Three-dimensional embossed leather production method

A production method and embossing technology, which are applied in the directions of leather drying, leather surface treatment, leather surface mechanical treatment, etc., can solve the problems of poor embossing effect, difficulty in wetting the leather, and inconspicuous three-dimensional effect, so as to facilitate promotion, Save production cost, good effect of finishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

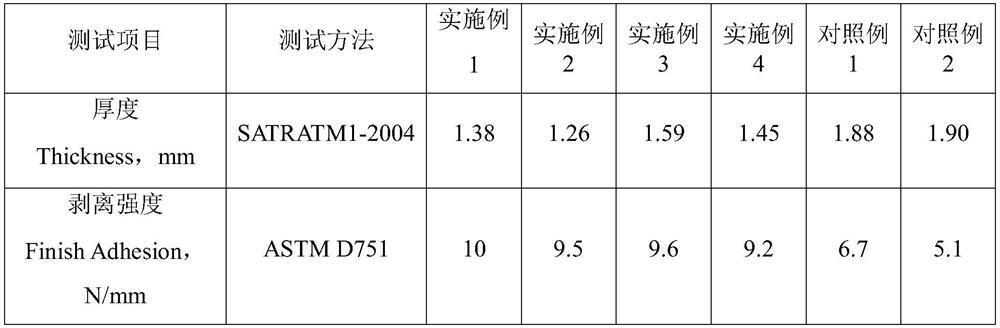

Examples

Embodiment 1

[0026] The manufacturing method of three-dimensional embossed leather comprises the following steps:

[0027] Grinding: use 180# and 220# sandpaper to grind the bottom of the dried cow split leather in turn, and use 180# and 280# sandpaper to grind the surface in turn, and sweep the dust;

[0028] Spray filling: spray the first filler on the surface of the leather embryo after grinding, the spray amount is 8g / square foot, and the first filler includes the following components in terms of mass percentage: 52% of water, the first water-based acrylic acid Resin dispersion MelioResin A-776-ID 38%, first penetrant Melio P-4893.B 10%, total 100%.

[0029] Roller coating filling: roll coating the second filling material twice on the surface of the leather embryo that has been sprayed and filled, the first roll coating amount is 10.5g / square foot, and the second roll coating amount is 3.5g / square foot. The second filler includes the following components in terms of mass percentage: w...

Embodiment 2

[0036] The manufacturing method of three-dimensional embossed leather comprises the following steps:

[0037] Grinding: use 180# and 220# sandpaper to grind the bottom of the dried cow split leather in turn, and use 180# and 280# sandpaper to grind the surface in turn, and sweep the dust;

[0038] Spray filling: spray the first filler on the surface of the leather embryo after grinding, the spray amount is 5g / square foot, and the first filler includes the following components in terms of mass percentage: 50% water, the first water-based acrylic acid Resin dispersion MelioResin A-776-ID 40%, first penetrant Melio P-4893.B 10%, total 100%.

[0039] Roller coating filling: roll coating the second filling material twice on the surface of the leather embryo filled by spraying, the first roll coating amount is 9g / square foot, and the second roll coating amount is 3g / square foot, the second filling The material includes the following components in terms of mass percentage: water 50%...

Embodiment 3

[0046] The manufacturing method of three-dimensional embossed leather comprises the following steps:

[0047] Grinding: use 180# and 220# sandpaper to grind the bottom of the dried cow split leather in turn, and use 180# and 280# sandpaper to grind the surface in turn, and sweep the dust;

[0048] Spray filling: spray the first filler on the surface of the leather embryo after grinding, the spray amount is 10g / square foot, and the first filler includes the following components in terms of mass percentage: 55% water, the first water-based acrylic acid Resin dispersion MelioResin A-776-ID 30%, first penetrant Melio P-4893.B 15%, total 100%.

[0049]Roller coating filling: roll coating the second filling material twice on the surface of the leather embryo filled by spraying, the first roll coating amount is 12g / square foot, the second roll coating amount is 4g / square foot, the second filling The material includes the following components in terms of mass percentage: water 55%, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com