Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Excellent initial adhesion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

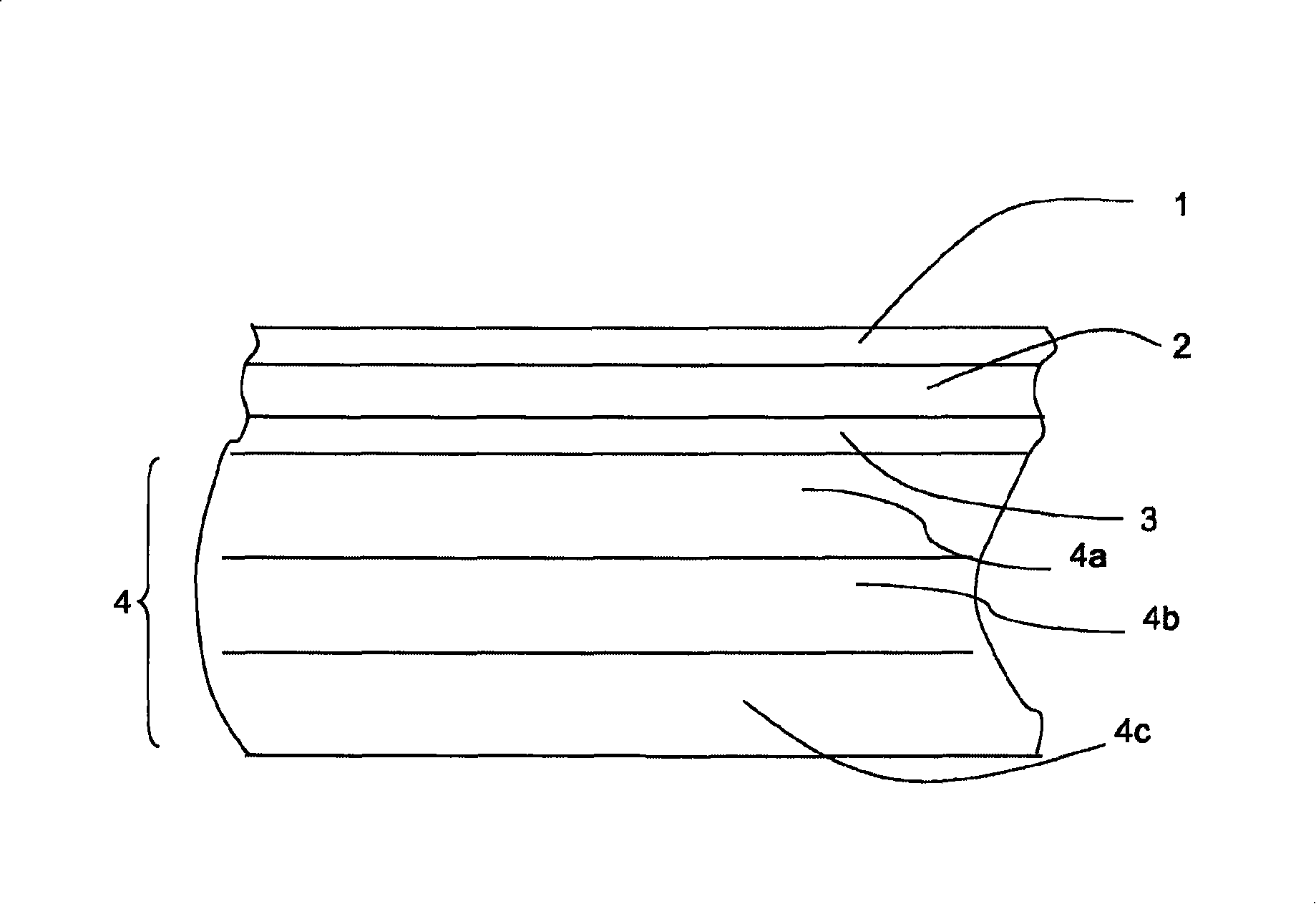

Surface protective film

InactiveCN101189317AExcellent stripping workabilityExcellent initial adhesionFilm/foil adhesivesElastomerPolyolefin

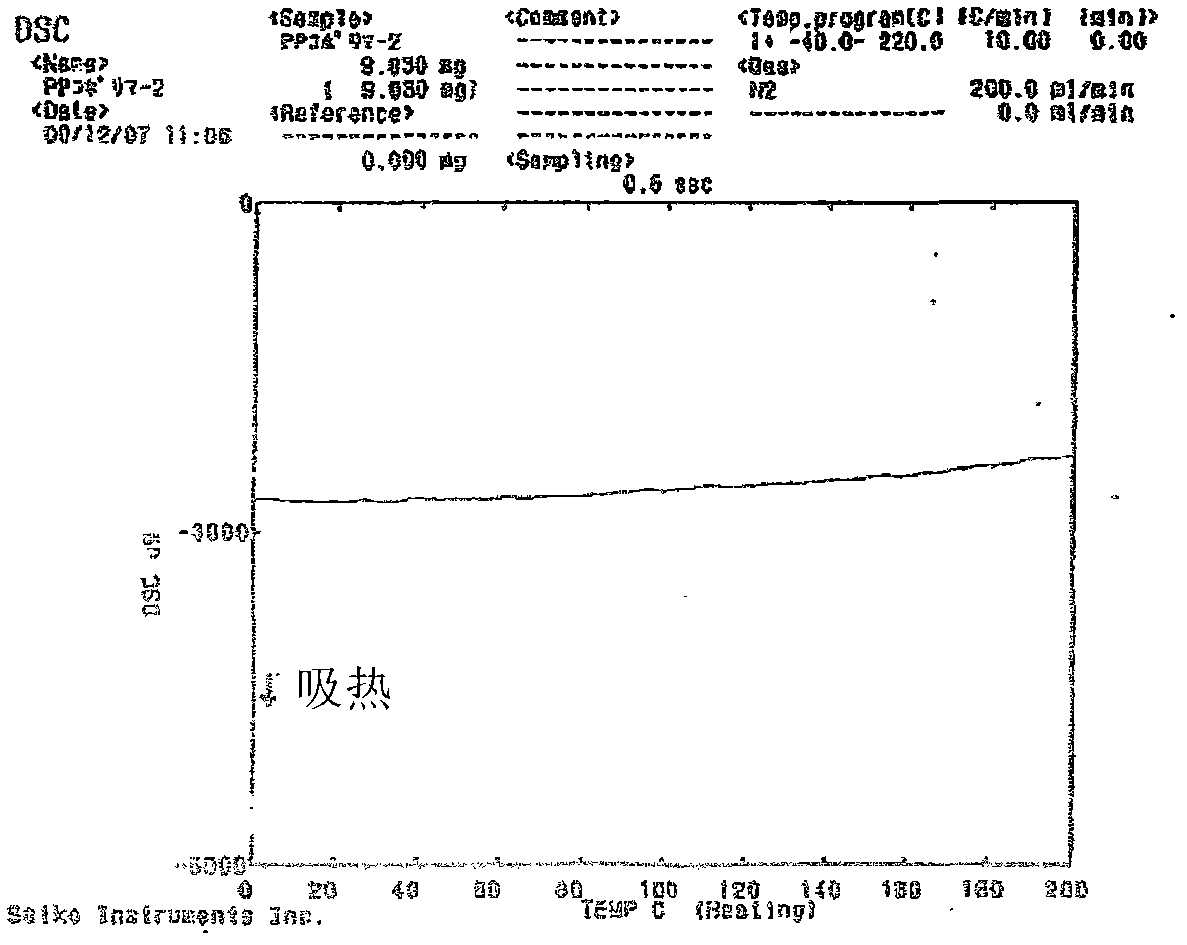

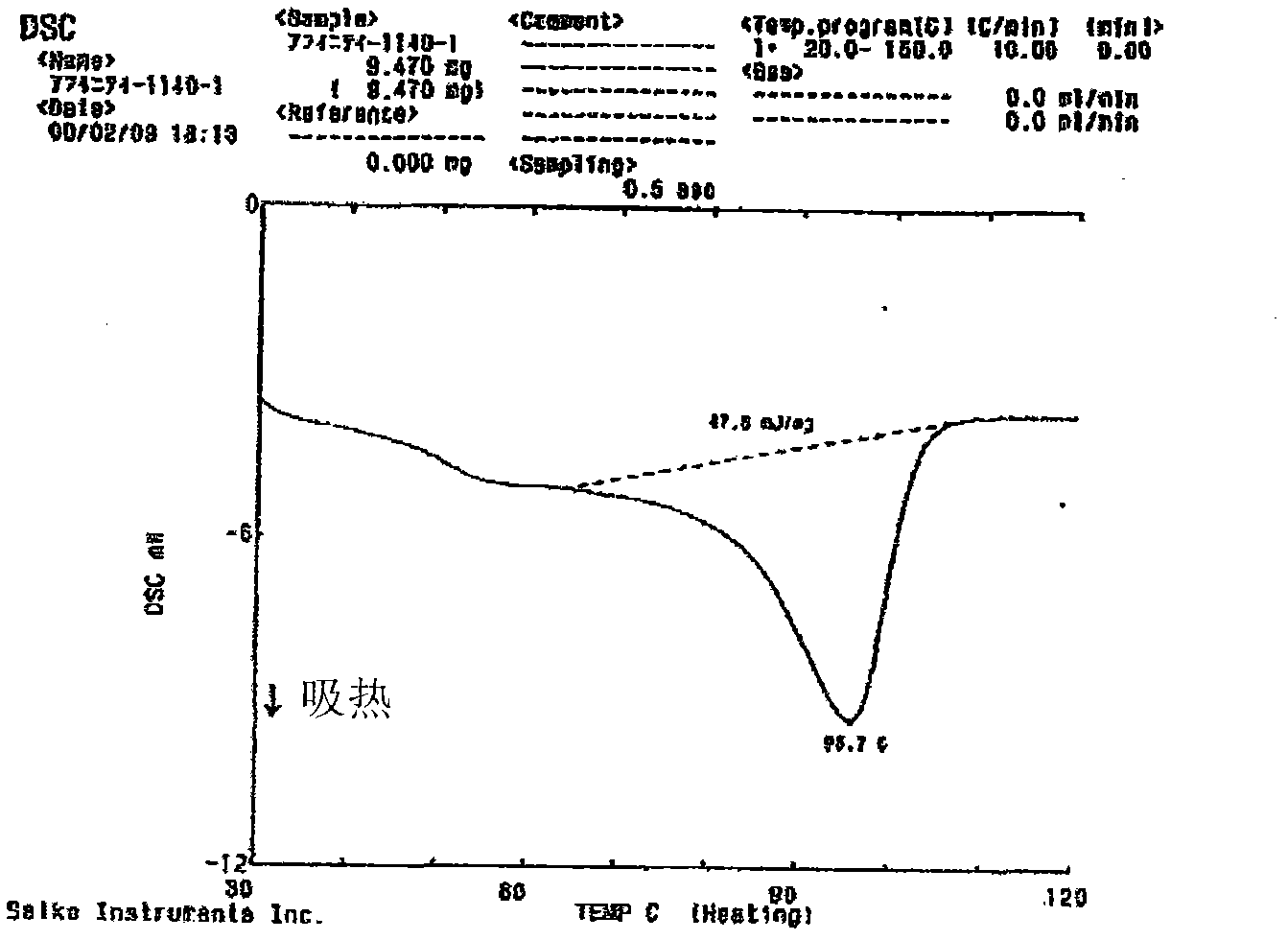

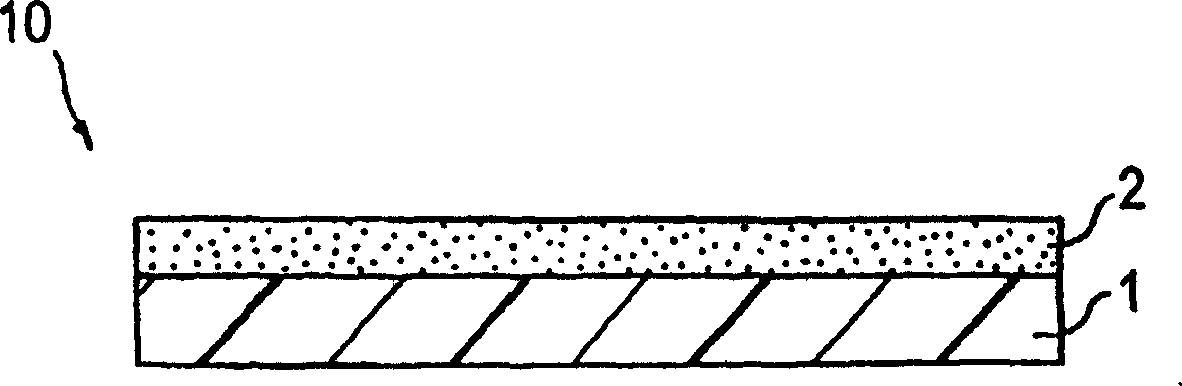

Disclosed is a surface protection film which has excellent initial adhesion and can be easily removed from an object to which it is adhered. The adhesive force of this surface protection film does not undesirably increase as time passes. Specifically disclosed is a surface protection film wherein a rubber adhesive layer is arranged on a polyolefin base. The rubber resin component is composed of a styrene elastomer which has a block copolymer of a styrene polymer block (A) and an olefin elastomer component (B), a block copolymer of a styrene polymer block (A) and a random copolymer block (B') of styrene and an elastomer component, or a hydrogenated product of either of the block copolymers as a main backbone. The rubber adhesive layer has a tensile storage modulus at a frequency of 10 Hz of not less than 2.5 109 Pa at -100 DEG C, and a shear storage modulus at a frequency of 10 Hz of from 5 104 to 5 106 Pa at 23 DEG C.

Owner:SEKISUI CHEM CO LTD

Waterproof color building sealing adhesive and its prepn process

InactiveCN101020804AWill not polluteEasy to operateMonocarboxylic acid ester polymer adhesivesCellulose adhesivesBrickAdhesive

The present invention is one kind of waterproof color building sealing adhesive and its preparation process. The waterproof color building sealing adhesive is produced with cement, quartz sand, water soluble cellulase, lignin, pigment, ethyl acetate copolymer latex powder, organic carboxylic metal salt powder and through homogeneous mixing. The adhesive of the present invention can form waterproof surface and possesses the features of waterproofing, adhering, beautiful appearance, high durability and environment friendship. It has integral joint filling and adhering functions and low cost, and is suitable for both joint filling and adhering of outer wall tile, floor tile, inner wall tile, stone material and plaza tile.

