Single-component healing capsule and self-healing concrete

A one-component, concrete technology, applied in the field of engineering materials, can solve the problems of difficult penetration of the healing agent, low self-healing efficiency, high viscosity, etc., and achieve the effects of good fluidity, high healing efficiency, and low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The present invention has no special limitation on the preparation method of the one-component healing capsule, and the technical solution for the preparation of the one-component healing capsule well-known to those skilled in the art can be adopted. In the present invention, the preparation of the one-component healing capsule preferably includes the following steps:

[0031] Mix polyurethane with diluent to obtain a one-component healing agent;

[0032] Injecting the one-component healing agent into the capsule wall with one end closed to obtain a semi-closed capsule;

[0033] The opening end of the semi-closed capsule is blocked with a plugging material to obtain a one-component healing capsule.

[0034] In the present invention, the closed capsule wall is preferably a single open capsule wall, or a double open capsule wall with a plugging material blocked at one end. In the present invention, there is no special limitation on the injection method of the one-compon...

Embodiment 1

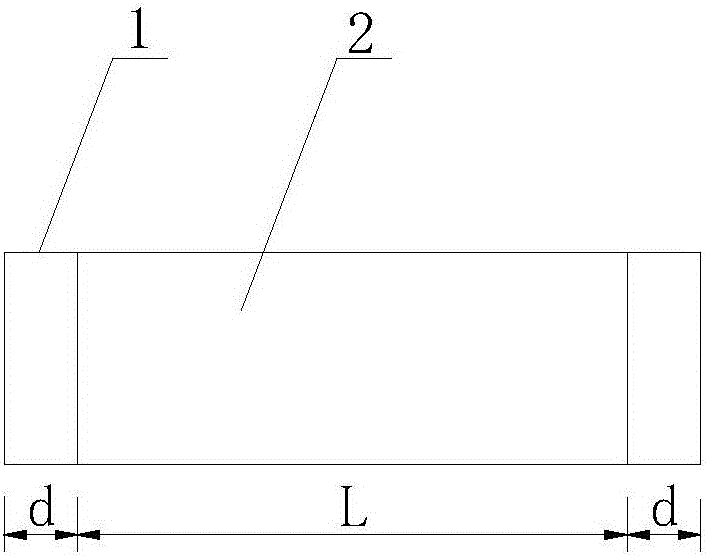

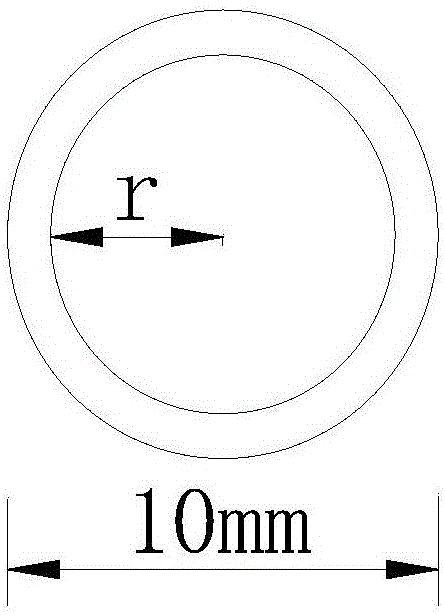

[0044] The structural diagram of the capsule in this embodiment is as follows: figure 1 As shown, the cross-sectional view of the capsule is shown in figure 2 As shown, an open-ended quartz glass tube 2 with an inner diameter of 9 mm, a wall thickness of 1 mm, and a length of 30 mm is used, and one end of the tube is sealed with a plexiglass (acrylic material) sheet 1 with a diameter of 10 mm and a thickness of 2 mm. Then use a syringe to inject optimized polyurethane healing agent (ratio of acetone to polyurethane mass is 0.2), after filling up, use plexiglass sheet 1 to block the other end. The cementing material used for sealing is α-ethyl cyanoacrylate, and it is ensured that there is no excess air in the tube to obtain a one-component healing capsule.

[0045] The viscosity of the healing agent was measured by an Anton Paar MCR302 rheometer parallel plate experiment, the temperature was set at 20°C, and the shear rate was from 1s -1 Increase to 10000s -1 , measure the...

Embodiment 2

[0047] Prepare cement mortar according to the ratio of water: cement: aggregate=1:1:3, first pour the mortar into half of the mold (160mm×40mm×40mm); then put one single-component healing capsule prepared in Example 1 horizontally Parallel to the center of the mold filled with half of the mortar, the capsule is placed in the same direction as the mold; finally fill the mold with mortar, and place the mold on a vibrating table for slight vibration and compaction; the sample is kept at 20°C and a relative humidity of 90 % constant temperature and humidity curing box for curing, demoulding after 12 hours to obtain self-healing concrete.

[0048] Performance testing of self-healing concrete:

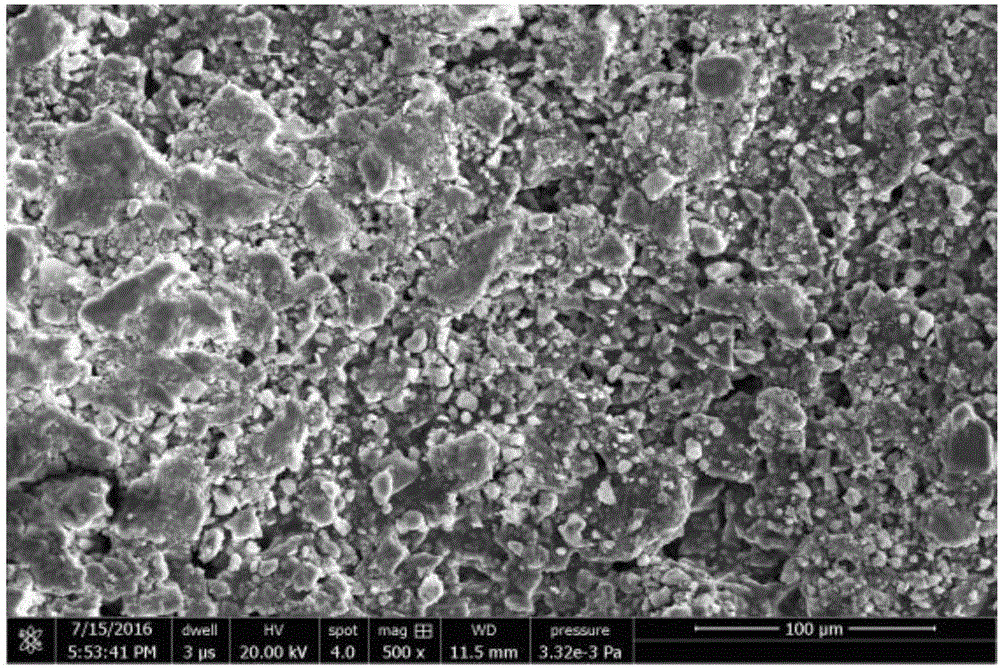

[0049] After 14 days of curing, the cracks of the healed sample were produced by the three-point bending test. During the test, the capsule cracking sound could be clearly heard, and the glass capsule did not slip in the concrete, which met the test requirements for the capsule to rupture wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com