Laminated polyester film and antireflection film

An anti-reflection film, polyester film technology, applied in the directions of coatings, layered products, synthetic resin layered products, etc., can solve the problems of poor film haze, poor stretchability, and adhesion problems. Achieves the effect of suppressing reflection and excellent moisture adhesion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

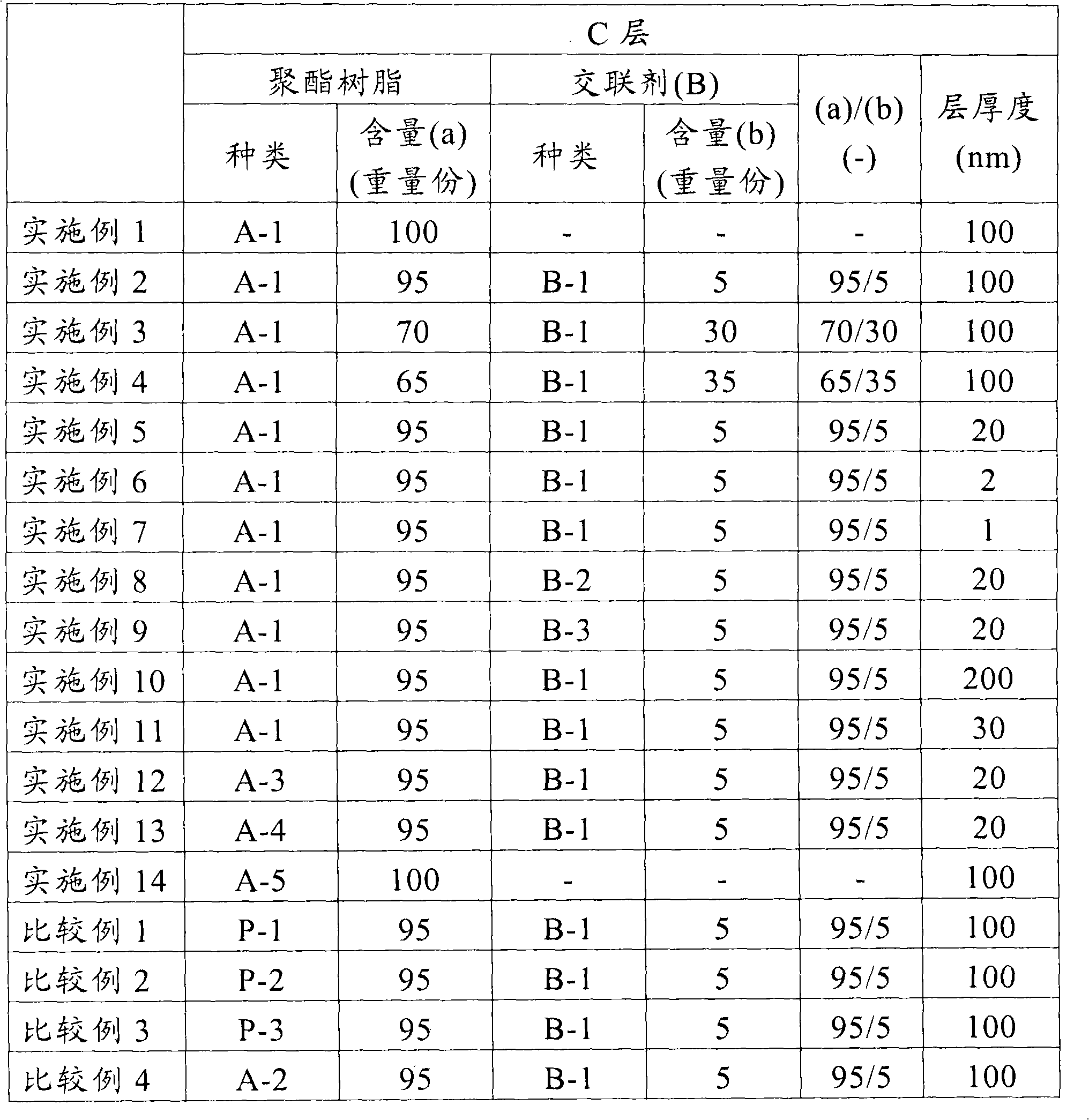

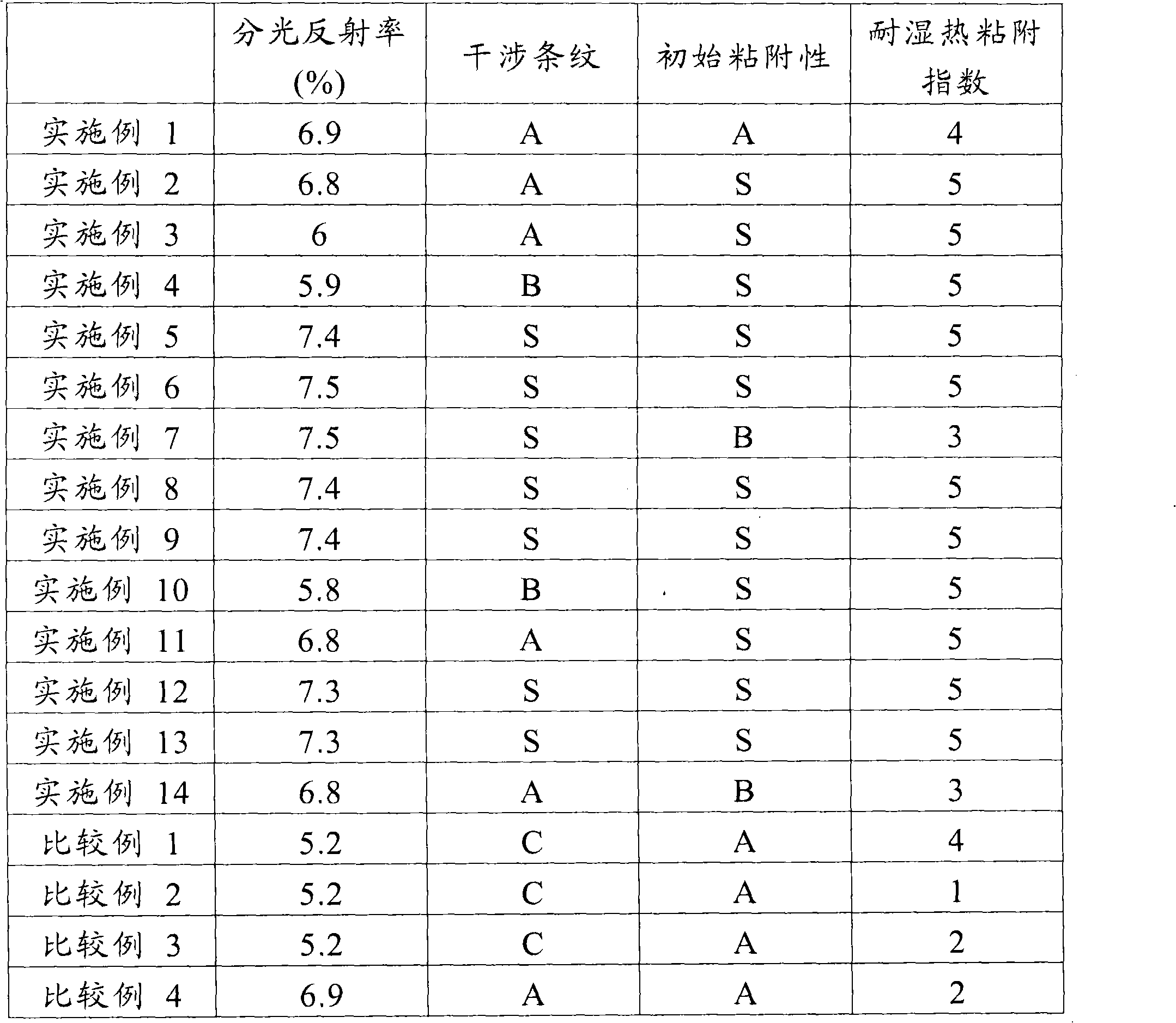

[0178] The present invention will be described below based on Examples and Comparative Examples, but the present invention is not limited thereto. In addition, the preparation methods of the resin etc. used in each Example and a comparative example are shown as a reference example.

reference example 1

[0179] (Reference example 1) Preparation of fluorene copolyester resin (A-1)

[0180] Under a nitrogen atmosphere, 75 molar parts of dimethyl succinate as a dicarboxylic acid component (Aa-2) without a fluorene skeleton, 9,9-bis [4-(2-hydroxyethoxy) phenyl] 80 molar parts of fluorene, 20 molar parts of ethylene glycol as the diol component (Ab-2) that does not have fluorene skeleton are fed in the transesterification reactor, to Add 100 parts by weight of tetrabutyl titanate (catalyst) relative to 1 million parts by weight of dicarboxylate derivative (dimethyl succinate), carry out esterification reaction at 160-200°C for 5 hours, and then distill out Methanol. Furthermore, it reacted for 30 minutes at 240 degreeC and the reduced pressure of 0.2 MPa, and obtained the polyester polyol.

[0181] Next, 25 mole parts of 1,2,4,5-benzenetetracarboxylic dianhydride, which is a polycarboxylic acid component (Aa-4) with a valence of more than 3, is fed into the polyester polyol, and ...

reference example 2

[0182] (Reference example 2) Preparation of fluorene copolyester resin (A-1) aqueous dispersion (A-1aq)

[0183] Add 531.6 parts of water, 2.0 parts of 25% by weight of ammonia water, and 33.4 parts of butyl cellosolve to 100.0 parts by weight of the above-mentioned fluorene copolyester resin (A-1) (hereinafter, simply referred to as "parts"), and dissolve at 40°C . Next, this reaction container was sealed, and the internal temperature of this container was raised to 120 degreeC, and it reacted for 2 hours, and the aqueous dispersion (A-1aq) of fluorene copolyester resin was obtained. The composition of the aqueous dispersion (A-1aq) of the fluorene copolyester resin is shown below.

[0184] · Fluorene copolyester resin (A-1): 100 parts (14.993% by weight)

[0185] · Water: 533.1 parts (79.925% by weight)

[0186] Ammonia: 0.5 parts (0.075% by weight)

[0187] - Butyl cellosolve: 33.4 parts (5.007% by weight).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com