Hot melt polyurethane adhesive for bonding honeycomb panel and preparation method of hot melt polyurethane adhesive

A hot-melt polyurethane and adhesive technology, applied in the direction of polyurea/polyurethane adhesive, adhesive, adhesive type, etc., can solve the problems of long initial bond strength and long open time, and achieve excellent initial bond force, excellent final The effect of bond strength and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A preparation method of the hot-melt polyurethane adhesive, comprising the steps of:

[0026] 1) Put the crystalline polyester polyol with a molecular weight of 500 and rosin acid in a molar ratio of 1:1.05 (adjustable according to requirements) in a reaction kettle, heat it to 210°C under the protection of nitrogen, and dehydrate until the acid value is less than 2.0. During the reaction process, nitrogen protection is used and a high vacuum is used for rapid dehydration. After the reaction is completed, the material is discharged in a molten state for use. The state of the product is a solid with a lower melting point. The molecular weight of the polymer in the present invention is 500, referred to as S -500;

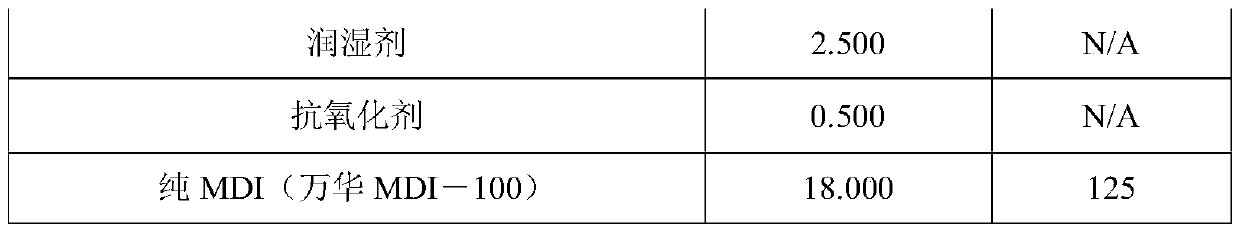

[0027] 2) Add the prepared S-500, poly-1,4-butylene adipate (PBA-2000), EVA (molecular weight is about 100,000), wetting agent and anti-aging agent into the reactor respectively , heat to dissolve to a uniform state, then vacuum dehydrate for 40 minutes, add d...

Embodiment 2

[0032] A preparation method of the hot-melt polyurethane adhesive, comprising the steps of:

[0033] 1) Put the crystalline polyester polyol with a molecular weight of 1000 and rosin acid in a molar ratio of 1:1.05 (adjustable according to demand) in a reactor, heat to 220°C under nitrogen protection, and dehydrate until the acid value is less than 2.0. During the reaction process, nitrogen protection and high vacuum are used for rapid dehydration. After the reaction is completed, the material is discharged in a molten state for use. The state of the product is a solid with a low melting point. The molecular weight of the polymer in the present invention is between 1000, referred to as for S-1000;

[0034] 2) Add the prepared S-1000, poly-1,4-butylene adipate (PBA-2000), EVA (molecular weight is about 100,000), wetting agent and anti-aging agent into the reactor respectively , heat to dissolve to a uniform state, then vacuum dehydrate for 50 minutes, add diisocyanate at 100°C...

Embodiment 3

[0039] A preparation method of the hot-melt polyurethane adhesive, comprising the steps of:

[0040] 1) Put crystalline polyester polyol with a molecular weight of 1500 and rosin acid in a molar ratio of 1:1.05 (adjustable according to demand) in a reactor, heat to 240°C under nitrogen protection, and dehydrate until the acid value is less than 2.0. During the reaction process, use nitrogen protection and use high vacuum for rapid dehydration. After the reaction is completed, the material is discharged in a molten state for use. The state of the product is a solid with a low melting point. The molecular weight of the polymer in the present invention is between 2000, referred to as for S-2000;

[0041] 2) Add the prepared S-2000, poly-1,4-butylene adipate (PBA-2000), EVA (molecular weight is about 100,000), wetting agent and anti-aging agent into the reactor respectively , heat to dissolve to a uniform state, then vacuum dehydrate for 60 minutes, add diisocyanate at 110°C and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com