Chloroprene polymer latex composition and use thereof

A chloroprene and polymer glue technology, applied in the directions of chloroprene adhesives, ester copolymer adhesives, adhesives, etc., can solve the problem of effective, no storage stability is implied, no record of combined use of acrylic acid It can improve the spray paintability and the effect of fast crystallization speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~14 and comparative example 1~12

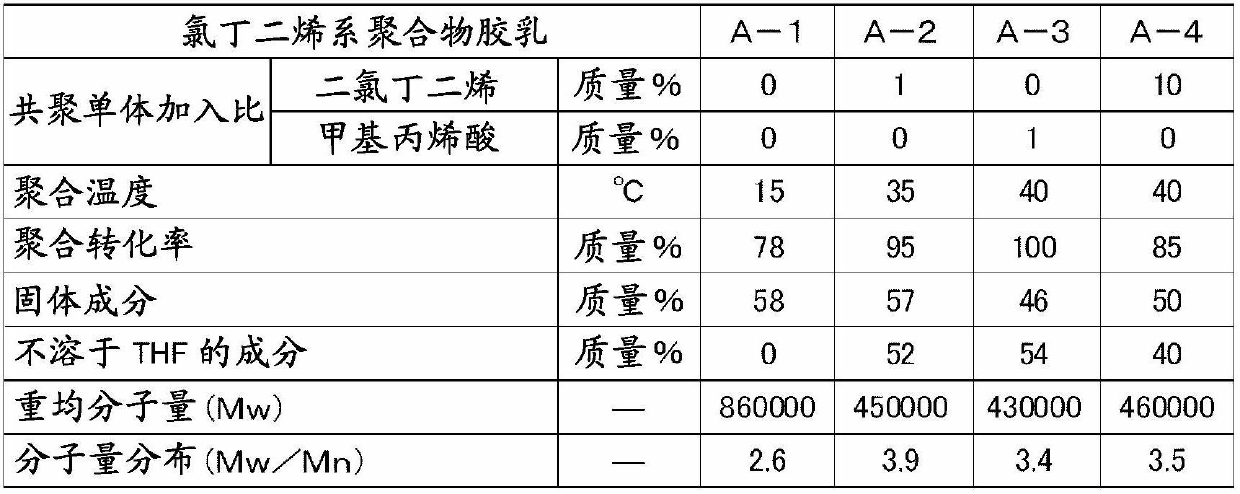

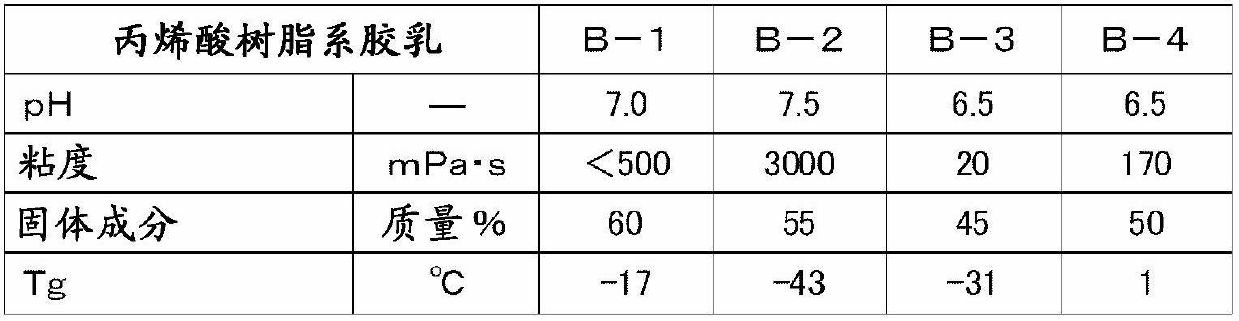

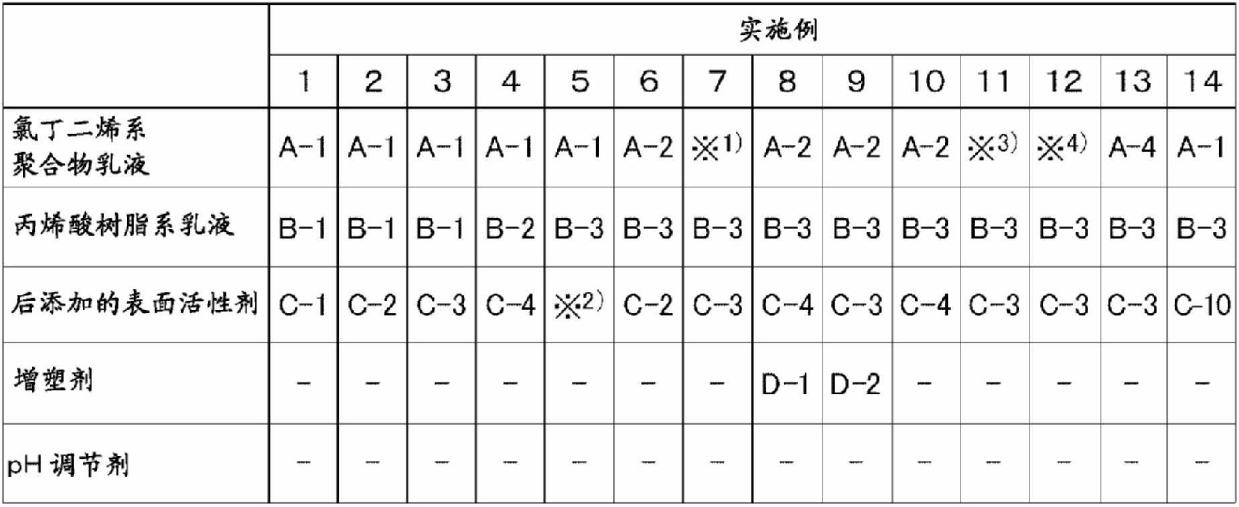

[0115] Using the components shown in Table 3, a surfactant was added to a predetermined amount of chloroprene polymer latex according to the mixing ratio described in Table 4 and Table 5, and then a predetermined amount of acrylic resin latex was blended into the mixture, Thus, the chloroprene polymer latexes of Examples 1-14 and Comparative Examples 1-12 were prepared.

[0116] table 3

[0117]

[0118]

[0119] ※ 1) A-1 / A-3=90 / 10 (wt / wt; wet)

[0120] ※ 2) C-1 / C-4=50 / 50 (wt / wt; dry)

[0121] ※ 3) A-1 / A-2=70 / 30 (wt / wt; wet)

[0122] ※ 4) A-1 / A-2=30 / 70 (wt / wt; wet)

[0123] Regarding the compositions obtained by leaving the prepared chloroprene polymer latex compositions for more than 3 days after blending, the open time (open time), initial adhesive force, thermal stability, spray Paintability (The number of samples for each evaluation was 5, and the average value thereof was obtained). In addition, the unit of the compounding quantity in Tables 4-5 is a mass p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com