Laminated polyester film

A technology of polyester film and polyester resin, applied in polyester coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of inability to obtain adhesion, boiling resistance adhesion, etc., and achieve boiling resistance transparency Excellent, excellent visibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

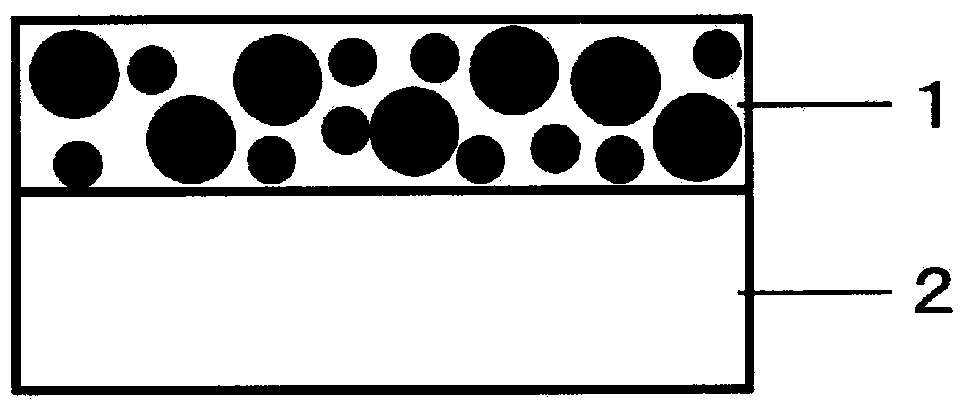

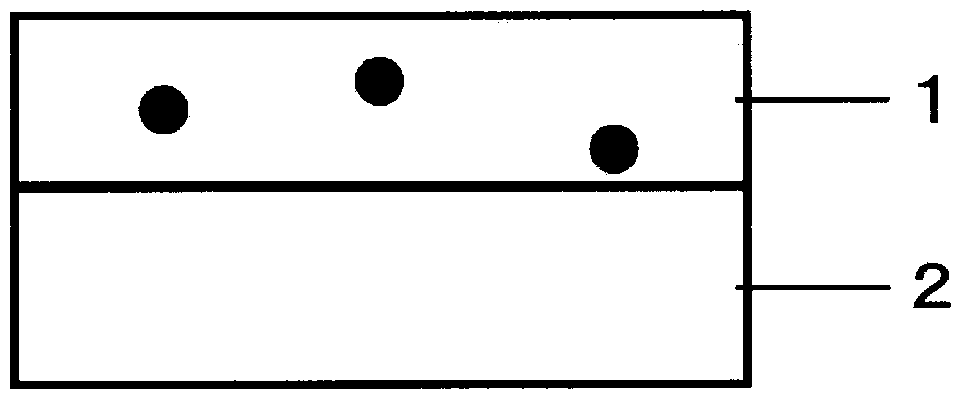

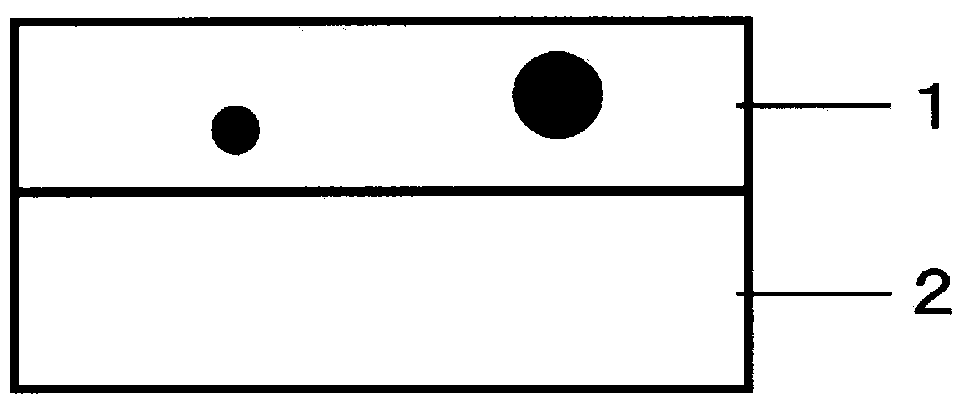

Image

Examples

Embodiment

[0206] The present invention will be described more specifically based on examples. However, the present invention is not limited to the following examples.

[0207] In addition, the synthesis method of the acryl-urethane copolymer resin and the polyester resin which has a naphthalene skeleton is shown in the reference example.

reference example 1

[0209] Preparation of aqueous dispersion of acrylic-urethane copolymer resin (a-1)

[0210] Under a nitrogen atmosphere and at room temperature (25° C.), 66 parts by weight of a polyester-based urethane resin (“HYDRAN” (registered trademark) AP-40(F) manufactured by DIC Corporation) and Solution 1 was obtained with 35 parts by weight of methyl methacrylate, 29 parts by weight of ethyl acrylate, and 2 parts by weight of N-methylolacrylamide. Next, 7 parts by weight of an emulsifier ("Riasopu" ER-30 manufactured by ADEKA Corporation) was added, and water was further added so that the solid content of the solution would become 50% by weight, whereby a solution 2 was obtained. At normal temperature (25°C), 30 parts by weight of water was added to the container 2, and the temperature was raised to 60°C. Thereafter, solution 2 was continuously dropped into container 2 over 3 hours while stirring. Furthermore, 3 parts by weight of a 5% by weight potassium persulfate aqueous solutio...

reference example 2

[0213] Preparation of aqueous dispersion of polyester resin (b-1) having naphthalene skeleton

[0214] Aqueous dispersion of polyester resin with the following copolymer composition

[0215]

[0216] (dicarboxylic acid component)

[0217] Dimethyl 2,6-naphthalene dicarboxylate: 88 mol%

[0218] Sodium 5-dimethyl sulfoisophthalate: 12 mol%

[0219] (glycol component)

[0220] A compound obtained by adding 2 moles of ethylene oxide to 1 mole of bisphenol S: 86 mol%

[0221]1,3-Propanediol: 14 mol%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com