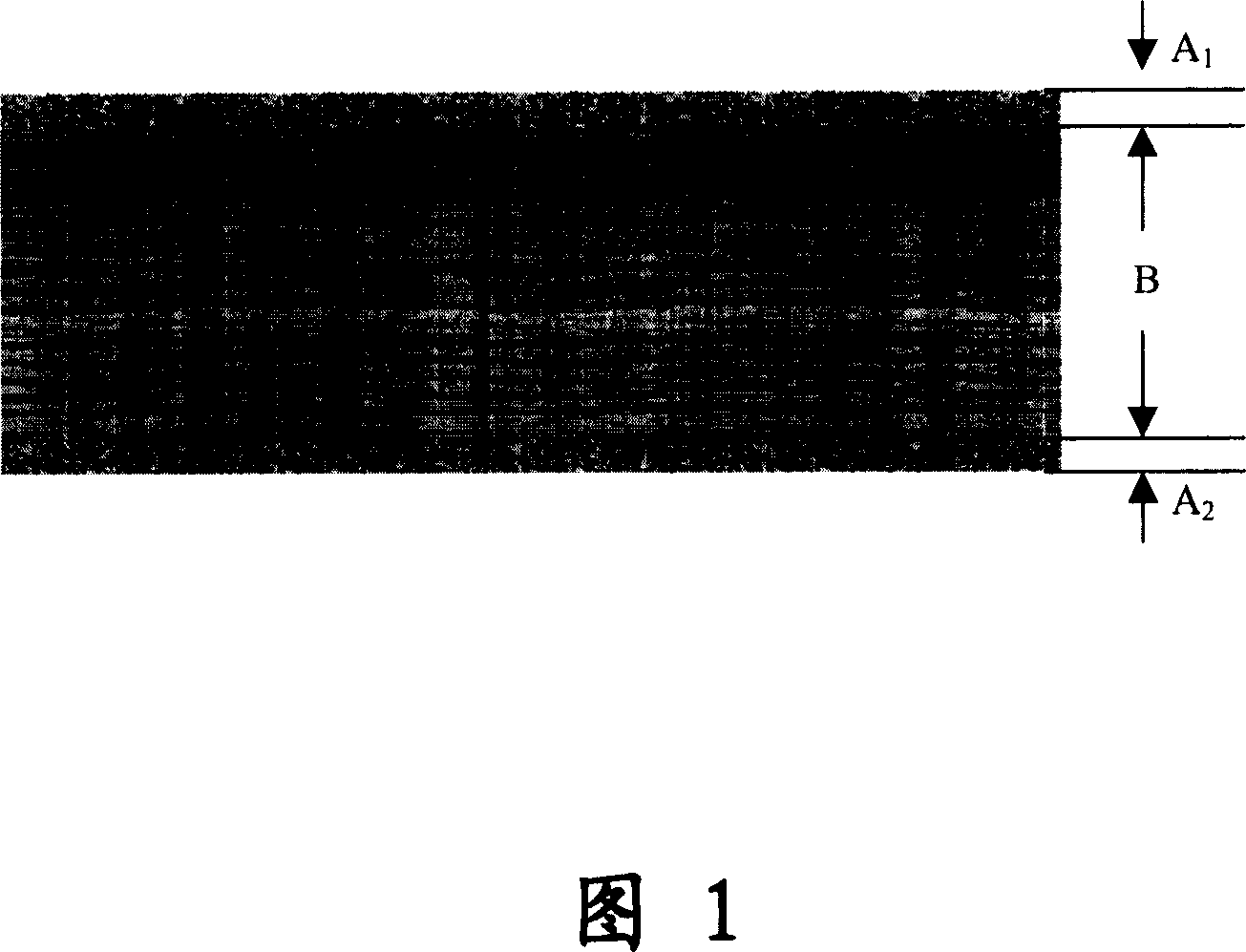

The invention belongs to the technical field of a cable material and relates to a halogen-free flame retardant new-energy wire and cable material for charging piles. The halogen-free flame retardant new-energy wire and cable material comprises the following ingredients (by weight): 40-80% of polyether polyurethane, 5-15% of a halogen-free flame retardant, 0.1-5% of anti-hydrolysis agent, 0.1-5% of a compatilizer, 3-10% of a nucleating agent, 0.1-5% of a plasticizer, 3-10% of a polymer assistant, 0.1-2% of carboxyl nitrile rubber powder, 0.1-2% of glass fiber treated by a silane coupling agent, and 0.1-5% of a tackifier. The polymer assistant is at least one component of PC, ABS, PS, PBT, PET and PA. The carboxyl nitrile rubber powder is a core-shell structure. The nucleating agent is a polyol diacetal-alumina graft. In a word, the halogen-free flame retardant new-energy wire and cable material has the following advantages: low hardness; high tensile property; high tear strength; environmental protection; and halogen-free flame retardant property. Through control of the nucleating agent, the material is endowed with good processability of cables with large wire diameter.

Owner:ADVANCED THERMOPLASTIC POLYMER TECH

Wood flour putty and preparation process thereof

InactiveCN1962769AImprove mildew resistanceImprove water resistanceFilling pastesPolymer scienceEmulsion

The invention discloses wood powder putty and preparing method, which comprises the following parts: 100% white emulsion, 15-40% wood powder, 1-3% anti-fungus agent, 1-3% curing agent, wherein the fineness of wood powder is 300-1000 order. The putty possesses excellent painting effect, which is superior to calcium carbonate putty. The invention also provides wooden wares and manufacturing method with the wood powder putty.

Owner:山东堡珍家居板材有限公司

Solvent-free urethane composition

ActiveCN1894299AReduce loadHigh hardnessPolyureas/polyurethane adhesivesPolyurea/polyurethane coatingsPolyolSolvent free

A solvent-free composition is prepared, which is a composition comprising a polyol component (A) and a polyisocyanate component (B), wherein the polyol component (A) is composed of a low-molecular-weight polyol (A1) with a molecular weight of 350 or less. The viscosity of the aforementioned low-molecular polyol (A1) may be 500 mPa·s or less at 25°C. The aforementioned low-molecular polyol (A1) may be, for example, C2-6 alkylene glycol or the like. In addition, the polyol component (A) may be composed of a low-molecular polyol (A1) and a polymer polyol (A2) as a diluent. The aforementioned polyisocyanate component (B) may be a modified product or a derivative of polyisocyanate (for example, a multimer of diisocyanate, etc.). The aforementioned solvent-free composition may further contain an epoxy group-containing compound (aliphatic diol glycidyl ether, aliphatic polyhydric alcohol glycidyl ether having a hydroxyl group, etc.) (C) that may have a hydroxyl group. Such a solvent-free composition has a small load on the environment, has excellent coating film properties, and has high application efficiency.

Owner:日本硅石株式会社

Acrylate modified polyurethane resin for leather finish and preparation method thereof

ActiveCN103772618AOvercome the disadvantage of low solid contentReduce the disadvantages of low solid contentCoatingsAlcoholAntioxidant

