One-component silane-modified polyether sealant for ALC board and preparation method thereof

A silane-modified polyether, one-component technology, used in polyether adhesives, adhesives, non-polymer adhesive additives, etc., can solve the problem of affecting the strength and sealing effect of the sealing material body, and destroying the integrity of the ALC sheet interface. To avoid problems of paintability, good adhesion of ALC boards, and suitable curing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

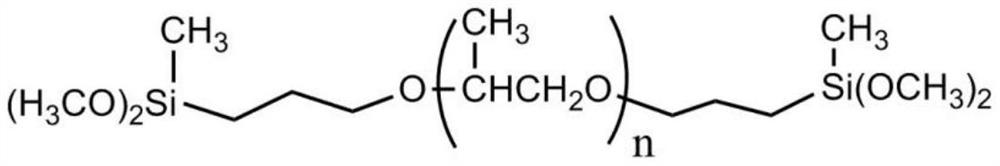

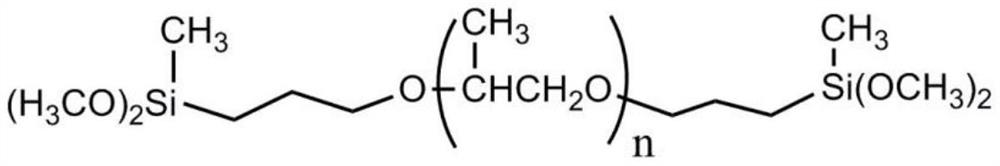

Method used

Image

Examples

Embodiment 1~10 and comparative example 1~4

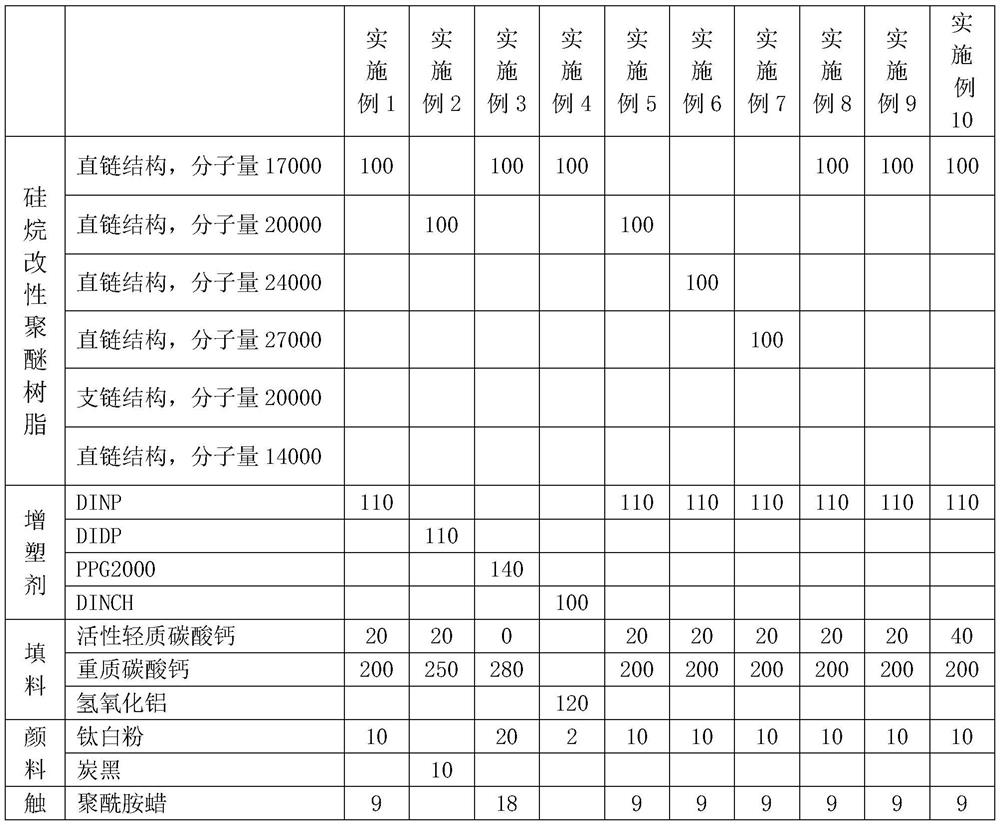

[0047] The formula of the one-component silane-modified polyether sealant of Examples 1-10 is shown in Table 1;

[0048] The formulations of the one-component silane-modified polyether sealants of Comparative Examples 1-4 are shown in Table 2.

[0049] The preparation steps of the one-component silane-modified polyether sealants of Examples 1-10 and Comparative Examples 1-4 are as follows:

[0050] S1. Dry the filler and the pigment at 120°C for 12 hours respectively, and set aside;

[0051] S2. Add modified silane resin, plasticizer, dried filler (pigment), thixotropic agent, UV absorber, light stabilizer, water remover, adhesion promoter and catalyst in turn to the planetary kettle and mix evenly , stirred for 40 minutes under the condition of vacuum pressure of -0.09MPa~-0.1MPa, and then the product was obtained after discharging.

[0052] Table 1 The formula of the one-component silane-modified polyether sealant of Examples 1-10

[0053]

[0054]

[0055] Table 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com