Retardation film and manufacturing method thereof, polarizing plate and image display device using same, 3D image display system using same

一种相位差薄膜、相位差层的技术,应用在偏振元件、其他家里用具、应用等方向,达到降低干涉条纹、降低界面反射、抑制干涉条纹的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach >

[0110]

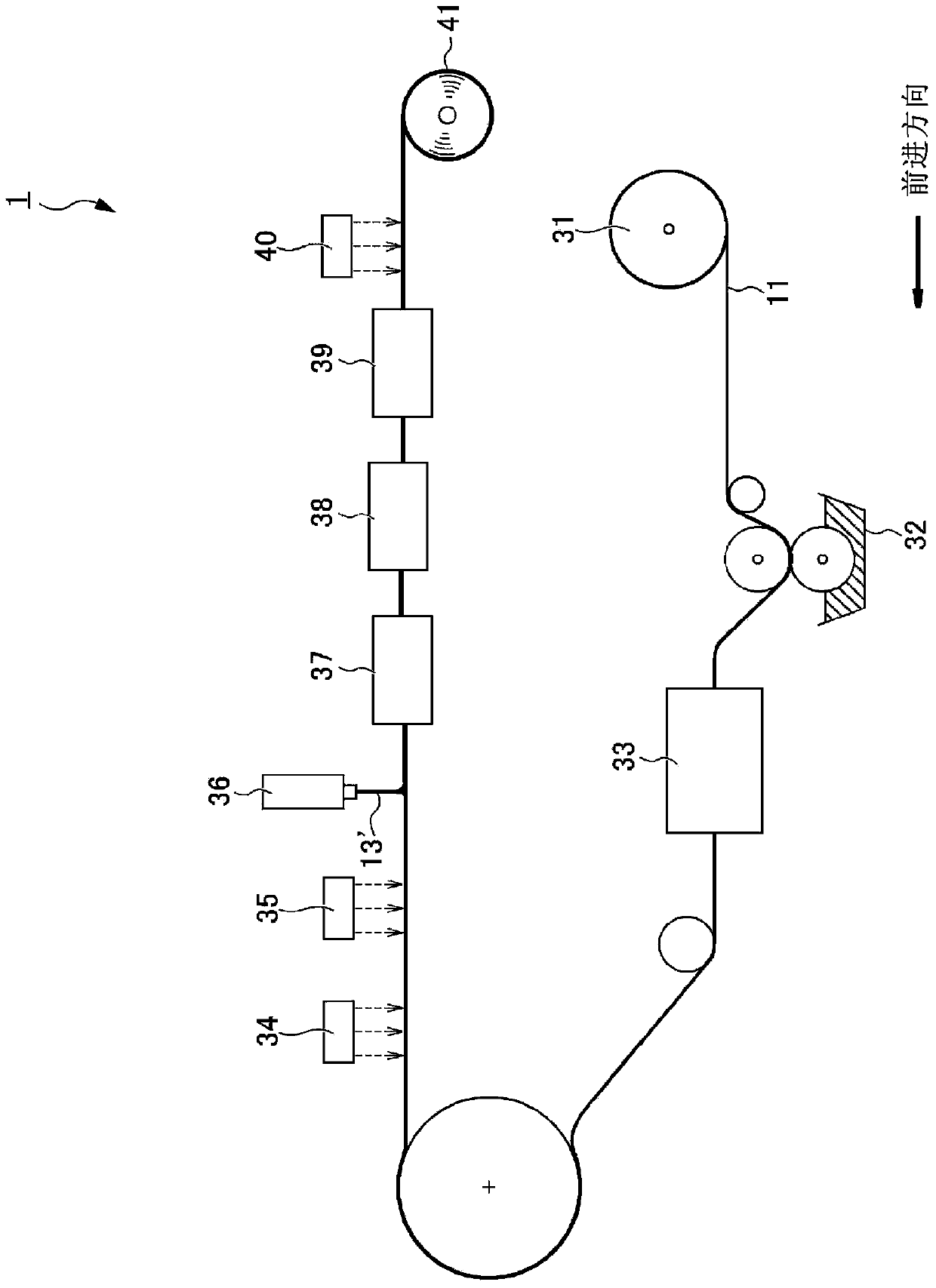

[0111] figure 1 It is a figure which shows the pattern retardation film suitable for the image display apparatus of 1st Embodiment of this invention. In the image display device of the first embodiment, in the vertical direction ( figure 1 The pixels on the continuous liquid crystal display panel in the left and right directions are corresponding directions) are alternately divided into right-eye pixels displaying right-eye images and left-eye pixels displaying left-eye images, respectively, through the right-eye images data and the left eye is driven with image data. As a result, the display screen of the image display device is alternately divided into a strip area displaying an image for the right eye and a strip area displaying an image for the left eye, and simultaneously displays the image for the right eye and the image for the left eye. In this image display device, a patterned retardation film 1 is arranged on the panel surface (the viewer's side surfac...

Embodiment 1-1

[0220] As a base material, a 40 μm (refractive index: 1.48) acrylic film with an anti-glare treatment was used on the surface, and a photo-alignment layer composition was applied on the back side by a die coating method so that the film thickness after curing was 200 nm. This photo-alignment layer composition is to have the photo-alignment material 100 mass parts of polyvinyl alcohol cinnamate (PVCi) group and the epoxy monomer of refractive index 1.70 (the epoxy monomer with the difunctional group of fluorene skeleton, Trade name: OGSOL CG-500, Osaka Gas Chemical (Japanese: Osaka Gas Chemical)) 3.0 parts by mass were dissolved in a mixed solvent containing isobutyl acetate and the solids accounted for 5%. Thereafter, the composition was dried for 2 minutes in a dryer adjusted to 100° C. to evaporate the solvent and heat-cure the composition to form a photo-alignment layer (refractive index: 1.57).

[0221] Next, this photo-alignment layer was irradiated with a cumulative ligh...

Embodiment 1-2

[0224] A retardation film was obtained in the same manner as in Example 1-1, except that the same epoxy monomer as in Example 1-1 was contained at a ratio of 5.0 parts by mass with respect to 100 parts by mass of the photo-alignment material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| haze | aaaaa | aaaaa |

| roughness | aaaaa | aaaaa |

| visible light transmittance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com