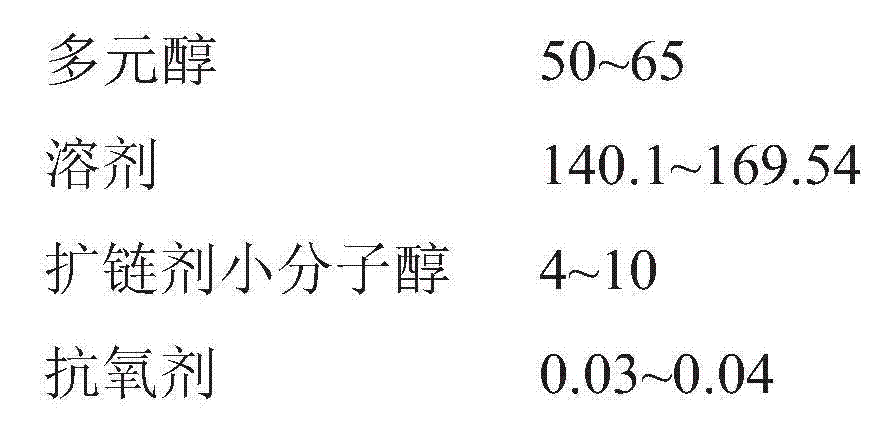

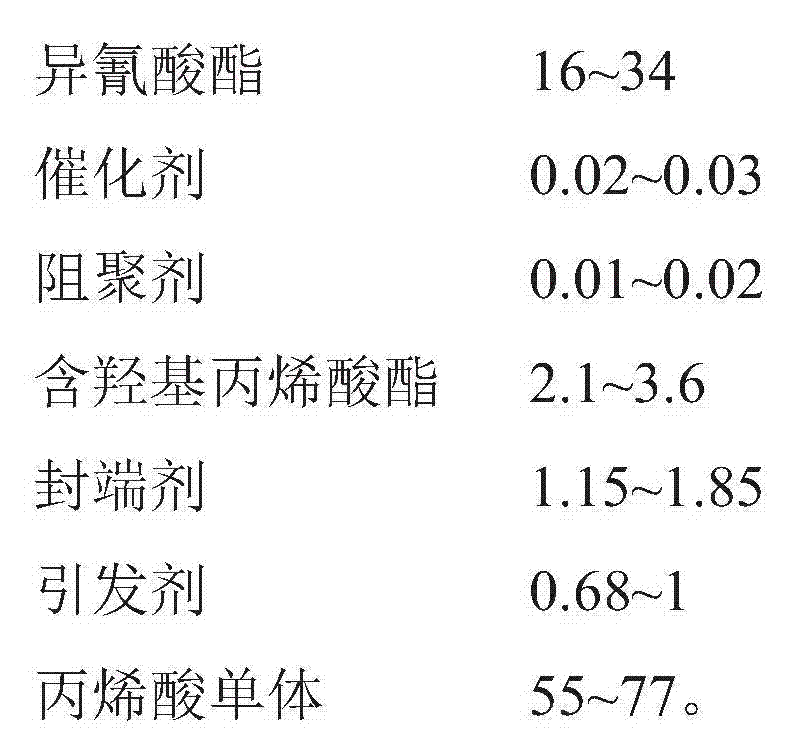

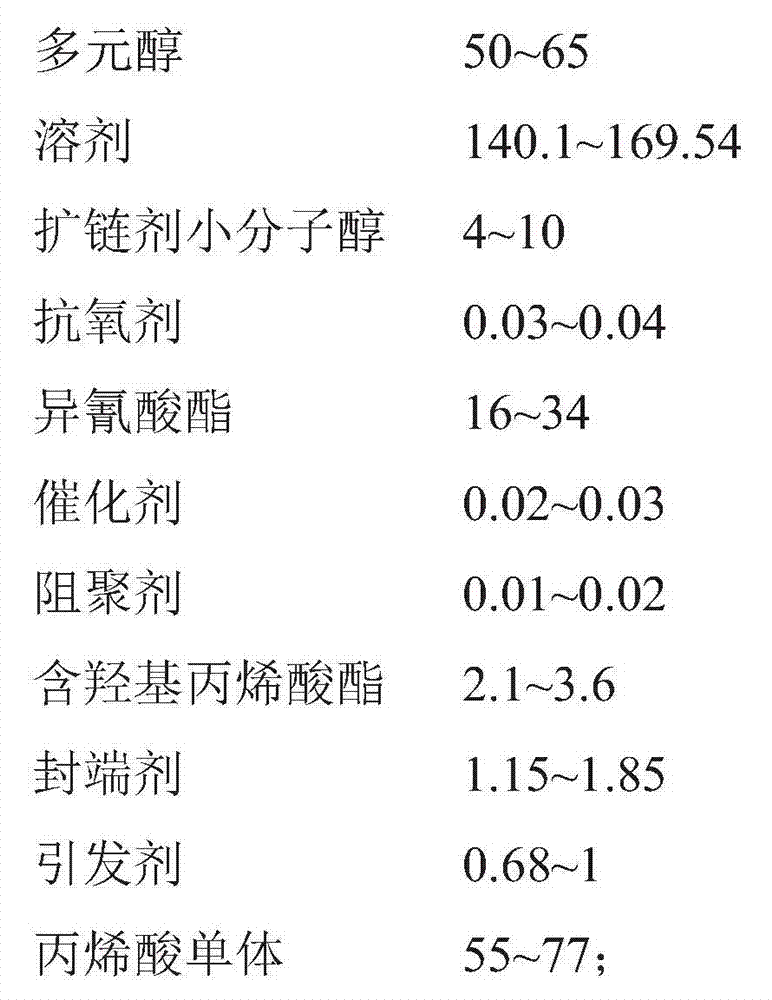

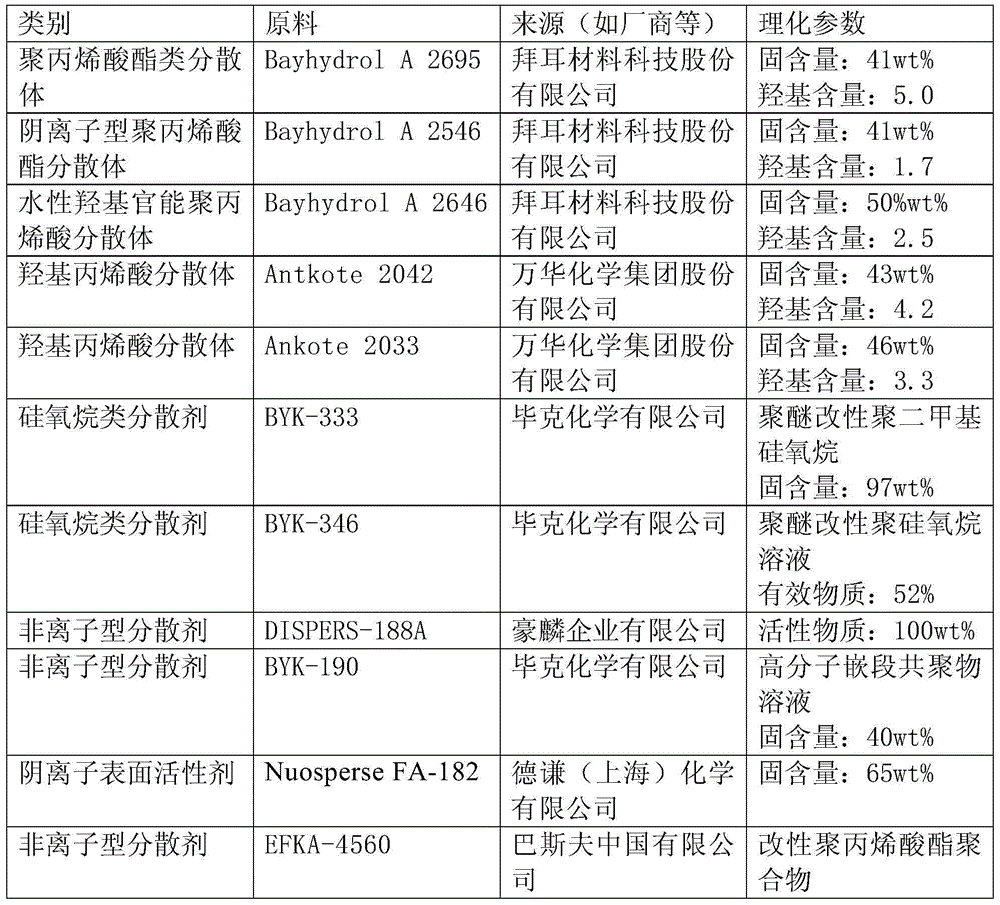

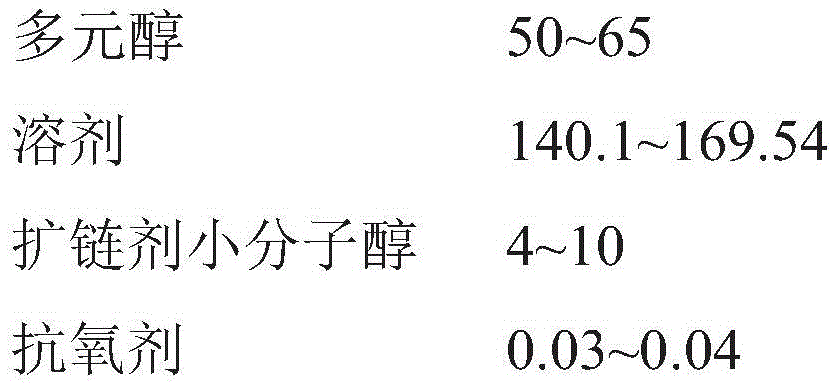

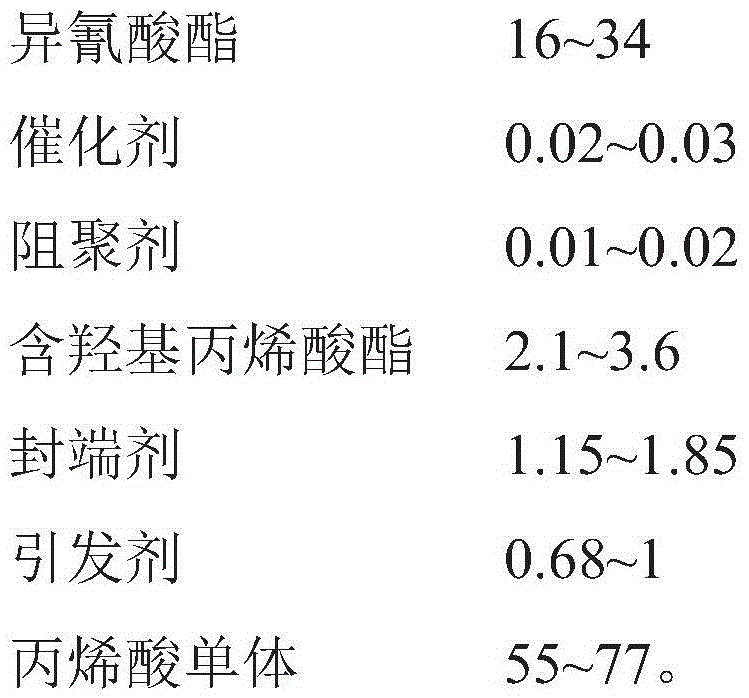

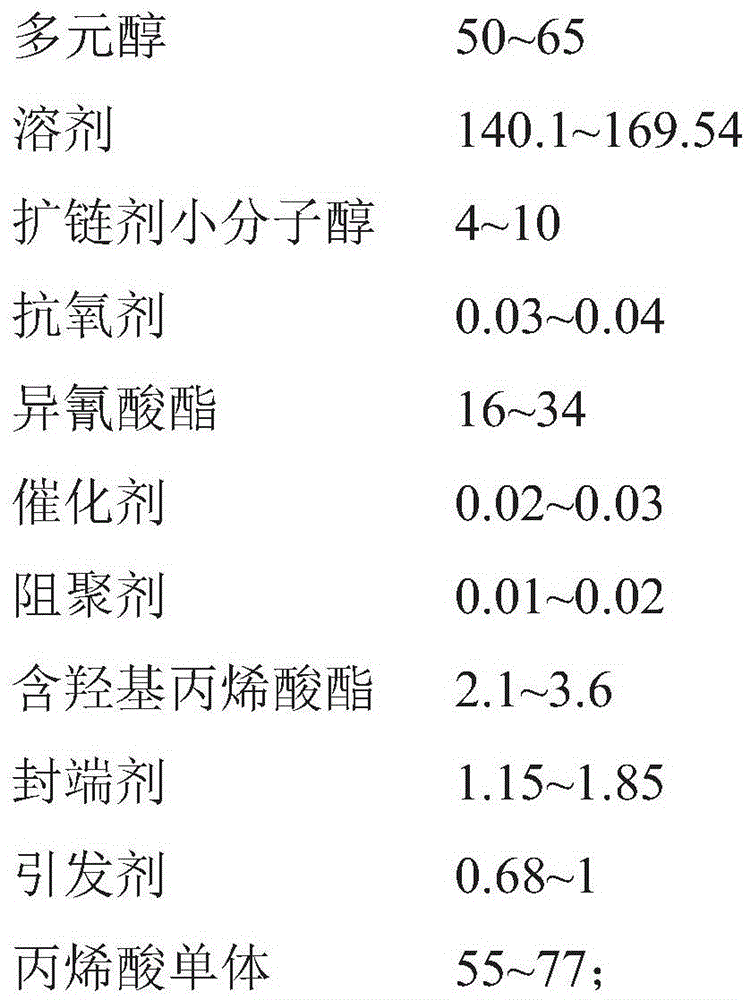

The invention discloses acrylate modified polyurethane resin for leather finish. The acrylate modified polyurethane resin for leather finish is characterized by being prepared from the following components in parts by weight: 50-65 parts of polyalcohol, 140.1-169.54 parts of solvent, 4-10 parts of chain extender micromolecular alcohol, 0.03-0.04 part of antioxidant, 16-34 parts of isocyanate, 0.02-0.03 parts of catalyst, 0.01-0.02 part of polymerization inhibitor, 2.1-3.6 parts of hydroxyl acrylate, 1.15-1.85 parts of end-capping reagent, 0.68-1 part of initiator and 55-77 parts of acrylic monomer. The invention further discloses a preparation method of the acrylate modified polyurethane resin for leather finish. By adopting polyurethane resin as a base material and acrylate as a main modifying material, the product provided by the invention has the advantages of two resins, and the cost is reduced by over 30% compared with that of pure polyurethane. The acrylate modified polyurethane resin for leather finish disclosed by the invention has excellent composite material performance and higher cost performance, so that the solid content is improved by over 50%.

Owner:DONGGUAN HONGDA POLYUREFHANE RESIN

Aging-resistant PC (Polycarbonate) -PBT (Polybutylene Terephthalate) plastic alloy

InactiveCN103351593AImprove heat resistanceImprove wear resistanceCrack resistancePolyethylene terephthalate

The invention discloses an aging-resistant PC-PBT plastic alloy, which is composed of the following components in weight part: 100 parts of PC, 20-40 parts of PBT, 4-8 parts of compatibilizer and 0.5-1.5 parts of age resister. The PC-PBT plastic alloy disclosed by the invention has the advantages of good thermal tolerance, good stress cracking resistance, excellent abrasive resistance, excellent chemical corrosive resistance, high low-temperature impact strength, easiness in machining and good coating property, and is mainly applied to bumpers, chassis and panels of superior quality cars, fenders of motorcycles and the like. The aging-resistant PC-PBT plastic alloy also has excellent thermal aging property, thereby being suitable for use in the extremely high temperature environment.