Owner:SOUTH CHINA UNIV OF TECH +1

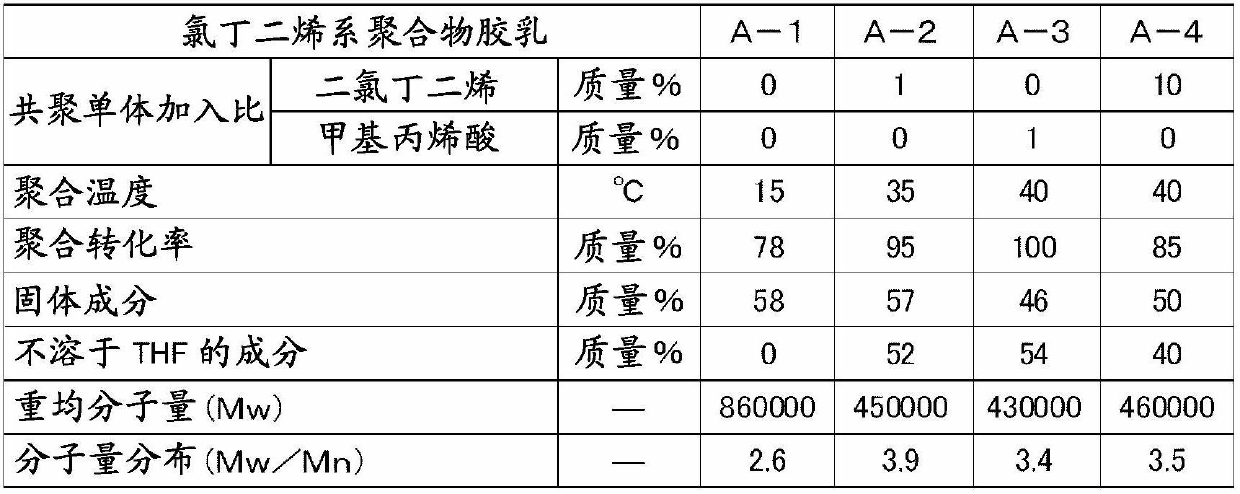

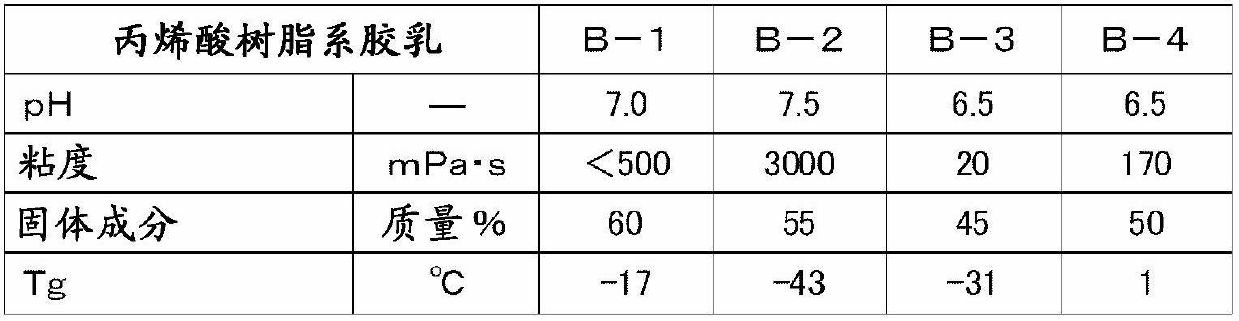

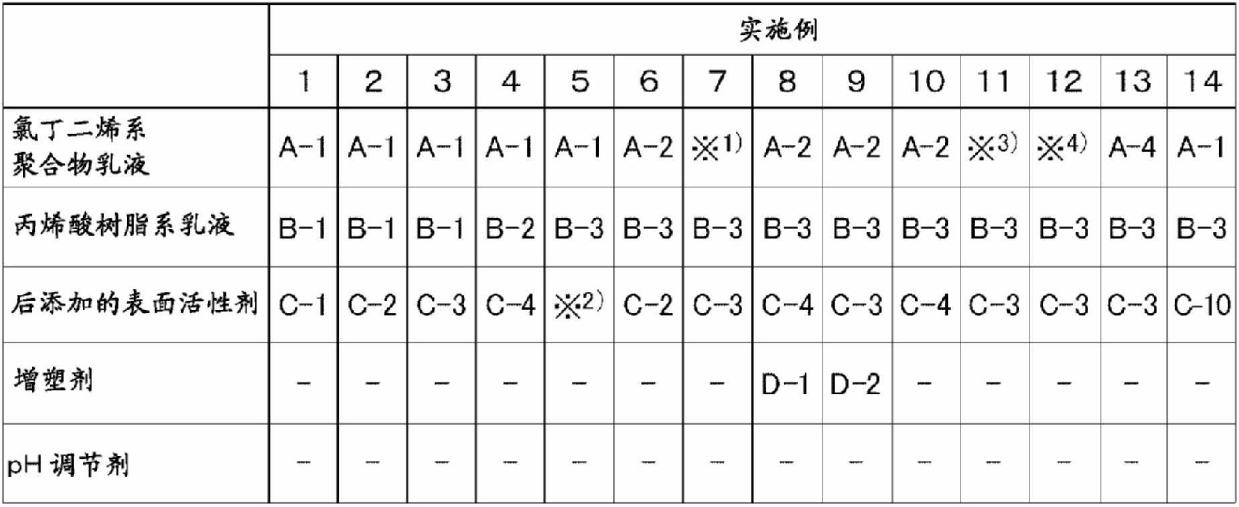

Chloroprene polymer latex composition and use thereof

ActiveCN102666708AFast crystallizationDoes not reduce storage stabilityEster polymer adhesivesChloroprene adhesivesWater basedAdhesive

Owner:RESONAC CORPORATION

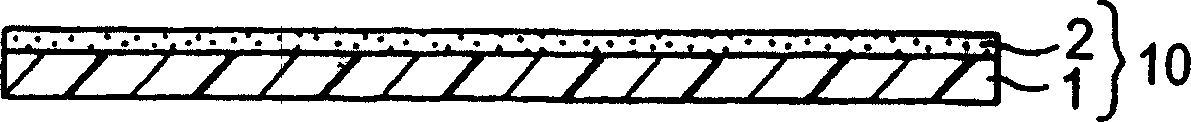

Two-sided differential adhesive tape and production method thereof

InactiveCN106833419AExcellent Exhaust ComplianceThen smooth and easyNon-macromolecular adhesive additivesFilm/foil adhesive release linersPolyesterSodium bicarbonate

The invention relates to a two-sided differential adhesive tape. The two-sided differential adhesive tape comprises a first release film, a first adhering layer, a polyester film, a second adhering layer and a second release film in turn from top to bottom, wherein a fluorine plastic release film is served as the first release film; the first release film is adhered to the first adhering layer; the polyester film is arranged between the first adhering layer and the second adhering layer; a single-silicon release film is served as the second release film; the second release film is adhered under the second adhering layer. According to the invention, the mixture of sodium bicarbonate particle and carbon powder is added, so that the radiating mode in the adhering layer can be effectively improved and the radiating effect can be obviously promoted. A novel two-sided differential adhesive tape with an excellent radiating function is supplied.

Owner:WUHU HONGSHENG TECH

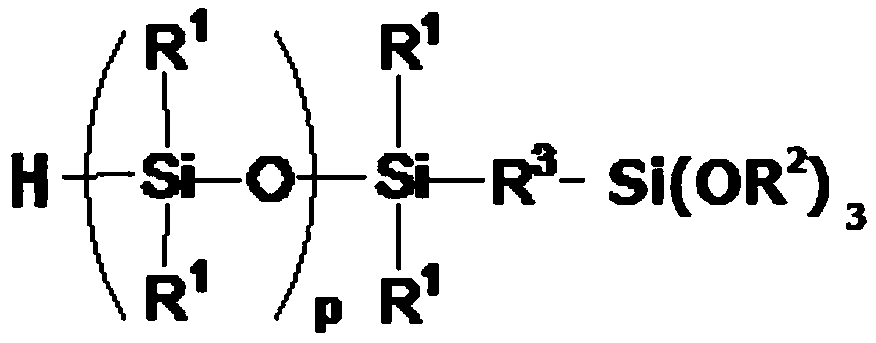

Curable organopolysiloxane composition, and protection agent or adhesive composition for electrical/electronic components

ActiveCN110088206AEasy curingExcellent initial adhesionNon-macromolecular adhesive additivesSemiconductor/solid-state device detailsPolymer sciencePtru catalyst

To provide a curable organopolysiloxane composition, etc. which has a particularly excellent effect of improving initial adhesiveness in small amounts and a thin layer with respect to various base materials, in addition to being able to achieve particularly excellent adhesive durability and high adhesive strength after curing. A curable organopolysiloxane composition, containing:(A) an organopolysiloxane having at least two alkenyl groups per one molecule; (B) a trialcoxysilyl containing siloxane having one silicon atom-bonded hydrogen atom and at least one trialcoxysilyl group per one molecule; (C) a chain or cyclic organopolysiloxane having at least two silicon atom-bonded hydrogen atoms per one molecule; (D) a chain organopolysiloxane having at least three silicon atom-bonded hydrogen atoms per one molecule; (E) a catalyst for a hydrosilylation reaction; (F) a catalyst for a condensation reaction; and (G) an adhesion promoter.

Owner:DOW TORAY CO LTD

Adhesive for solar battery back sheets

ActiveCN104011104AImprove hydrolysis resistanceExcellent initial adhesionPolyureas/polyurethane adhesivesPhotovoltaic energy generationMeth-Polyol

An object of the present invention is to provide a urethane adhesive for solar battery back sheets, which has satisfactory initial adhesion to a film in the production of a solar battery back sheet, satisfactory initial adhesive property after curing and high adhesive property at high temperature, and also has a sufficient hydrolysis resistance over the long term and is excellent in overall balance; a solar battery back sheet which is obtainable by using the adhesive; and a solar battery module. Disclosed is an adhesive for solar battery back sheets, including a urethane resin obtainable by the reaction of an acrylic polyol with an isocyanate compound, wherein the acrylic polyol is obtainable by polymerizing polymerizable monomers, the polymerizable monomers include a monomer having a hydroxyl group and other monomers, the monomer having a hydroxyl group includes a hydroxyalkyl (meth)acrylate, and the other monomers include acrylonitrile and (meth)acrylic ester(s).

Owner:HENKEL KGAA

Adhesive for laminated sheets

InactiveCN104583261AModerate curing rateExcellent long-term hydrolysis resistancePolyureas/polyurethane adhesivesSynthetic resin layered productsXylylenePolymer science

Disclosed is an adhesive for laminated sheets comprising: a urethane resin obtainable by mixing an acrylic polyol with an isocyanate compound; and a silane compound; wherein the silane compound contains a glycidyl based silane compound, wherein the acrylic polyol is obtainable by polymerizing polymerizable monomer, the polymerizable monomer contains a monomer having a hydroxyl group and the other monomer, and the other monomer contains acrylonitrile, and the isocyanate compound contains at least one selected from xylylene diisocyanate and hexamethylene diisocyanate. The adhesive for laminated sheets has a moderate curing rate and is excellent in initial adhesion to a film and in long-term hydrolysis resistance at high temperature; it is also excellent in weatherability.

Owner:HENKEL KGAA

Urethane adhesive for laminated sheets

PendingCN107001574AAppearance effectLamination process influenceLayered productsPolyureas/polyurethane adhesivesChemistryAdverse effect

Disclosed is an adhesive for laminated sheets comprising a urethane resin obtainable by blending: (A) an acrylic polyol; (B) at least one selected from carboxylic acids and carboxylic anhydrides; and (C) an isocyanate compound, wherein the acrylic polyol (A) is obtainable by the polymerization of a polymerizable monomer, has a glass transition temperature of from -35 to 20 degrees centigrade, and has a hydroxyl value of from 0.5 to 40 mgKOH / g. The adhesive for laminated sheets is excellent in initial adhesion to a film, peel strength after aging and hydrolysis resistance for a long time under high temperature when a laminated sheet is produced, and wherein the adhesive does not impart an adverse effect to the appearance of the laminated sheet and the lamination process of films while improving the curability. The laminated sheet is suitably prepared using the adhesive for laminated sheets. An article comprising the laminated sheet can be prepared using the laminated sheet.

