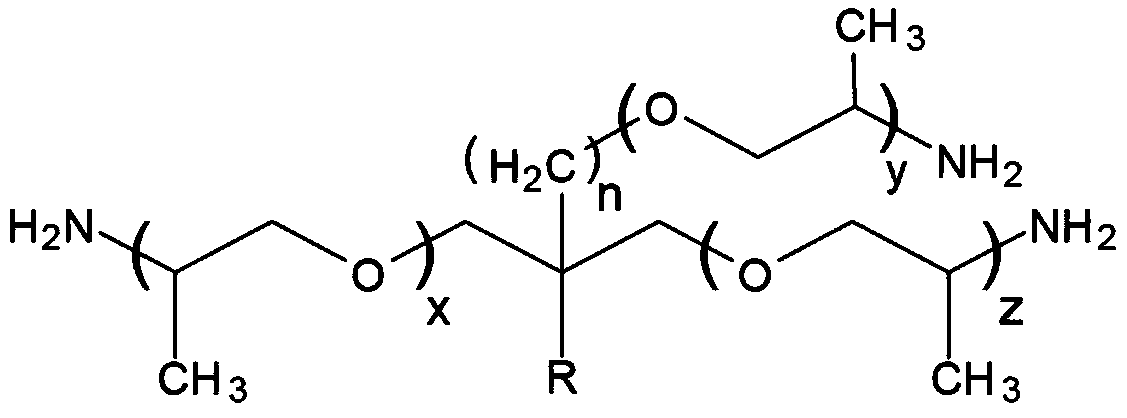

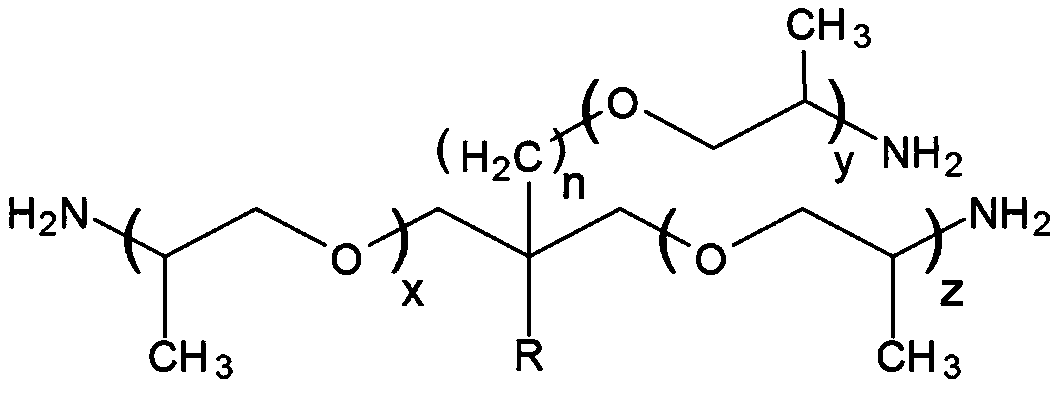

Preparation method of polyamide polyamine-polyether amine cylinder adhesive

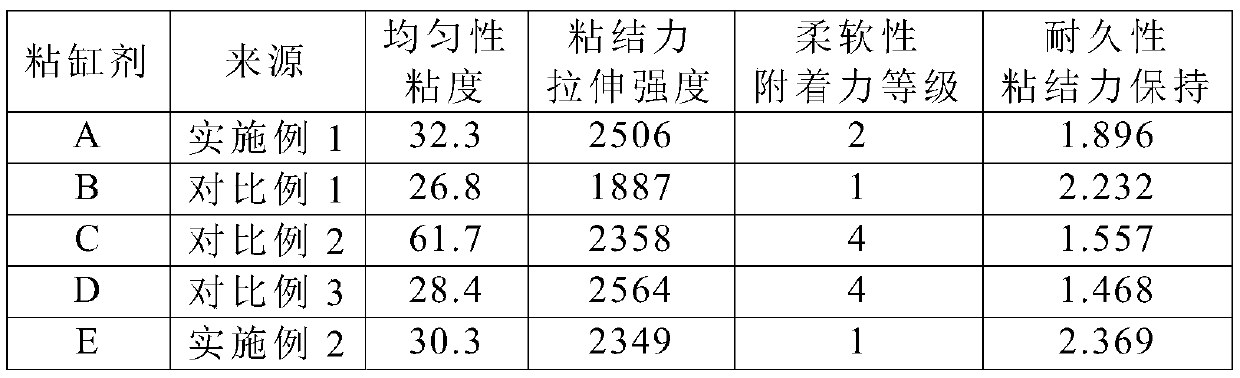

A technology of polyamide polyamine and polyether amine, which is applied in the field of papermaking aids, can solve the problems of unsatisfactory durability, broken holes in paper sheets, and increased molecular weight of polymers, and achieves good initial adhesion, long duration, The effect of good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030]In a stainless steel reaction kettle with conditions such as weighing, jacket heating, cooling, nitrogen protection, stirring, temperature, pressure indication, and feeding, add 17.9g of tallow, replace with nitrogen, start stirring, heat up to 140°C, and vacuumize To 5kPa and keep for 15 minutes, the constant weight in the kettle is 17.1g (about 0.02mol). Add 214.8g (1.47mol) of adipic acid, fill with nitrogen to slightly positive pressure, add 155g (1.5mol) of diethylenetriamine dropwise, raise the temperature to 140°C and stir and mix for 2 hours, then raise the temperature by 10°C per hour until 180°C, keep warm 2 hours. Start the vacuum system, gradually evacuate to an absolute pressure of 100Pa, and keep warm for 2 hours. Stop heating, fill with nitrogen to slightly positive pressure, add 670 g of hot deionized water to dilute the reaction material to a solid content of 33%, which is the aqueous solution of polyamide polyamine intermediate.

[0031] The aqueous s...

Embodiment 2

[0041] Add 16.2g of palm oil to a stainless steel reactor with conditions such as weighing, jacket heating, cooling, nitrogen protection, stirring, temperature, pressure indication, and feeding, replace with nitrogen, start stirring, heat up to 140°C, and vacuumize To 5kPa and keep for 15 minutes, the constant weight in the kettle is 16.0g (about 0.01mol). Add 214.8g (1.47mol) of adipic acid, fill with nitrogen to slightly positive pressure, dropwise add 103.2g (1mol) of diethylenetriamine and 73.1g (0.5mol) of triethylenetetramine, raise the temperature to 140°C and stir and mix for 2 hours. Then the temperature was increased by 10°C per hour until 180°C, and kept for 2 hours. Start the vacuum system, gradually evacuate to an absolute pressure of 100Pa, and keep warm for 2 hours. Stop heating, fill with nitrogen to slightly positive pressure, add 650 g of hot deionized water to dilute the reaction material to a solid content of 35%, which is the aqueous solution of polyamide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com