Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

98results about How to "Improve anti-blocking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

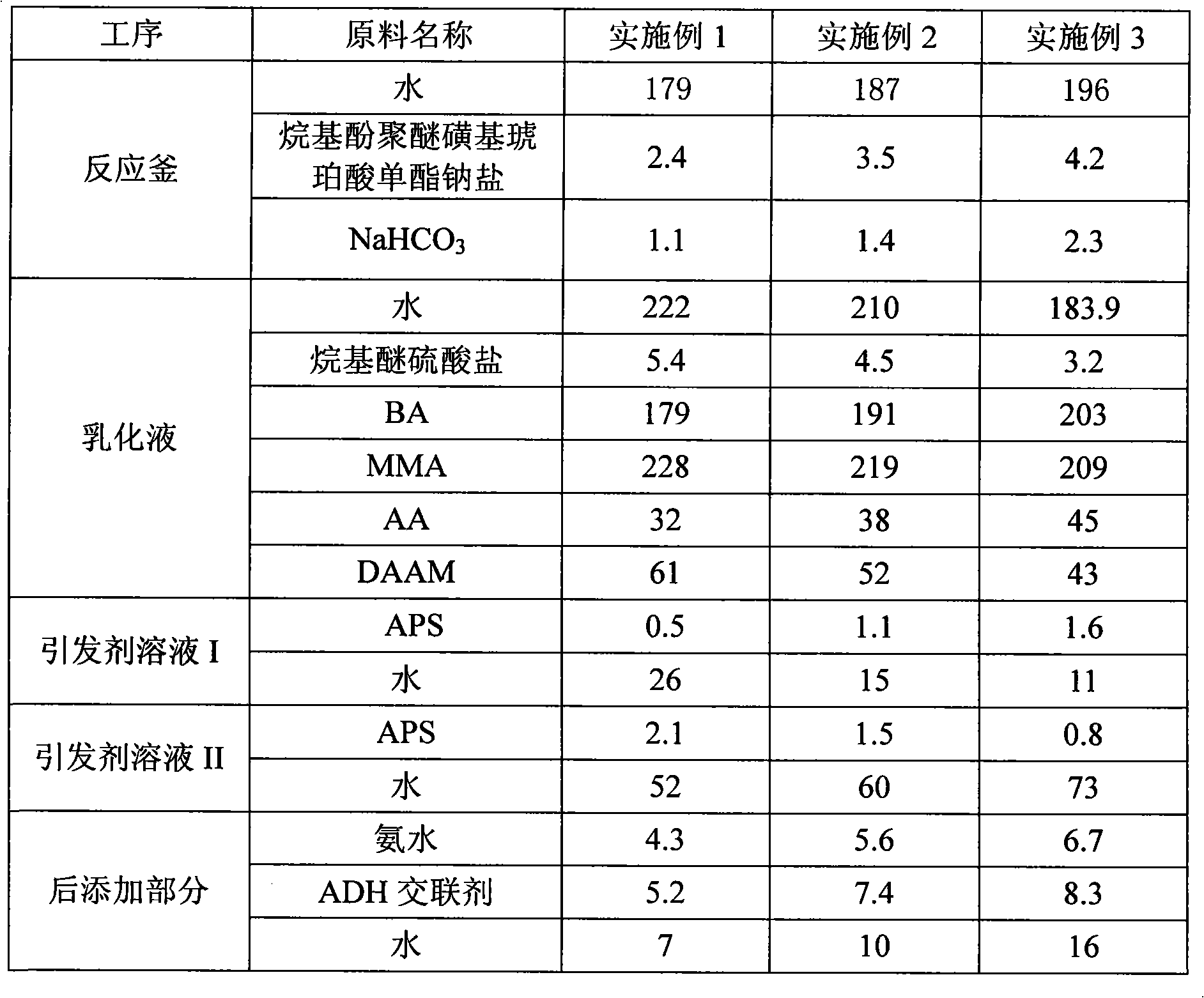

Acrylic ester emulsion and preparation method thereof

The invention discloses acrylic ester emulsion and a preparation method thereof. The preparation method comprises the following steps of: gradually dropwise adding emulsion which contains an anion emulsifier, butyl acrylate, butyl methacrylate, acrylic acid and diacetone acrylamide, and initiator solution into solution which contains sodium alkylphenol polyether sulfosuccinate and an initiator with stirring, controlling the temperature to be between 85 and 88 DEG C, after dropwise adding, reducing the temperature to between 35 and 40 DEG C, adding water, ammonia water and an ADH cross linkingagent, and stirring to obtain the acrylic ester emulsion. The acrylic ester emulsion obtained by the preparation method has relatively high blocking resistance and wear resistance.

Owner:上海展辰涂料有限公司

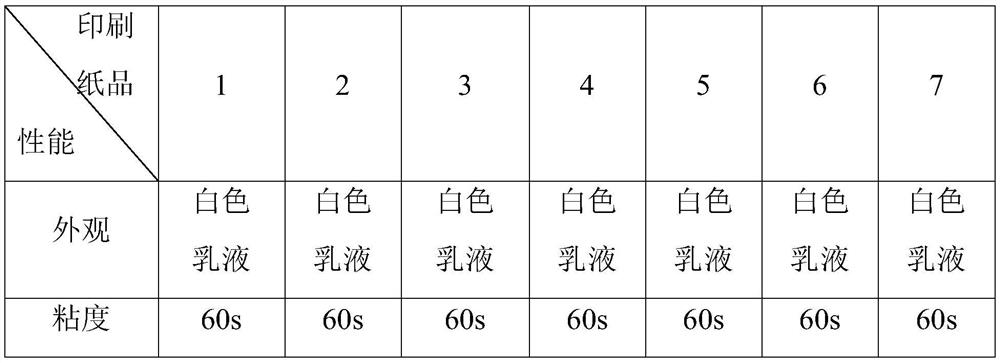

Water-based paper polishing oil and preparation method thereof

ActiveCN101798776AImprove wear resistanceImprove stain resistancePaper coatingCoatingsWater basedBenzene

The invention provides a water-based paper polishing oil and a preparation method thereof. The water-based paper polishing oil is characterized by comprising the following components in parts by weight: 45-75 parts of styrene-acrylic-organic silicon copolymer emulsion with a core-shell structure, 2-10 parts of water-soluble acrylic resin, 0.5-2 parts of dispersing agent, 0.5-3 parts of wax emulsion, 0.5-2 parts of flatting agent, 0.2-2 parts of defoaming agent, 0-0.5 part of smoothing agent, 0.2-2 parts of neutralizing agent and 5-20 parts of water. The preparation method comprises the following steps: preparing the styrene-acrylic-organic silicon copolymer emulsion with the core-shell structure, preparing a water-soluble acrylic resin solution, and mixing the emulsion and the solution with other raw materials. The water-based paper polishing oil of the invention has the advantages of high polishing performance, high anti-blocking performance and good abrasion resistance.

Owner:上海睿途新材料科技有限公司

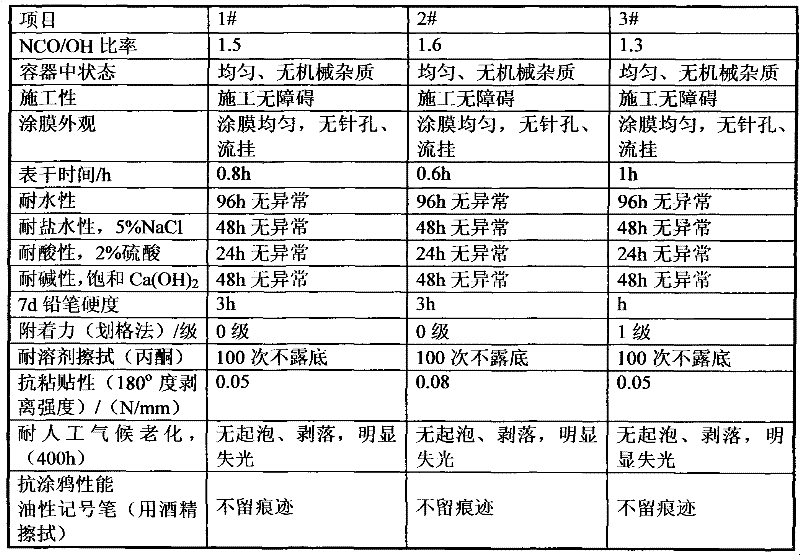

Aqueous anti-doodling and anti-affixing paint and its preparation method

InactiveCN102477249AImprove water resistanceLess water residuePolyurea/polyurethane coatingsCross-linkEmulsion

The invention relates to an aqueous anti-doodling and anti-affixing paint. The paint provided by the invention comprises a component A and a component B, wherein the component A contains, by weight, 50-70 parts of an anionic polyacrylate dispersion and 5-10 parts of a modified silane emulsion; and the component B contains, by weight, 20-25 parts of a water dispersive aliphatic polyisocyanate curing agent. The invention also relates to a preparation method of an aqueous anti-doodling and anti-affixing paint film. With the use of the polyacrylate dispersion as a base material, the aqueous anti-doodling and anti-affixing paint can have a high gloss and its scratch resistance can be improved. With the use of the water dispersive aliphatic polyisocyanate as a cross-linking agent, the paint can have excellent weatherability and yellow-stain resistance. Dual-component crosslinking and solidification can endow the paint with high surface hardness, compact film and excellent anti-doodling performance.

Owner:SHENZHEN JIADA HIGH TECH IND DEV

Special high-temperature resistant waterproof air and moisture permeable resin for coating printing and preparation method thereof

InactiveCN103265682AImprove heat resistanceGood flexibilityFibre treatmentMoisture permeabilitySilsesquioxane

The invention discloses special high-temperature resistant waterproof air and moisture permeable resin for coating printing and a preparation method thereof. The resin is prepared by the following steps of: obtaining a prepolymer through a reaction between polyether polyol and diisocyanate; and modifying the prepolymer by use of polyhedral oligomeric silsesquioxane to obtain the resin, wherein the average molecular weight of the resin is 50000-150000g / mol, the viscosity is 60000-100000cps / 25 DEG C, and the solid content of the resin is 30-55%. In the polyurethane resin prepared by the method disclosed by the invention, the moisture permeability can reach 7500g / m<2>.24H, and the water pressure resistance is greater than 10000mmH2O; moreover, the polyurethane resin has the processing characteristic of tolerating a temperature of 200-230 DEG C for continuous 30S during coating printing; and the resin has highly-permeable coating and soft and smooth handfeel, and is washable and very suitable for the direct coating and coating printing technology of fabric coating processing.

Owner:宜兴市华夏化工材料有限公司

Aqueous coating material with ultralow VOC (Volatile Organic Compound) release and preparation method thereof

The invention relates to an environmental-friendly aqueous coating material with ultralow VOC (Volatile Organic Compound) release and a preparation method thereof. An emulsion A with low vitrification temperature and an emulsion A with high vitrification temperature are adopted to be physically blended according to a certain ratio, so as to serve as a basic film-forming substance; during the preparation of the aqueous woodenware coating material, good film forming can be achieved by only adding a small amount of film forming assistant, the aqueous woodenware coating material is low in raw material cost and simple in preparation process, and meanwhile, a coating film has excellent permeability, glossiness, water resistance and adhesion resistance.

Owner:BEIJING UNIV OF CHEM TECH

High wear resistance water-borne gloss oil and preparing method thereof

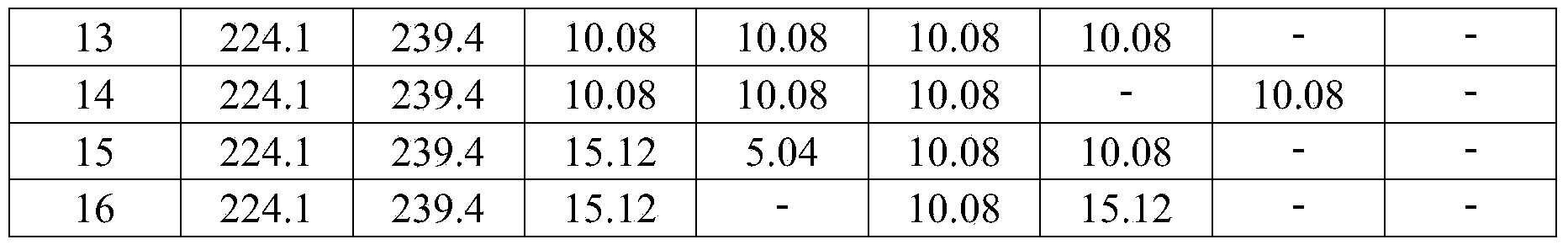

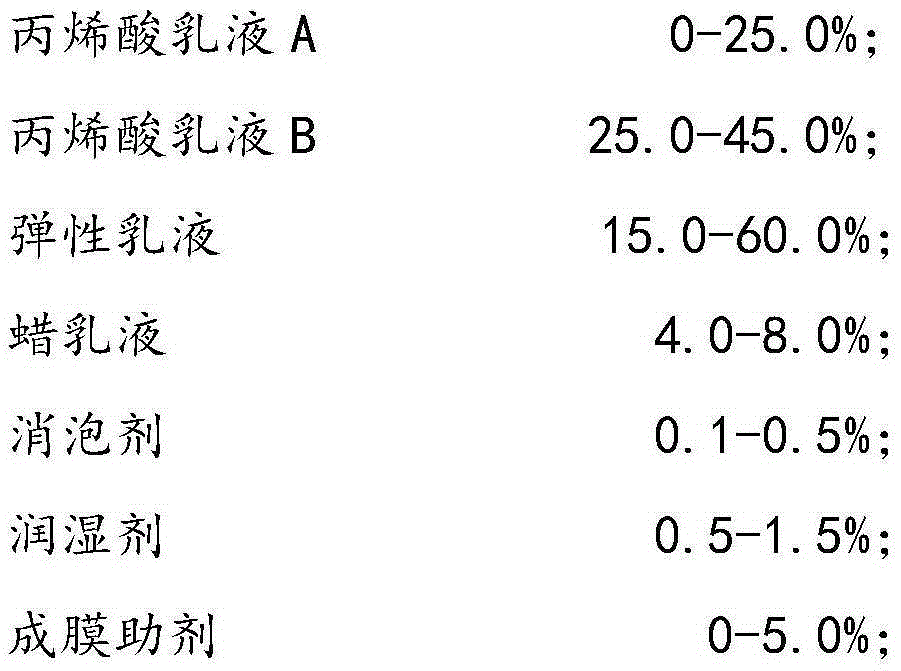

The invention discloses high wear resistance water-borne gloss oil, comprising the following components with the contents in percent by weight: 0-25.0% of acrylic emulsion A, 25.0-45.0% of acrylic emulsion B, 15.0-60.0% of elastic emulsion, 4.0-8.0% of wax emulsion, 0.1-0.5% of defoaming agent, 0.5-1.5% of wetting agent and 0-5.0% of coalescing agent. The invention further provides a preparing method of the high wear resistance water-borne gloss oil, and mainly adopts a method of adding the materials step by step to prepare the high wear resistance water-borne gloss oil. The water-borne gloss oil prepared by adopting the method has higher wear resistance, and has the advantages of high gloss, good flexibility, fastness in drying, good anti-adhesion property and excellent online performance.

