Inorganic magnesium-based adhesive for bonding and grouting broken stone cultural relics and preparation method of inorganic magnesium-based adhesive

A technology of stone cultural relics and magnesium-based glue, applied in inorganic adhesives, adhesives, adhesive additives, etc., can solve the problems of poor aging resistance of organic glues, destroy the aesthetic value of cultural relics, reduce bonding strength, etc., and achieve weather resistance. Excellent properties, wide application temperature range, low density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

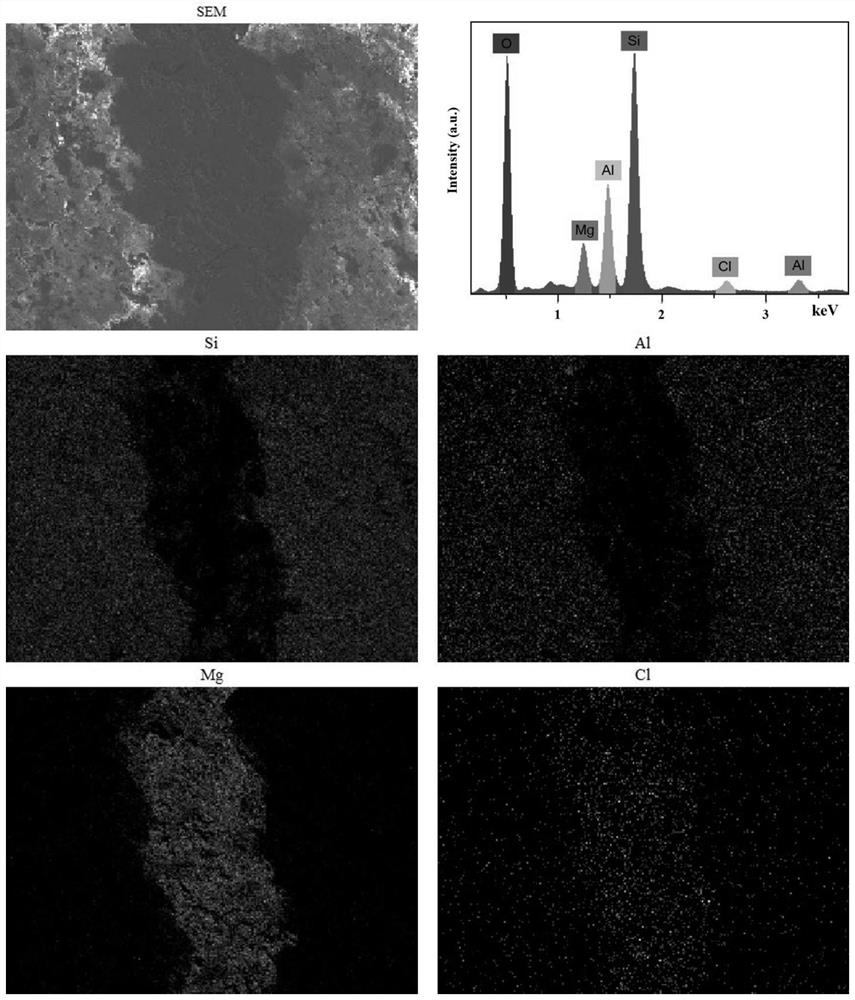

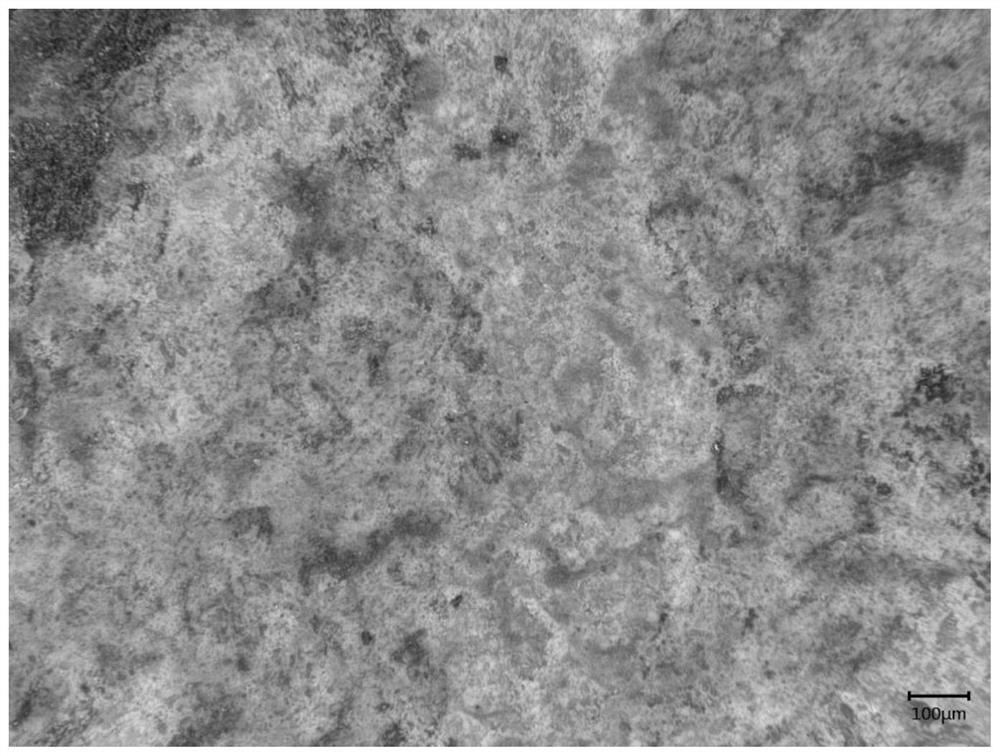

Image

Examples

preparation example Construction

[0029] Also disclosed is a method for preparing an inorganic magnesium-based adhesive for bonding and grouting fractured stone cultural relics, characterized in that the steps are as follows:

[0030] 1) Distill deionized water into MgCl according to the mass ratio 2 ·6H 2 O:H 2 O=1: (0.89~1.42) ratio joins in the magnesium chloride hexahydrate, prepares the magnesium chloride solution;

[0031] 2) Add a small amount of MgO powder with a mass fraction of 28% to 45% to MgCl several times 2 In the solution, stir evenly while adding to obtain a preliminary MMH slurry;

[0032] 3) adding salicylic acid with a mass fraction of 0.5% to 3% to the above-mentioned preliminary MMH slurry and ultrasonicating for 30 minutes to disperse the salicylic acid evenly therein to obtain the MMH adhesive;