Owner:HENKEL KGAA

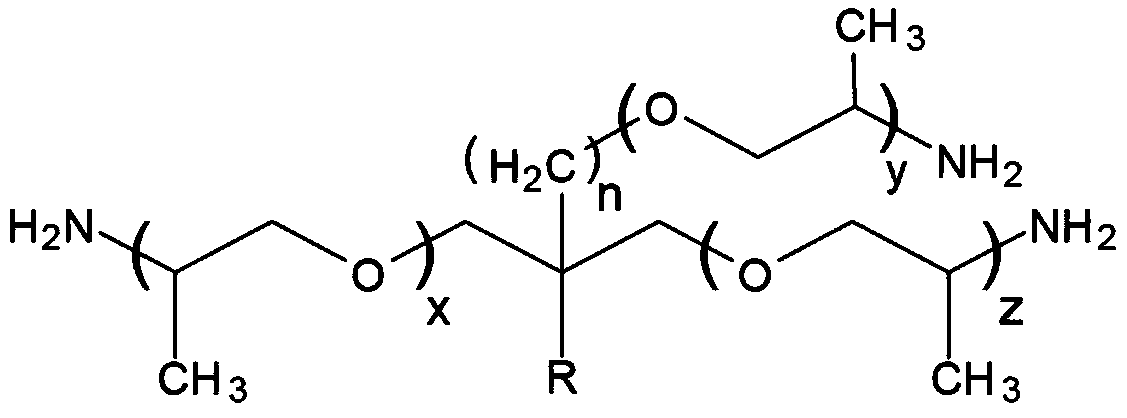

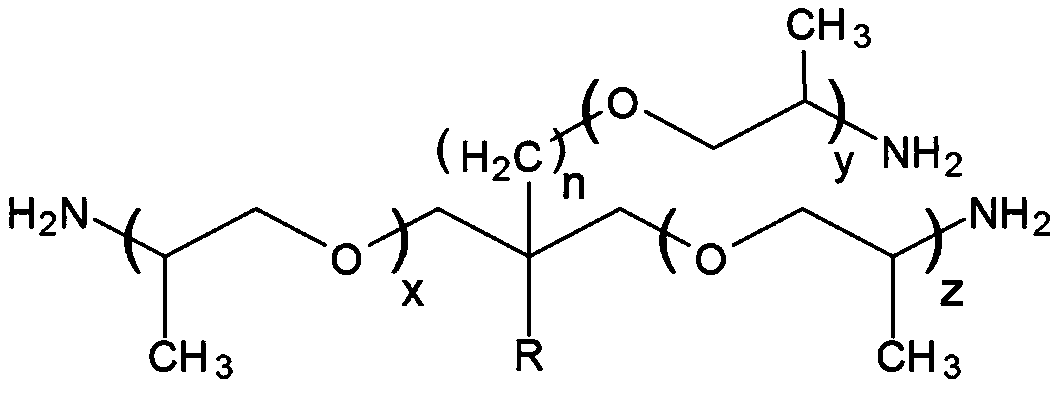

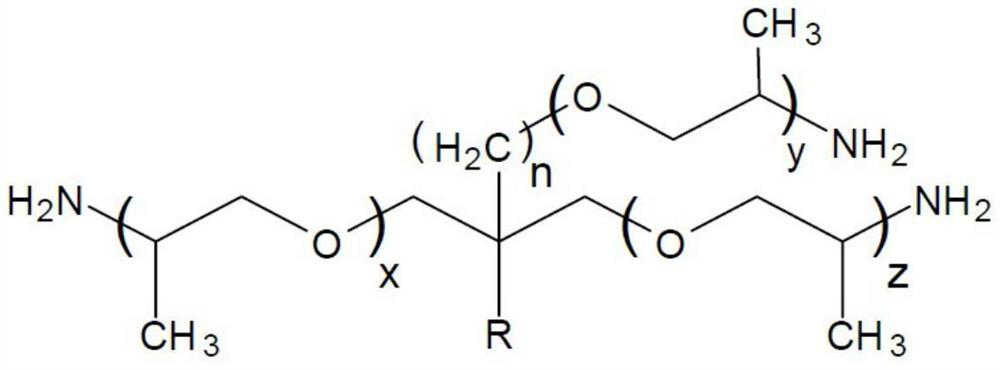

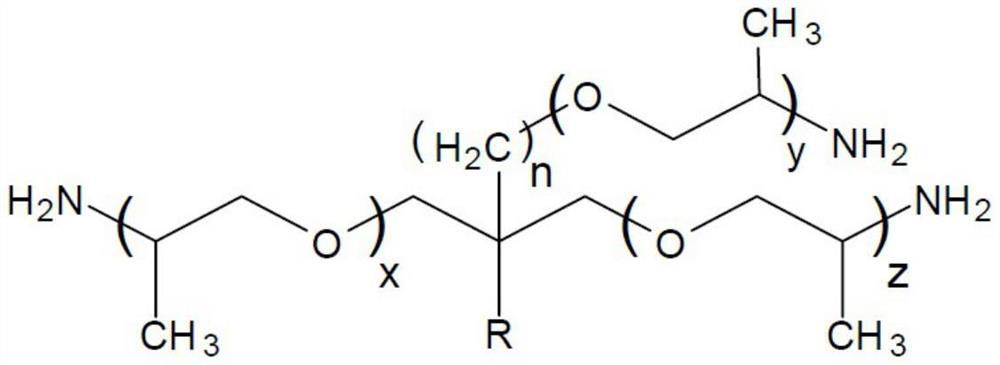

Preparation method of polyamide polyamine-polyether amine cylinder adhesive

The invention discloses a preparation method of a polyamide polyamine-polyether amine cylinder adhesive. The method comprises the following steps: under the protection of introduced nitrogen, firstlycarrying out condensation polymerization on an alkenyl amine derivative, grease and dibasic acid or corresponding dibasic ester under normal pressure, then continuously carrying out condensation polymerization under a vacuum condition until the molecular weight is not increased any more, and adding water to form an aqueous solution of a polyamide polyamine intermediate; and adding branched polyether amine into the aqueous solution, carrying out a closed reaction, heating to carry out a cross-linking reaction, finally adding an organic acid to terminate the reaction, and adding water to diluteto obtain the polyamide polyamine-polyether amine cylinder adhesive. The cylinder adhesive prepared by the invention has good adhesion, flexibility, water solubility, uniformity, durability and the like, and the use of epoxy chloropropane is avoided.

Owner:ZHEJIANG TRANSFAR WHYYON CHEM

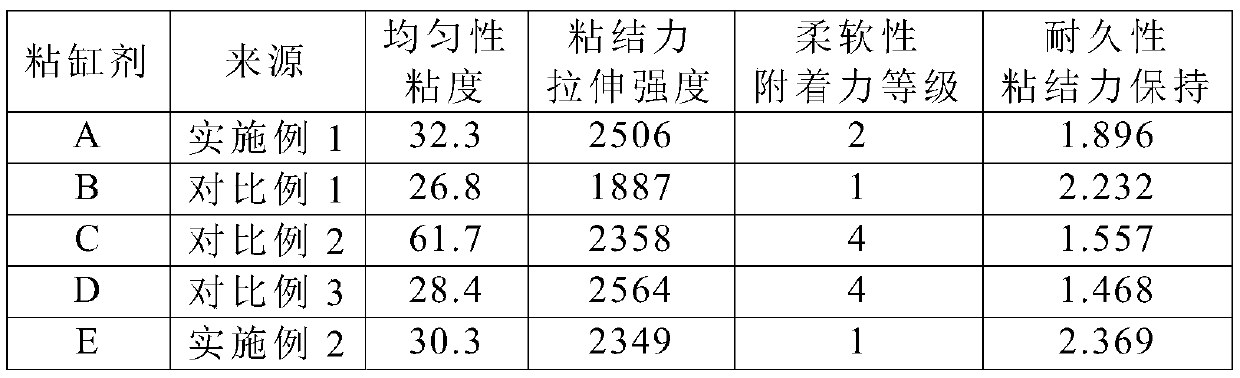

UV photosensitive adhesive, UV protective film applying UV photosensitive adhesive for wafer and preparation method of UV protective film for wafer

ActiveCN109161367AHigh bonding strengthImprove cohesionNon-macromolecular adhesive additivesFilm/foil adhesivesMicrospherePolyvinyl chloride

The invention discloses a UV photosensitive adhesive, the UV photosensitive adhesive comprises the following components by mass percent: 10%-15% of star SIS, 10%-15% of poly-terpene A, 1%-5% of poly-terpene B, 0.5 per mill-0.8 per mill of a light stabilizer, 1 per mill-4 per mill of an ageing agent, 3 per mill-20 per mill of hollow microspheres, and 60 per mill-75 per mill of a solvent. The UV photosensitive adhesive rapidly reaches the higher bonding strength at the room temperature, is excellent in adherence to substrates like PO (Propylene Oxide) and PVC (Polyvinyl Chloride), can resist the high temperature of 100 DEG C within a short period of time, and is soft, the initial viscosity is quite excellent, and the ageing-resistant performance is excellent. A UV protective film applyingthe UV photosensitive adhesive for a wafer not only has an obvious visbreaking effect after the UV-irradiation, but also can tackify a rubber pressure sensitive adhesive before the pressure sensitiveadhesive.

Owner:新纶电子材料(常州)有限公司

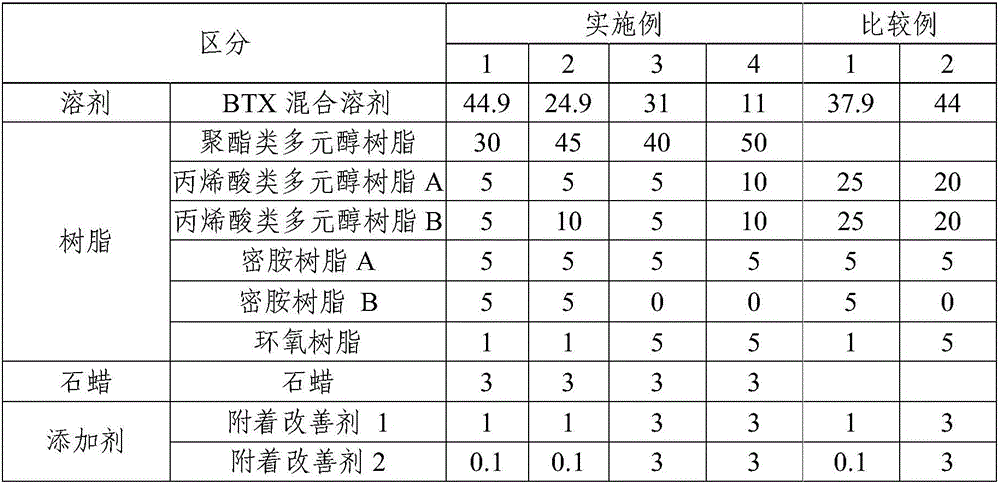

Base coating composition for non-ferrous metal

ActiveCN106280913AExcellent initial adhesionExcellent adhesion between layersPolyester coatingsPolyesterEpoxy

The invention relates to a base coating composition for non-ferrous metal, which can exhibit excellent initial stage adhesion, interlayer adhesion, recoating performance and scratch resistance in the coating of non-ferrous metal by containing polyester polyhydric alcohol resin, acrylic acid polyhydric alcohol resin, melamine resin, epoxy resin and the balance of a solvent, and a coating object.

Owner:KCC CORP CO LTD

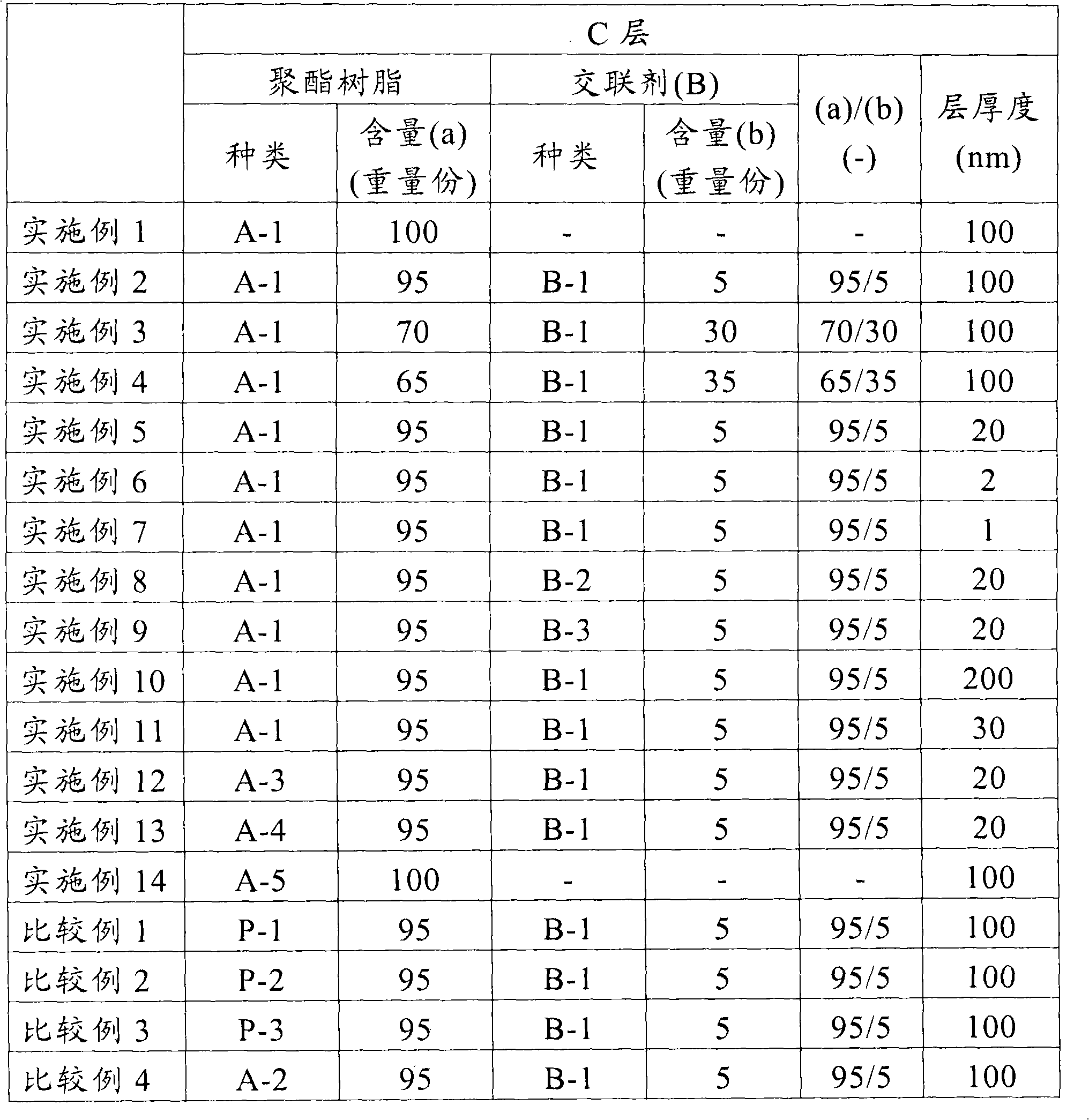

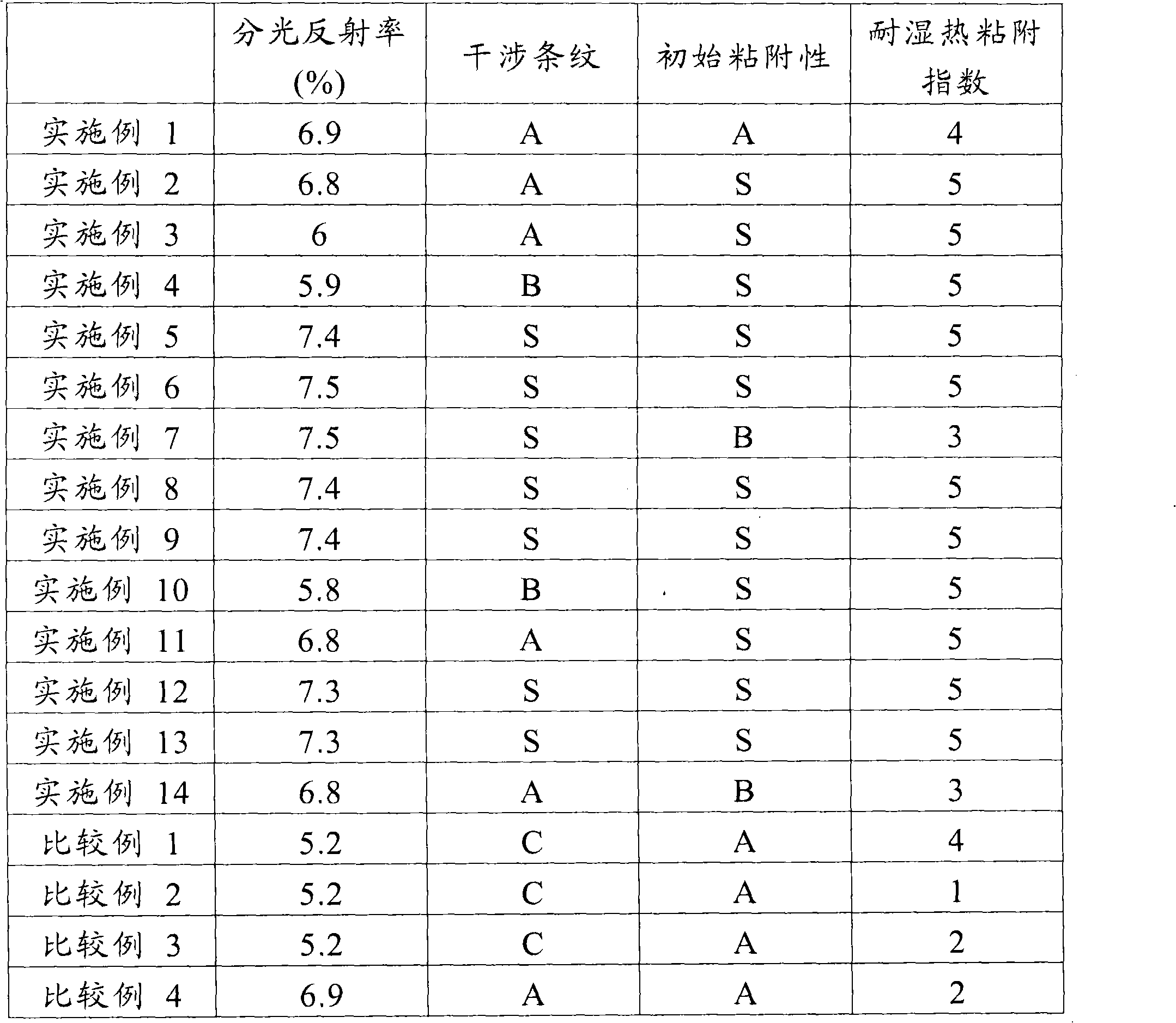

Laminated polyester film

ActiveCN104245806AHigh transparencyInhibition (excellent visibilitySynthetic resin layered productsPolyurea/polyurethane coatingsPolymer scienceCarbamate