Owner:上海奇想青晨新材料科技股份有限公司

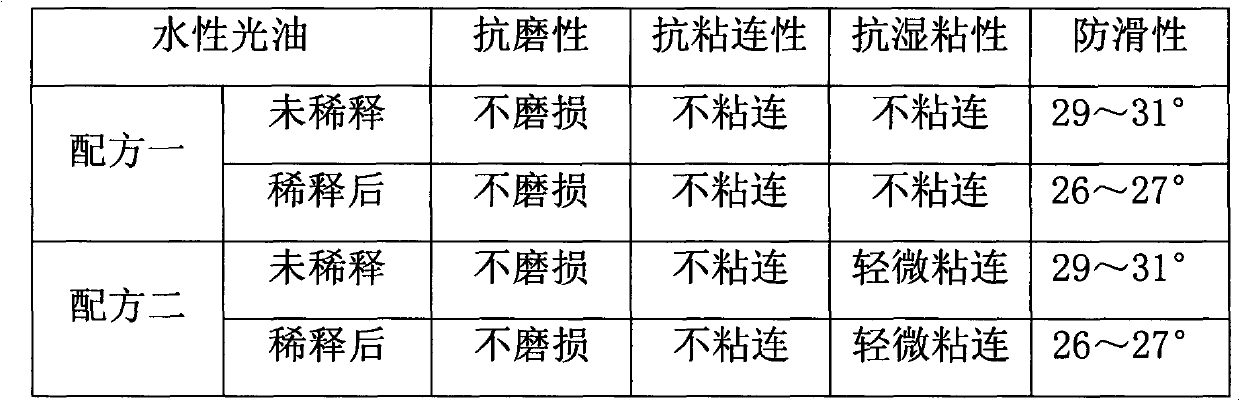

Aqueous gloss oil for beer cartons and preparation method thereof

ActiveCN101906735AImprove skid resistanceImprove anti-wear performanceNon-fibrous pulp additionPaper coatingHigh resistanceWear resistant

The invention discloses aqueous gloss oil for beer cartons, which is prepared from the following raw materials in percentage by mass: 70%-80% of modified styrene-acrylate emulsions, 10%-20% of styrene-acrylate emulsions, 2%-6% of wear-resistant wax slurry, 0.1%-0.3% of defoamers, 0.1%-0.3% of preservatives and 3%-5% of isopropyl alcohol. The preparation method comprises the following steps of: firstly adding the modified styrene-acrylate emulsions at normal temperature, and then slowly and sequentially adding the defoamers, the styrene-acrylate emulsions, the wear-resistant wax slurry, the preservatives and the isopropyl alcohol when stirring; after adding various raw materials, stirring for 10 minutes at the rotary speed of 500-1000 revolutions / minute to uniformly disperse various raw materials in the system for obtaining the aqueous gloss oil for the beer cartons. The aqueous gloss oil has the advantages of high skid resistance, wear resistance, adhesion resistance, wet-adhesion resistance and waterproofing performance, is suitable for the glossing of the beer cartons and has a good protection action on the beer cartons.

Owner:GUANGDONG YINGKE GRP CO LTD

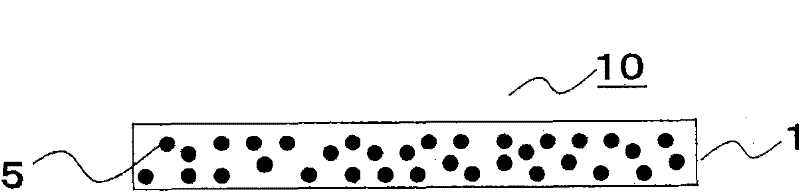

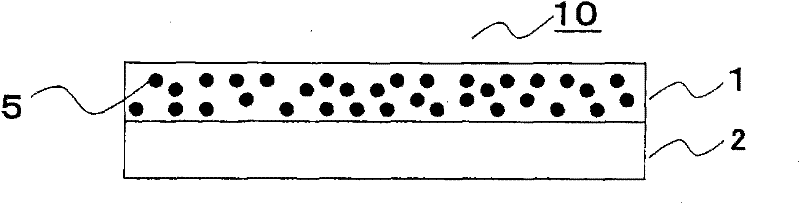

Base material for surface protective sheet and surface protective sheet

InactiveCN102199317AImprove slipSlip is moderately excellentFilm/foil adhesivesThin material handlingPolyolefinMetallurgy

Provided is the following base material for a surface protective sheet. The slipping property of the back surface of the sheet is moderately excellent, and scratches in the surface of an adherend laminated to contact the back surface of the sheet can be suppressed. Also provided is a surface protective sheet containing such base material for a surface protective sheet. The base material for a surface protective sheet of the present invention is a base material for a surface protective sheet including a base material layer (A) , in which at least one surface of the base material for a surface protective sheet is the surface of the base material layer (A); the base material layer (A) contains a polyolefin-based resin as a main component; the base material layer (A) contains polymer fine particles having an average particle diameter of 3 to 20 mum at a content of 0.1 to 20 wt% with respect to 100 parts by weight of the polyolefin-based resin; the surface of the base material layer (A) has a surface roughness Ra of 0.15 to 0.60 mum; the surface of the base material layer (A) has a coefficient of dynamic friction (I) with respect to an aluminum plate of 0.35 to 1.00.

Owner:NITTO DENKO CORP

Water-based polyurethane modified acrylic ester emulsion and preparation method thereof, and water-based wood coating

