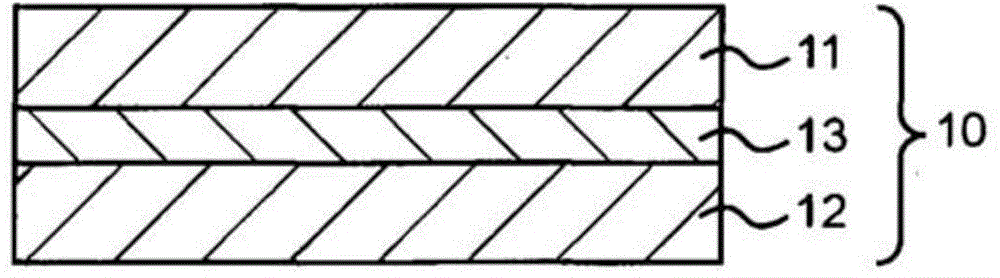

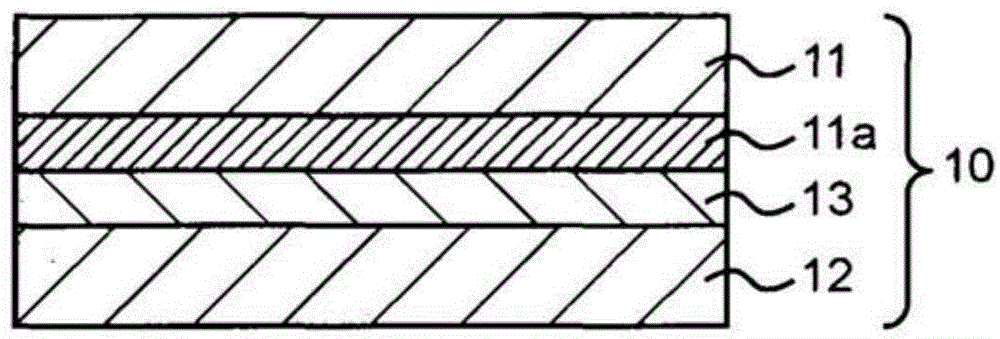

Adhesive for laminated sheets

A technology of adhesives and laminates, applied in the direction of adhesive types, polyurea/polyurethane adhesives, adhesives, etc., can solve problems such as reduced adhesive strength, achieve excellent weather resistance, moderate curing rate, The effect of excellent initial adhesion and hydrolysis resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0196]

[0197] As shown in Table 2, 93.1 g of acrylate polyol (A1) [186.2 g of acrylate polyol (A1) in ethyl acetate (solid content: 50.0% by weight)] was mixed with 2.8 g [3.0% based on 100 % solid content of acrylate polyol (A1)] Glycidyl-based silane compound (B1) was mixed, then 2.8 g of isocyanate compound (C1) and 1.3 g of isocyanate compound (C2) were added, followed by mixing. Also, ethyl acetate was added to the mixture to prepare a binder solution having a solid content of 30% by weight. The following tests were carried out using the solution thus prepared as a binder.

[0198]

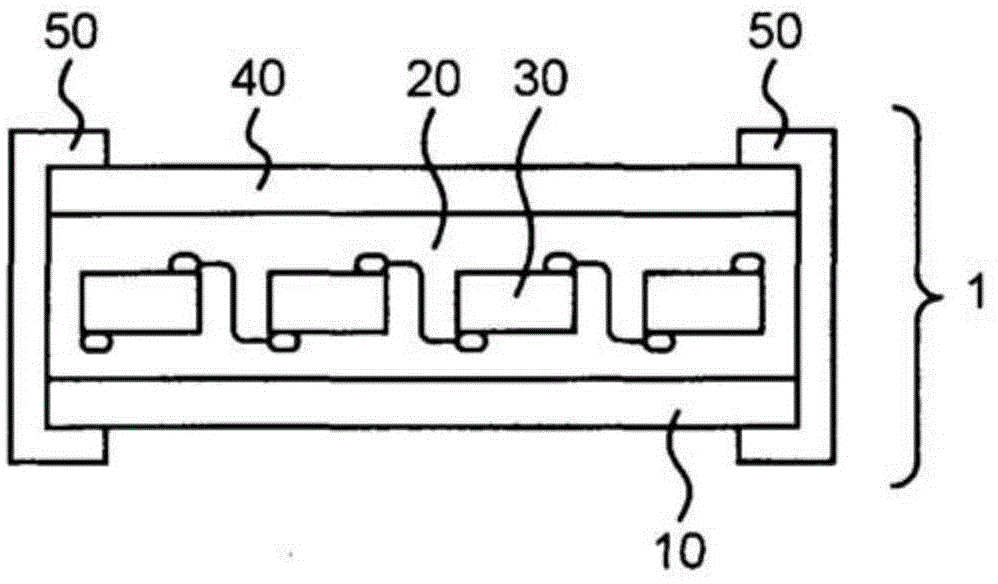

[0199] First, the adhesive of Example 1 was applied to a transparent polyethylene terephthalate (PET) sheet (O300EW36 (trade name), manufactured by Mitsubishi Polyester Film Co., Ltd.) so that the weight of the solid component 10g / m 2 , and then dried at 80° C. for 10 minutes to obtain a PET sheet coated with an adhesive.

[0200] Then, a 50 μm-thick surface-treated transparent polyo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com