Owner:深圳市高科塑化有限公司

Urush modulating method

InactiveCN101525521AImprove finishing performanceShorten drying timeNatural resin coatingsChemical/physical/physico-chemical stationary reactorsLacquerAcid value

The invention belongs to the filed of chemical modification processing of paint, in particular relates to a urush modulating method, and provides a high-quality raw lacquer modulating method. The modulating process comprises the following steps: filtering raw lacquer by 300-mesh grass cloth to remove impurities; pouring settled tung oil into a polyreaction pot, and adding bismuth nitrate into the polyreaction pot; regulating the acid value of the tung oil to make the acid value reach between 6.7 and 6.9; keeping the temperature of the tung oil after acid value regulation between 35 and 45 DEG C and adding the raw lacquer and a coloring material for mixing; and grinding the mixture of the raw lacquer, the tung oil and the coloring material, and packaging the mixture to obtain a finished product. The urush modulating method improves the labor production efficiency by adopting a novel process to shorten the drying time, improves the coating performance and physicochemical performance of urush, and makes products have high purity and good quality.

Owner:洪克俭 +1

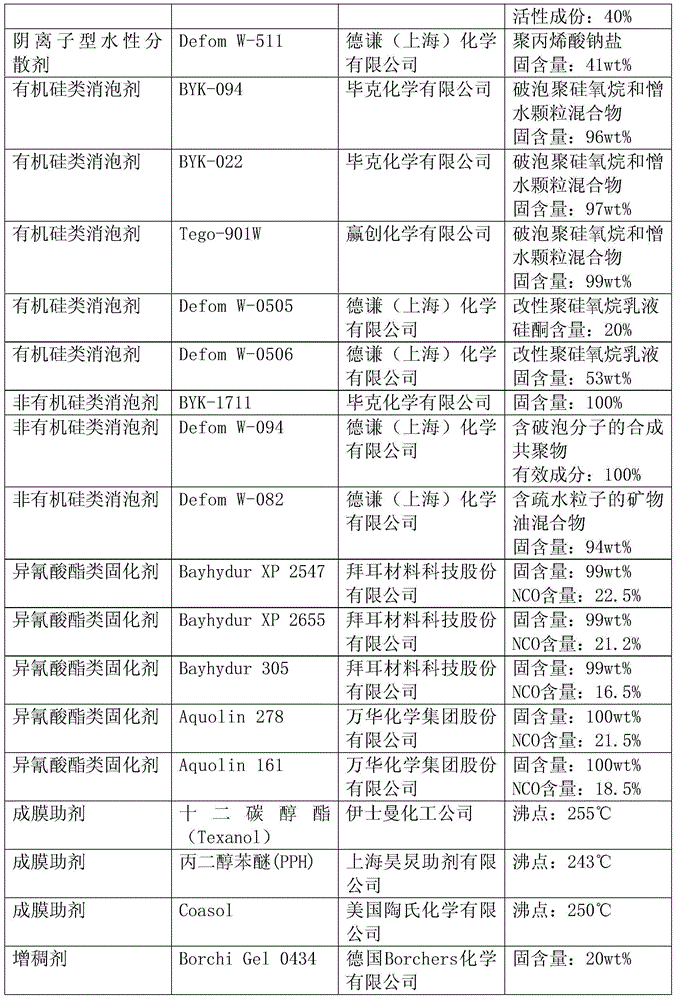

Special flooring waterborne polyurethane sub-gloss varnish product and preparation method and application thereof

ActiveCN106147566AExtended opening hoursExtend construction timePolyurea/polyurethane coatingsSurface finishNational standard