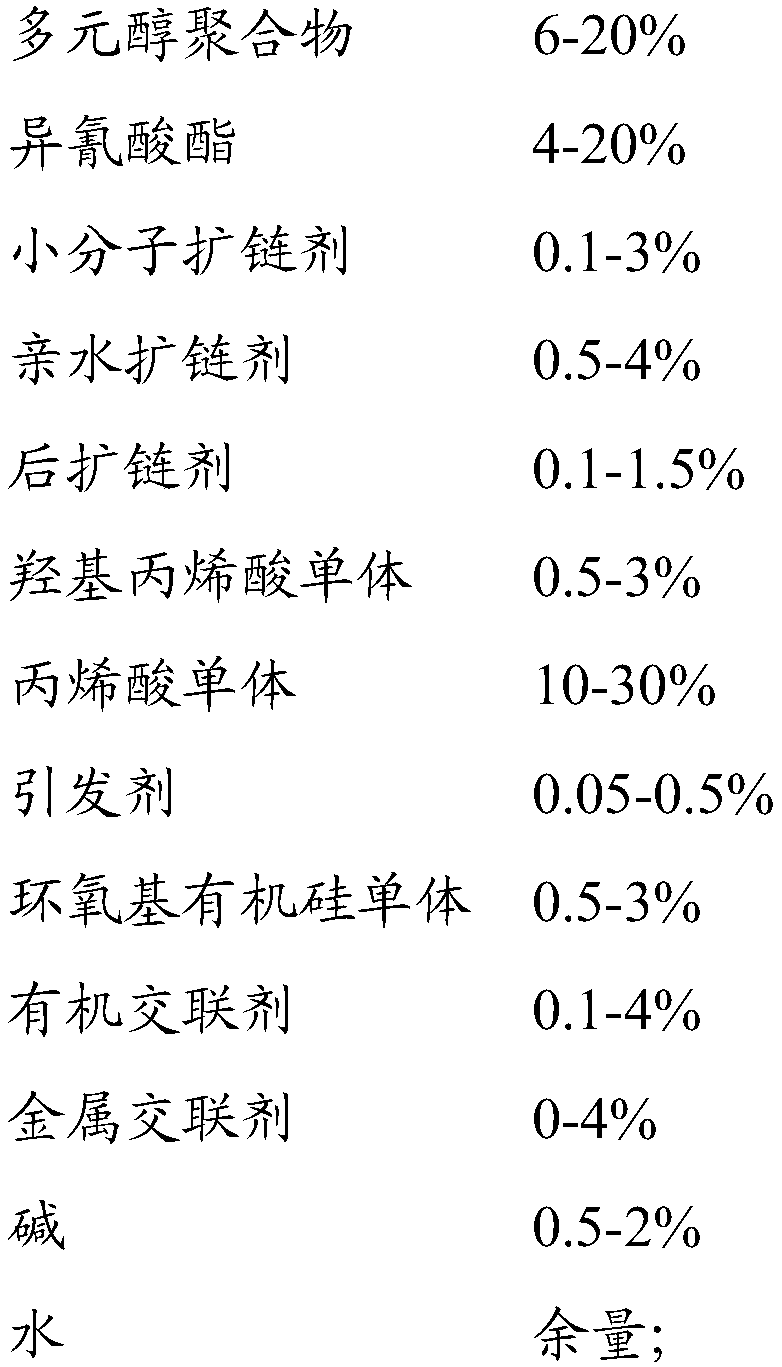

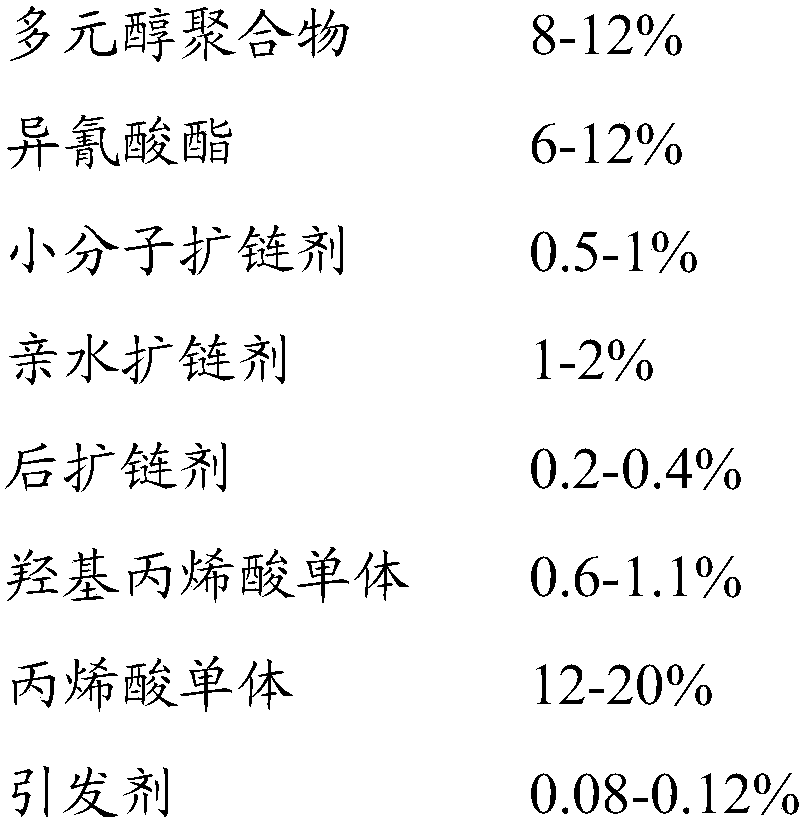

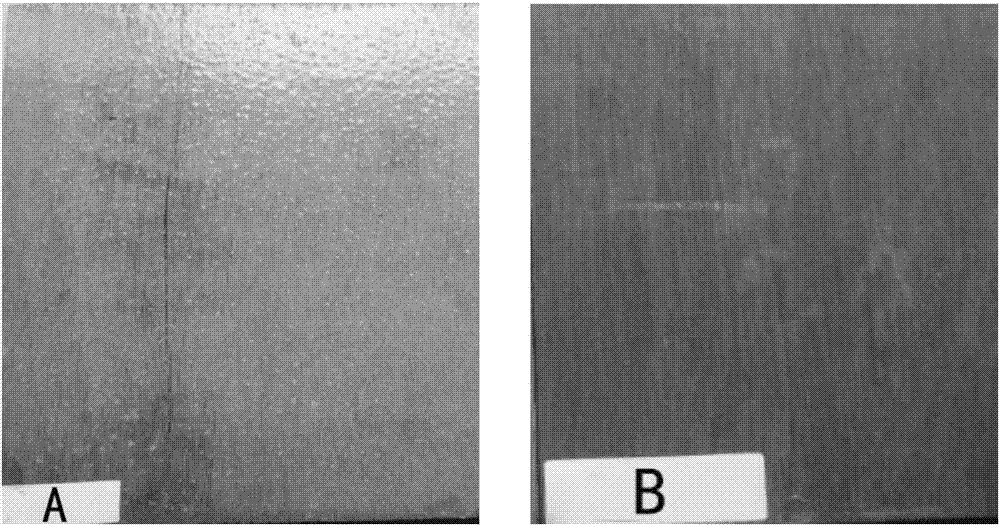

The invention relates to water-based polyurethane modified acrylic ester emulsion and a preparation method thereof, and water-based wood coating. The water-based polyurethane modified acrylic ester emulsion is prepared from the following raw materials in percentage by weight: 6 to 20 percent of a polyol polymer, 4 to 20 percent of isocyanate, 0.1 to 3 percent of a micromolecular chain extender, 0.5 to 4 percent of a hydrophilic chain extender, 0.1 to 1.5 percent of an after chain extender, 0.5 to 3 percent of a hydroxy acrylic acid monomer, 10 to 30 percent of an acrylic acid monomer, 0.05 to0.5 percent of an initiator, 0.5 to 3 percent of an epoxy organosilicon monomer, 0.1 to 4 percent of an organic crosslinking agent, 0 to 4 percent of a metal crosslinking agent, 0.5 to 2 percent of alkali and the balance of water. The emulsion has high stability; and after the emulsion is prepared into the water-based wood coating and the wood product is coated with the coating, the drying speed is high and the adhesion resistance is excellent.

Owner:GUANGZHOU GUANZHI NEW MATERIAL TECH

Water-based wooden toy paint

InactiveCN102093795AEasy to dryGood weather resistancePolyurea/polyurethane coatingsWater basedToxic material

The invention relates to a water-based wooden toy paint, which is prepared by mixing and stirring the following raw materials in percentage by mass: 30 to 40 percent of waterborne acrylic emulsion, 15 to 25 percent of waterborne polyurethane dispersion, 3 to 5 percent of functional resin, 1 to 2 percent of film forming aid, 0.2 to 0.4 percent of wetting agent, 0 to 0.2 percent of leveling agent, 0.01 to 0.02 percent of preservative, 10 to 45 percent of pigment, 0 to 15 percent of water-based color paste, 0.5 to 1 percent of thickening agent and the balance of deionized water. The invention has the advantages that: the water-based wooden toy paint does not contain heavy metals and other toxic substances, meets the toy safety standard, cannot harm the health of children, and also has the characteristics of high drying speed, high film hardness, fullness, wear resistance, water resistance, after tackiness resistance and the like.

Owner:FUZHOU DEXIAN CHEM CO LTD

Waterborne wood floor paint for roller painting of containers

ActiveCN107163743AImprove wear resistanceImprove crack resistanceAntifouling/underwater paintsPaints with biocidesFoaming agentMildew

The invention discloses waterborne wood floor paint for roller painting of containers. The waterborne wood floor paint comprises a first component, a second component and water in a mass ratio of 100:5-10:10-20. The first component is prepared from a composite modified self-crosslinking acrylic polymer, a composite modified wear-proof polymer, an anti-foaming agent, a dispersing agent, a waterborne flatting agent, a thickening agent, a leveling agent, smoothening and anti-adhesion additives, an anti-mildew bactericide and the balance water. The second component is prepared from a composite modified cross-linking agent and water. The waterborne wood floor paint for roller painting of the containers is great in effect, environmental friendly, especially suitable for roller painting, excellent in anti-foaming performance and abrasion resistance, high in hardness, excellent in anti-cracking performance under cold and hot conditions, anti-adhesion performance at a high temperature and water resistance, quick in drying, moderate in cost, easy in construction and high in efficiency.

Owner:广东伊思曼新材料科技股份有限公司

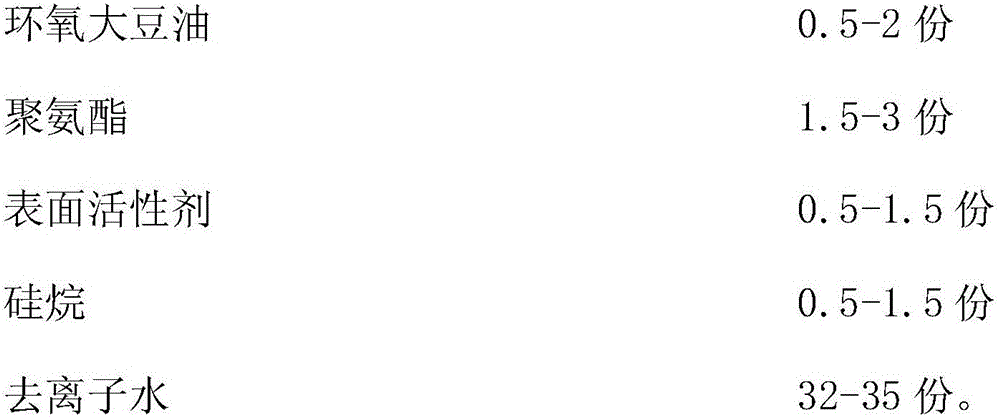

Water-based ink for printing thin film and preparation method thereof

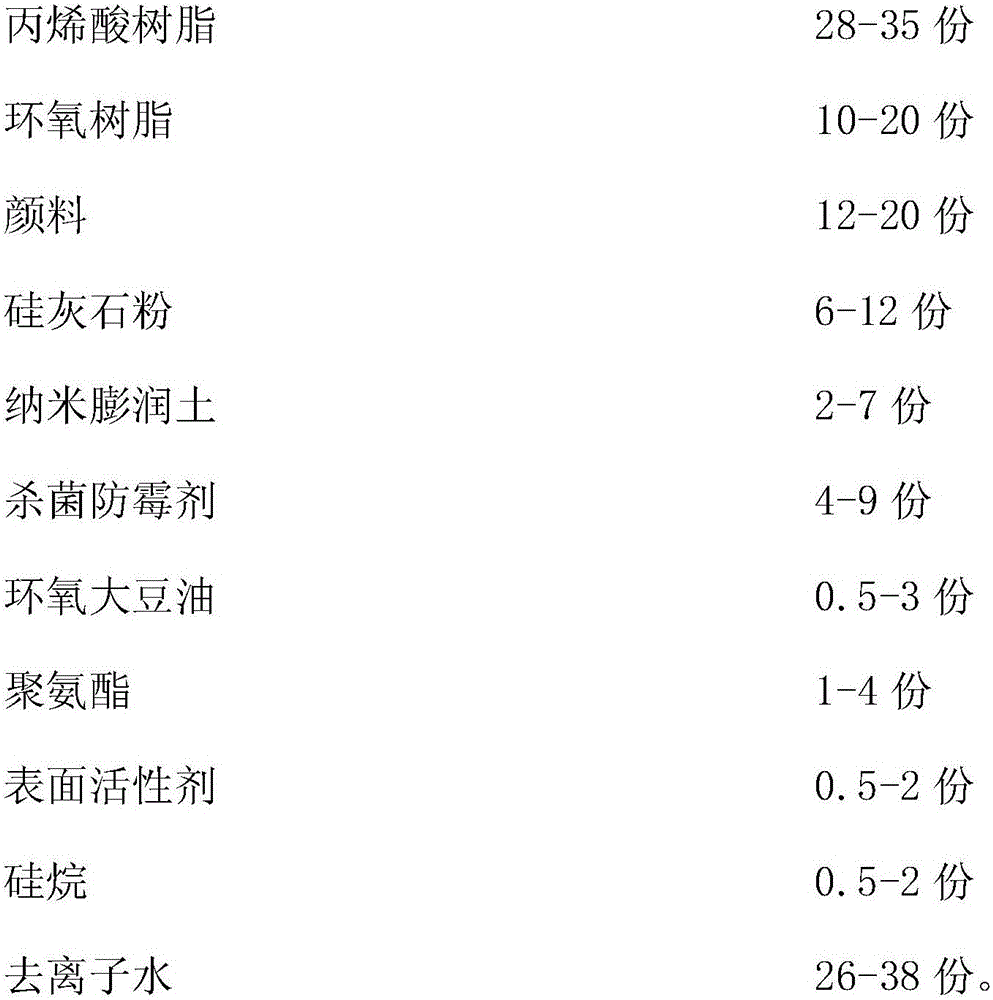

The invention relates to water-based ink for printing a thin film and a preparation method thereof. The water-based ink is prepared from the following raw materials in parts by weight: 28-35 parts of acrylic resin, 10-20 parts of epoxy resin, 12-20 parts of a pigment, 6-12 parts of wollastonite powder, 2-7 parts of nano bentonite, 4-9 parts of a sterilization mildew-proof agent, 0.5-3 parts of epoxy soybean oil, 1-4 parts of polyurethane, 0.5-2 parts of a surfactant, 0.5-2 parts of silane and 26-38 parts of de-ionized water. According to the water-based ink provided by the invention, the wollastonite powder is added so that the wearing resistance and anti-adhesion property of the ink can be improved; the added sterilization mildew-proof agent is prepared from Chinese herbal medicine ingredients, is safe and environment-friendly and has no injuries to health of human bodies; the ink provided by the invention has stable performance, good glossiness and dispersity and high drying speed; and in a utilization process, the ink does not fall off and is not faded, and the printing effect is lasting.

Owner:安徽省天乐塑业有限公司

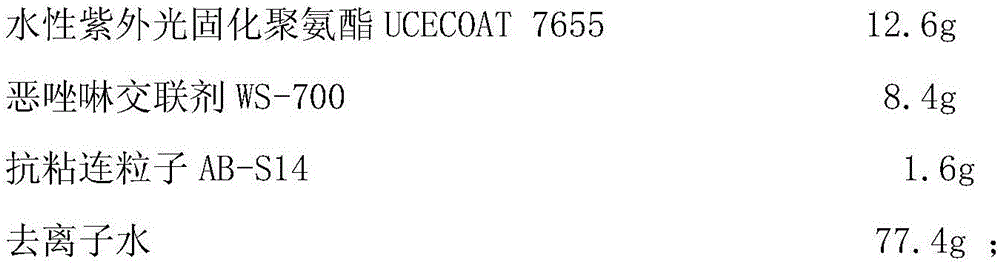

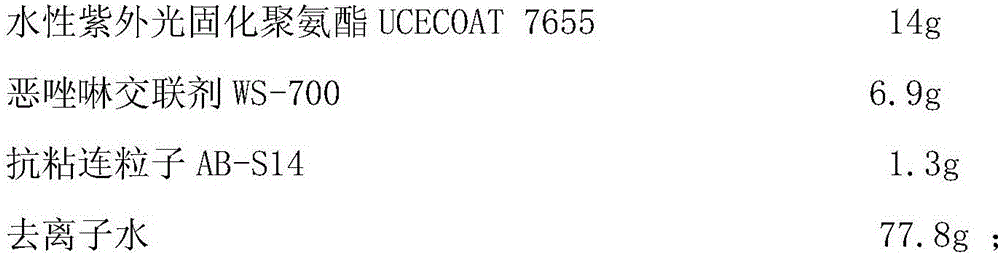

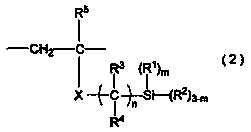

Optical polyester film and method of manufacture thereof

ActiveCN105754128AStrong adhesionExcellent reworkabilityPolyurea/polyurethane coatingsFlat articlesWater basedPolyester

The invention discloses an optical polyester film and a method of manufacture thereof.In the optical polyester film, at least one side of a biaxially stretched basic film is coated with a bottom coating, the bottom coating is made from the components according to percent by weight: 63-96% of water-based ultraviolet-cured polyurethane resin free of carboxylic acid, 3-30% of oxazoline cross-linking agent, and 1-7% of nano-scale anti-blocking particles that are 80 to 200 nm in particle size.The optical polyester film has excellent adhesion and high transparency, has good bonding resistance and is applicable to high-end film material fields such as LCD (liquid crystal display) display device field and high-end IMD (in-mod decoration) processing.