The purpose of the present invention is to provide a laminated polyester film which has excellent translucency and excellent suppression of an iris-like pattern (interference fringe), i.e., excellent visibility, when a hard coat layer is laminated; has excellent initial adhesion to the hard coat layer, adhesiveness at high temperatures and high humidity (wet heat-resistant adhesion), and UV-resistant adhesion (adhesion after UV irradiation); and has excellent adhesion when immersed in boiling water (boiling-resistant adhesion) and boiling-resistant translucency. This objective is achieved by a laminated polyester film having a resin layer (X) on at least one surface of a polyester film, wherein the resin layer (X) is formed from a coating composition comprising an acrylic / urethane copolymer resin (a) and a polyester resin (b) having a naphthalene backbone, and the film haze change amount (DeltaHz) before and after a boiling treatment test (DeltaHz = the film haze after the boiling treatment test - the film haze before the boiling treatment test) is less than 3.0%.

Owner:TORAY IND INC

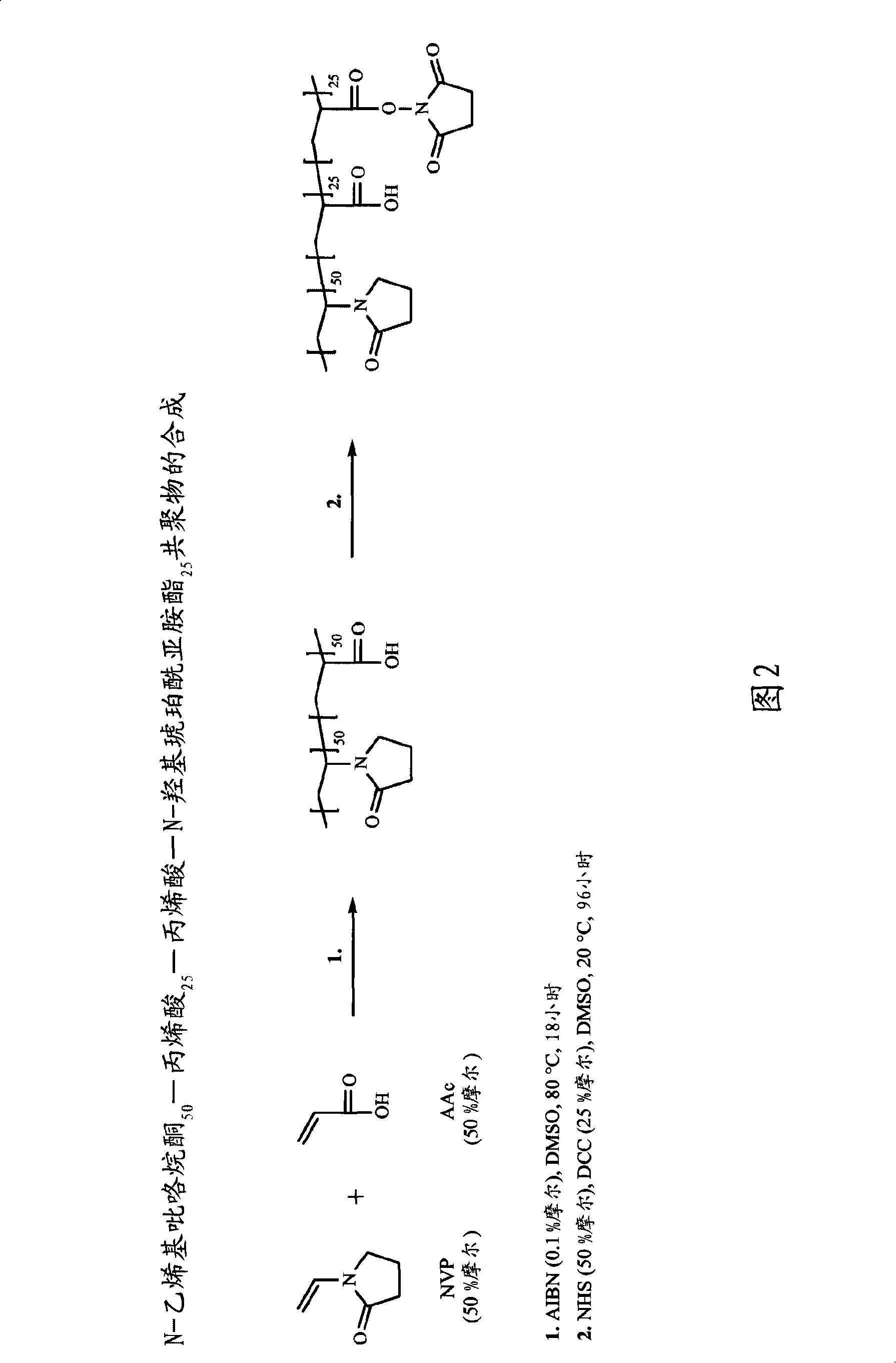

Tissue-adhesive materials

ActiveCN101378791BExcellent initial adhesionImprove adhesionSurgeryCoatingsContact layerBiodegradable polyester

A multi-lamellar tissue-adhesive sheet comprises a structural layer or laminate conjoined to a tissue-contacting layer. The structural layer or laminate comprises one or more synthetic polymers having film-forming properties, and the tissue- contacting layer of material contains tissue-reactive groups. The synthetic polymers having film-forming properties are preferably biodegradable polyesters, and the tissue-reactive groups are most preferably NHS-ester groups.

Owner:TISSUEMED LTD

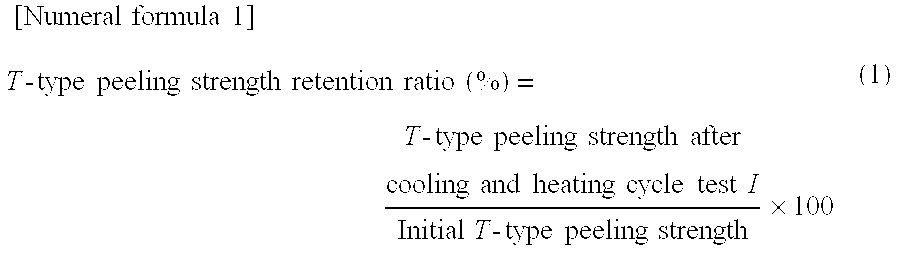

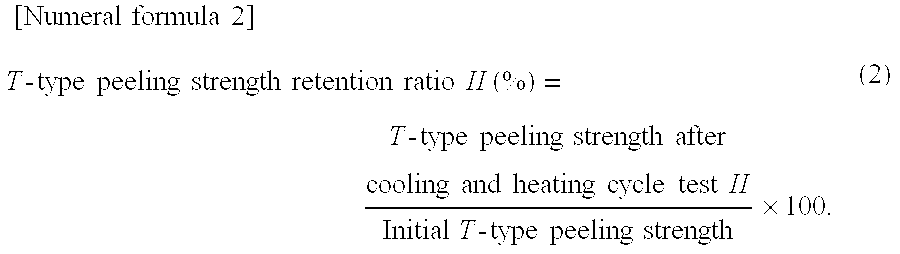

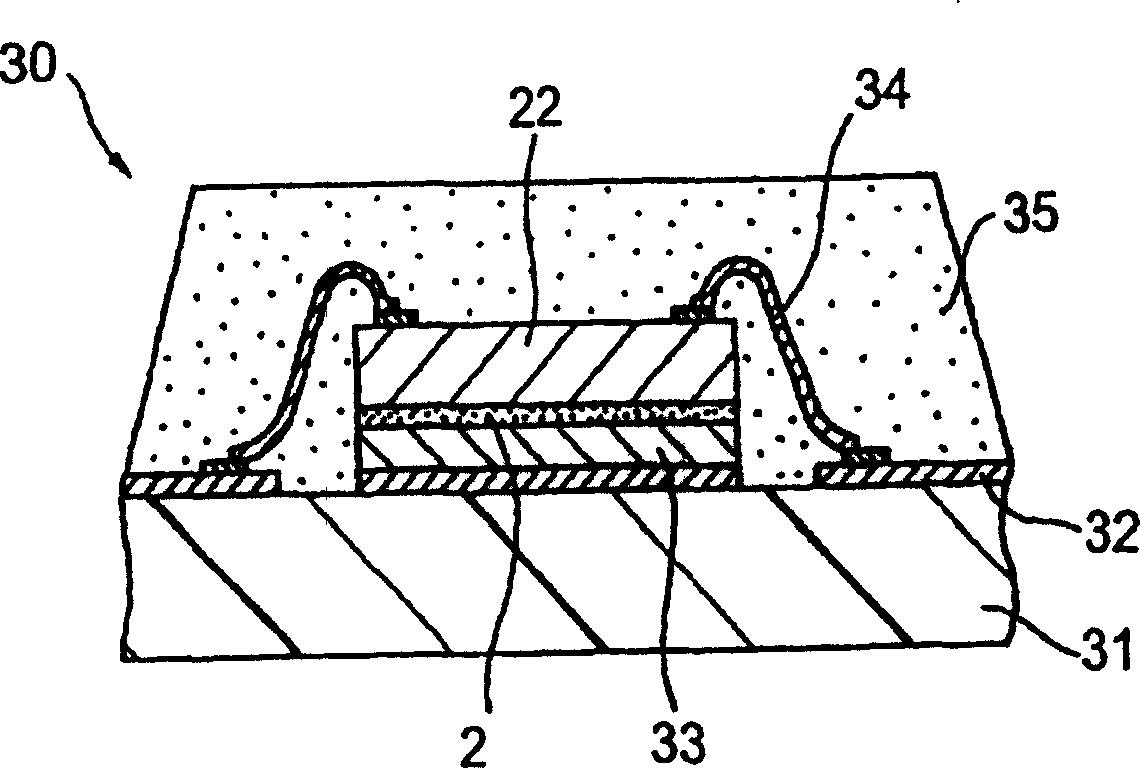

Resin composition for sealing electrical electronic components, method of producing electrical electronic component, and sealed electrical electronic component

ActiveUS20130331521A1Excellent bonding durabilityImprove adhesion strengthOther chemical processesSemiconductor/solid-state device detailsPolyesterElastomer

It is provided that a resin composition for sealing electrical electronic components which is not susceptible to gelation even when stagnant under high temperature conditions, and which are excellent in initial bond strength to an aluminum material, and which exhibits superior durability under a cooling and heating cycle load and the like. It is also provided that a sealed electrical electronic component with the resin composition for sealing electrical electronic components. A resin composition for sealing electrical electronic components, containing a crystalline polyester-based elastomer (A), a phenol-modified xylene resin (B1) and / or a phenol resin (B2), and a polyolefin resin (C), and having a melt viscosity of 5 dPa·s or more and 3000 dPa·s or less when dried to a water content of 0.1% or less, heated to 220° C., subjected to a pressure of 1 MPa, and extruded through a die with a hole diameter of 1.0 mm and a thickness of 10 mm.

Owner:TOYO TOYOBO CO LTD

Block copolymer composition, adhesive composition, and adhesive sheet

The present invention is a block copolymer composition comprising an aromatic vinyl-isoprene-aromatic vinyl triblock copolymer (A) and an aromatic vinyl-isoprene diblock copolymer (B),(i) a ratio (MwDa / MwDb) of a weight average molecular weight MwDa of a polyisoprene block in the triblock copolymer (A) to a weight average molecular weight MwDb of a polyisoprene block in the diblock copolymer (B) being 0.5 or more to less than 1,(ii) a ratio of an aromatic vinyl monomer unit in all polymer components of the block copolymer composition being 10 to 30 mass %, and(iii) the block copolymer composition having a breaking strength of less than 8 MPa and an elongation at break of less than 1,100%; a pressure-sensitive adhesive composition comprising the block copolymer composition and a tackifying resin; and a pressure-sensitive adhesive sheet comprising a pressure-sensitive adhesive layer that comprises the pressure-sensitive adhesive composition.

