A special floor water-based polyurethane matt varnish product and its preparation method and application

A product and varnish technology, applied in the field of special floor waterborne polyurethane matt varnish products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

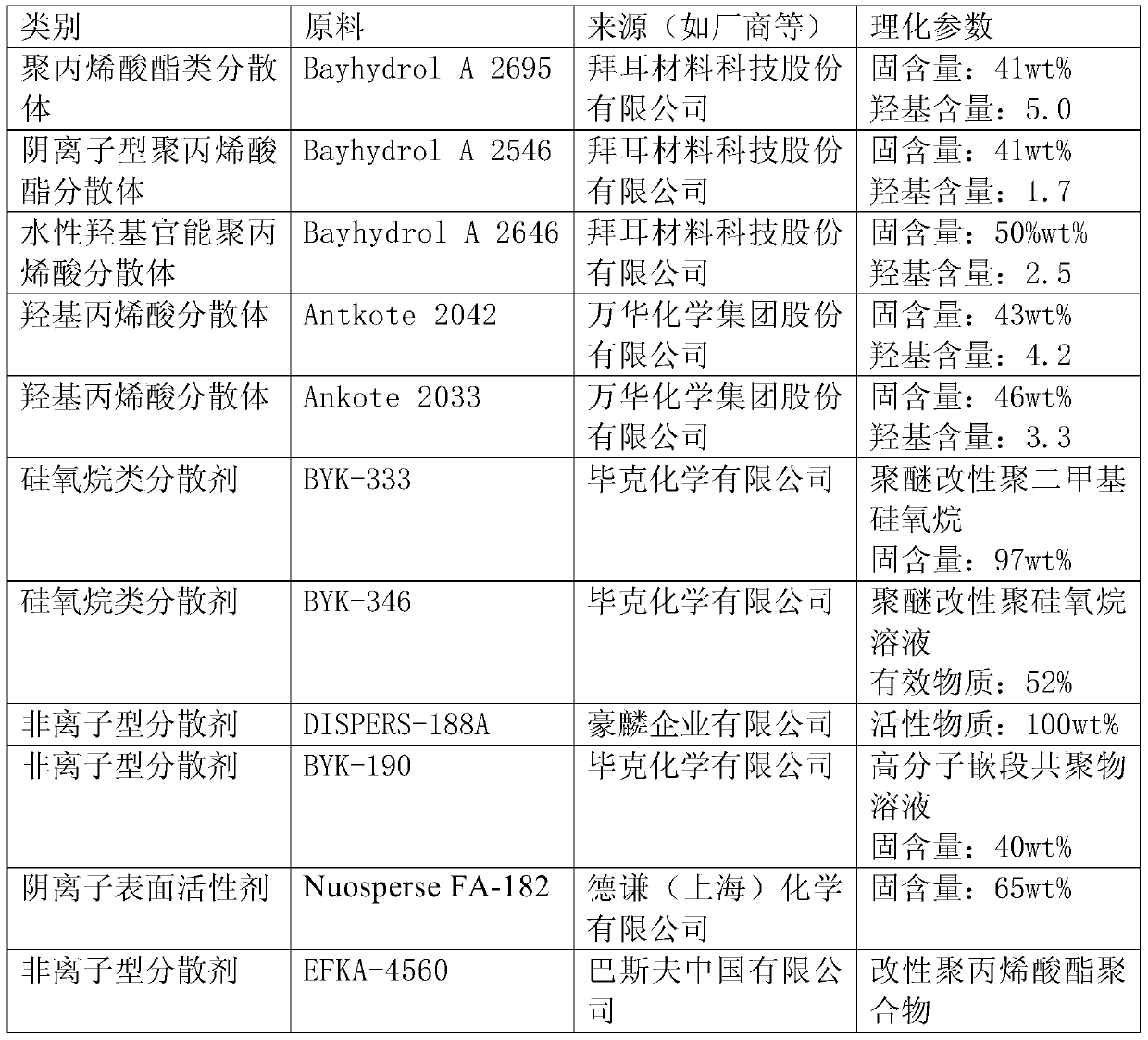

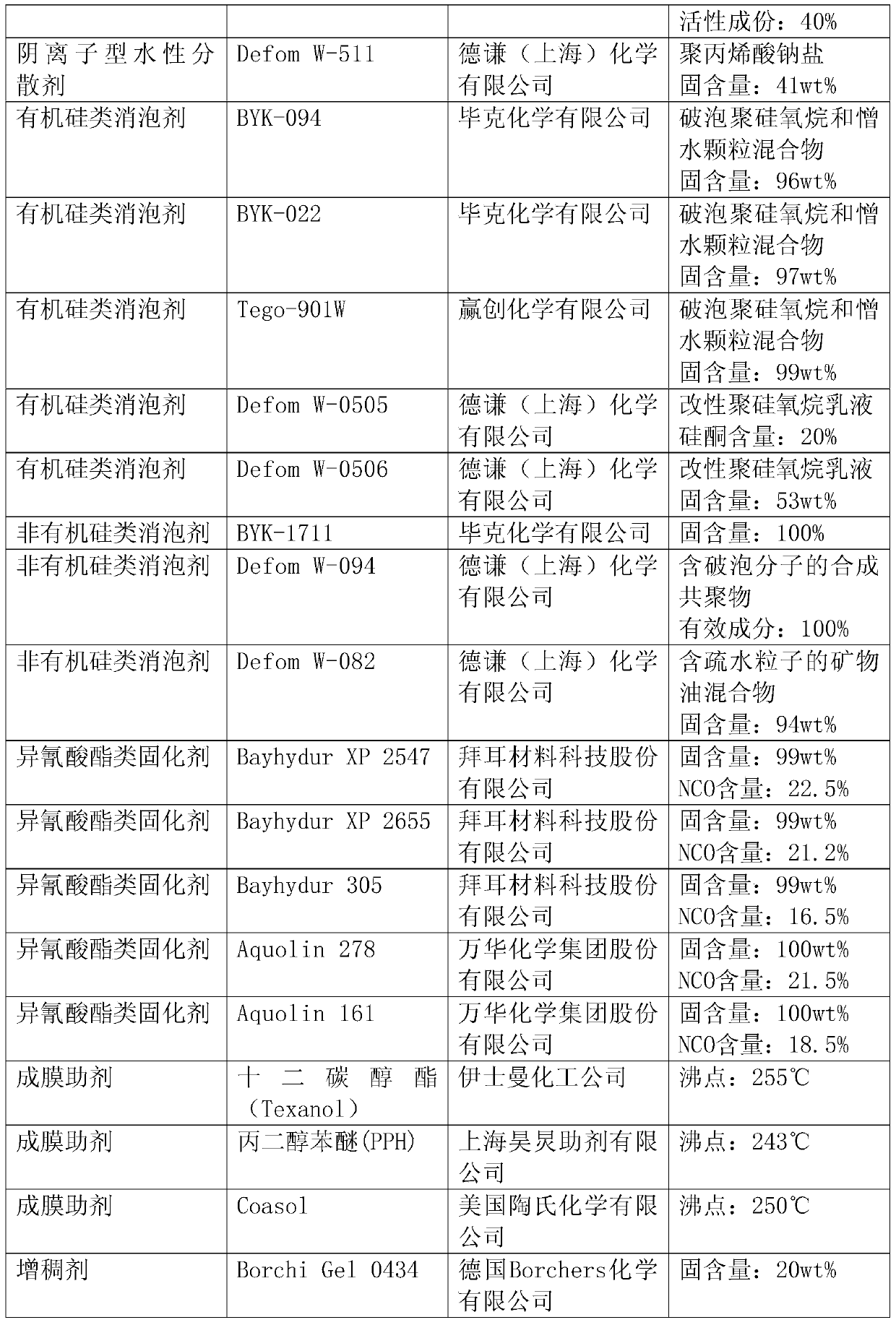

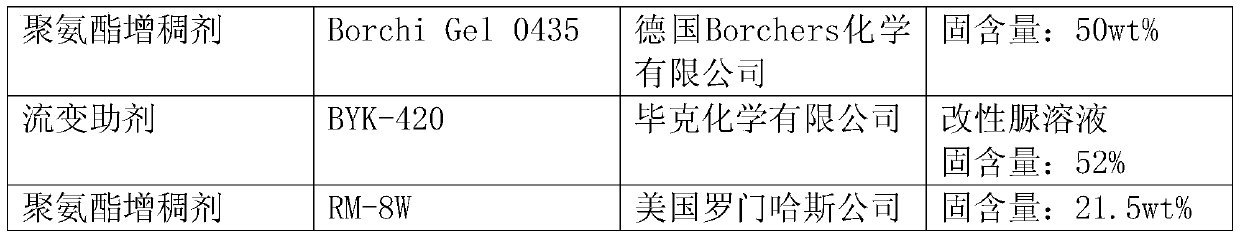

Method used

Image

Examples

preparation example Construction

[0124] The present invention also provides a kind of preparation method of described varnish product, described method comprises the steps:

[0125] 1) provide first packaging, component A is packed in described first packaging, obtain the first container described in claim 1; Wherein, component A is as follows preparation:

[0126] a-1) Under stirring conditions, add the first polyacrylate dispersion, film-forming aid, thickener, first silicone dispersant, silicone defoamer and water to the second polyacrylate dispersion in parts by weight In the dipolymer acrylate dispersion, the first mixed solution is obtained;