Owner:HEFEI LUCKY SCI & TECH IND

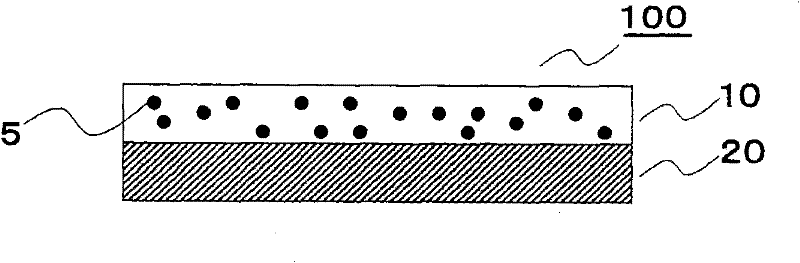

Protective film for optical thin films and method for preparing protective film

PendingCN108728006AImprove scratch resistanceImprove anti-blockingNon-macromolecular adhesive additivesFilm/foil adhesivesTectorial membraneInorganic particle

The invention discloses a protective film for optical thin films and a method for preparing the protective film. The protective film comprises PE (polyethylene) base film layers and glue layers. Glueis coated on the surfaces of the PE base film layers and is dried to form the glue layers, the PE base film layers comprise layers A and layers B, the layers A are PE layers, the layers B are PE layers with added organic or inorganic particles, and the PE base film layers are formed from the layers A and the layers B by means of co-extrusion; the glue comprises, by weight, 26-36 parts of acrylateresin, 60-70 parts of ethyl acetate, 3-6 parts of isocyanate curing agents and 0.5-1 part of antistatic agents. The protective film and the method have the advantages that layer structures of the PE base film layers, raw materials and ratios for the glue and processes for preparing the protective film are comprehensively controlled, accordingly, the protective film which is excellent antistatic properties and scratch resistance, appropriate in stripping force and free of glue residues can be obtained, the impedance value of the protective film is within the range from 10<7> to 10<11>, and thestripping force of the protective film is 1.6-2.5 N / m.

Owner:芜湖夏鑫新型材料科技有限公司

Aliphatic polycarbonate resin composition

The invention provides the transparency, the blocking resistance, and the aliphatic family polycarbonate resin composition with an excellent machine strength. The polycarbonate resin composition of the present invention contains the amorphous silica about the aliphatic polycarbonate resin 100 parts by mass at a ratio of 0.05-4 parts by mass.

Owner:SUMITOMO SEIKA CHEM CO LTD

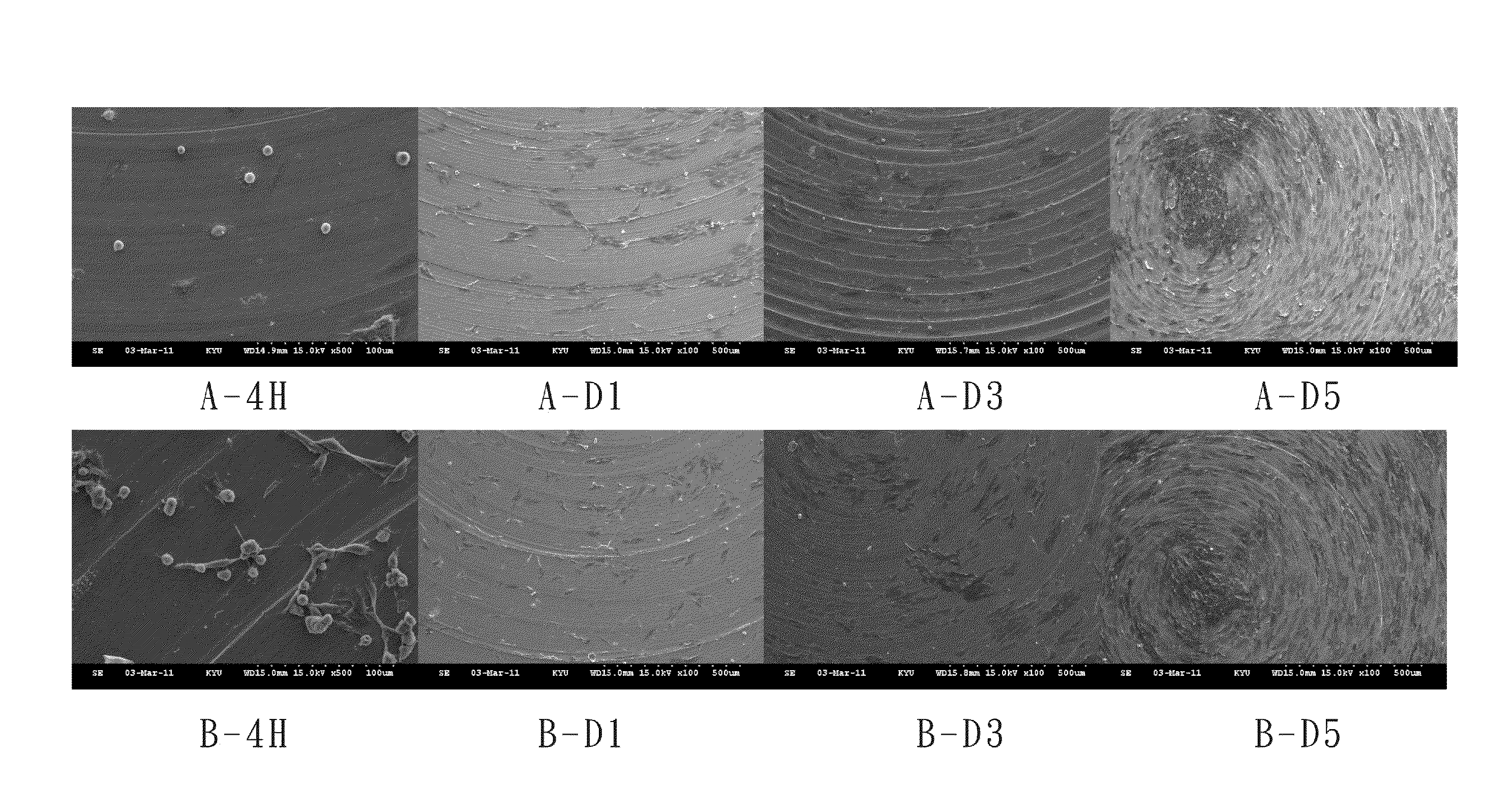

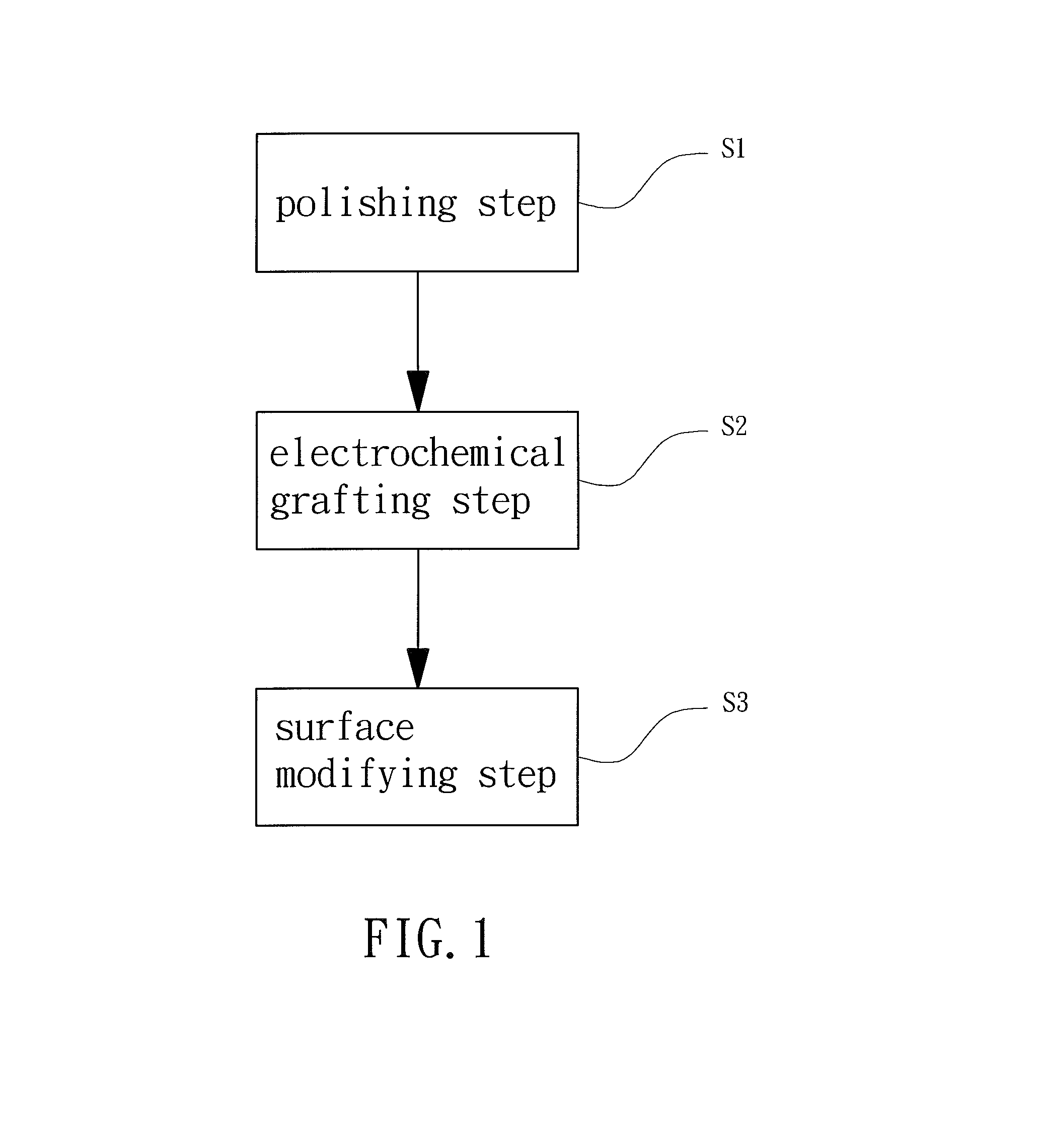

Method for Processing a Surface of a Metal Implant and the Metal Implant Produced by the Method

ActiveUS20130087460A1Increase uniformity of oxidation of surfaceEfficient qualityDuplicating/marking methodsActive material electrodesOxygenHigh pressure

A method for treating a surface of a metal implant includes a polishing step, a grafting step. The polishing step includes polishing a surface of a metal implant to remove an uneven, natural oxide layer on the surface of the metal implant and to generate an even oxide layer on the surface of the metal implant. The grafting step includes grafting an anti-adhesion macromolecule on an outer face of the even oxide layer. A covalent bond between the anti-adhesion macromolecule and oxygen atoms on the outer face of the even oxide layer is formed, thus that a macromolecular anti-adhesion layer on the outer face of the even oxide layer can be created. The surface modifying step includes changing a property of the surface of the metal implant with the macromolecular anti-adhesion layer by high temperature and high pressure, providing the metal implant with high hydrophilicity.

Owner:METAL INDS RES & DEV CENT

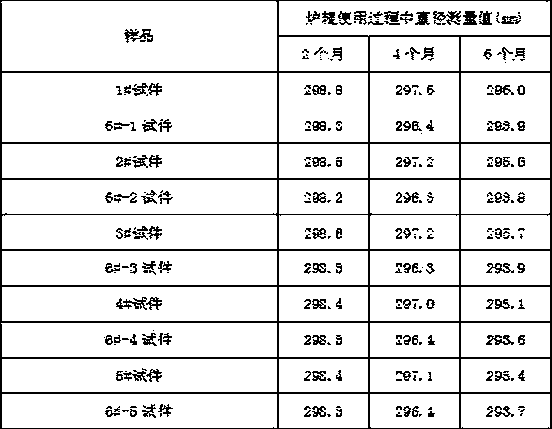

High temperature alloy for heat-resisting furnace roller and heat-resisting furnace roller for thermal treatment furnace

ActiveCN104032198AExtended service lifeImprove organizational stabilityOxidation resistantSuperalloy

The invention relates to high temperature alloy for a heat-resisting furnace roller, and the heat-resisting furnace roller prepared from the high temperature alloy in the field of an alloy material. The high temperature alloy comprises the following components by weight percent: 0.25-0.45% of C, 0.5-2.0% of Si, 0.5-1.5% of Mn, 26-29.5% of Cr, 36-40% of Ni, 11-15% of Co, 1-4% of W, 1.0-2.5% of Mo, 0.4-1.4% of Nb, 0.02-0.2% of Ce, and the balance being Fe and inevitable impurities. Compared with the high temperature alloy adopted by the heat-resisting furnace roller in the prior art, the heat-resisting furnace roller prepared from the high temperature alloy disclosed by the invention has high endurance strength, oxidation resistance and corrosion resistance under the working condition at 1150-1200 DEG C, and has certain oxidation product tumor resistance and anti-blocking property, and the service life of the prepared heat-resisting furnace roller can be prolonged.

Owner:中冶京诚(扬州)冶金科技产业有限公司

Water-based UV touch oil and preparation method thereof

PendingCN112625574AImprove wear resistanceImprove anti-blockingPolyurea/polyurethane coatingsPolymer scienceEmulsion

The invention provides water-based UV touch oil and a preparation method thereof, belonging to the technical field of touch oil. The water-based UV touch oil is prepared by mixing a main film-forming substance, namely a water-based self-extinction polyurethane emulsion, an ultraviolet curing component, namely water-based urethane acrylate, an acrylic UV monomer and other additives. After the water-based UV touch oil is subjected to ultraviolet curing to form a film, the wear resistance, the anti-blocking performance and the alcohol resistance of a touch coating are greatly improved. In this way, the excellent characteristics of the waterborne self-extinction polyurethane are reserved, the abrasion resistance, alcohol resistance and anti-blocking performance of the touch coating are improved through ultraviolet curing, and the curing method further has the advantages of rapid curing, environmental friendliness and capability of saving energy. Besides, the waterborne self-extinction polyurethane emulsion contains large-particle-size particles (0.1 [mu]m to 0.3 [mu]m), so the microcosmic roughness of a film-forming surface is increased, good matte effect and tactile sensation are obtained, and public preferences are conformed to.

