Hot melt adhesive composition, manufacturing method of the same, and car headlamp

A technology of hot-melt adhesives and compositions, applied in the direction of adhesive types, polyurea/polyurethane adhesives, mineral oil hydrocarbon copolymer adhesives, etc., can solve the problem of simultaneously improving initial viscosity, reactivity and Problems such as processability, increased processing cost, etc., achieve the effect of excellent initial adhesion, effective curing, excellent anti-foaming and cross-linking ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

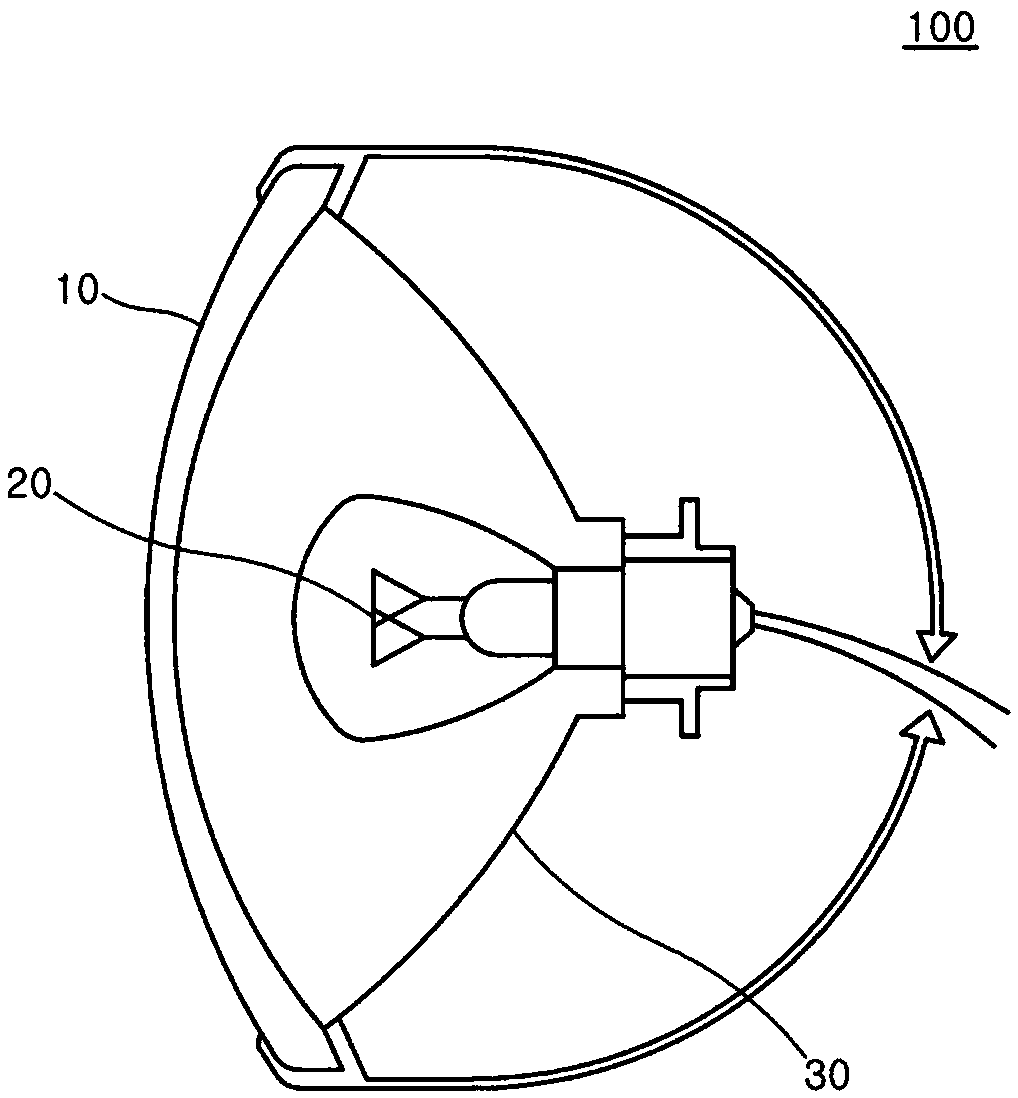

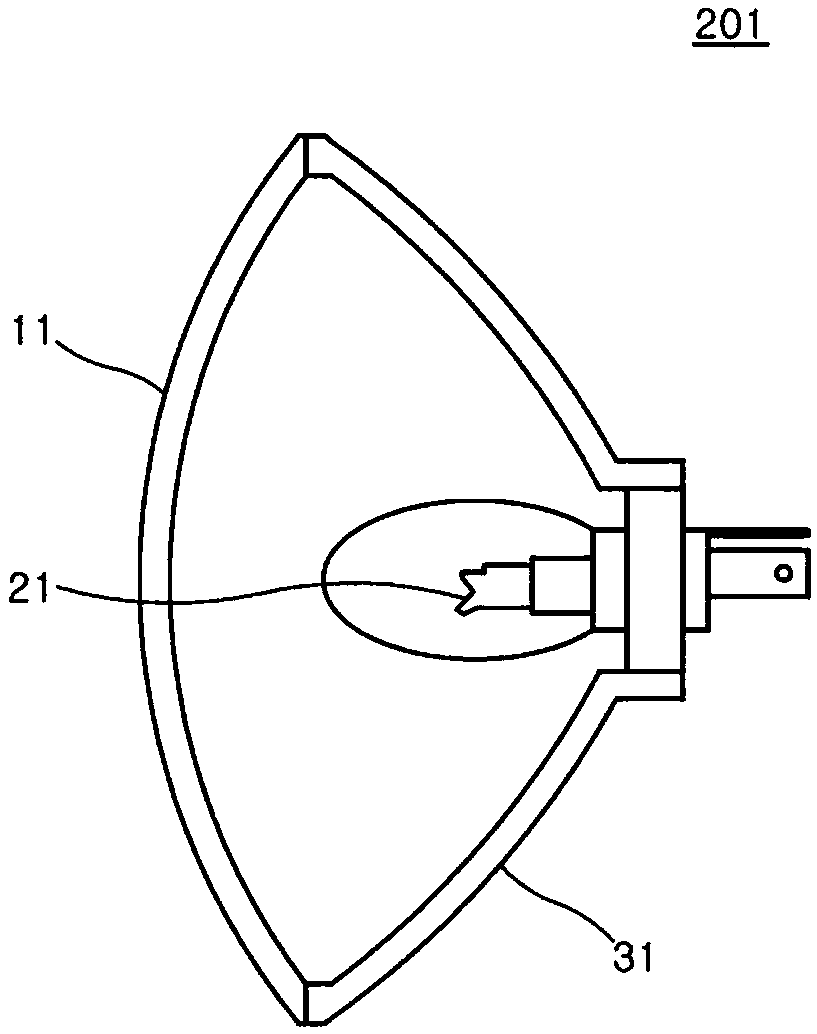

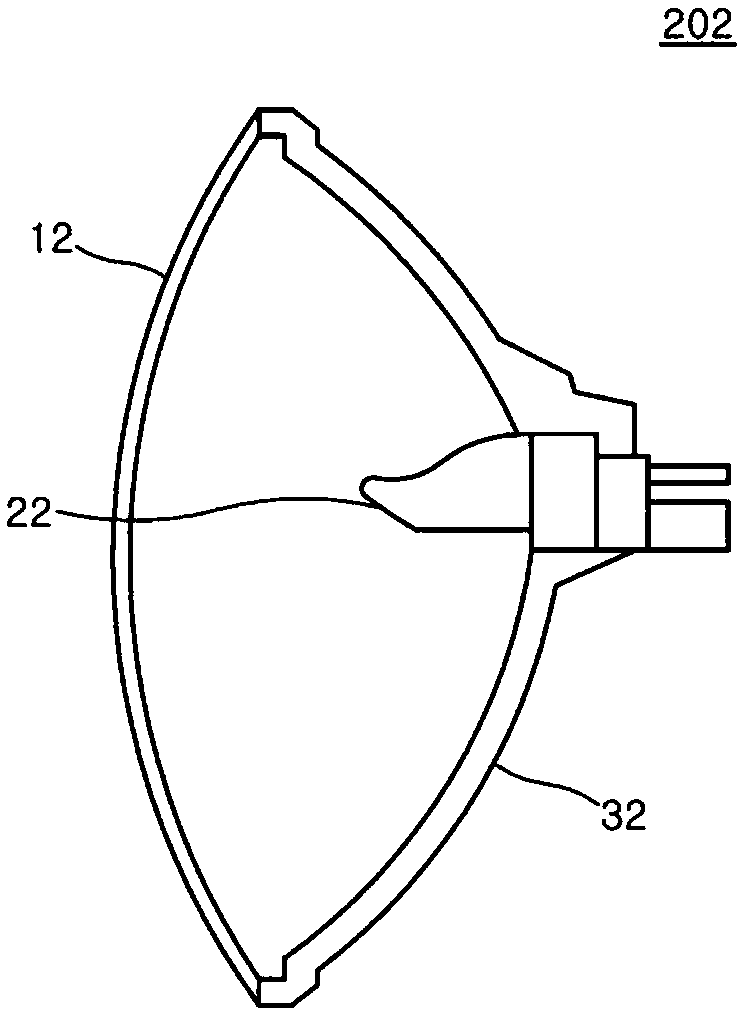

Image

Examples

example 1

[0080] 15 wt% of polyether polyol and 15 wt% of polyester polyol were introduced into the reactor, and then the contents of the reactor were heated to 160°C and stirred at a speed of 150 rpm to melt the plasticizer. Next, 9 wt % of diphenylmethane diisocyanate and 0.2 parts by weight of an amine catalyst were added to the heated reactor, followed by reaction at 200° C. for 30 minutes. Then, 40 wt% of petroleum resin, 11 wt% of polyester elastomer resin, and 10 wt% of ethylene-vinyl acetate resin were added to the reactor, followed by stirring at 150 rpm for 30 minutes, thereby preparing a hot melt adhesive composition .

[0081] Example 2 and Comparative Examples 1 to 5

[0082] Hot melt adhesive compositions were prepared in the same manner as described in Example 1 except that the compositions and their contents were changed as shown in Table 1 below.

[0083] Methods used to evaluate physical properties

[0084] (1) Melt viscosity: The hot-melt adhesives prepared in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com