[0127] a-2) Add the second silicone dispersant and non-organic silicon defoamer into the first mixed solution prepared in step a-1) in parts by weight under stirring conditions to obtain component A ;

[0128] In another preferred example, after step a-2), a step is further included: adding water to the product obtained in step a-2) to prepare component A.

[0...

Embodiment 1

[0190] Example 1 Varnish Product 1

[0191] Component A: the Bayhydrol A 2546 of 16.64 parts by weight, the coalescent (dodecyl alcohol ester) of 0.81 parts by weight, the thickener (BYK-420) of 0.32 parts by weight, the thickener of 0.44 parts by weight ( Borchi Gel 0435), 0.55 parts by weight of dispersant (BYK-346), 0.22 parts by weight of antifoaming agent (BYK-094) and 2.92 parts by weight of deionized water were successively dropped into 42.72 parts by weight of Bayhydrol at a dispersion rate of 1500rpm A 2695, stirred for 15 minutes. Then 0.44 parts by weight of dispersant (BYK-333) and 0.22 parts by weight of antifoaming agent (BYK-1711) were sequentially put into it, and dispersed at a stirring rate of 1500 rpm for 15 minutes. After uniform dispersion, 34.72 parts by weight of deionized water was added, and then dispersed at a dispersion rate of 800 rpm for 10 minutes to prepare component A.

[0192] Component B: 22 parts by weight of Bayhydur XP 2547.

[0193] Mat...

Embodiment 2

[0199] Example 2 Varnish Product 2

[0200] Component A: the Bayhydrol A 2546 of 16.64 parts by weight, the coalescent (dodecyl alcohol ester) of 0.90 parts by weight, the thickener (BYK-420) of 0.32 parts by weight, the thickener of 0.44 parts by weight ( Borchi Gel 0435), 0.45 parts by weight of dispersant (BYK-346), 0.22 parts by weight of antifoaming agent (BYK-094) and 2.92 parts by weight of deionized water were successively added to 42.72 parts by weight of Bayhydrol at a dispersion rate of 1500rpm A 2695, stirred for 15 minutes. Then, 0.34 parts by weight of dispersant (BYK-333) and 0.22 parts by weight of defoamer (BYK-1711) were sequentially put into it, and dispersed at a stirring rate of 1500 rpm for 15 minutes. After uniform dispersion, 34.72 parts by weight of deionized water was added, and then dispersed at a dispersion rate of 800 rpm for 10 minutes to prepare component A.

[0201] Component B: 21.978 parts by weight of Bayhydur XP 2547.

[0202] Matt varnis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com