Composition for adhesive layer of non-aqueous secondary battery, adhesive layer of non-aqueous secondary battery, separator equipped with adhesive layer of non-aqueous secondary battery, electrode equipped with adhesive layer of non-aqueous secondary battery, non-aqueous secondary battery, and method for producing same

A secondary battery, non-aqueous technology, used in non-aqueous electrolyte battery electrodes, secondary batteries, battery electrodes, etc., can solve problems such as decreased productivity and defects, and achieve improved process adhesion and anti-blocking properties, battery characteristics excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] >

[0060] The polymerization method of the particulate polymer A is not particularly limited, and any method such as a solution polymerization method, a suspension polymerization method, a bulk polymerization method, or an emulsion polymerization method can be used, for example. In addition, as the polymerization reaction, addition polymerization such as ionic polymerization, radical polymerization, and living radical polymerization can be used. In addition, emulsifiers, dispersants, polymerization initiators, chain transfer agents, etc. that can be used for polymerization can use commonly used emulsifiers, dispersants, polymerization initiators, and chain transfer agents, and the amount of use can also be set to a commonly used quantity.

[0061]

[0062] The particulate polymer B functions to make the adhesive layer for a nonaqueous secondary battery formed using the composition for an adhesive layer for a nonaqueous secondary battery containing the particulate po...

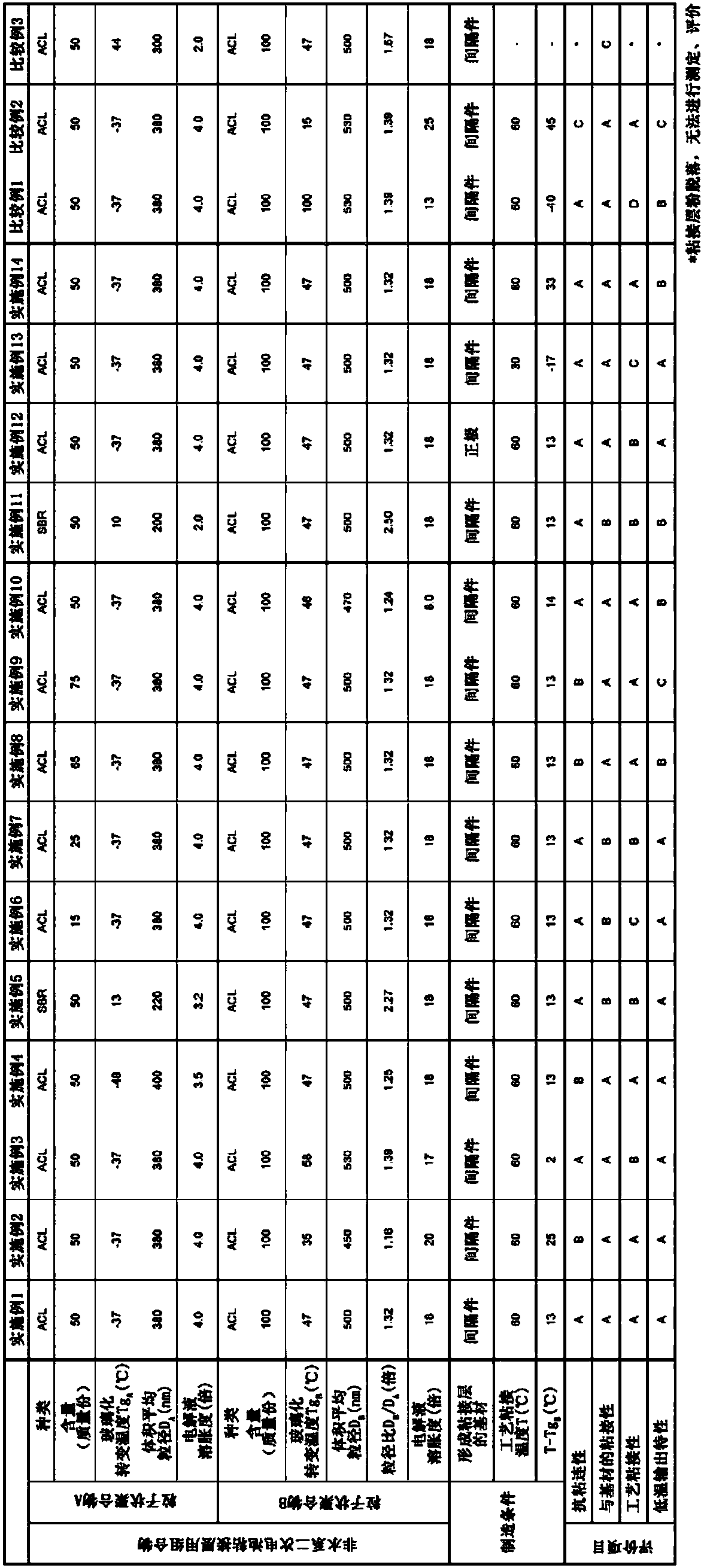

Embodiment 1~11 and comparative example 1~3

[0151] The process adhesiveness of the electrode (positive electrode) and a separator via the adhesive layer for nonaqueous secondary batteries was measured and evaluated as peeling strength as follows. In addition, in this measurement, the positive electrode which is an electrode was made to face a separator as an example, but it can also measure by the same method even if a negative electrode and a separator are made to face. Specifically, the produced positive electrode and the separator with an adhesive layer for a non-aqueous secondary battery were each cut out to a length of 50 mm and a width of 10 mm. Then, the cut positive electrode and the separator with an adhesive layer were laminated with the adhesive layer interposed therebetween. Then, the obtained laminated sheet was pressed with a roll press machine with a process bonding temperature (T) of 60° C. and a load of 10 kN / m to bond the positive electrode and the separator, thereby obtaining a test piece.

[0152] T...

Embodiment 12

[0154] The produced positive electrode with an adhesive layer for a non-aqueous secondary battery and the separator were each cut to a length of 50 mm and a width of 10 mm. Then, the cut-out non-aqueous secondary battery positive electrode with an adhesive layer and a separator without an adhesive layer were laminated with the adhesive layer interposed therebetween. Then, the obtained laminated sheet was pressed with a roll press machine having a process temperature (T) of 60° C. and a load of 10 kN / m to bond the positive electrode and the separator, thereby obtaining a test piece.

[0155] The surface of the test piece on the current collector side of the positive electrode was facing downward, and a cellophane tape (cellophane tape specified in JIS Z1522) was attached to the surface of the positive electrode on the current collector side. In addition, cellophane strips are fixed to a horizontal test stand. Then, the stress at the time of pulling one end of the spacer vertic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com