Hot-rolled steel plate for container with yield strength 750mpa and manufacturing method thereof

A technology of hot-rolled steel sheet and yield strength, which is applied in the field of hot-rolled steel sheet for containers with a yield strength of 750Mpa and its manufacturing field, can solve the problems of high production cost and easy formation of rust red scale, and achieve long service life and high strength performance. , the effect of high strength and elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

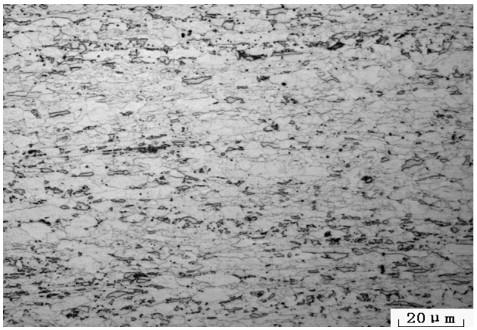

[0049] In the following, the present invention will be further described in conjunction with Examples 1 to 3.

[0050] Table 1 shows the chemical composition (by weight percentage) of the steel in the example of the present invention, and the balance is Fe and unavoidable impurities.

[0051] Table 1 The chemical composition of the steel in the embodiment of the present invention, unit: weight percentage

[0052]

[0053] According to the requirements of the material composition design of the present invention, the molten iron is pre-desulfurized, the converter top and bottom composite blowing, the Ar blowing station (or LF furnace) ensures that the bottom blowing Ar stirring time is greater than 5 minutes, and the RH furnace performs fine adjustment of the composition and vacuum cycle degassing treatment , To ensure that the RH pure degassing time is greater than 15 minutes, and at the same time, feed an appropriate amount of calcium-iron wire, blow Ar protection throughout the proc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com