Owner:惠州市毕升堂科技有限公司

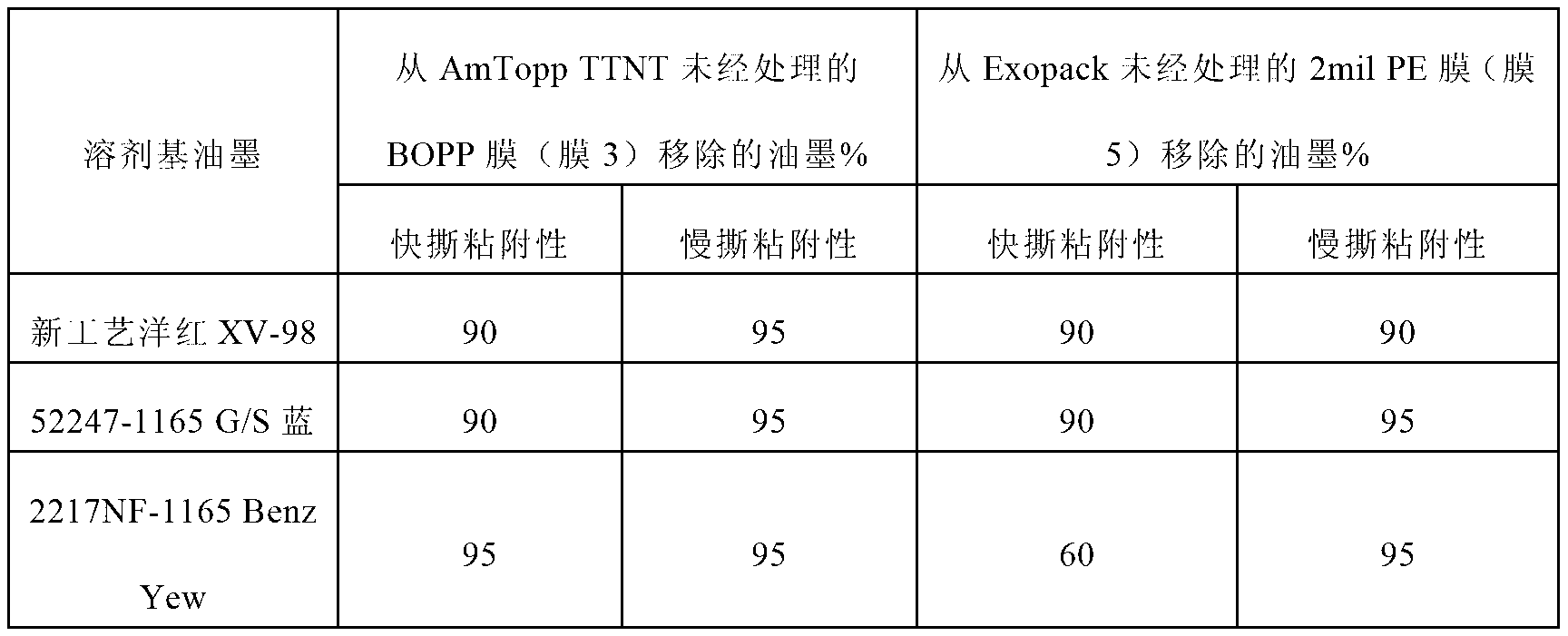

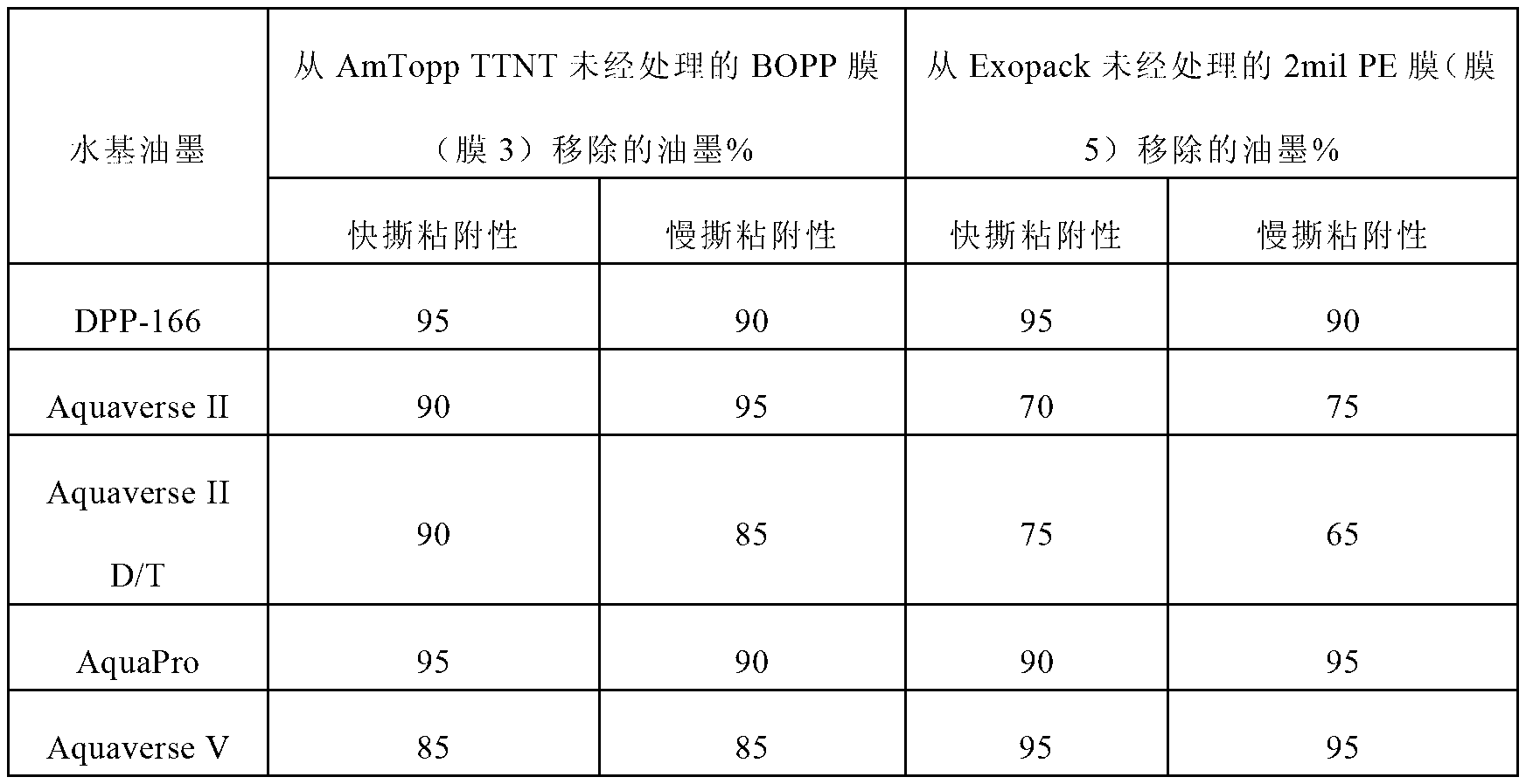

Chlorine-free ink and coating compositions & a method for printing on untreated polyolefin films with improved adhesion

InactiveCN103189455AImprove adhesionExcellent Adhesive PropertiesInksCoatingsPolyolefinPre treatment

Provided are chlorine-free ink and coating compositions that demonstrate improved adherence when applied to untreated flexible plastic film substrates. The provided compositions eliminate the need for a separate step of pre-treating a plastic film before applying an ink or coating composition. Also provided are methods for producing a printed article using the provided ink and coating compositions and methods of adhering chlorine-free inks or coatings that exhibit improved adhesion characteristics to untreated plastic films.

Owner:SUN CHEM CORP

Printing ink and preparation method thereof

The invention discloses printing ink and a preparation method of the printing ink and belongs to the field of plastic product processing. The printing ink comprises the following raw materials in parts by weight: 25-35 parts of alkyd resin, 8-15 parts of epoxy resin, 7-13 parts of alcohol, 5-8 parts of triethanolamine, 3-5 parts of light calcium carbonate, 0.5-2 parts of bactericide, 1-4 parts of lavender perfume, 12-17 parts of pigment, 0-3 parts of defoaming agent, 1-4 parts of dispersant and 1-4 parts of surfactant. The printing ink is environmentally friendly and nontoxic, free from a pungent smell and stable in performance, and has good glossiness; the abrasive resistance and blocking resistance of the printing ink can be improved by addition of light calcium carbonate; a printing effect is permanent; a drying rate is high; and the printing ink does not fall off in a use process.

Owner:安徽金星包装有限公司

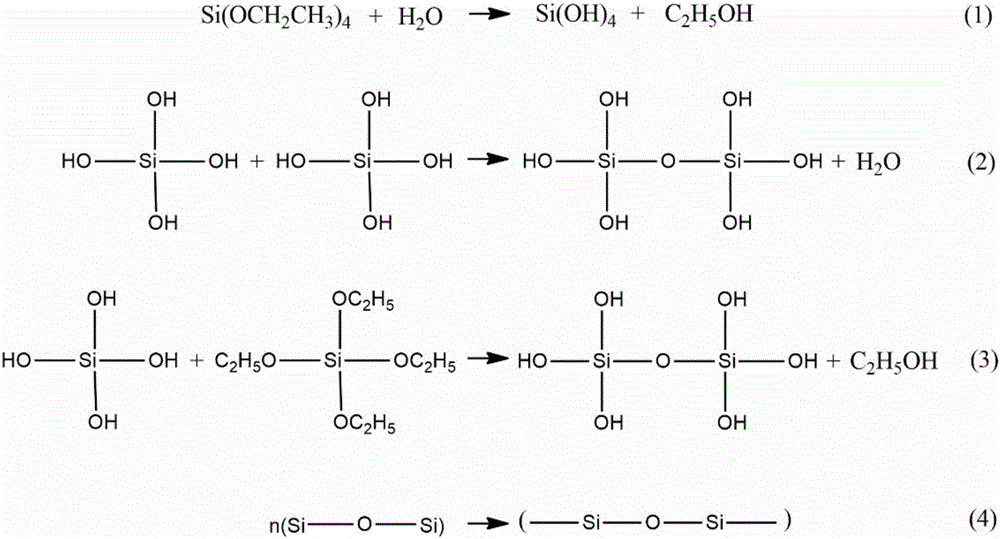

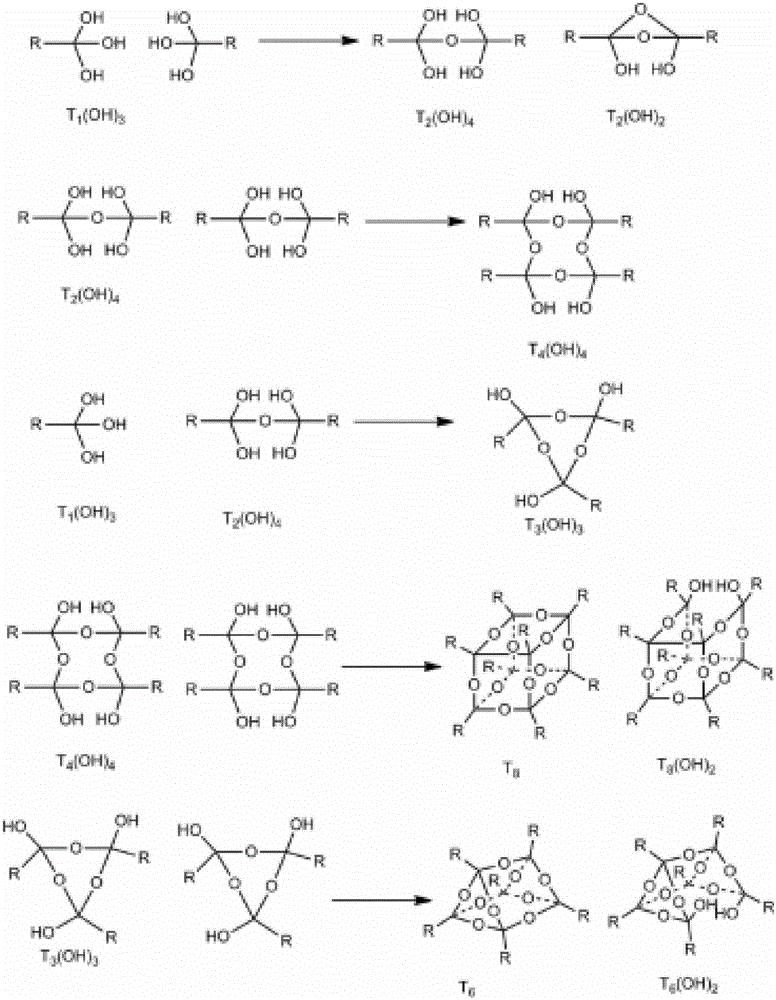

Silicon dioxide-based anti-adhesion agent used for polyolefin thin film and preparation method thereof

ActiveCN105906839AUniform particle size distributionReduce surface tensionTetraethyl orthosilicateChemistry

The invention relates to a silicon dioxide-based anti-adhesion agent used for a polyolefin thin film and a preparation method thereof. The silicon dioxide-based anti-adhesion agent is suitable for plastic thin film production enterprises. The preparation method includes the following steps of: 1) preparing silicon dioxide sol from tetraethyl orthosilicate under alkaline conditions; 2) adding a surfactant and a proper oil phase organic substance, and stirring the mixture to prepare a micelle with silicon dioxide as a shell layer; 3) adding trimethoxy silane containing an R group and a catalyst to the micelle with the silicon dioxide as the shell layer, and stirring the mixture to prepare silicon dioxide-based microspheres at a certain temperature, wherein the surfaces of silicon dioxide are modified by silane; and 4) drying the microspheres to remove the oil phase to obtain silicon dioxide hollow microspheres. The silicon dioxide-based anti-adhesion agent is a compound having definite structural and molecular formulas and molecular weight, but is a hollow microsphere which has a hierarchical pore structure and is based on silicon dioxide. The anti-adhesion agent can reinforce a plastic thin film and improves creep resistance, wherein a large quantity of micro projections and gaps are formed on the surface of the thin film, thereby increasing roughness of the thin film, reducing friction coefficient and preventing adhesion of the thin films.