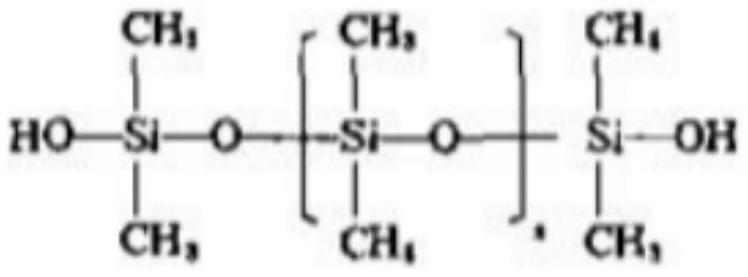

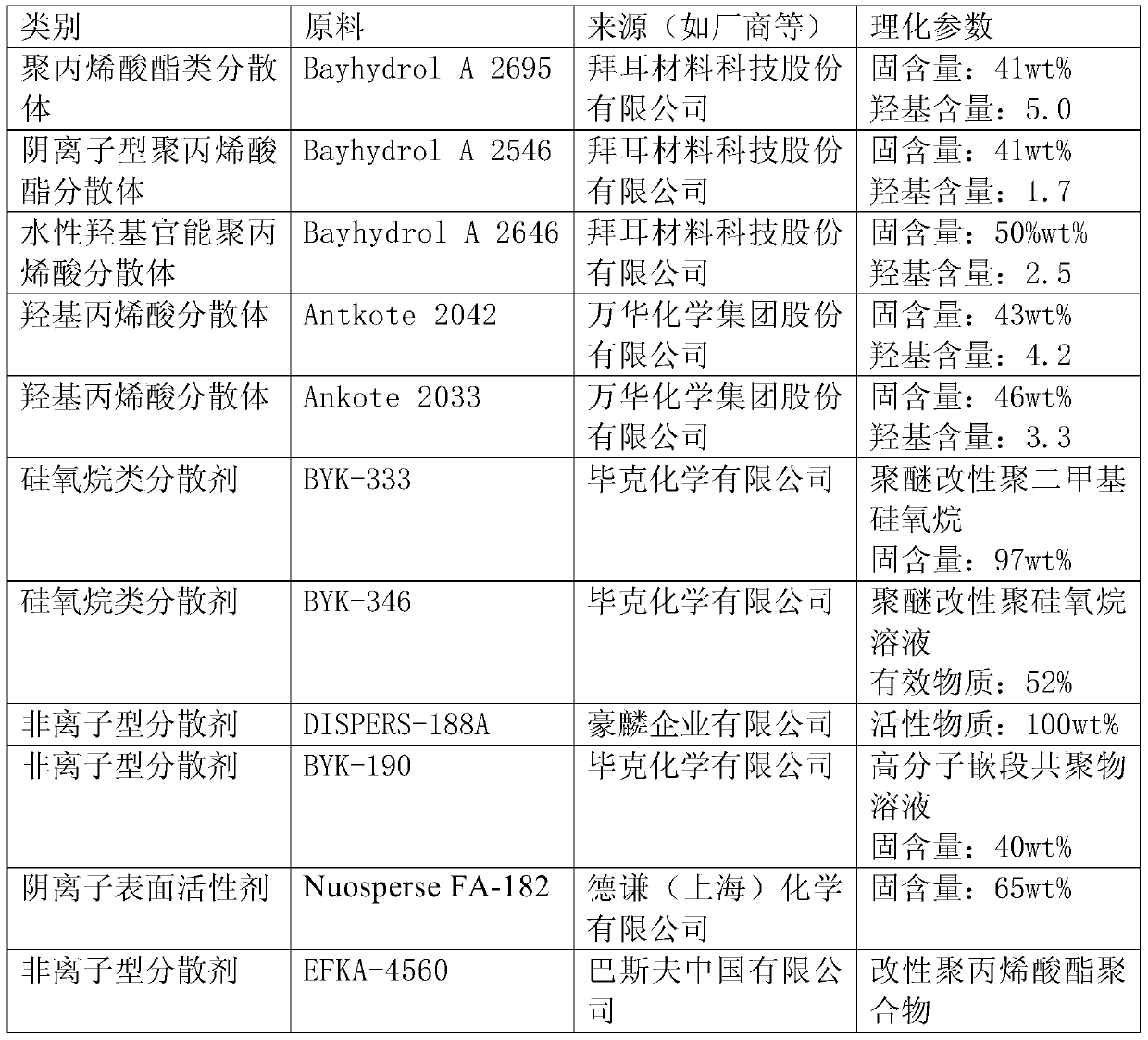

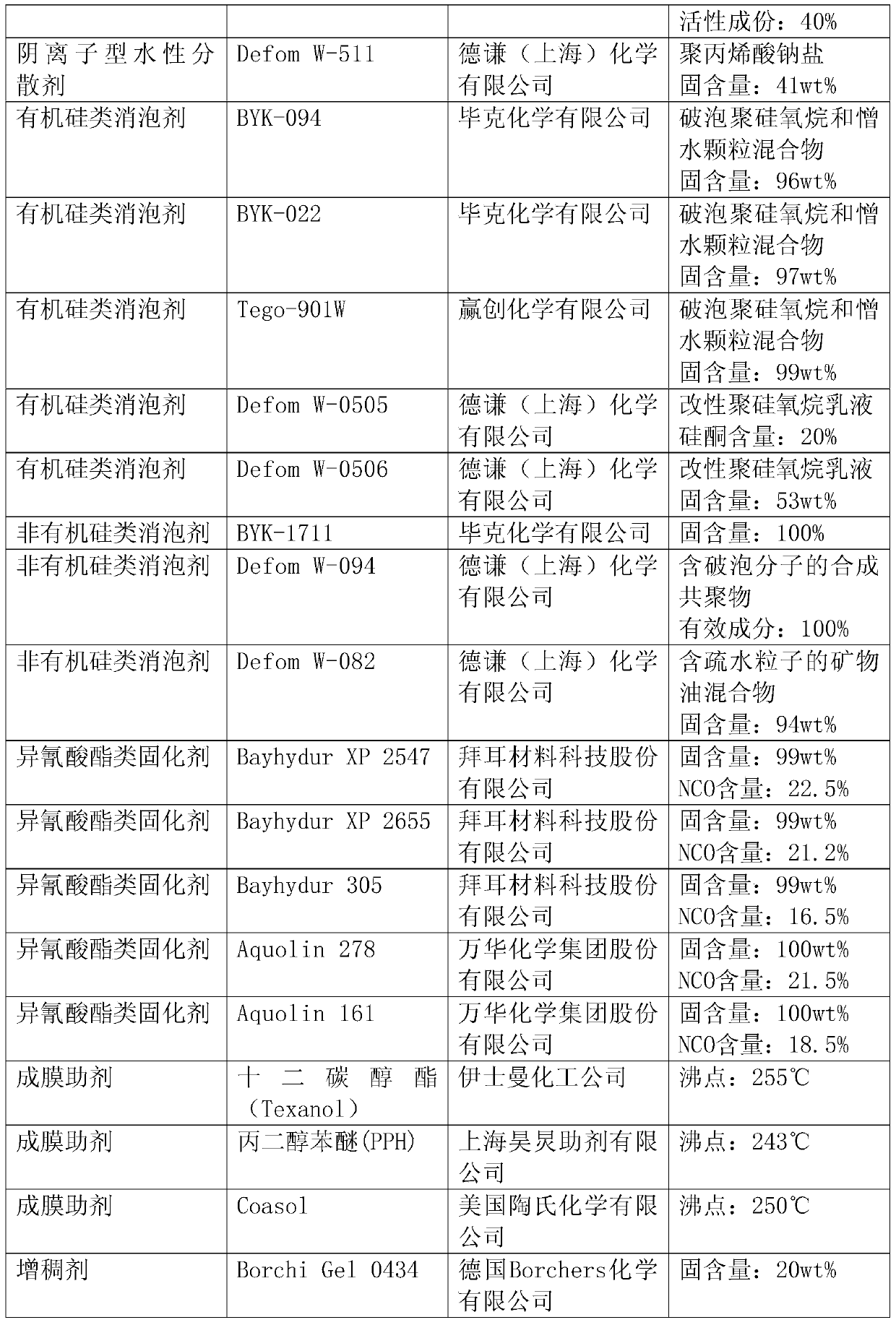

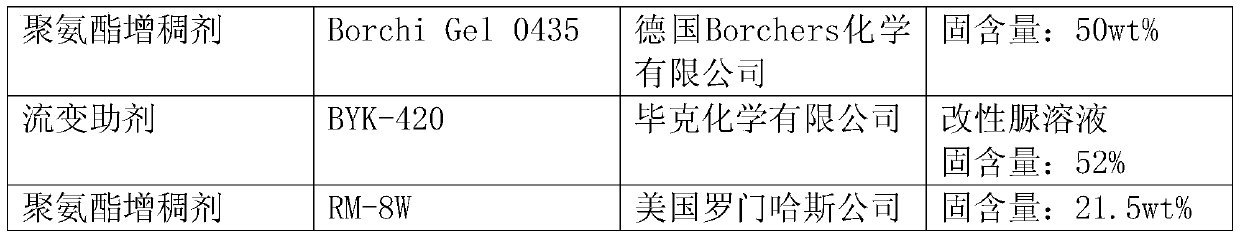

The invention relates to a special flooring waterborne polyurethane sub-gloss varnish product and a preparation method and application thereof. Particularly, the varnish product comprises a first container and a second container; the first container comprises a component A which is prepared from, by weight, 40-70 parts of polyacrylate dispersoid, 0.01-5 parts of siloxane dispersing agent, 0.01-5 parts of organosilicone defoaming agent and 0.01-5 parts of non-organosilicone defoaming agent; the second container comprises a component B which is prepared from 10-35 parts by weight of isocyanate curing agent. The invention further discloses the preparation method and application of the varnish product. The varnish product is excellent in surface finishing effect and chemical resistance, other comprehensive properties are balanced, and the varnish product can well meet various indexes of requirements of the national standard.

Owner:NIPPON PAINT CHINA

Ultraviolet (UV) base oil metal tank UV printing and coating method

ActiveCN103909754AGood flexibilityImprove impact resistancePolyurea/polyurethane coatingsOther printing apparatusUltravioletSolvent

The invention relates to an ultraviolet (UV) base oil metal tank UV printing and coating method which includes the following steps: 1) pre-printing computer direct platemaking; 2) inner coating which includes adopting inner coating to coat the inner surface; 3) conducting instantaneous high temperature processing on the surface of a base material; 4) instantaneous continuous completion of UV base oil coating, UV base oil solidification through a UV lamp and UV ink printing; 5) follow-up continuous solidification of a UV ink layer through a UV lamp group; 6) conducting polishing and coating to protect printed patterns from being scrapped and damaged. By means of the method, the UV base oil outer coating replaces the traditional solvent type base oil outer coating, the film layer is thin, natural gas energy consumed by tunnel type drying room drying and solidification and waste gas discharged to the nature are greatly reduced, the energy is saved, and the environment is protected. In addition, the new process that the UV base oil coating and UV ink printing are finished together continuously is achieved, the printing and coating production efficiency can be greatly improved, and meanwhile coating capacity of a coating line is released.

Owner:SHANGHAI BAOYIN METAL DECORATION

Outdoor wall corrosion-resistant coating and preparation method thereof

InactiveCN107652849AAvoid coating peelingLow costAntifouling/underwater paintsPaints with biocidesDamp environmentHydroxypropylmethyl cellulose

The invention discloses an anticorrosion coating for outdoor walls and a preparation method thereof, which is composed of the following components in parts by weight: 10-20 parts of epoxy resin, 1-3 parts of hydroxypropyl methylcellulose, and 1-3 parts of titanium dioxide 2 parts, 5-8 parts of 4-methyl-3-pentenone, 7-12 parts of film-forming agent, 1-2 parts of dodecyl dimethyl betaine, 30-90 parts of water, 3-parts of thickener 5 parts, preservative 2‑5 parts. Wherein, the anticorrosion agent is composed of one of quaternary ammonium salt, tribromophenol, ageratum, eggshell powder, imidazolidinyl urea, citric acid, ethoxylated glyceryl monostearate, sorbitol, and quinoa extract one or several components. The coating prepared by the present invention has the characteristics of anti-corrosion, can effectively inhibit the activity of microorganisms such as bacteria or fungi, and prevent the coating from falling off due to the reproduction of microorganisms. It is suitable for long-term humid environments and solves the problem of existing coatings. It is easy to be corroded and peeled off due to microbial reproduction in a humid environment, and it has an excellent finishing effect while reducing costs.

Owner:FOSHAN CITY SANSHUI DISTRICT MANYA ENVIRONMENTAL PROTECTION TECH CO LTD

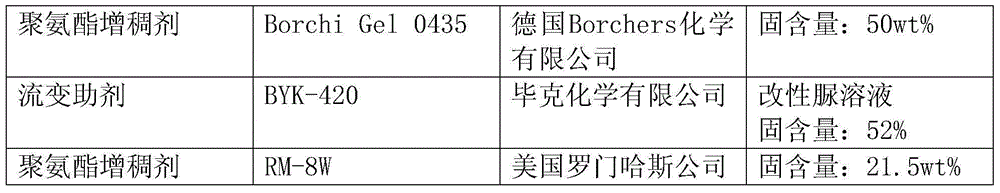

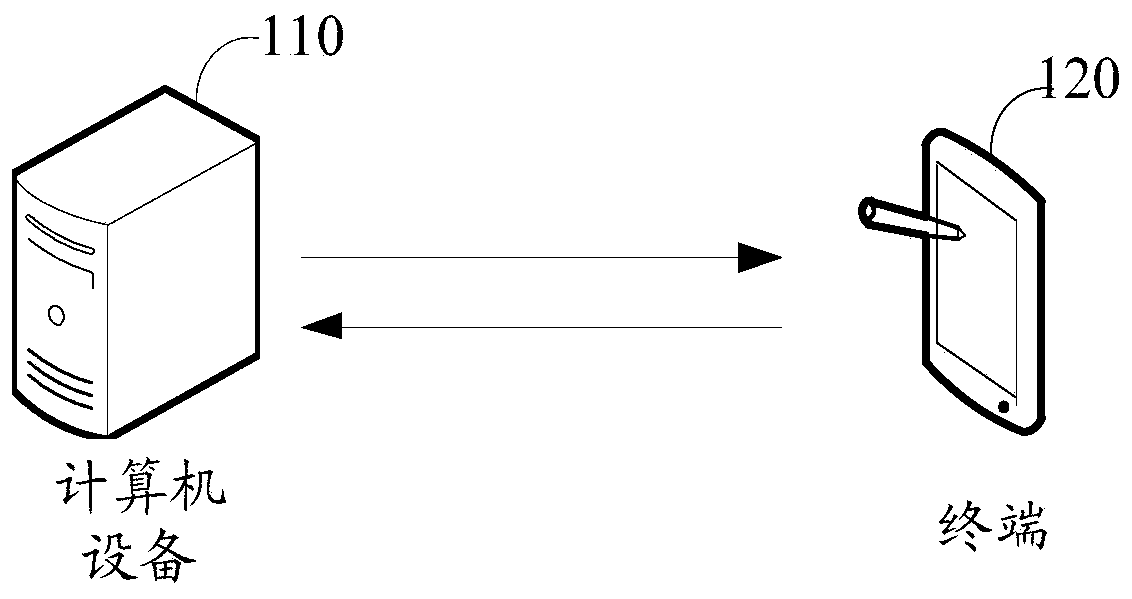

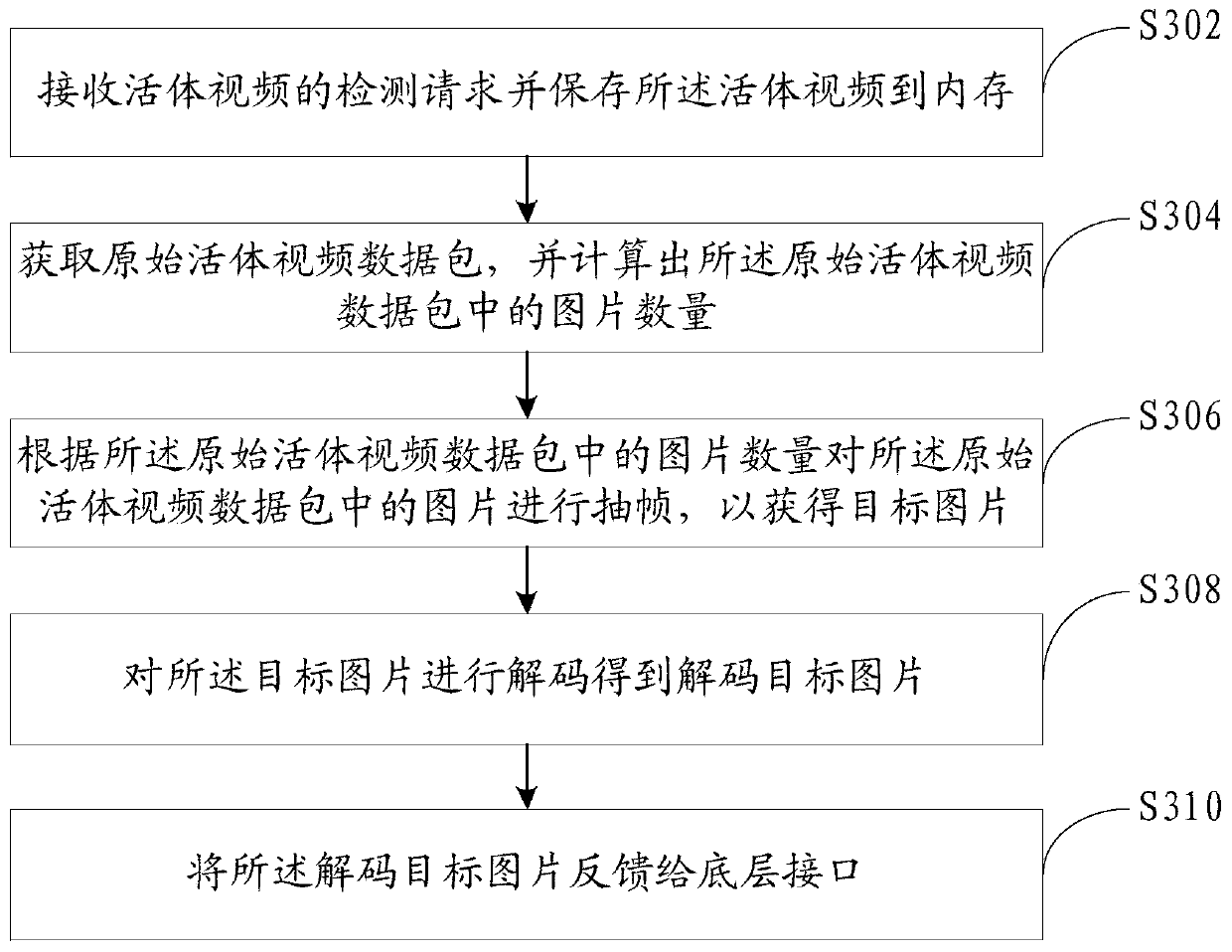

Living body video picture processing method and device, computer equipment and storage medium

PendingCN111428568AImprove finishing performanceHigh precisionProcessor architectures/configurationSelective content distributionData packTerm memory

The invention relates to living body detection of a biological recognition technology, and provides a living body video picture processing method and device, computer equipment and a storage medium. The method comprises the following steps: receiving a detection request of a living body video and storing the living body video into a memory; obtaining an original living body video data packet, andcalculating the number of pictures in the original living body video data packet; performing frame extraction on the pictures in the original living body video data packet according to the number of the pictures in the original living body video data packet to obtain a target picture; decoding the target picture to obtain a decoded target picture; and feeding back the decoded target picture to a bottom layer interface. The device, the computer equipment and the storage medium are all used for processing the living body video pictures based on the steps of the method. According to the method, intermediate processing links are reduced by directly operating in the memory, the living body video arrangement processing performance is improved, the processing speed of living body video detectiondecoding videos is increased, and the performance loss of a GPU is reduced.