Owner:ZEON CORP

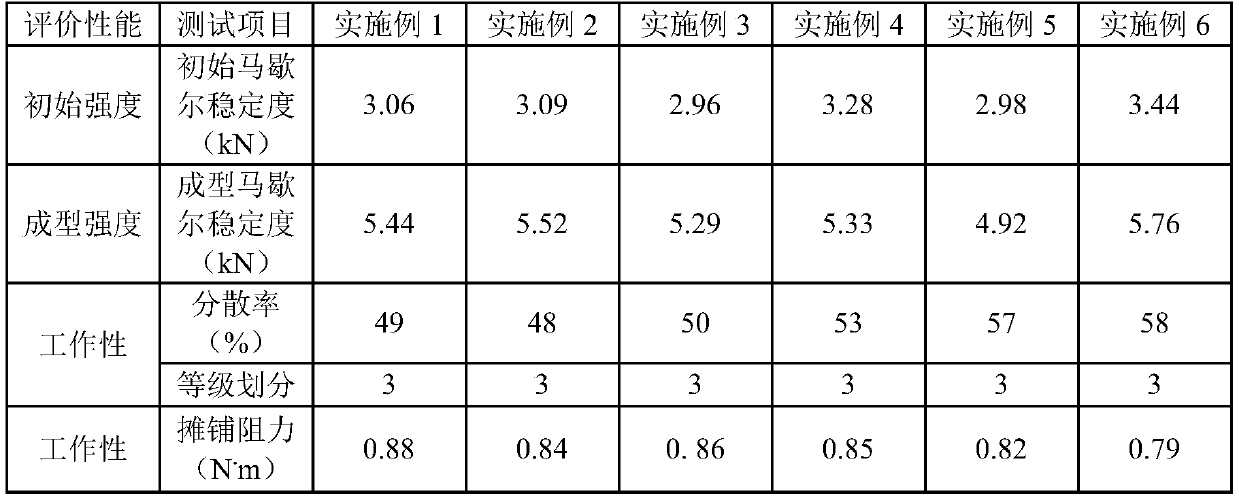

Cold-patch additive material and preparation method and application thereof

ActiveCN109971187AEasy to storeConvenience to workBuilding insulationsPolymer scienceTrichloroethylene

The invention relates to a cold-patch additive material and a preparation method and application thereof. The material is prepared from 17%-20% of trichloroethylene, 11%-16% of SBS, 9%-13% of EVA, 42%-46% of diesel and13%-21% of clean oil; during preparation, the SBS is added into the trichloroethylene until no solid residues exist to obtain a prepolymer A, the EVA is added into the diesel until no solid residues exist to prepare a prepolymer B, the prepolymer A and the prepolymer B are poured into the clean oil to prepare the cold-patch additive material; when a modified asphalt mixture is prepared, the cold-patch additive material accounts for 10%-14%, asphalt accounts for 72%-80%, and a diluent accounts for 10%-14%. The cold-patch additive material and the preparation method and application thereof have the advantages that a capsule technology and a polymer thickening and reinforcing technology are introduced, the storage performance, workability, initial strength, durability and bonding performance of the modified asphalt mixture can be improved, and it is ensured that the modified asphalt mixture has excellent performance.

Owner:CHANGAN UNIV

Laminated polyester film and antireflection film

ActiveCN102112309ASuppression of interference fringesExcellent initial adhesionSynthetic resin layered productsElectrical equipmentPolymer sciencePolyester resin

Owner:TORAY IND INC

Optical polyester film and optical laminated polyester film

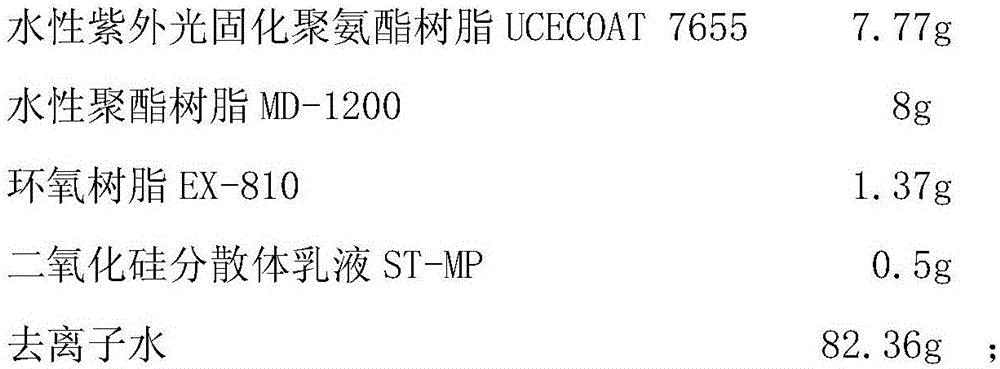

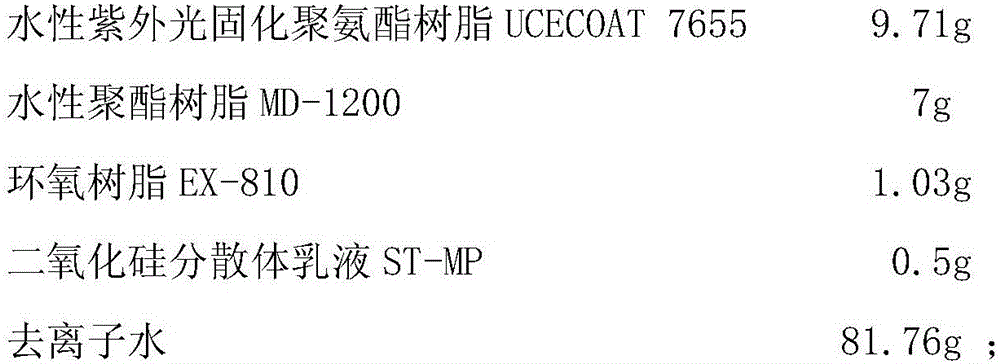

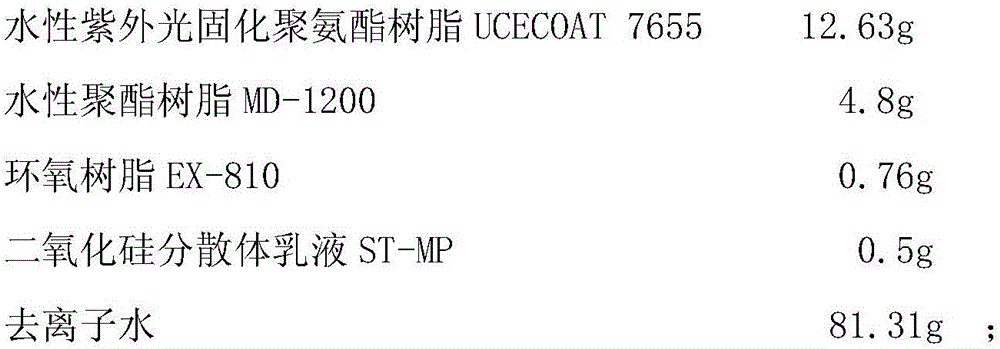

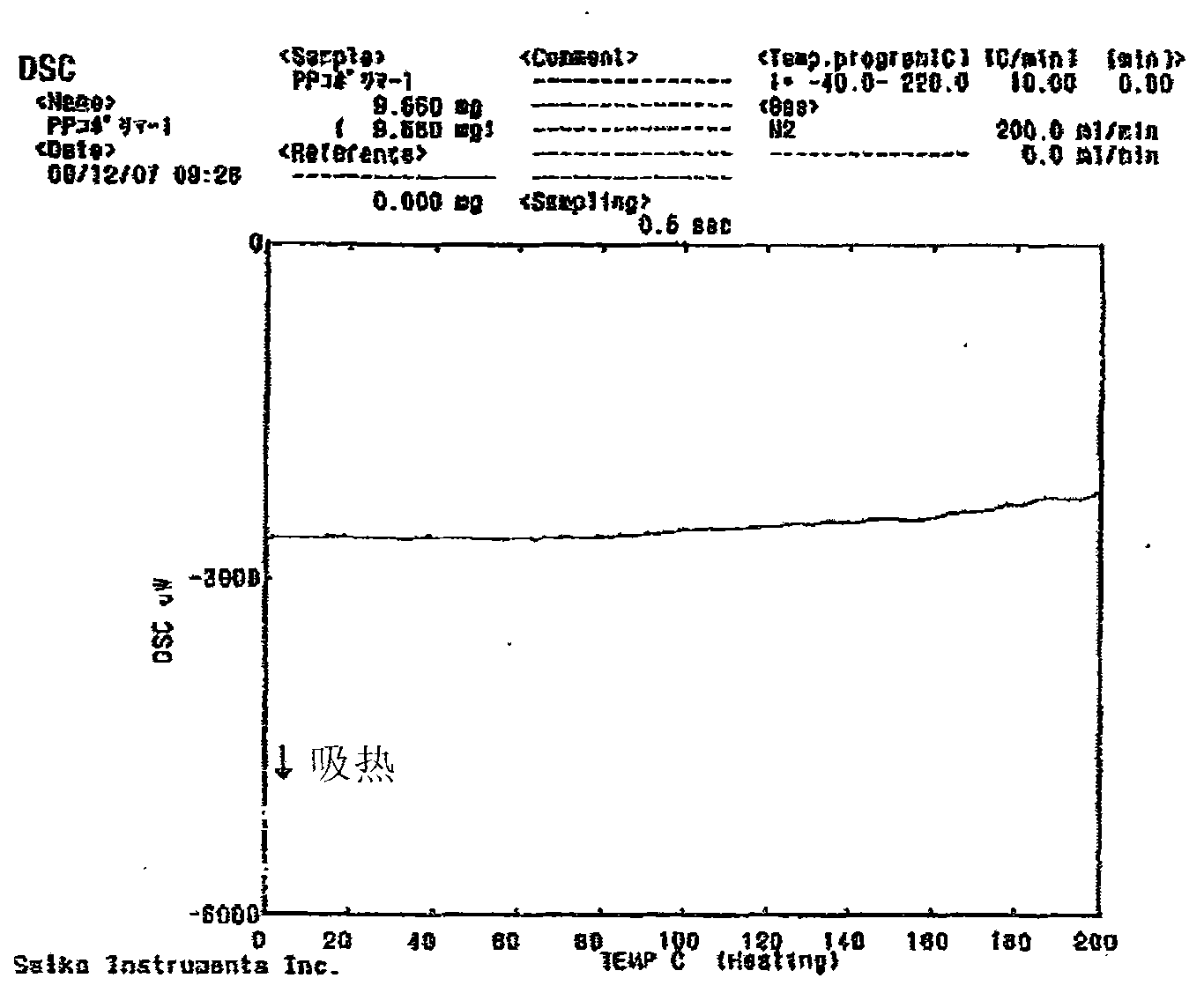

InactiveCN105774155AStrong adhesionExcellent initial adhesionSynthetic resin layered productsPolyurea/polyurethane coatingsEpoxyHigh humidity

The invention discloses an optical polyester film and an optical laminated polyester film.At least one face of a biaxially oriented base film of the optical polyester film is coated with a bottom coating containing an adhesive and anti-adhesion particles, and the adhesive is prepared from, by weight, waterborne ultraviolet light cured polyurethane resin 40-90%, waterborne polyester resin 9-40% and epoxy resin 1-20%.The polyester film layer has excellent initial adhesion to an optical functional layer, also has good adhesion under the conditions of high temperature and high humidity, meanwhile has high transparency and excellent adhesion resistance and is suitable for the fields of LCD, PDP and other display devices.

Owner:HEFEI LUCKY SCI & TECH IND

Gold alloy wire for bonding wire having high initial bondability, high bonding reliability, high roundness of compression ball, high straightness, high resin flowability resistance, and low specific resistance

InactiveUS20090232695A1Easy to integrateEasily influencedSolid-state devicesWelding/cutting media/materialsMetallurgyImpurity

There are provided a gold alloy wire for a bonding wire having high initial bonding ability, high bonding reliability, high roundness of a compression ball, high straightness, high resin flowability resistance, and low specific resistance. The gold alloy wire having high initial bonding ability, high bonding reliability, high roundness of a compression ball, high straightness, high resin flowability resistance, and low specific resistance contains one or more of Pt and Pd of 500 to less than 1000 ppm in total, Ir of 1 to 100 ppm, Ca of more than 30 to 100 ppm, Eu of more than 30 to 100 ppm, Be of 0.1 to 20 ppm, if necessary, one or more of La, Ba, Sr, and Bi of 30 to 100 ppm in total, if necessary, and a balance being Au and inevitable impurities.