Owner:广州赫尔普化工有限公司

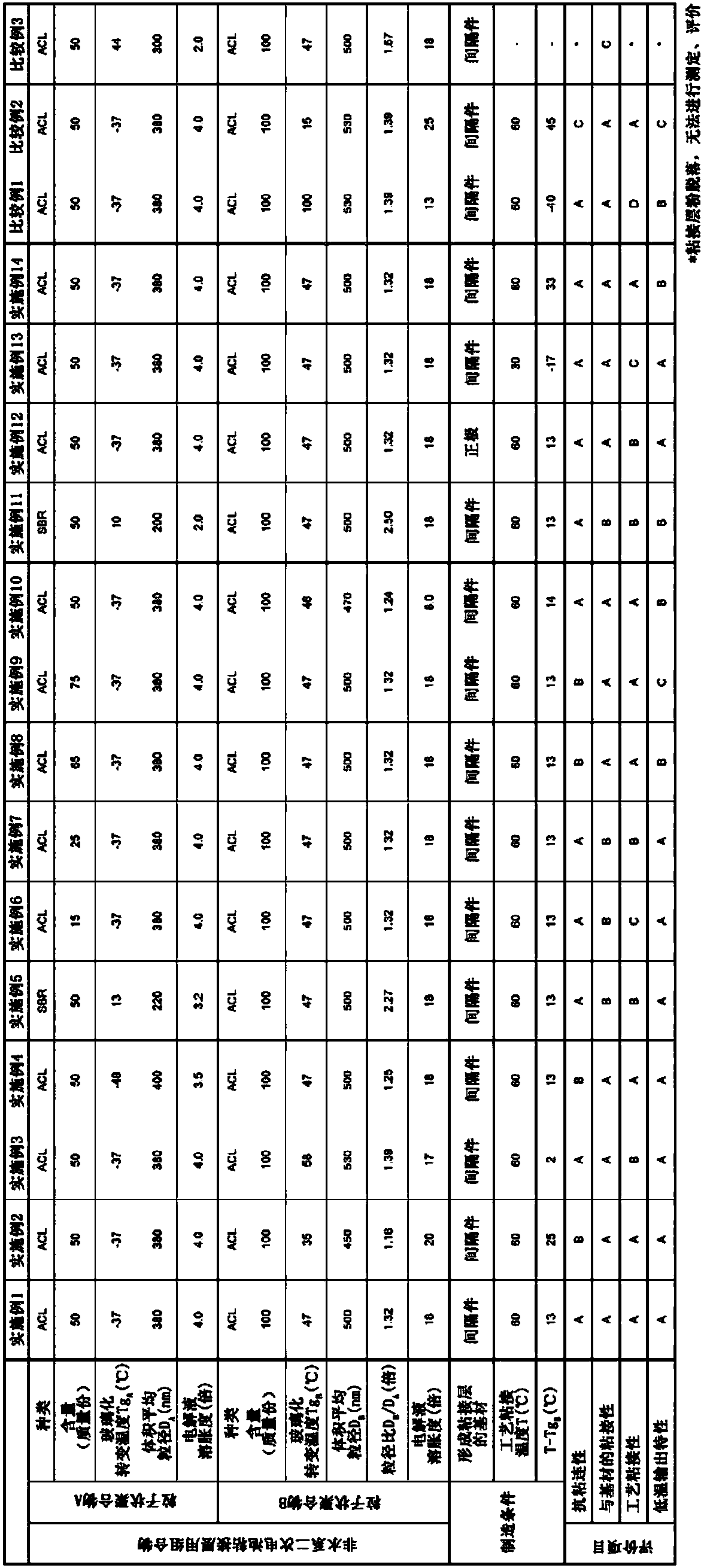

Composition for adhesive layer of non-aqueous secondary battery, adhesive layer of non-aqueous secondary battery, separator equipped with adhesive layer of non-aqueous secondary battery, electrode equipped with adhesive layer of non-aqueous secondary battery, non-aqueous secondary battery, and method for producing same

ActiveCN108140785AHigh process adhesionImprove anti-blockingFinal product manufactureAmide/imide polymer adhesivesParticulatesPolymer science

Provided is a composition for an adhesive layer of a non-aqueous secondary battery, said composition making it possible to form an adhesive layer that can achieve both high process adhesiveness and high blocking resistance in a battery member such as an electrode, a separator, or the like. This composition for an adhesive layer of a non-aqueous secondary battery contains: a particulate polymer A having a glass transition temperature of 20DEG C or less and a volume average particle size of 100 nm or more but less than 450 nm; and a particulate polymer B having a glass transition temperature of30DEG C or more but less than 60DEG C and a larger volume average particle size than the volume average particle size of the particulate polymer A.

Owner:ZEON CORP

Anti-adhesion low-smoke halogen-free and flame-retardant polyolefin cable material

InactiveCN111635580AGood smoke suppression and flame retardant propertiesImprove anti-blockingPlastic/resin/waxes insulatorsPolymer sciencePolyolefin

The invention discloses an anti-adhesion low-smoke halogen-free and flame-retardant polyolefin cable material. The invention belongs to the technical field of cable materials, and solves the problem of possible adhesion between cables. The cable material is prepared by adopting the following method of: by weight part, weighing 85-95 parts of an ethylene-vinyl acetate copolymer, 55-65 parts of highdensity polyethylene, 30-38 parts of magnesium hydroxide, 50-70 parts of aluminum hydroxide, 0.15-0.35 part of melamine urate, 10-22 parts of red phosphorus, 20-40 parts of a hyperdispersant, 17-23 parts of silicon dioxide, 7-13 parts of zinc hydroxystannate, 15-21 parts of nano BaSO4, 1-2 parts of polylactic acid and 0.5-1.5 parts of sodium hyaluronate evenly, conducting internal mixing for 10-15min at 130-140DEG C for 10-15min, and then performing extruding and granulating at 115-140DEG C, thereby achieving the effects of enabling the cable material to have good smoke-suppressing and flame-retardant properties and high anti-adhesive properties.

Owner:上海方之德新材料有限公司

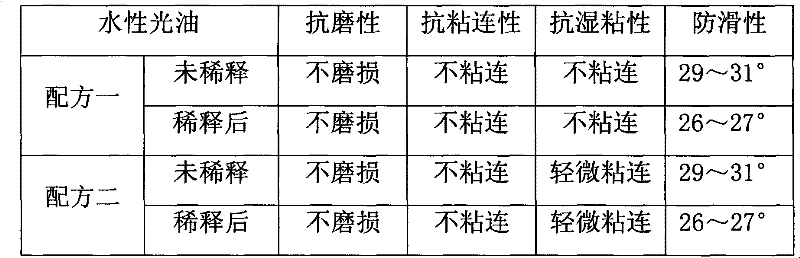

Aqueous gloss oil for beer cartons and preparation method thereof

ActiveCN101906735BImprove skid resistanceImprove anti-wear performanceNon-fibrous pulp additionPaper coatingWear resistantSlurry

Owner:GUANGDONG YINGKE GRP CO LTD

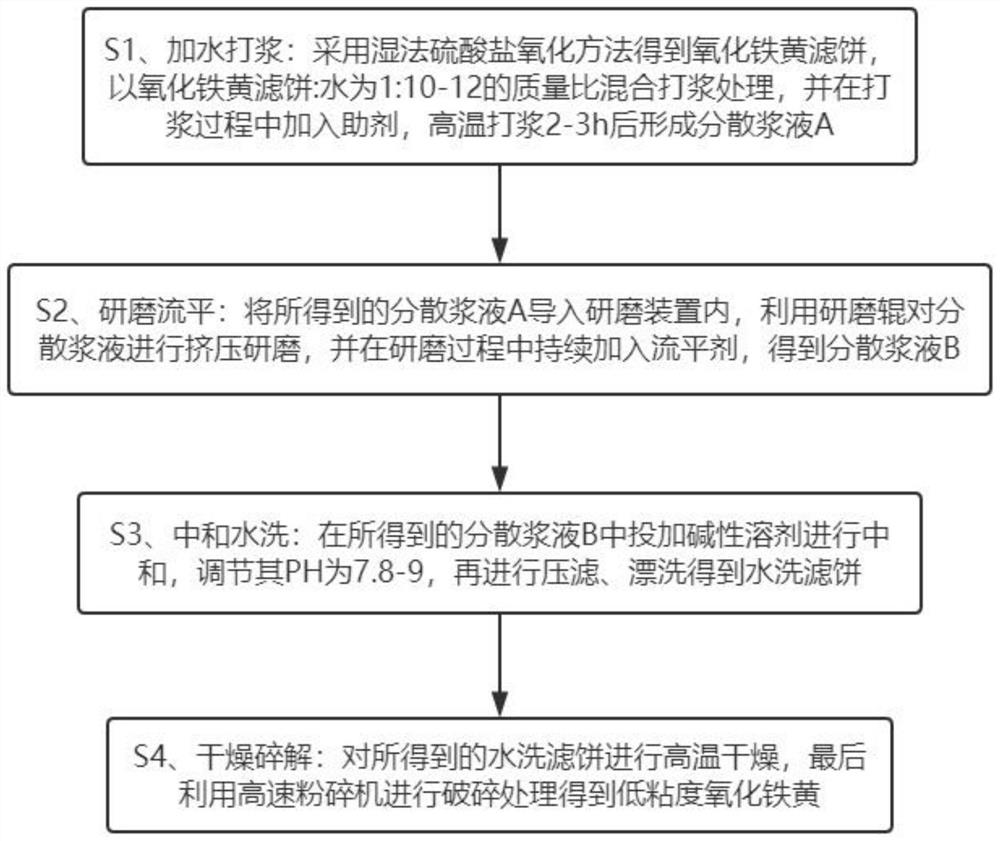

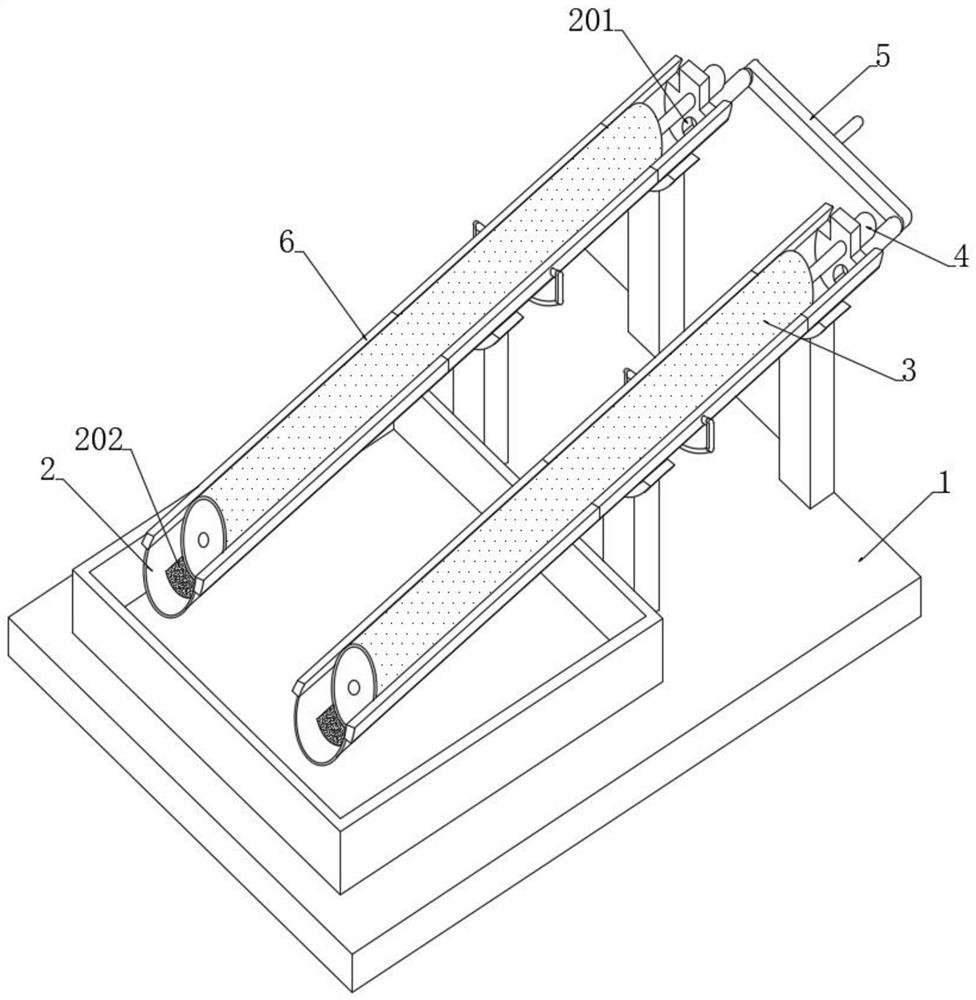

Production process of low-viscosity iron oxide yellow

InactiveCN112111180ALow viscosityReduce surface tensionCoatingsGrain treatmentsPhysical chemistrySlurry