Owner:PING AN TECH (SHENZHEN) CO LTD

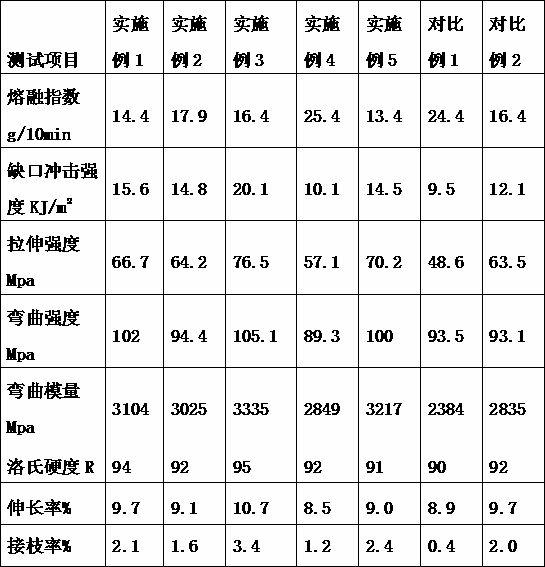

Copolymer of grafting maleic anhydride on molten polypropylene and preparation method for copolymer

The invention discloses copolymer of grafting maleic anhydride on molten polypropylene and a preparation method for the copolymer. The preparation method comprises the following steps of: uniformly stirring the following raw materials in percentage by weight: 85 to 98.6 percent of polypropylene, 0.5 to 8 percent of maleic anhydride, 0.5 to 10 percent of beta-pinene, 0.2 to 3.5 percent of initiator and 0.2 to 2 percent of antioxidant; and performing melt extrusion granulation by using a stepwise heating mode. A weight ratio of the maleic anhydride to the beta-pinene in the copolymer is 1:0.5-1:20. A second comonomer of beta-pinene is introduced, the grafting rate of grafting the maleic anhydride on the polypropylene is improved, and the beta-pinene has a crosslinking function and can keep the impact strength.

Owner:ZHONGSHAN DIANSHI PLASTIC

Copolymer of glycidyl methacrylate and polypropylene and preparation method thereof

The invention discloses copolymer of glycidyl methacrylate and polypropylene and a preparation method thereof. The preparation method comprises the following steps of: uniformly stirring the following raw materials in percentage by weight: 85 to 98 percent of polypropylene, 0.5 to 8 percent of glycidyl methacrylate, 0.5 to 13 percent of divinylbenzene, 0.1 to 3.5 percent of initiator and 0.1 to 2 percent of antioxidant, and performing melt extrusion granulation by using a stepwise heating mode. A weight ratio of the glycidyl methacrylate to the divinylbenzene in the copolymer is 1:0.6-1:16. A second cograft monomer of divinylbenzene is introduced, and the grafting rate of grafting the glycidyl methacrylate on the polypropylene is improved.

Owner:ZHONGSHAN DIANSHI PLASTIC

Urush modulating method

InactiveCN101525521BImprove finishing performanceShorten drying timeNatural resin coatingsChemical/physical/physico-chemical stationary reactorsLacquerAcid value

The invention belongs to the filed of chemical modification processing of paint, in particular relates to a urush modulating method, and provides a high-quality raw lacquer modulating method. The modulating process comprises the following steps: filtering raw lacquer by 300-mesh grass cloth to remove impurities; pouring settled tung oil into a polyreaction pot, and adding bismuth nitrate into thepolyreaction pot; regulating the acid value of the tung oil to make the acid value reach between 6.7 and 6.9; keeping the temperature of the tung oil after acid value regulation between 35 and 45 DEGC and adding the raw lacquer and a coloring material for mixing; and grinding the mixture of the raw lacquer, the tung oil and the coloring material, and packaging the mixture to obtain a finished product. The urush modulating method improves the labor production efficiency by adopting a novel process to shorten the drying time, improves the coating performance and physicochemical performance of urush, and makes products have high purity and good quality.

Owner:洪克俭 +1

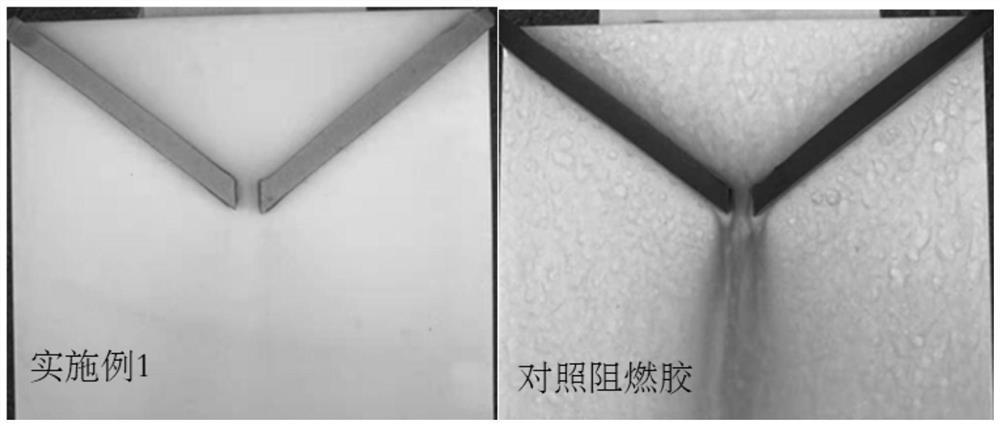

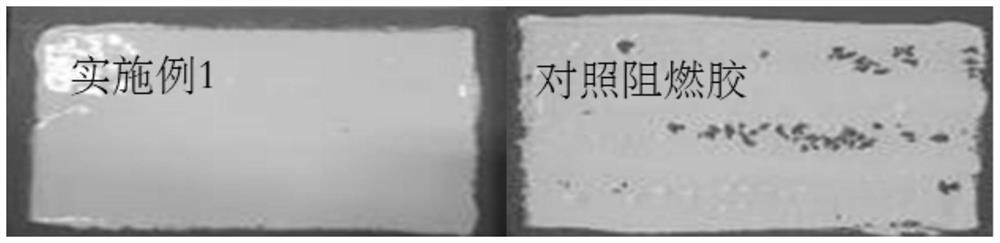

Single-component modified silicone flame-retardant sealant and preparation method thereof

PendingCN112680163AEasy to operateReduce demandNon-macromolecular adhesive additivesPolyether adhesivesHydrogen halidePolymer science

The invention discloses a single-component modified silicone flame-retardant sealant and a preparation method thereof, and belongs to the field of high polymer materials. According to the single-component modified silicone flame-retardant sealant disclosed by the invention, siloxane-terminated polyether resin is used as a colloid skeleton raw material, so that the definition of modified silicone in national standard is met, and meanwhile, the problems that a traditional silicone adhesive product is poor in adhesion to a porous material, silicone oil is separated out and causes pollution, and surface coating cannot be carried out can be effectively solved; a halogen-free environment-friendly flame retardant is used, so that toxic gases such as halogen hydride and the like cannot be released due to high temperature under the condition of ensuring the flame retardant effect; and by matching with other components such as a UV-aging-resistant agent and a plasticizer, the obtained flame-retardant sealant product also has good mechanical properties and weather resistance and durability. The invention further provides a preparation method of the single-component modified silicone flame-retardant sealant, the method is simple in operation steps and low in requirements on instruments and process conditions, and industrial large-scale production can be realized.

Owner:盛势达(广州)化工有限公司

Anti-freezing coating for external wall and preparation method of anti-freezing coating

The invention discloses an anti-freezing coating for an external wall and a preparation method of the anti-freezing coating. The anti-freezing coating is prepared from components in parts by weight asfollows: 10-20 parts of polyethylene, 1-3 parts of powdered ink, 1-2 parts of titanium dioxide, 5-8 parts of protein powder, 7-12 parts of a film forming agent, 1-2 parts of shell powder, 30-90 partsof water, 3-5 parts of a thickening agent and 2-5 parts of an anti-freezing agent. The coating prepared on the basis of the formula has the characteristic of short curing time and can keep the characteristic of rapid curing particularly under the low-temperature condition, thereby meeting the requirement of low-temperature construction and being suitable for the low-temperature weather in autumnand winter in north, the problem of poor low-temperature curing effect of an existing coating is solved, and the finishing effect is excellent while the cost is reduced.

Owner:FOSHAN CITY SANSHUI DISTRICT MANYA ENVIRONMENTAL PROTECTION TECH CO LTD

A special floor water-based polyurethane matt varnish product and its preparation method and application

ActiveCN106147566BExtended opening hoursExtend construction timePolyurea/polyurethane coatingsSurface finishNational standard

The invention relates to a special flooring waterborne polyurethane sub-gloss varnish product and a preparation method and application thereof. Particularly, the varnish product comprises a first container and a second container; the first container comprises a component A which is prepared from, by weight, 40-70 parts of polyacrylate dispersoid, 0.01-5 parts of siloxane dispersing agent, 0.01-5 parts of organosilicone defoaming agent and 0.01-5 parts of non-organosilicone defoaming agent; the second container comprises a component B which is prepared from 10-35 parts by weight of isocyanate curing agent. The invention further discloses the preparation method and application of the varnish product. The varnish product is excellent in surface finishing effect and chemical resistance, other comprehensive properties are balanced, and the varnish product can well meet various indexes of requirements of the national standard.