Owner:TANAKA DENSHI KOGYO KK

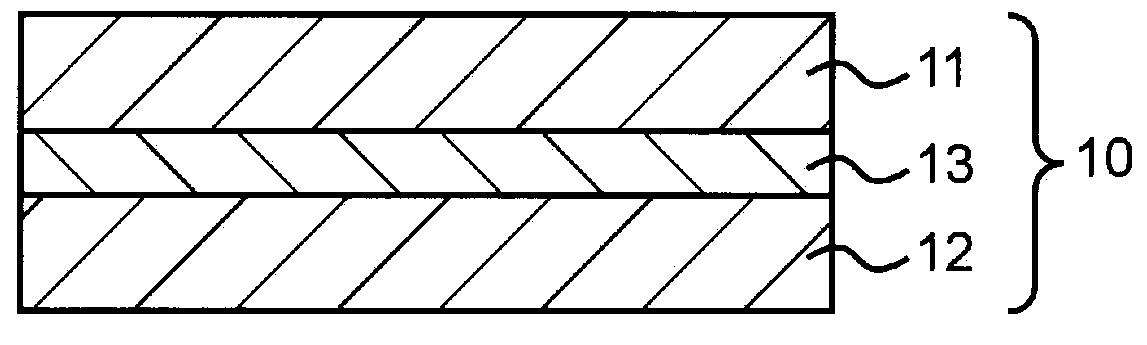

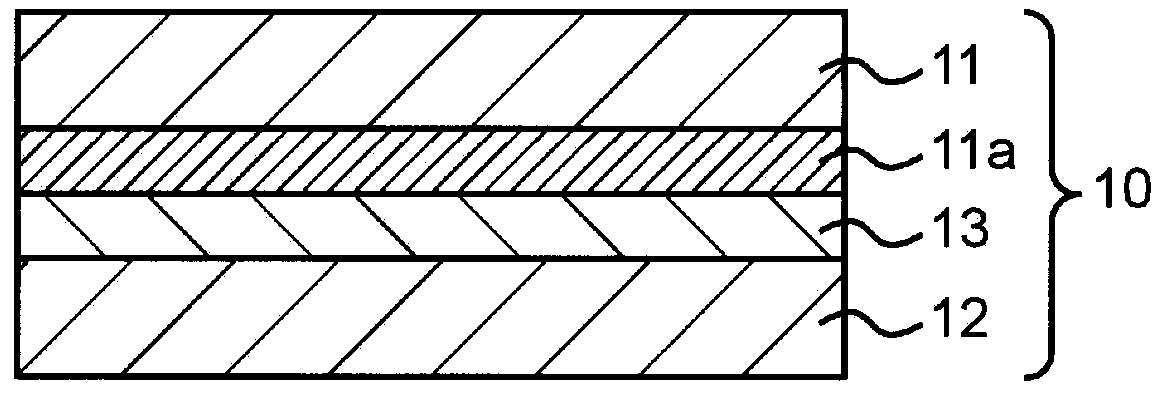

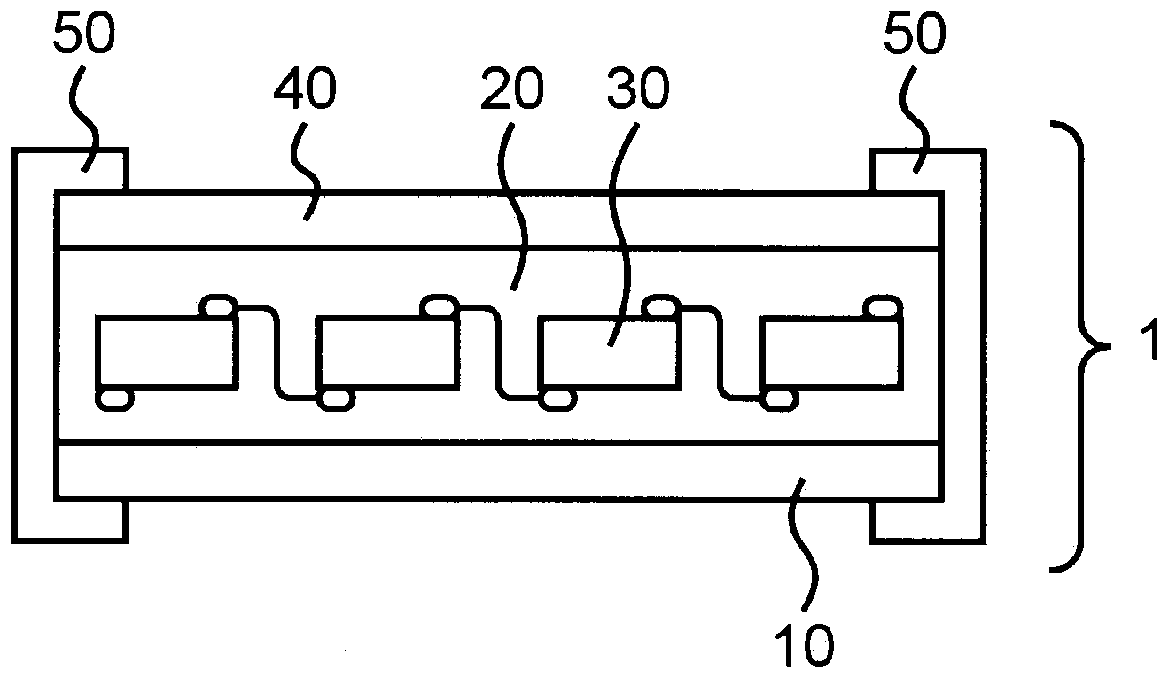

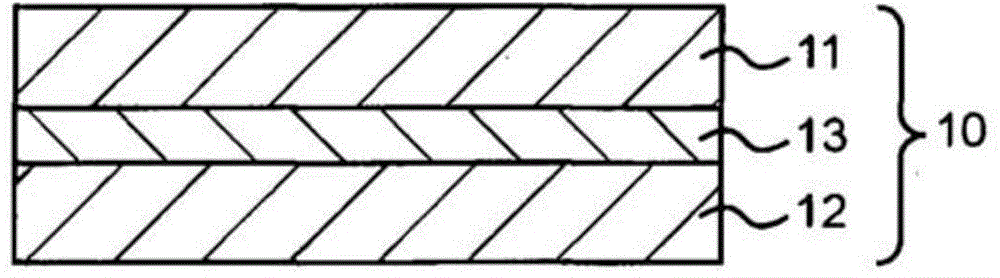

Adhesive sheet

InactiveCN103254808AGood weather resistanceExcellent initial adhesionMonocarboxylic acid ester polymer adhesivesFilm/foil adhesivesLow-density polyethylenePolyolefin

The invention provides an adhesive sheet. The adhesive sheet has the advantages of excellent weatherability, good initial adhesiveness, excellent peeling property and good age adhesiveness even the adhesive sheet is in the ageing process after outdoor exposure or high temperature preservation, and good stress relaxation property. The adhesive sheet is obtained through forming an adhesive layer on at least one side of a substrate layer, the substrate includes at least one layer selected from a white series layer and a black series layer, the adhesive layer is formed through an adhesive containing a propylene series copolymer (A) and a resin (B), the propylene series copolymer (A) includes propylene and C2-12 alpha-olefin except propylene as copolymerization components, and the resin (B) comprises at least one selected from a crystalline olefin blocked C-B-C thermoplastic elastomer (B represents a conjugated diene polymer block and C represents a crystalline polyolefin block) hydride, homopolymerized polypropylene, an ethylene / alpha-olefin biopolymer, a propylene / alpha-olefin biopolymer, low density polyethylene, high density polyethylene and straight-chain low density polyethylene.

Owner:NITTO DENKO CORP

Waterproof color building sealing adhesive and its prepn process

InactiveCN100558840CWill not polluteEasy to operateMonocarboxylic acid ester polymer adhesivesCellulose adhesivesCelluloseAdhesive

The invention provides a kind of waterproof color caulking adhesive for building and its preparation method, comprising cement, quartz sand, water-based cellulose ether, lignin, pigment, vinyl acetate copolymer latex powder, organic carboxylic acid metal salt powder Mix evenly to prepare the building waterproof color caulking adhesive of the present invention. The adhesive of the present invention forms a highly waterproof surface during use, has the characteristics of waterproof, adhesive, beautiful, durable, and environmentally friendly, and integrates joint filling and bonding. It is a functional building material, and its price is comparable to that of cement. Modified materials are comparable. It is suitable for bonding and caulking of exterior wall tiles, floor tiles, interior wall tiles, stone and square tiles.

Owner:SOUTH CHINA UNIV OF TECH +1

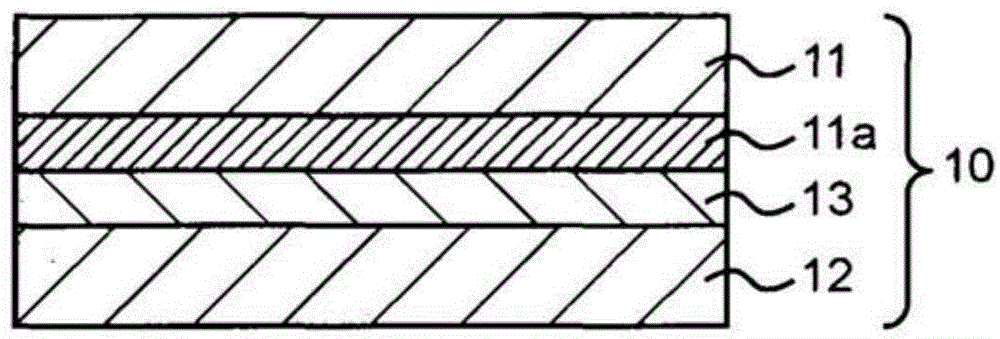

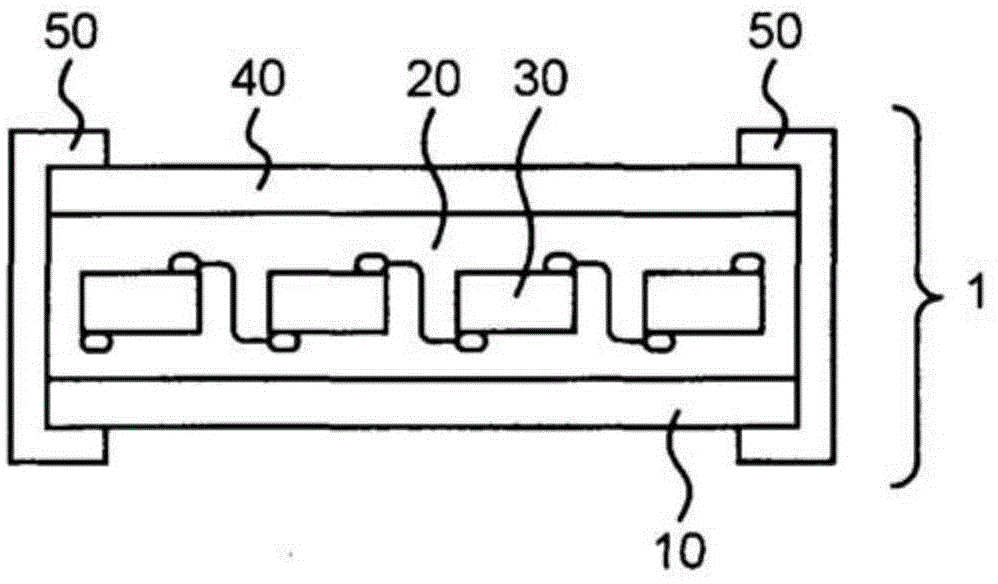

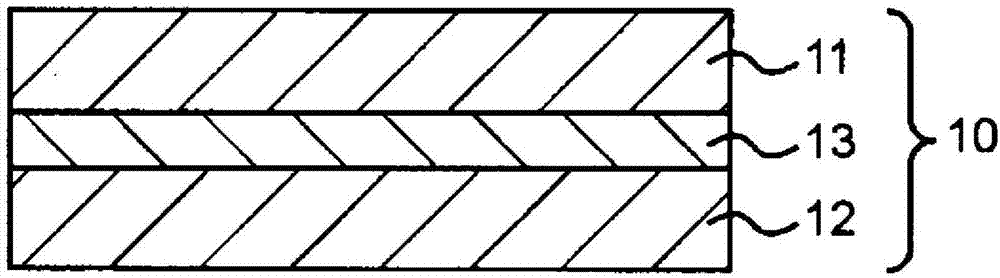

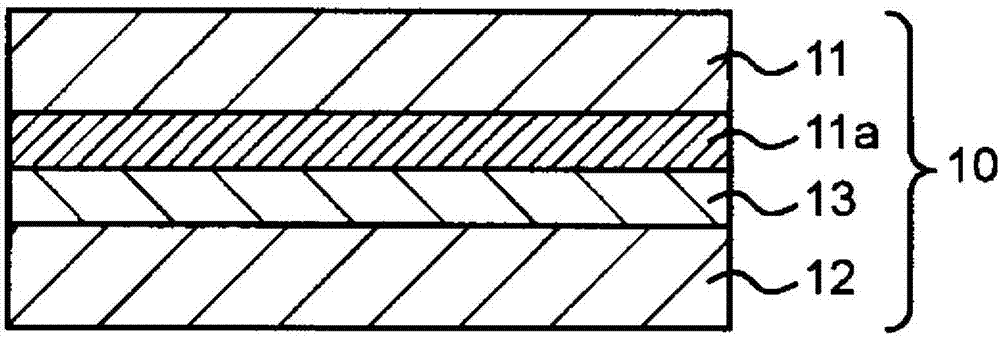

Heat curable adhesive composition, article, semiconductor apparatus and method

InactiveCN1662624AExcellent initial adhesionImprove heat resistanceNon-macromolecular adhesive additivesSemiconductor/solid-state device detailsEpoxySemiconductor chip

Provided are a heat curable adhesive composition and an adhesive article suited for dicing of a semiconductor and die-bonding of the diced semiconductor chip, and a semiconductor apparatus and a process for preparing a semiconductor apparatus using the adhesive composition and article. In one embodiment, the present invention provides a heat curable adhesive composition comprising a caprolactone-modified epoxy resin and a tack reducing component. Another embodiment of the present invention provides an adhesive article comprising a heat curable adhesive layer of a heat curable adhesive composition comprising a caprolactone-modified epoxy resin, a tack reducing component, and a backing layer carrying said adhesive layer on at least a portion of the backing layer.

Owner:3M INNOVATIVE PROPERTIES CO

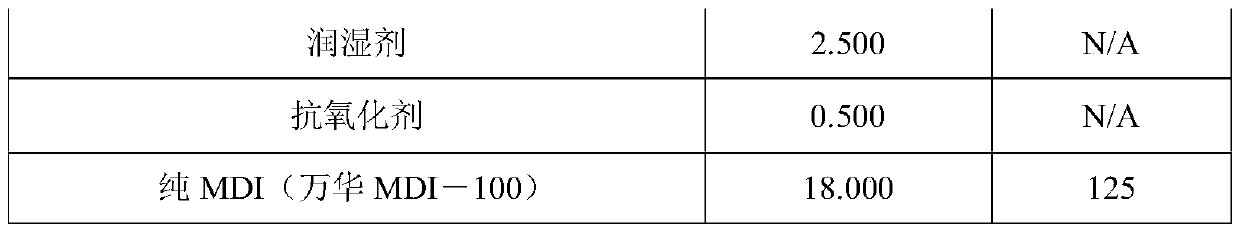

Hot melt polyurethane adhesive for bonding honeycomb panel and preparation method of hot melt polyurethane adhesive

PendingCN110343503AExcellent initial adhesionSuitable opening timePolyureas/polyurethane adhesivesPolyesterPolyol

The invention discloses a hot melt polyurethane adhesive for bonding a honeycomb panel. The hot melt polyurethane adhesive is prepared from the following raw materials in percentage by mass: 40-50% ofpolymer polyols, 15-25% of modified rosin resin, 10-20% of EVA, 1-5% of an additive and 15-20% of polyisocyanate; the modified rosin resin is prepared by reacting linear even carbon polyols and adipic acid in different proportions to obtain polyester polyol with different molecular weights, and then esterifying the polyester polyol with rosin acid to obtain the modified rosin resin with the molecular weight of 500-1500; and the molecular weight of the EVA is 90,000-110,000. According to the hot melt polyurethane adhesive, the initial adhesive force is excellent, the opening time is appropriate, the adhesive force on a base material is good, and final adhesive strength is excellent.