The invention discloses a production process of low-viscosity iron oxide yellow, and belongs to the technical field of iron oxide yellow production. According to the process, water is added into an iron oxide yellow filter cake, pulping is conducted at high temperature, and an assistant is added in the high-temperature pulping process for dispersing to obtain dispersed slurry A, wherein the assistant is selected from one or more of a dispersion wetting agent and an active dispersing agent. In the process, the viscosity of the slurry is rapidly and effectively reduced and the surface characteristics of the slurry are changed in the pulping process through the assistant. Then the obtained dispersed slurry A is dispersed and ground by using a grinding device, a leveling agent is continuouslyand uniformly added in the grinding process, and grinding and leveling are performed to obtain dispersed slurry B, wherein the leveling agent is selected from one or more of acrylic acid leveling agents and organic silicon leveling agents, the wettability, smoothness and anti-blocking property of the slurry are effectively improved by utilizing leveling dispersion, and finally, the low-viscosity iron oxide yellow is prepared through filter pressing, rinsing, drying and crushing.

Owner:YIXING YUXING IND & TRADE

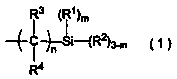

Composition containing vinyl alcohol polymer

InactiveCN103797065AEasy to operateImprove water resistanceNon-fibrous pulp additionCoatings with pigmentsPolymer scienceDegree of polymerization

The purpose of the present invention is to provide a composition with which it is possible to obtain a film that is superior in terms of being handled and has high water resistance and blocking resistance; a coating agent comprising the composition; a coated object obtained using the coating agent; a thermosensitive recording material; an ink jet recording material; a peelable paper stencil; and a method for producing a coated object. The present invention relates to a composition comprising a vinyl alcohol polymer (A), which contains repeating units having groups represented by formula (1) and which satisfies formula (I), and compound (B) comprising at least one atom selected from the group consisting of silicon, titanium, and zirconium, wherein the content of compound (B) is 0.01 to 900 parts by mass per 100 parts by mass of vinyl alcohol polymer (A). 370<=P*S<=6,000 (I) P: viscosity-average degree of polymerization, S: content of repeating units (mol%).

Owner:KURARAY CO LTD

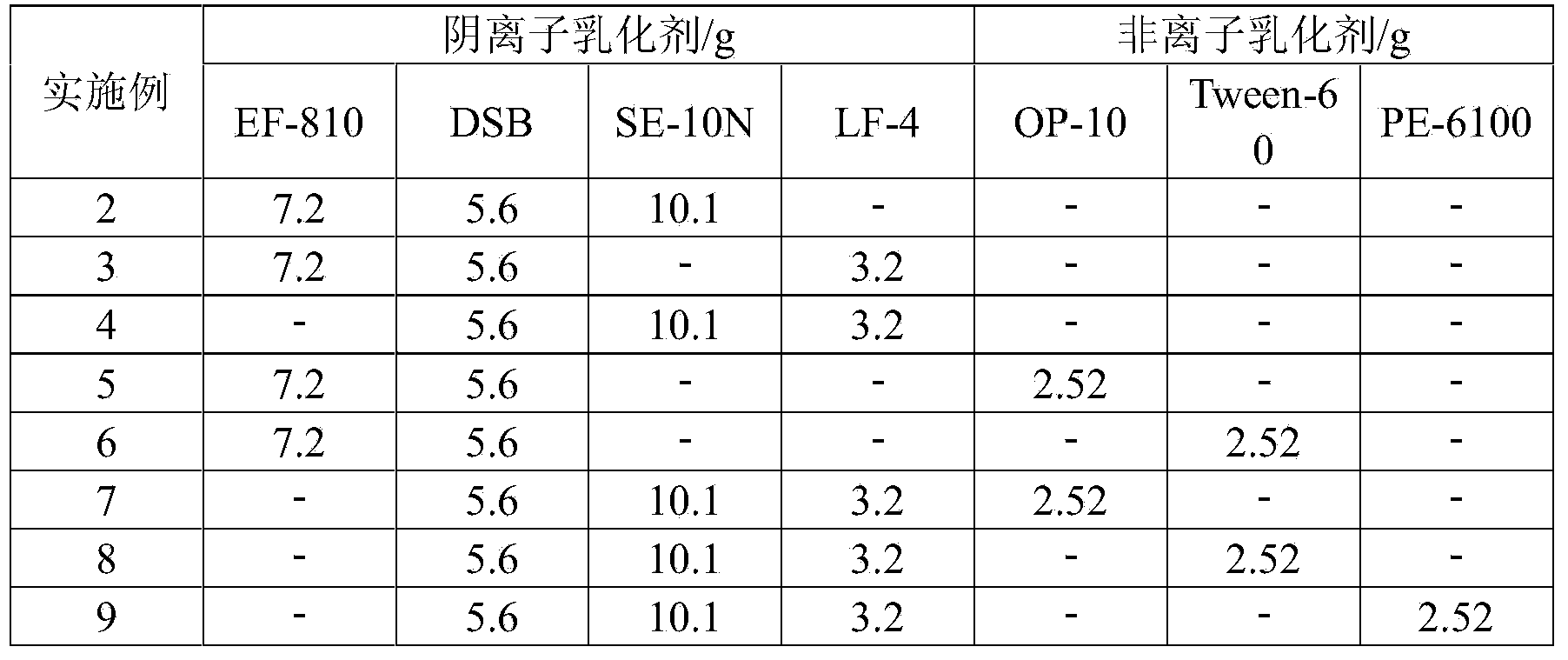

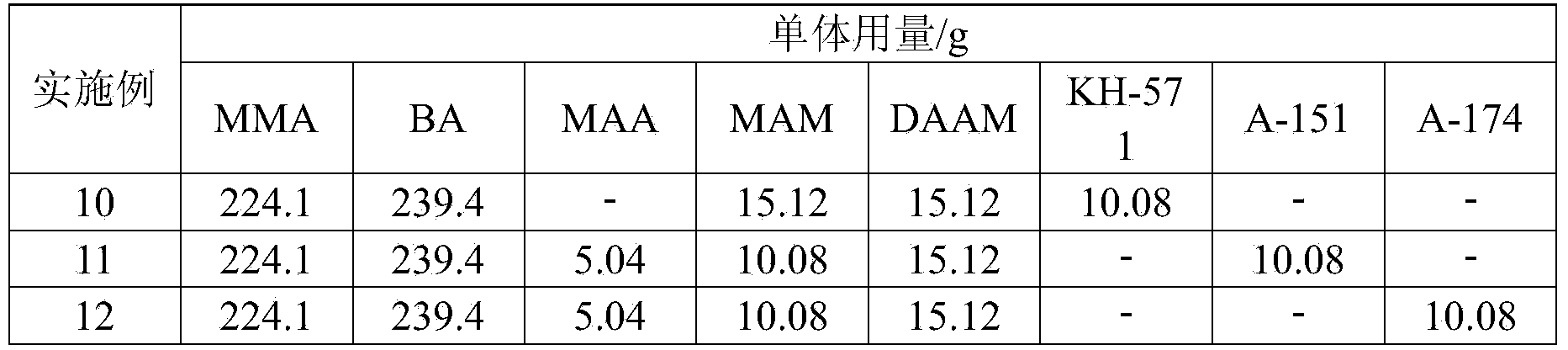

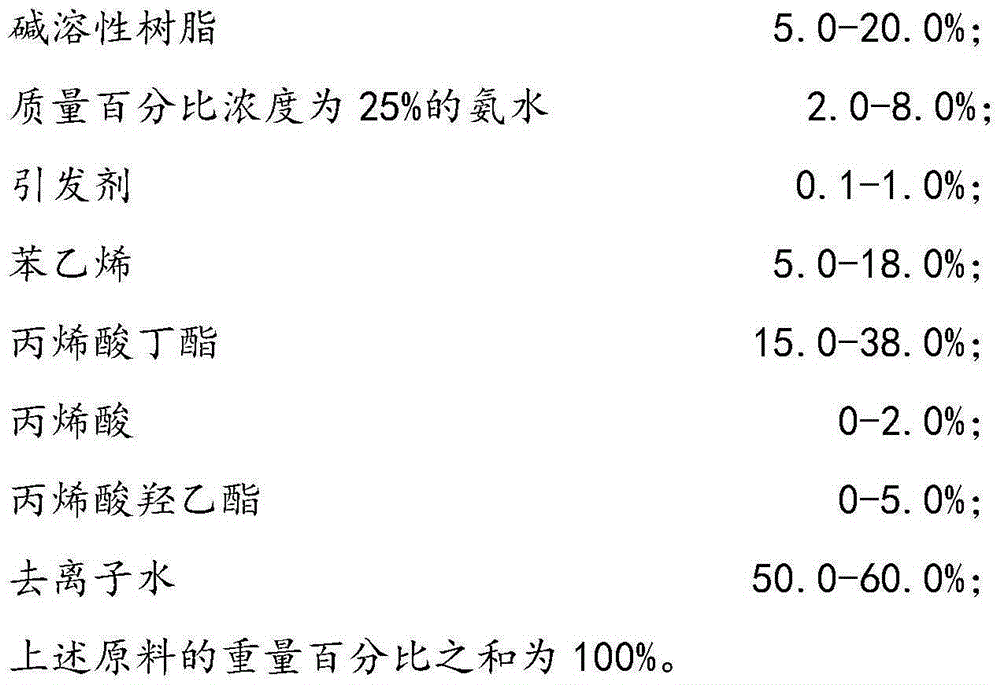

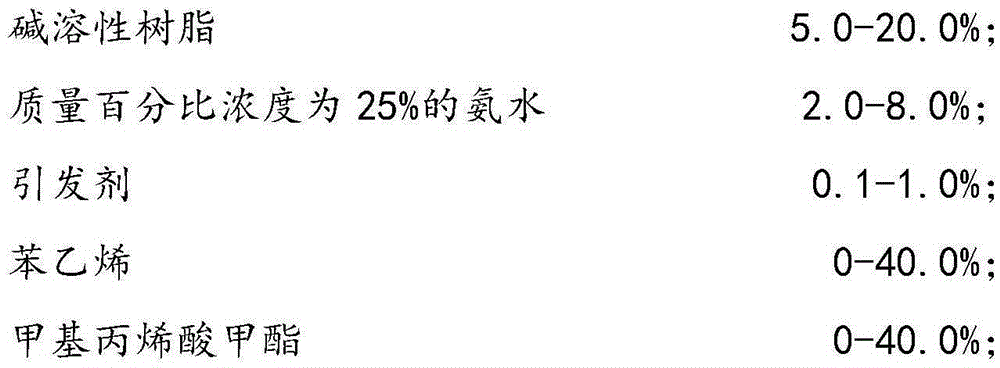

Preparation method of hydroxyl acrylate emulsion for waterborne wood paint

The invention discloses a preparation method of a hydroxyl acrylate emulsion for waterborne wood paint. The method comprises the following steps: using a core-shell synthesis technique, firstly generating a soft core with very small particle size by adopting microemulsion polymerization, and then polymerizing a layer of hard shell with a room-temperature self-crosslinking function; wherein the hydroxyl-containing function can be uniformly or emphatically distributed in the core and the shell layer as required, and the monomer composition of the shell layer contains a proper amount of functional monomer diacetone acrylamide capable of carrying out room-temperature self-crosslinking and is matched with adipic dihydrazide to carry out room-temperature self-crosslinking; the obtained product has the characteristics of small particle size, high transparency, good polishability, good hardness and good tolerance, and is suitable for being used as single-component or double-component wood paint, especially varnish primer.