Owner:NIPPON PAINT CHINA

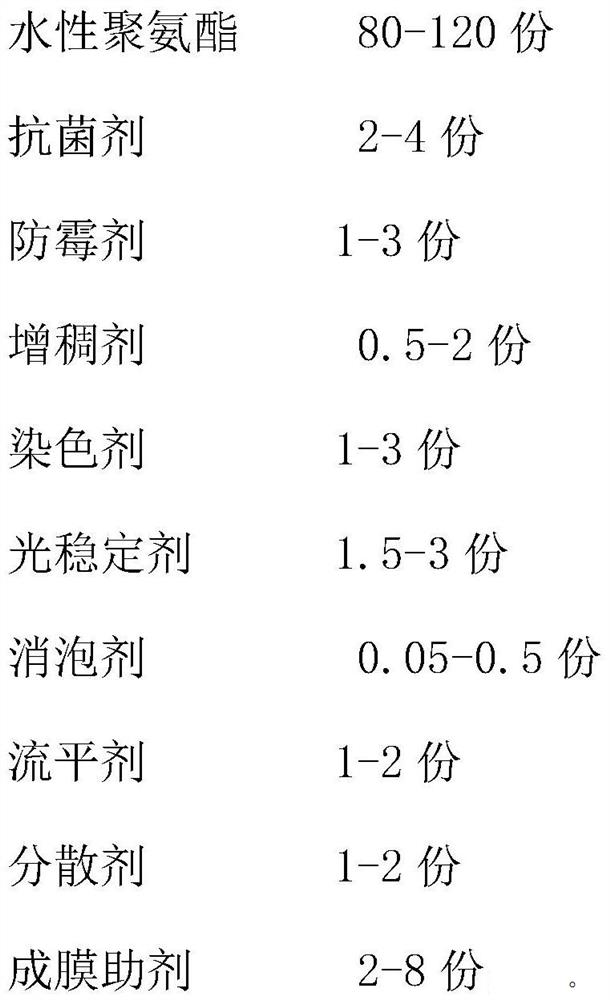

Manufacturing process of nano antibacterial and mildew-proof waterborne polyurethane coating

InactiveCN112778889AImprove antibacterial propertiesGood anti-mildew effectAntifouling/underwater paintsPaints with biocidesKetoneAntibacterial agent

The invention discloses a manufacturing process of a nano antibacterial and mildew-proof waterborne polyurethane coating, which comprises the following steps: firstly, selecting a proper amount of waterborne polyurethane, putting the waterborne polyurethane into a reaction kettle, heating, then adding an antibacterial agent and a mildew-proof agent, heating to 70-90 DEG C, then adding a thickening agent, a light stabilizer, a defoaming agent and a flatting agent, heating to 80-100 DEG C, cooling to room temperature, and adding a coloring agent, a dispersing agent and a coalescing agent into the mixture. The waterborne polyurethane coating prepared by adopting the preparation method disclosed by the invention can have good antibacterial performance and mildew-proof performance, can reduce the breeding speed of microorganisms in the coating, can ensure the viscosity of the coating, cannot damage film-forming substances in the coating, and can ensure a good coating effect of the coating; and nano titanium dioxide is adopted as an antibacterial agent, and benzothiazole-3-ketone is adopted as an anti-mildew agent, so that environmental protection and non-toxicity can be realized, and great guarantee is provided for the body health of constructors and users.

Owner:甘彤

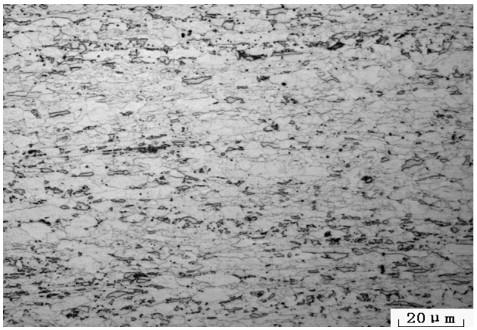

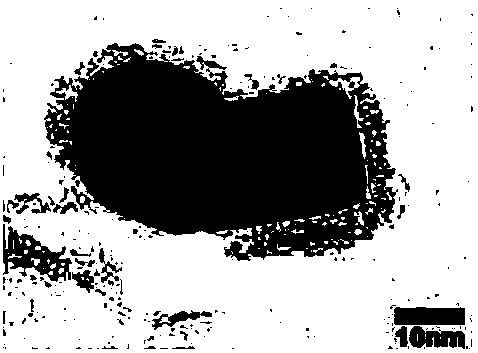

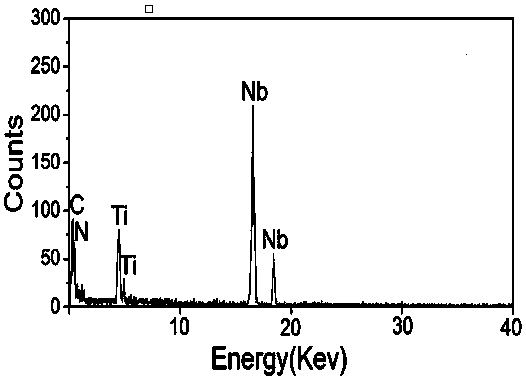

Hot-rolled steel plate for container with yield strength 750mpa and manufacturing method thereof

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

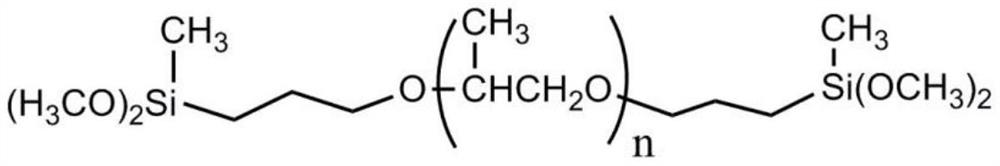

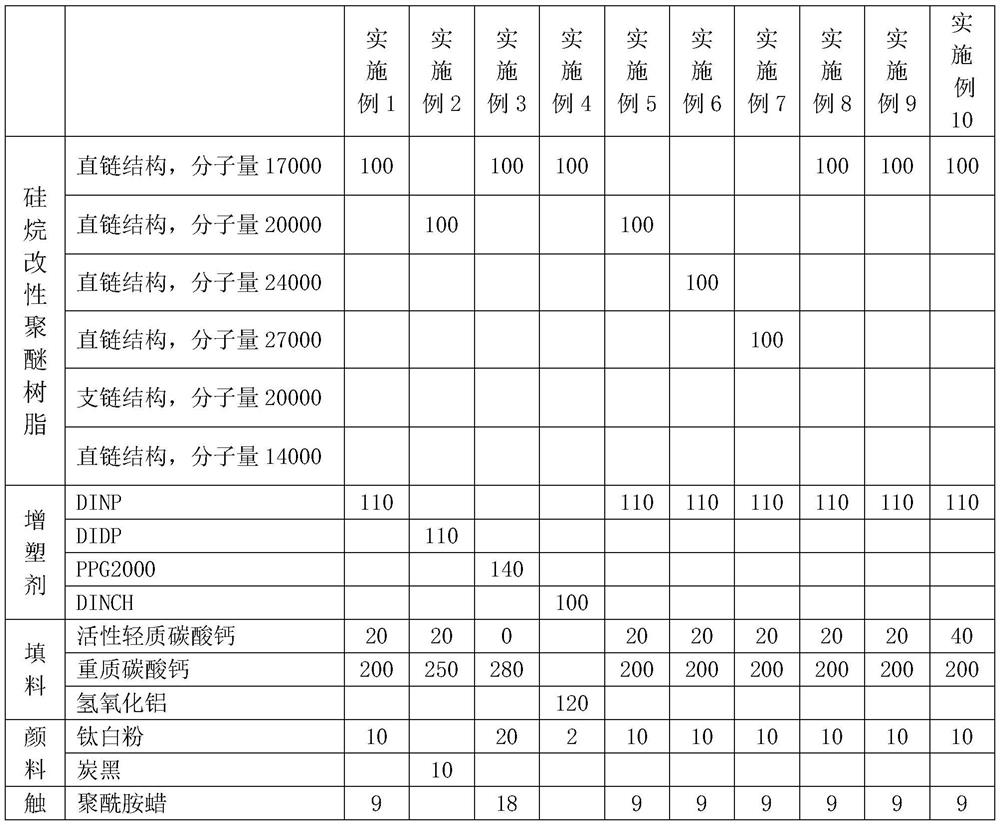

One-component silane-modified polyether sealant for ALC board and preparation method thereof

ActiveCN108587545BGood adhesionLow modulusNon-macromolecular adhesive additivesPolyether adhesivesUv absorbancePolymer science

The invention discloses a single-component silane-modified polyether sealant for ALC boards, which contains the following raw materials in parts by mass: 100 parts of silane-modified polyether resin, 90-150 parts of plasticizer, and 100-100 parts of filler 300 parts, 0~25 parts of pigment, 0~20 parts of thixotropic agent, 0.5~5 parts of UV absorber, 0.5~5 parts of light stabilizer, 0.5~5 parts of water remover, 2~3 parts of first adhesion promoter 0.5-1 part of the second adhesion promoter, 0.05-2 parts of the catalyst. The present invention selects silane-modified polyether resin with a linear structure of 16000-28000 g / mol in number average molecular weight and bis(acetylacetonate) dibutyltin and / or tetraethyl silicate and bis(acetyloxy) The reaction product of dibutyltin is matched, and the first adhesion promoter and the second adhesion promoter and other components are coordinated to prepare a one-component silane-modified polyether sealant for ALC boards, and the prepared single-component The silane-modified polyether sealant has ultra-low modulus, high elongation, fast curing, good ALC board adhesion, and is safe and environmentally friendly, with good stability and excellent coating performance.

Owner:GUANGZHOU JOINTAS CHEM

A kind of flame retardant and high temperature resistant oriented strand board and its preparation method

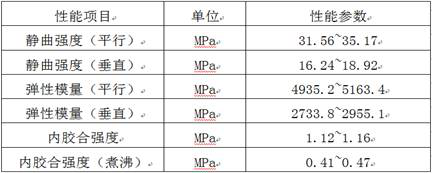

ActiveCN110682394BImprove thermal stabilityImprove flame retardant performanceFlat articlesDomestic articlesWood shavingsPhysical chemistry

The invention provides a flame-retardant and high-temperature resistant oriented particle board, which comprises a surface layer and a core layer, the surface layer is composed of large shavings; the core layer is composed of large shavings and fine shavings, and the paving angle between the surface layer and the core layer is 45-90°. The present invention also provides a method for preparing flame-retardant and high-temperature-resistant oriented strand board, including shavings, initial washing of shavings, drying, re-washing of shavings, draining, balancing, curing, drying, mixing, sizing, paving, hot pressing, Trimming, sanding. The beneficial effects of the present invention are: the flame-retardant and high-temperature-resistant oriented particle board of the present invention has good thermal stability, is not easy to delaminate and crack when heated, and can ensure stable flame-retardant performance; it is difficult to release toxic substances when heated; the added flame-retardant components can effectively adhere to On the surface of shavings, it has good flame retardant performance and can withstand high temperature attack; it has good physical and mechanical properties and good durability.