Owner:佛山市顺德区蓝德堡实业有限公司

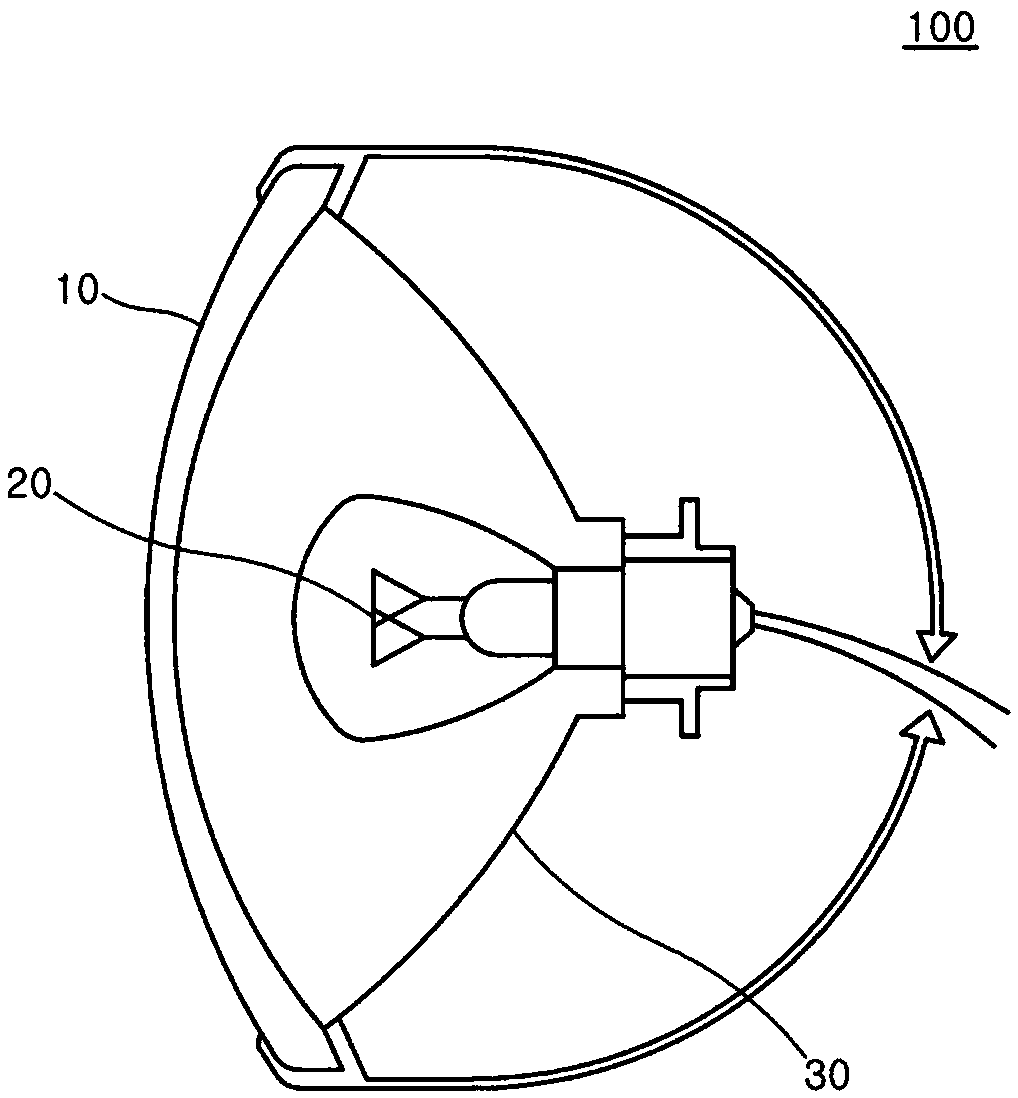

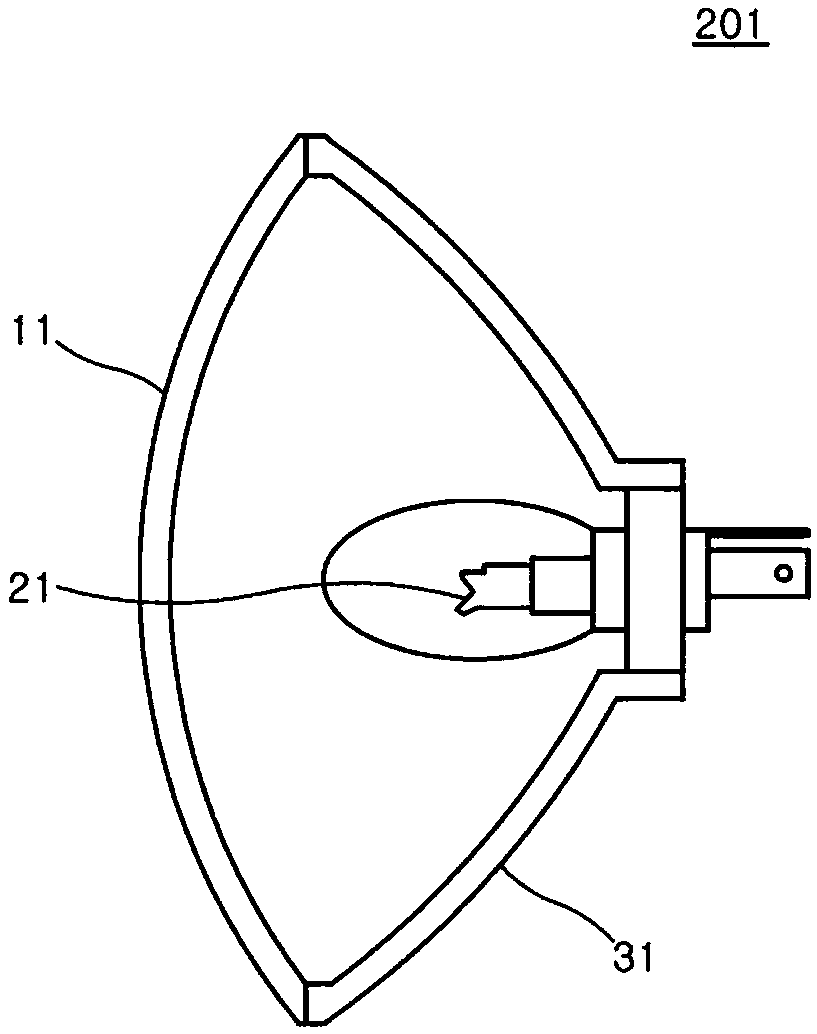

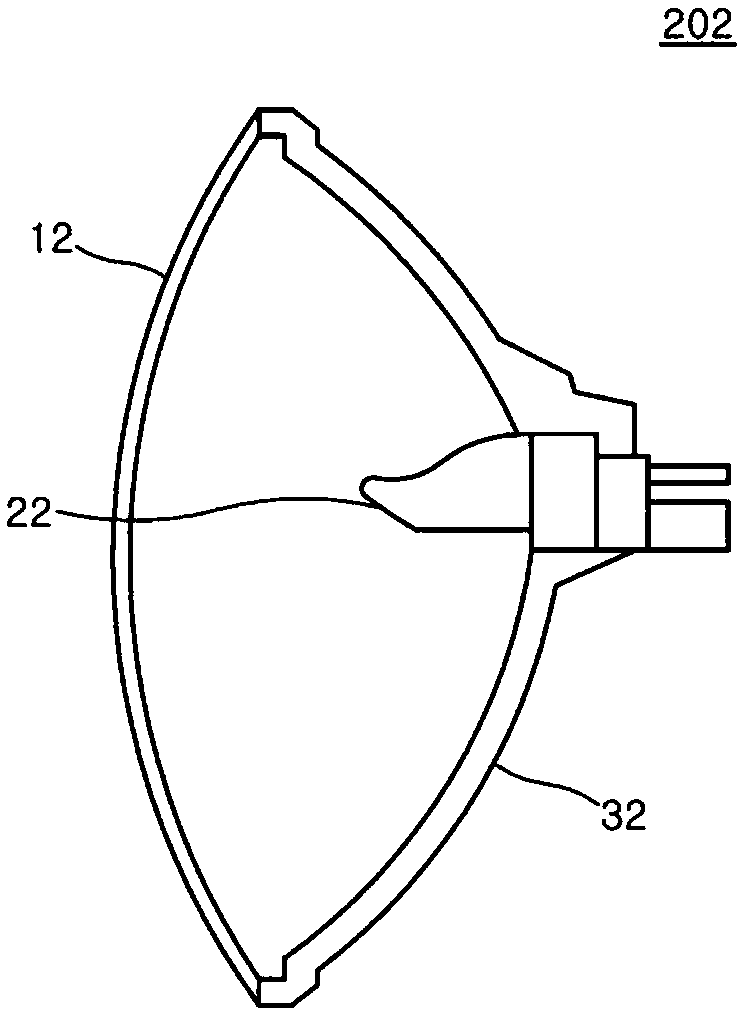

Hot melt adhesive composition, manufacturing method of the same, and car headlamp

ActiveCN108373897AExcellent initial adhesionHigh initial bond strengthMineral oil hydrocarbon copolymer adhesivesVehicle headlampsElastomerPolyester

An embodiment of the present invention relates to a hot melt adhesive composition comprising 35 to 40 wt% of petroleum resin, 10 to 14 wt% of polyester elastomer resin, 10 to 14 wt% of ethylene vinylacetate resin, 14 to 19 wt% of polyether polyol, 15 to 21 wt% of polyester polyol, 8 to 10 wt% of methylene diphenyl diisocyanate, and 0.1 to 0.5 wt% of an amine catalyst, wherein the hot melt adhesive composition has 20,000 to 50,000 cps of melting viscosity measured at 150 DEG C. The hot melt adhesive composition according to the present invention is excellent in workability as well as initial adhesion, initial adhesive force, initial adhesive properties and heat resistance, has excellent crosslinking properties and bubble preventing properties after final curing, has an excellent curing time reduction effect, and is excellent in impact resistance after curing.

Owner:HYUNDAI MOBIS CO LTD +1

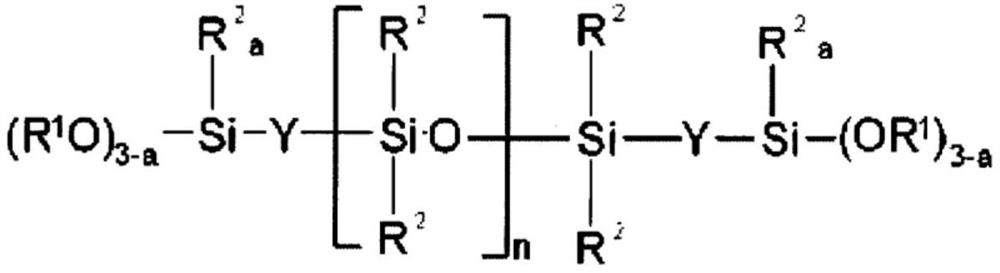

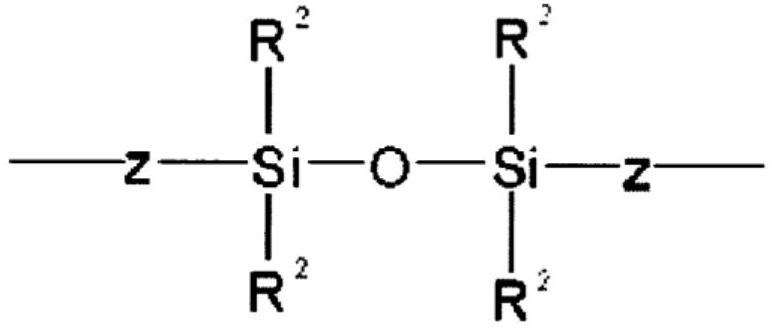

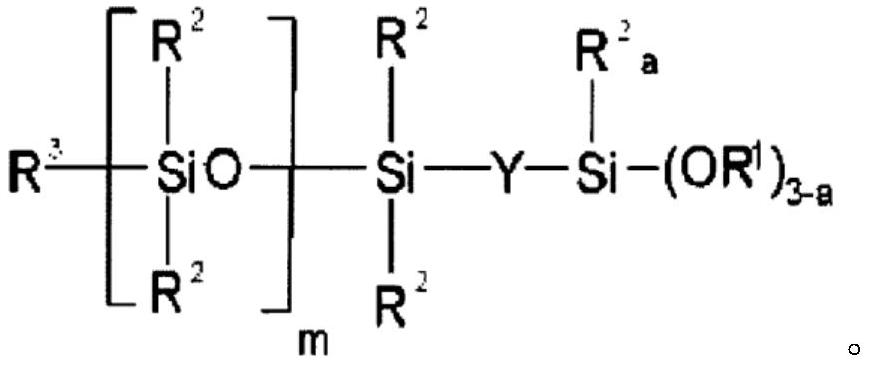

Room-temperature-curable organopolysiloxane composition and protective agent or adhesive composition for electric/electronic components

The invention relates to a curable organopolysiloxane composition that is easily cured at room temperature and has excellent adhesiveness to various substrates, and also relates to provide a protective agent or an adhesive composition for electric / electronic components that includes the organopolysiloxane composition, and an electric / electronic device in which an electric / electronic component is encapsulated or sealed with the curable organopolysiloxane composition. A multicomponent room-temperature-curable organopolysiloxane composition comprising: (A) a diorganopolysiloxane having a molecular chain terminal blocked with a hydroxysilyl group, (B) a diorganopolysiloxane having a molecular chain terminal blocked with an alkoxysilyl group, (C) a functional filler, (D) a compound having two or more alkoxy groups bonded to a silicon atom in one molecule, and (E) a catalytic amount of a catalyst for condensation reaction, the aforementioned compounds being individually stored, and also the use of the multicomponent room-temperature-curable organopolysiloxane composition are provided.

