Copolymer of glycidyl methacrylate and polypropylene and preparation method thereof

A polypropylene copolymer and glycidyl ester technology, which is applied in the field of molten polypropylene grafted glycidyl methacrylate copolymer and its preparation field, can solve the problem of reduced impact resistance, increased material fluidity, deterioration of matrix performance, etc. problems, to achieve the effect of improving impact strength, low equipment requirements, and improving paintability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

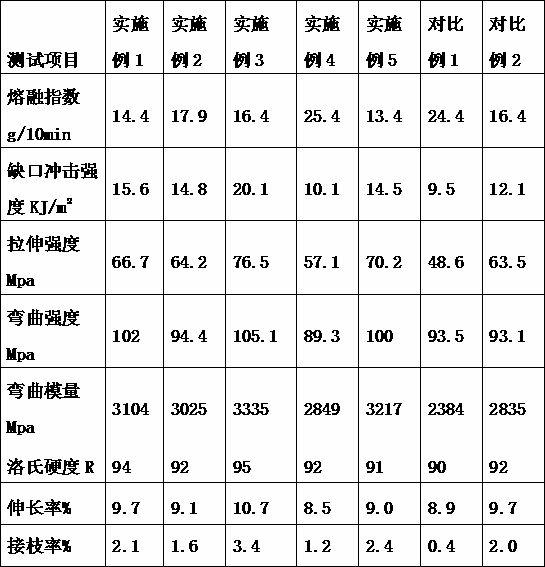

Examples

Embodiment 1

[0028] Mix glycidyl methacrylate 3%, di-tert-butyl peroxide 1.2%, p-divinylbenzene 2.5%, antioxidant 168 0.2%, antioxidant 1010 0.2%, pre-mix for 3 minutes, then add 92.9% polypropylene powder is fed into a high-speed batch mixer and stirred together for 5 minutes. Put the stirred mixture in a twin-screw machine to melt, extrude and granulate. The process conditions are: twin-screw first to third zone temperature 140°C, fourth to ninth zone temperature 160°C, head temperature 170°C, main screw speed 80 rpm , feeding screw speed 20 rev / min.

Embodiment 2

[0030] Mix glycidyl methacrylate 2.0%, di-tert-butyl peroxide 0.8%, p-divinylbenzene 1.5%, antioxidant 168 0.2%, antioxidant 1010 0.2%, pre-mix for 3 minutes, then add 95.3 % polypropylene into a high-speed batch mixer and then mixed together for 5 minutes. Put the stirred mixture in a twin-screw machine to melt, extrude and granulate. The process conditions are: twin-screw first to third zone temperature 150°C, fourth to ninth zone temperature 180°C, head temperature 195°C, main screw speed 150 rpm , The feeding screw speed is 45 rev / min.

Embodiment 3

[0032] Mix glycidyl methacrylate 5.0%, di-tert-butyl peroxide 1.8%, p-divinylbenzene 3.0%, antioxidant 168 0.2%, antioxidant 1010 0.2%, pre-mix for 3 minutes, then add 89.8% polypropylene to a high speed batch mixer and then blend together for 5 minutes. Put the stirred mixture in a twin-screw machine to melt, extrude and granulate. The process conditions are: twin-screw first to third zone temperature 145°C, fourth to ninth zone temperature 170°C, head temperature 185°C, main screw speed 100 rpm , The feeding screw speed is 35 rev / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com