Owner:寿光市鲁丽木业股份有限公司

A kind of acrylate-modified polyurethane resin for leather finishing and preparation method thereof

ActiveCN103772618BOvercome the disadvantage of low solid contentReduce the disadvantages of low solid contentCoatingsAlcoholAntioxidant

The invention discloses acrylate modified polyurethane resin for leather finish. The acrylate modified polyurethane resin for leather finish is characterized by being prepared from the following components in parts by weight: 50-65 parts of polyalcohol, 140.1-169.54 parts of solvent, 4-10 parts of chain extender micromolecular alcohol, 0.03-0.04 part of antioxidant, 16-34 parts of isocyanate, 0.02-0.03 parts of catalyst, 0.01-0.02 part of polymerization inhibitor, 2.1-3.6 parts of hydroxyl acrylate, 1.15-1.85 parts of end-capping reagent, 0.68-1 part of initiator and 55-77 parts of acrylic monomer. The invention further discloses a preparation method of the acrylate modified polyurethane resin for leather finish. By adopting polyurethane resin as a base material and acrylate as a main modifying material, the product provided by the invention has the advantages of two resins, and the cost is reduced by over 30% compared with that of pure polyurethane. The acrylate modified polyurethane resin for leather finish disclosed by the invention has excellent composite material performance and higher cost performance, so that the solid content is improved by over 50%.

Owner:DONGGUAN HONGDA POLYUREFHANE RESIN

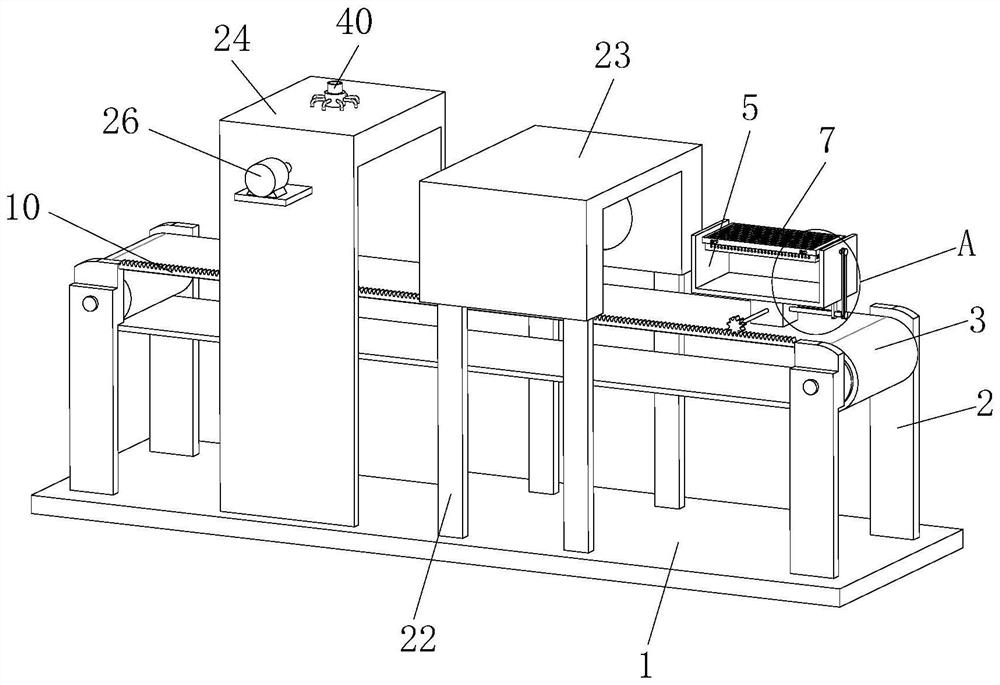

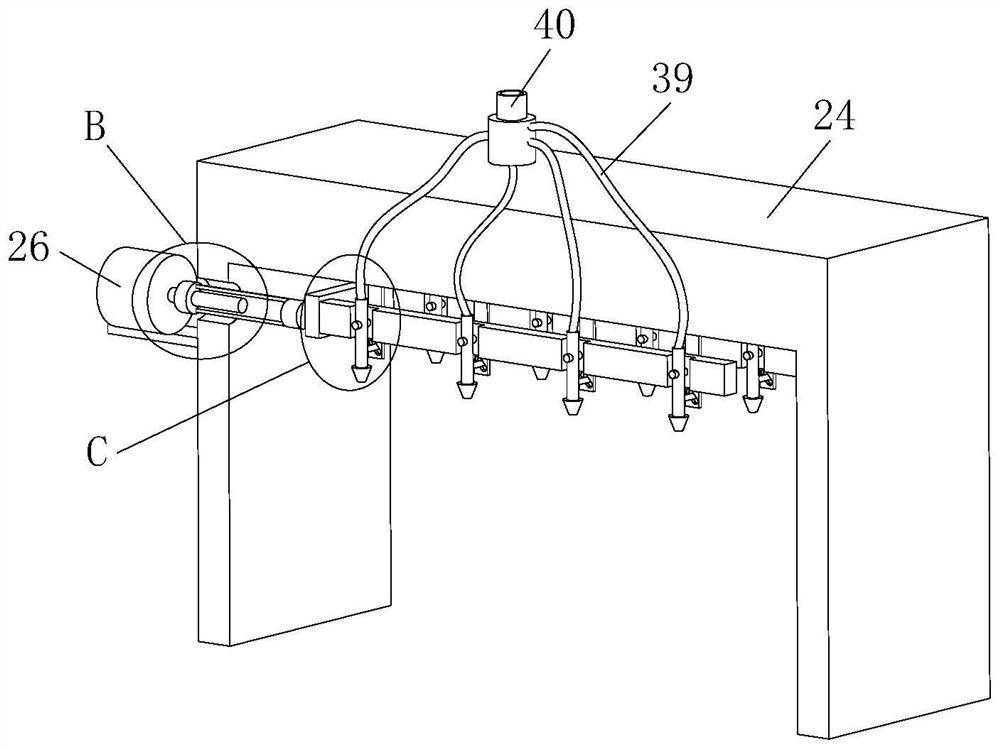

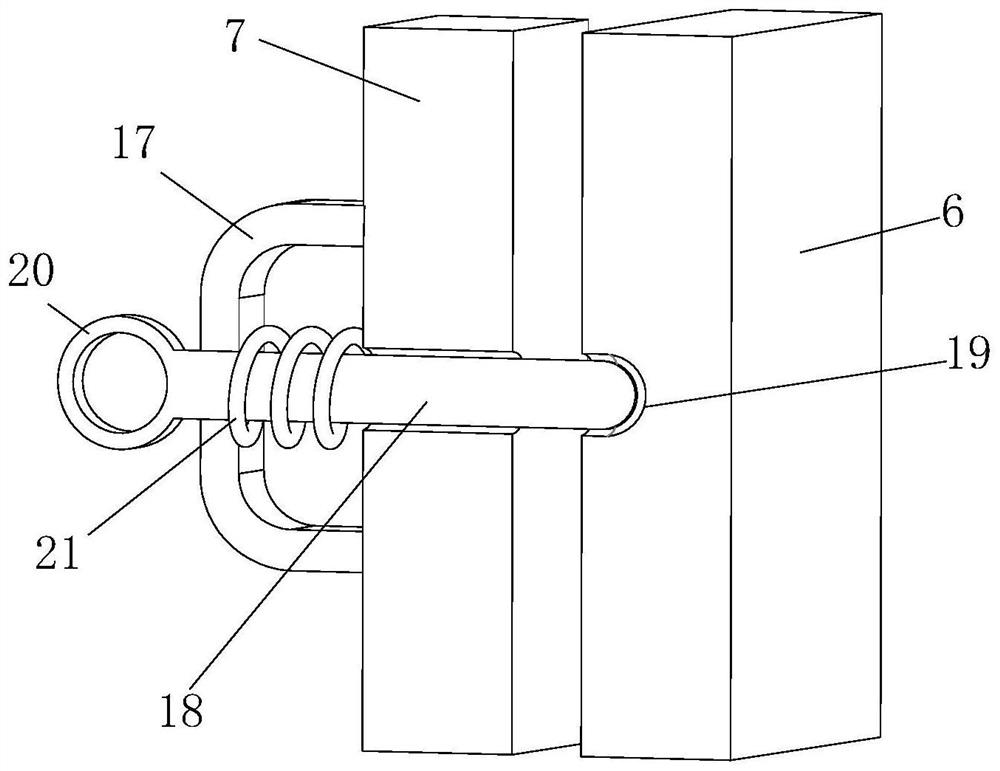

Environment-friendly medium density fiberboard fiber preheating combined process and production equipment thereof

InactiveCN114654556AReduce moisture contentMoisture content hasWood working apparatusFlat articlesFiberMedium density fiberboard

The invention discloses an environment-friendly medium density fiberboard fiber preheating combination process and production equipment thereof, and belongs to the field of medium density fiberboard machining.The environment-friendly medium density fiberboard fiber preheating combination process and production equipment thereof comprise a bottom plate, two vertical plates are fixedly connected to the top face of the bottom plate in a front-back symmetry mode, and a conveying belt is installed between the vertical plates; a plurality of shells are fixedly connected to the side wall of the conveying belt, a fixing plate is fixedly connected to the top faces of the shells, a leakage net is arranged in a cavity of the fixing plate, a cover plate is movably connected to the top face of the leakage net, a driving mechanism is arranged on the side wall of the fixing plate, and two fixing mechanisms are arranged on the front side wall and the rear side wall of the cover plate respectively. Four supporting plates are fixedly connected to the top face of the bottom plate, the same microwave heating box is fixedly connected to the top faces of the supporting plates, and a steam injection heater is installed at the position, close to the left side, of the top face of the bottom plate.