[0033] 4) Add ionized water and fillers in an appropriate amount to obtain a paste that is convenient for bonding and grouting.

[0034] The present invention can also optimize the perform...

Embodiment 1

[0042] 1. Preparation of adhesive

[0043] Accurately weigh 18.00g H 2 O and 20.33 g MgCl 2 ·6H 2 O, deionized water is added in the magnesium chloride, the preparation magnesium chloride solution. Then, 31.11g of MgO powder was added to MgCl several times in small amounts 2Stir in the solution. After stirring evenly, 0.701 g of salicylic acid was added, and the sample was placed in an ultrasonic cleaner for 30 minutes of ultrasonication, so that the salicylic acid was evenly dissolved in it to obtain the MMH adhesive.

[0044] 2. Adhesive performance test

[0045] (1) Mechanical strength test Pour the prepared adhesive into a cubic silicone mold (20mm×20mm×20mm), and then shake the mold gently to discharge the air in it. After 2 days, the samples were removed from the molds. Maintain in an environment with a temperature of 25±10°C and a relative humidity of 60±20%. The compressive strength of the samples after curing for 7 days and 28 days were respectively tested wit...

Embodiment 2

[0048] The preparation method of the adhesive is the same as in Example 1. The prepared MMH adhesive was used to bond sandstone samples (lapping surface: 50mm×30mm). First, apply the adhesive evenly on the butt joint surface, and then fix the joint. After the adhesive is completely cured (28 days), the flexural strength is 4.394 MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com