Owner:CHANGSHU BATF TECH CO LTD

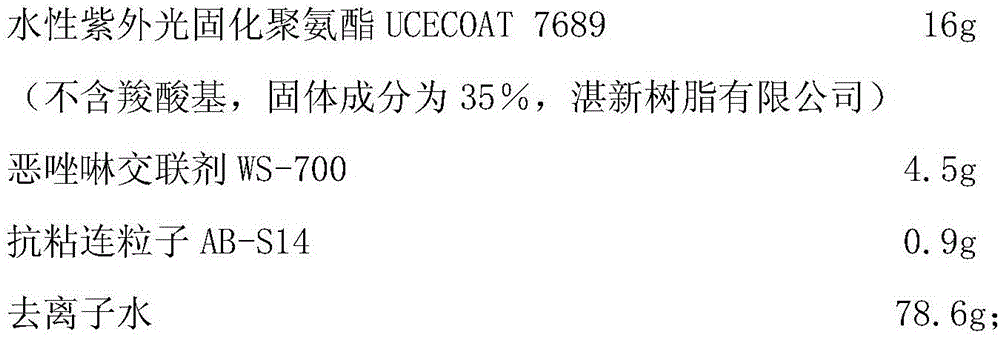

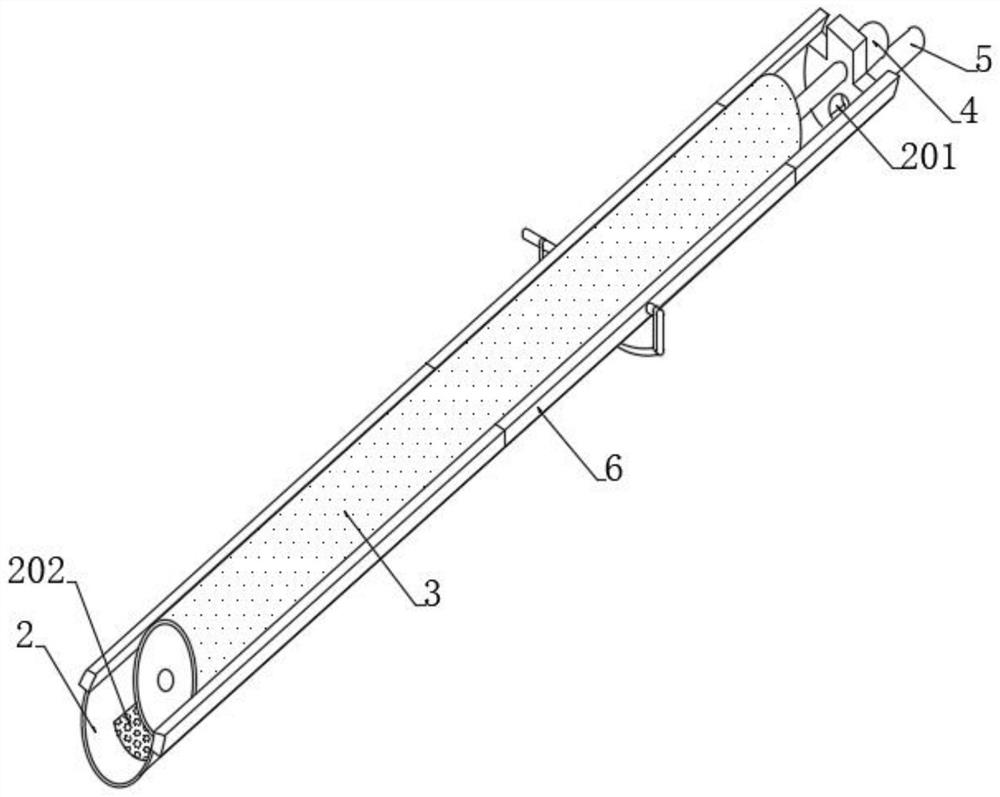

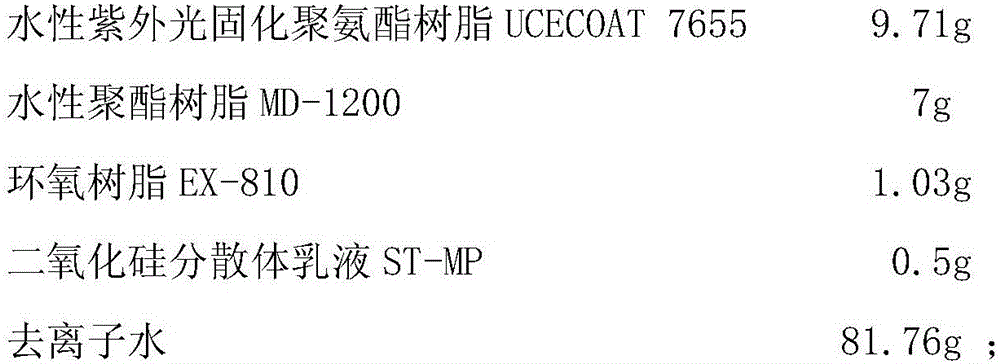

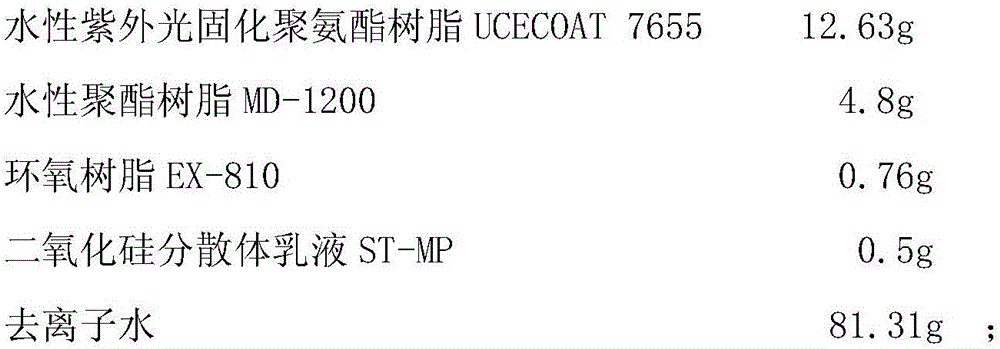

Optical polyester film and optical laminated polyester film

InactiveCN105774155AStrong adhesionExcellent initial adhesionSynthetic resin layered productsPolyurea/polyurethane coatingsEpoxyHigh humidity

The invention discloses an optical polyester film and an optical laminated polyester film.At least one face of a biaxially oriented base film of the optical polyester film is coated with a bottom coating containing an adhesive and anti-adhesion particles, and the adhesive is prepared from, by weight, waterborne ultraviolet light cured polyurethane resin 40-90%, waterborne polyester resin 9-40% and epoxy resin 1-20%.The polyester film layer has excellent initial adhesion to an optical functional layer, also has good adhesion under the conditions of high temperature and high humidity, meanwhile has high transparency and excellent adhesion resistance and is suitable for the fields of LCD, PDP and other display devices.

Owner:HEFEI LUCKY SCI & TECH IND

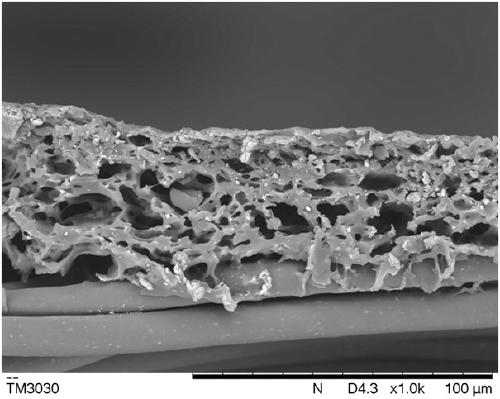

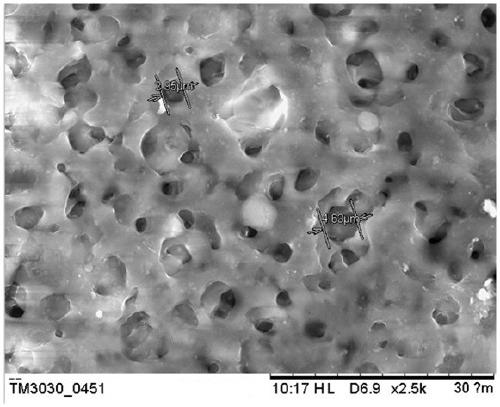

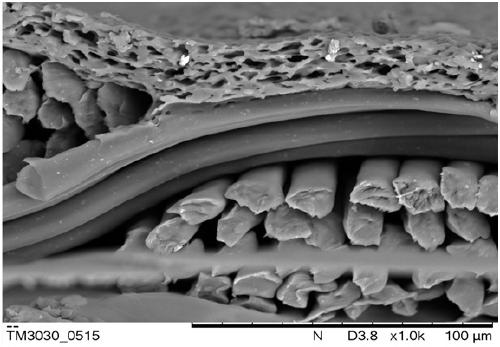

Preparation method of waterborne micro porous waterproof and moisture permeable film

The invention discloses a preparation method of a waterborne micro porous waterproof and moisture permeable film. The preparation method comprises the following steps that S1, materials are prepared,the raw materials in parts by weight are weighed in proportion: 100 parts of a waterborne polyurethane emulsion, 5-8 parts of methylbenzene, 10-20 parts of ammonium hydroxide, 2-3 parts of a water-proofing agent and 65-70 parts of water; S2, mixing is conducted, the raw materials weighed in step 1 are mixed to obtain a colloidal mixture; S3, coating is conducted, release paper is evenly coated with the mixture; and step 4 is conducted before the mixture is in a solidified state after coating; S4, drying is conducted, the release paper coated with the mixture is sent into an oven for drying, temperatures with at least three levels are set in the oven, the first-level temperature is 78 DEG C to 80 DEG C, the second-level temperature is 100 DEG C to 120 DEG C, and the third-level temperatureis 150 DEG C to 160 DEG C; and S5, stripping is conducted, after drying, the release paper is stripped to obtain the waterborne micro porous waterproof and moisture permeable film. A film product prepared by the preparation method has the functions of moisture permeability and anti water drop, water dropping on the film surface does not expand, and meanwhile the micro porous waterproof and moisture permeable film has excellent elasticity.

Owner:HUAMAO (XIAMEN) WEAVING DYEING & FINISHING CO LTD

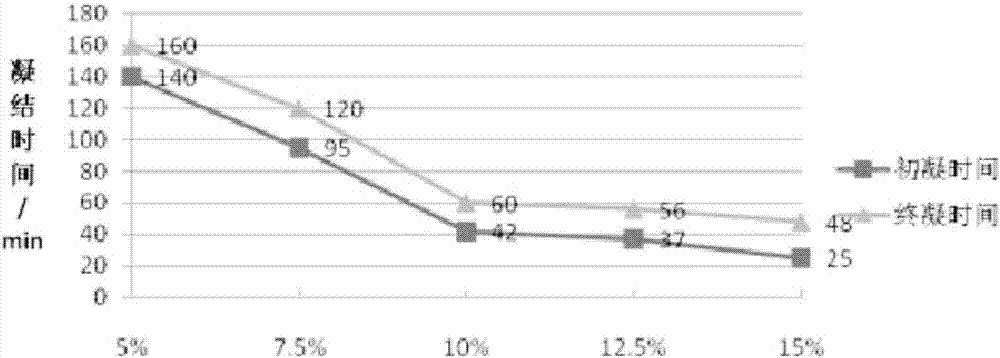

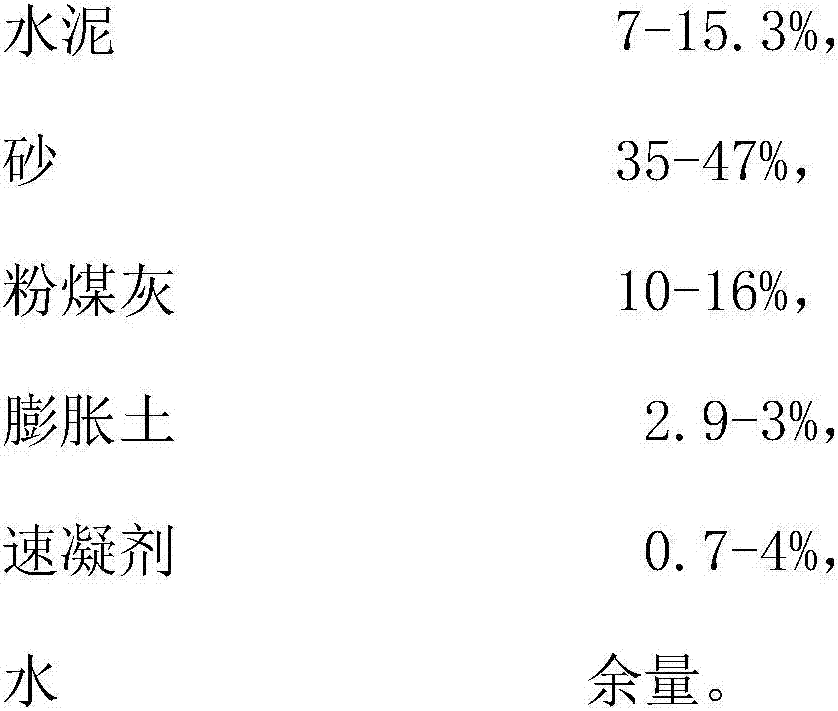

Composite type TBM synchronous grouting material and grouting method

InactiveCN107060818AShorten the setting timeOvercome insufficient groutingUnderground chambersDrilling compositionFly ashMaterials science

The invention discloses a composite type TBM synchronous grouting material and a grouting method. The technical scheme key point of the composite type TBM synchronous grouting material is that the grouting material is composed of raw materials, by weight, of 7%-15.3% of cement, 35%-47% of sand, 10%-16% of fly ash, 2.9%-3% of expansive soil, 0.7%-4% of an accelerator and the balance water. According to the composite type TBM synchronous grouting material, the solidification time is greatly shortened, the problem of insufficient grouting is solved, the operation efficiency is improved, and the engineering quality is ensured.

Owner:CHONGQING CONSTR ENG GRP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com