Owner:福人木业(莆田)有限公司

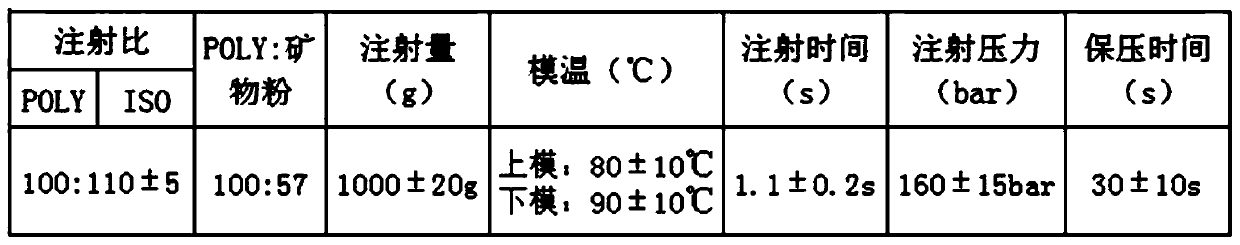

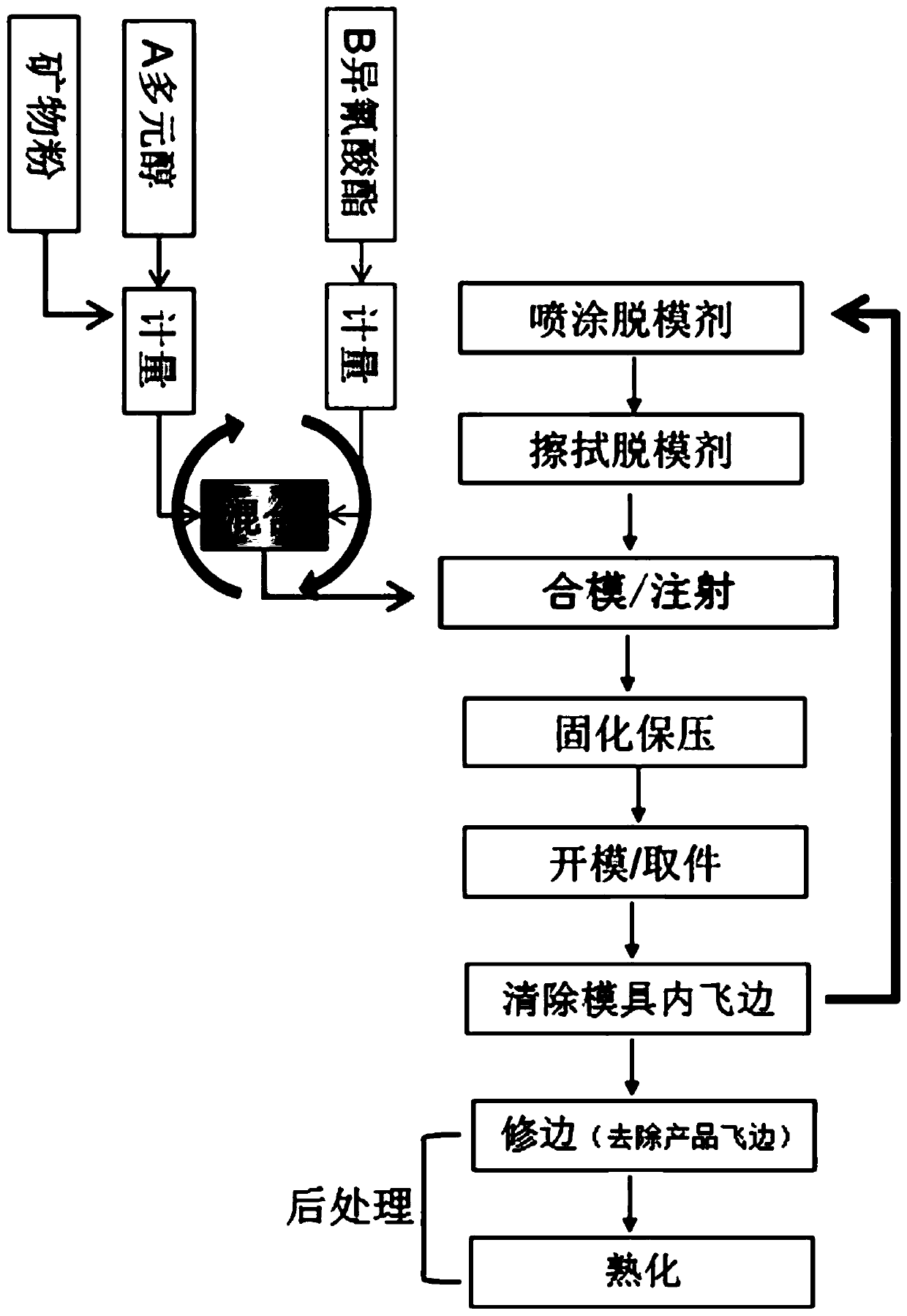

Reaction injection molding technology for automobile spoiler

InactiveCN111469365AImprove finishing performanceImprove mechanical propertiesFlat articlesPolyolMechanical engineering

The invention relates to a reaction injection molding technology for an automobile spoiler. The reaction injection molding technology comprises the following steps of 1, removing burrs in an automobile spoiler mold; 2, spraying a release agent in the automobile spoiler mold; 3, wiping the release agent; 7, adjusting the temperature of an upper mold body to be 80+ / -10 DEG C, and adjusting the temperature of a lower mold body to be 90+ / -10 DEG C; 8, carrying out curing and pressure maintaining, wherein the pressure maintaining time is 30+ / -10 s; and 9, opening the upper mold body and the lower mold body (opening the mold) to take out a product, namely the automobile spoiler. According to the reaction injection molding technology, polyether polyol (POLY), weighed isocyanate (ISO) and weighedmineral powder are mixed into liquid in proportion, the mixed liquid is injected into the automobile spoiler mold at the moment of mixing for curing and pressure maintaining so as to form the automobile spoiler, a thin-wall article is easily produced through the steps, the produced automobile spoiler has good coating performance and excellent mechanical properties, the product design is free, andin addition, the equipment and mold cost is low.

Owner:广东维杰汽车部件制造有限公司

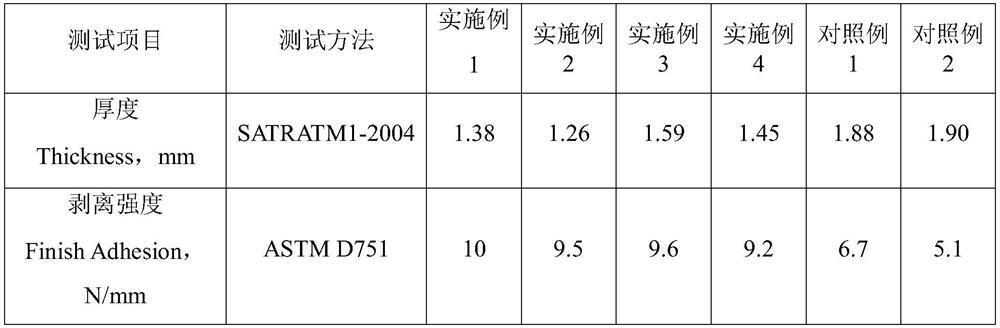

Three-dimensional embossed leather production method

ActiveCN109628660BExcellent adhesionImprove finishing performanceLeather surface mechanical treatmentLeather surface finishingAcrylic resinSurface grinding

The invention relates to a three-dimensional embossed leather manufacturing method and belongs to the technical field of leather manufacturing. The method includes steps that the raw leather is sequentially subjected to leather grinding, spray filling, roll coating filling, static drying, rolling finish, embossing plate, surface grinding, and softening to become three-dimensional embossed leather,specifically, the step of spray filling includes that spraying a first filling on the surface of the ground raw leather; the spray quality is 5-10 g per square foot; and the first filling is composedof, by mass, 50%-55% of water, 30%-40% of a first aqueous acrylic resin dispersion, and 7%-15% of a first penetrant, and the water, the first aqueous acrylic resin dispersion and the first penetrantaccount for 100% in total. The finished three-dimensional embossed leather according to the method has a strong sense of three-dimensionality, has good peeling strength and a good coating effect, andthe method is relatively simple and convenient to promote.

Owner:漳州香洲皮革有限公司

Stain-resistant porcelain-like coating used for study room

InactiveCN106554669AStorage stableGood stain resistanceAntifouling/underwater paintsPaints with biocidesIonEmulsion

The invention discloses a stain-resistant porcelain-like coating used for study room. The stain-resistant porcelain-like coating comprises the following raw materials by mass parts: 25-35 parts of polyvinyl alcohol, 15-20 parts of a synthetic resin emulsion, 1-2 parts of hydroxymethyl cellulose, 3-5 parts of sodium hexametaphosphate, 0.1-0.3 parts of a viscosity stabilizing agent, 15-20 parts of light calcium carbonate, 5-15 parts of heavy calcium carbonate, 5-8 parts of ash calcium-powder, and 15-19 parts of deionized water. The coating has the advantages of stable storage, scrubbing resistance and good stain resistance, due to smoothness of luster of a film, the ink trace on the film can be scrubbed with water, the ink molecules cannot be stayed in the film molecules, the appearance shows strong stain and ink repellent performance, and the coating effect is good.

Owner:李尧

Anti-aging pc-pbt plastic alloy

The invention discloses an aging-resistant PC-PBT plastic alloy, which is composed of the following components in weight part: 100 parts of PC, 20-40 parts of PBT, 4-8 parts of compatibilizer and 0.5-1.5 parts of age resister. The PC-PBT plastic alloy disclosed by the invention has the advantages of good thermal tolerance, good stress cracking resistance, excellent abrasive resistance, excellent chemical corrosive resistance, high low-temperature impact strength, easiness in machining and good coating property, and is mainly applied to bumpers, chassis and panels of superior quality cars, fenders of motorcycles and the like. The aging-resistant PC-PBT plastic alloy also has excellent thermal aging property, thereby being suitable for use in the extremely high temperature environment.

Owner:深圳市高科塑化有限公司

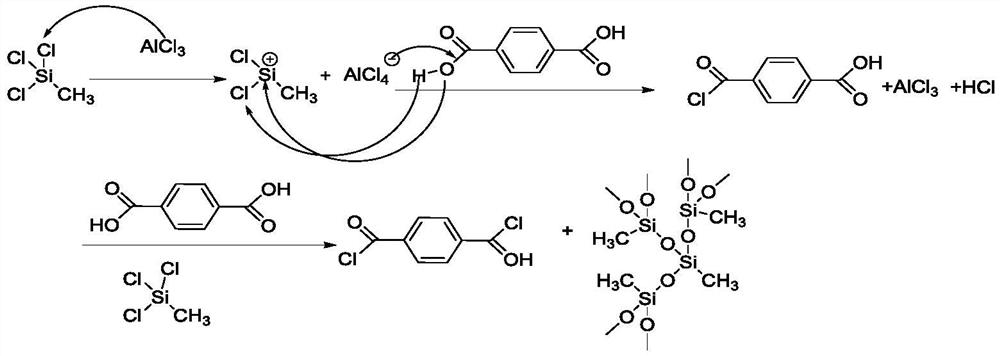

Process for preparing paraphthaloyl chloride

ActiveCN111848392AReduce generationImprove finishing performanceFireproof paintsOrganic compound preparationPtru catalystCarbon Chloride

The invention relates to a new process for preparing paraphthaloyl chloride. The process comprises the following steps: reacting terephthalic acid with methyltrichlorosilane at 40-77 DEG C for 6-12 hours by using carbon tetrachloride as a solvent and Lewis acid as a catalyst, and introducing hydrogen chloride gas into an absorption device to prepare hydrochloric acid; after the reaction is finished, evaporating the solvent carbon tetrachloride under reduced pressure for reuse, evaporating the product paraphthaloyl chloride under reduced pressure, cooling, crystallizing and drying to obtain thehigh-quality paraphthaloyl chloride; cooling mother liquor, adding water to quench the Lewis acid, carrying out solid-liquid separation on byproduct polymethylsilsesquioxane, and drying to obtain polymethylsilsesquioxane with favorable quality.

Owner:QINGDAO UNIV OF SCI & TECH

A kind of technology for preparing terephthaloyl chloride

ActiveCN111848392BReduce generationImprove finishing performanceFireproof paintsOrganic compound preparationMethyltrichlorosilaneCarbon Chloride

A new process for preparing terephthaloyl chloride, carbon tetrachloride is used as solvent, Lewis acid is used as catalyst, terephthalic acid and methyl trichlorosilane are reacted at 40-77°C for 6-12h, hydrogen chloride gas enters the absorption device to produce into hydrochloric acid. After the reaction is completed, the solvent carbon tetrachloride is evaporated under reduced pressure for mechanical use, and then the product terephthaloyl chloride is evaporated under reduced pressure, the temperature is lowered, crystallized, and dried to obtain high-quality terephthaloyl chloride. After cooling the mother liquor and adding water to quench the Lewis acid, the by-product polymethylsilsesquioxane is subjected to solid-liquid separation and dried to obtain polymethylsilsesquioxane with good quality.

Owner:QINGDAO UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com