Owner:DOW TORAY CO LTD

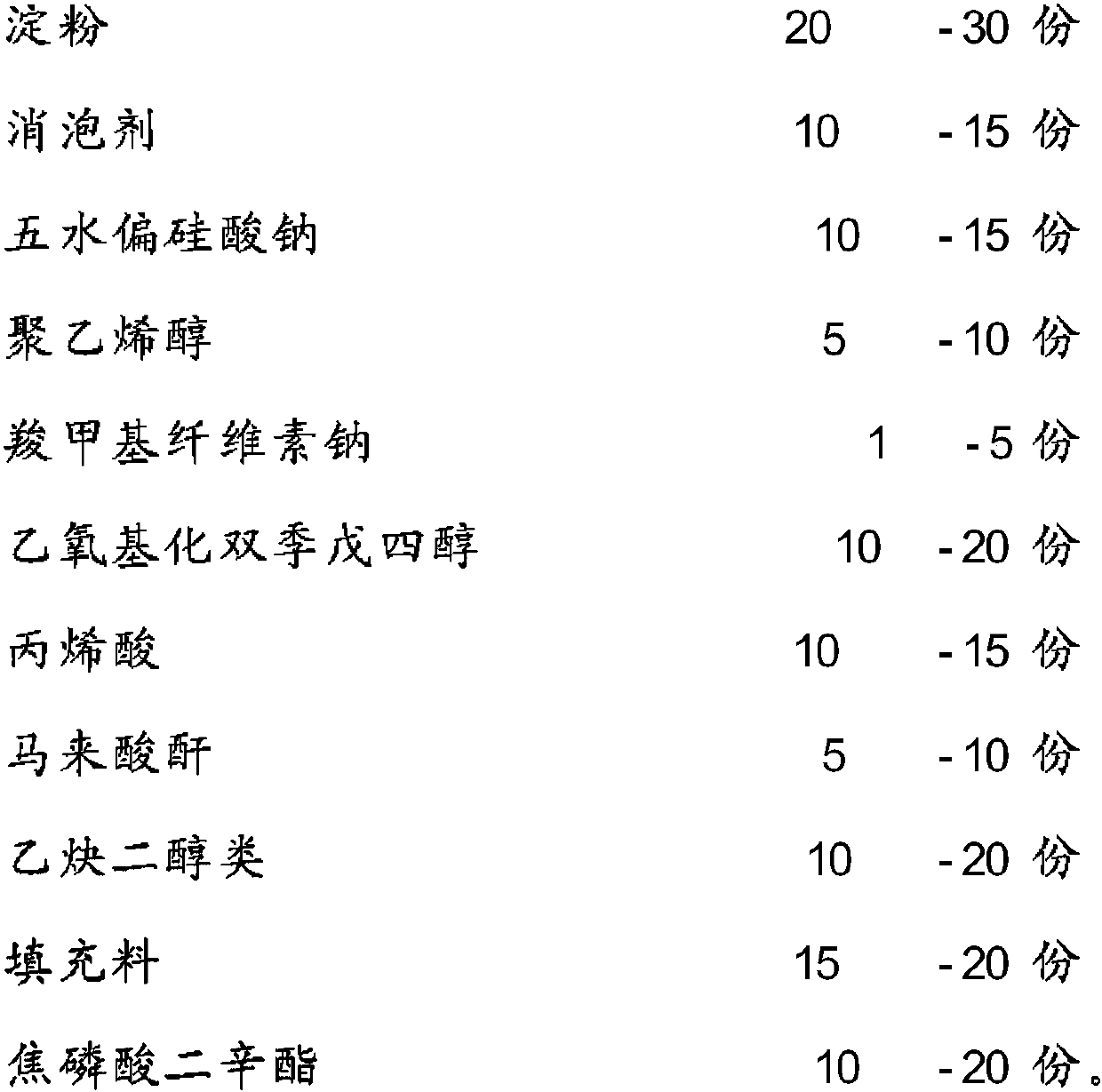

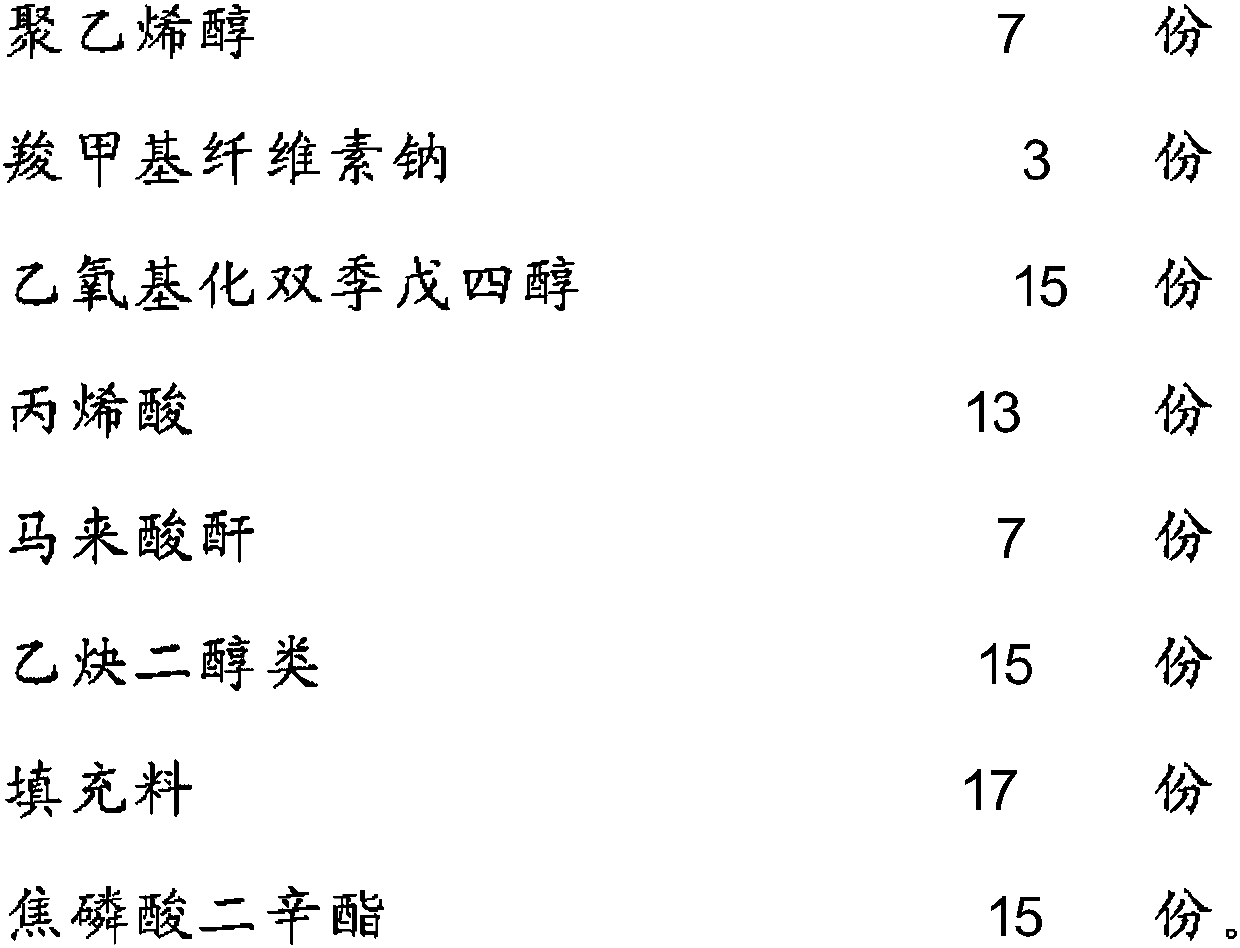

Low-pressure paste additive

InactiveCN107652904AImprove shear resistanceImprove heat resistanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesSodium metasilicatePaperboard

The invention provides a low-pressure paste additive, belongs to the technical field of paperboard production, and specifically relates to a low-pressure paste additive. The low-pressure paste additive comprises starch, an antifoaming agent, sodium metasilicate pentahydrate, polyvinyl alcohol, sodium carboxymethylcellulose, ethoxylated dipentaerythritol, acrylic acid, maleic anhydride, ethynyl diol, a filling material and dioctyl pyrophosphate. According to the invention, a mixed paste has excellent shear-force resistance and heat resistance, and the stable viscosity of the paste is maintainedin the process of recycling, so the paste has great stability; a molecule in an additive can replace a hydroxyl group in a starch molecule, so stable crosslinking is formed; the starch molecule is encircled by an additive molecule, and capacities of resisting heat and shear force are reinforced, so the viscosity stability of the paste is maintained in the process of recycling; thus, the situationthat continuous size decrease and sharp viscosity decrease of the starch molecule due to shearing and heating during recycling causes poor bonding is reduced or avoided.

Owner:东莞市森宝新能源有限公司

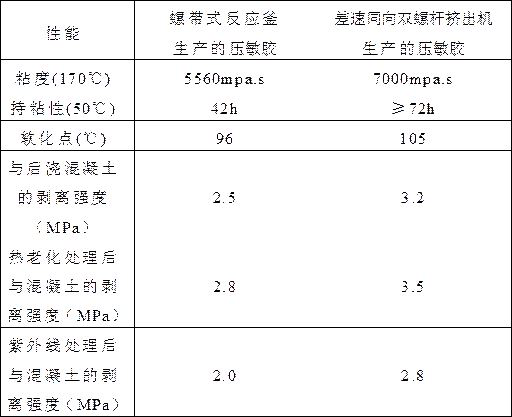

A kind of production process of pressure-sensitive adhesive for waterproof membrane

ActiveCN109370489BClear colorGood weather resistanceMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesPolymer scienceAdhesive

The invention discloses a production process of a pressure-sensitive adhesive for a waterproof roll. The production process comprises the following steps: by taking a styrene-isoprene-styrene block copolymer, hydrogenated C5 petroleum resins, hydrogenated rosin resins, naphthenic oil, rutile titanium dioxide, an antioxidant and an ultraviolet light absorber as raw materials, producing the pressure-sensitive adhesive by adopting a differential co-rotating twin screw extruder. Time in the mixing process is short, material ageing can be avoided, and the differential co-rotating twin screw extruder is capable of realizing continuous production. The produced adhesive can be timely delivered to a pre-laying roll production line, so that the adhesive is used up in time; and therefore, the adhesive does not need to be stored for a long time. Moreover, the produced pressure-sensitive adhesive is bright in color, excellent in weather resistance, excellent in initial adhesion and holding power and high in peel strength with concrete.

Owner:湖北纽凯伦轨道交通新材料有限公司

A kind of preparation method of polyamide polyamine-polyetheramine cylinder sticking agent

ActiveCN111440324BHigh initial molecular weightGood water solubilityPolyamide coatingsOrganic acidPolymer science

The invention discloses a preparation method of a polyamide polyamine-polyetheramine cylinder sticking agent. The method adopted in the present invention is as follows: under the protection of nitrogen gas, the polycondensation reaction of alkenylamine derivatives and oils and dibasic acids or corresponding dibasic esters is carried out under normal pressure, and then the polycondensation reaction is continued under vacuum until the molecular weight is no longer become larger, add water to form an aqueous solution of polyamide polyamine intermediate; add branched polyetheramine to the aqueous solution, seal the reaction, raise the temperature to carry out crosslinking reaction, finally add organic acid to terminate the reaction, add water to dilute to obtain polyamide polyamine ‑Polyetheramine cylinder sticking agent. The cylinder sticking agent prepared by the invention has good cohesive force, softness, water solubility, uniformity and durability, etc., and avoids the use of epichlorohydrin.

Owner:ZHEJIANG TRANSFAR WHYYON CHEM

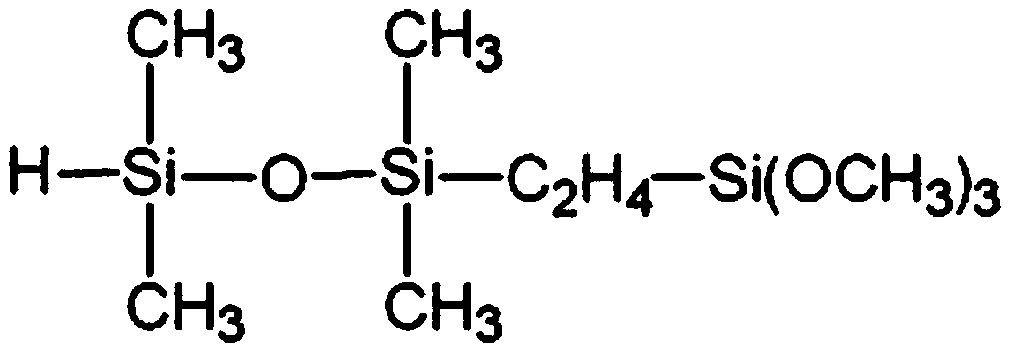

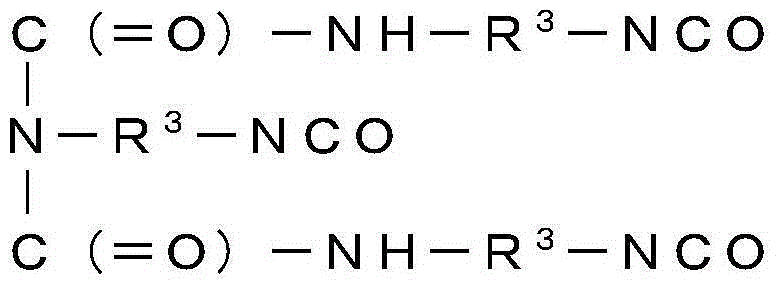

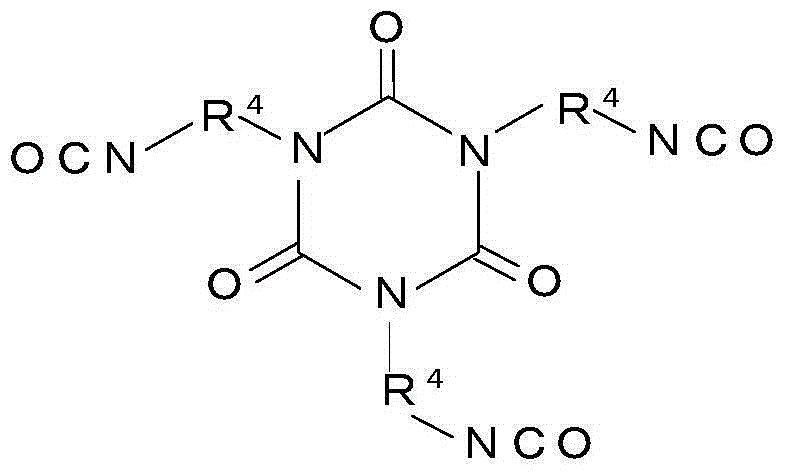

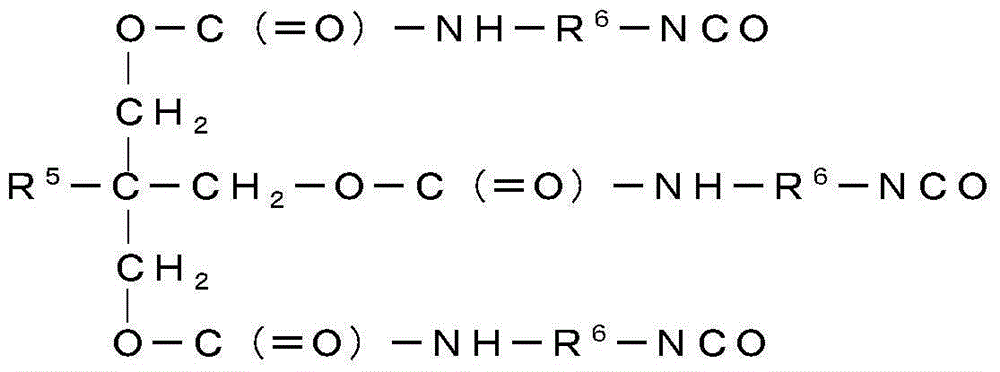

Undercoat used for base material with copper film, base material with copper film, manufacturing method for base material with copper film, and conductive film

ActiveCN105462468AGood adhesionGood alkali-resistant adhesion and acid-resistant adhesionVacuum evaporation coatingSputtering coatingDouble bondTM compound

An objective of the invention is to provide an undercoat. The undercoat has excellent initial-stage adhesion, acid-resisting adhesion, and alkali-resisting adhesion with a base material and a copper film. The invention relates to an undercoat of a base material with a copper film. The undercoat contains acrylic copolymer (A) with hydroxyl, alkyl ester groups, nitrile groups, and required primary amide groups, polyisocyanates (B) at least containing three isocyanate groups, an active energy line aggregate compound (C) at least containing three carbon-carbon double bond groups, and a reactive alkoxy silyl group compound (D) represented by a formula (1): X1-Si(R1)a(OR2)3-A, wherein in the formula (1), X1 is a group containing the following functional groups, the functional groups react with at least a group selected from a group formed by hydroxyl, isocyanate groups, and groups containing polymeric carbon-carbon double bonds, R1 represents hydroxyl with 1-9 hydrogen or carbon number, R2 represents hydroxyl with 1-8 carbon number, and a represents 0, 1, or 2.

Owner:ARAKAWA CHEM IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com