High wear resistance water-borne gloss oil and preparing method thereof

A water-based varnish, high wear-resistant technology, applied in the direction of coatings, wax coatings, etc., can solve the problems of reduced processing suitability, reduced gloss, increased production costs, etc., to achieve increased elasticity and toughness, improved wear resistance, Effect of improving friction resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

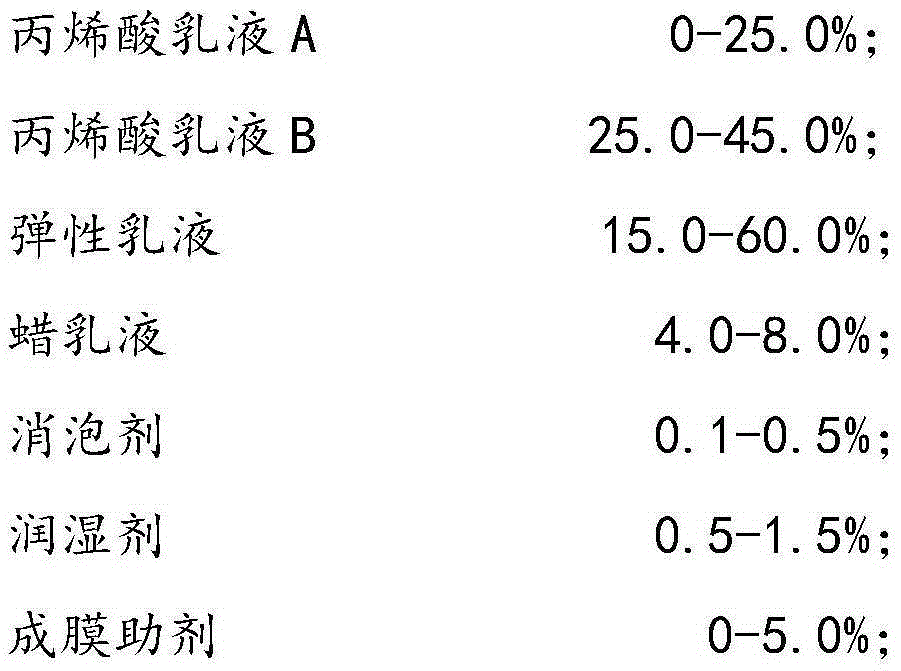

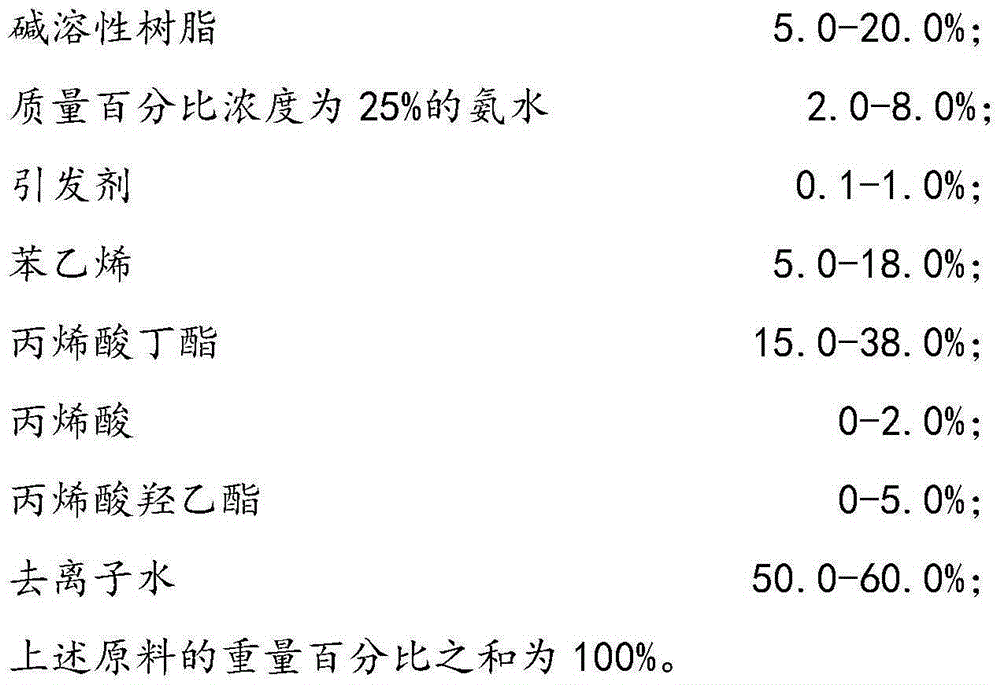

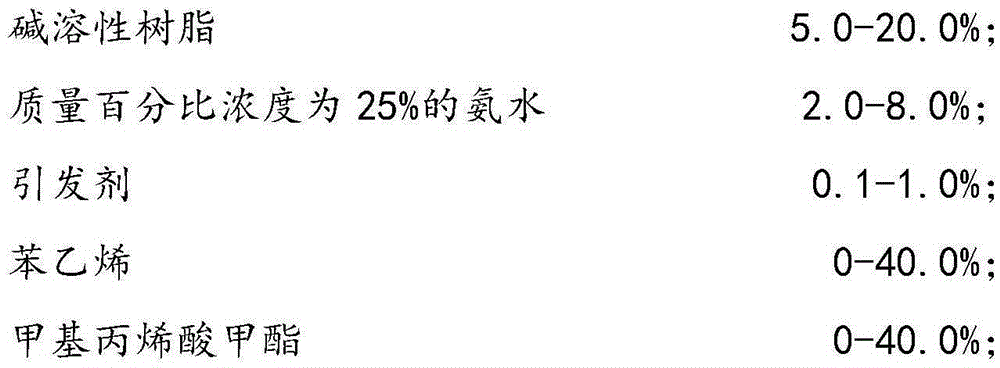

Method used

Image

Examples

Embodiment 1

[0039] At a stirring speed of 400-600rpm, first pour 38.4% of acrylic emulsion B into a clean container, and then add 36.0% of acrylic emulsion A, 10.0% of elastic emulsion, 8.0% of wax emulsion and 0.1% of defoamer , stirring at a speed of 800-1000rpm for 20-60 minutes; then slowly dripping 0.5% of wetting agent, 4.0% of propylene glycol monobutyl ether film-forming aid and 3.0% of deionized water at a stirring speed of 400-600rpm, Reduce the rotation speed to 150-300rpm, stir for more than 15 minutes to eliminate foam, and put it in a tank to get the finished varnish.

Embodiment 2

[0041] At a stirring speed of 400-600rpm, first pour 38.4% of acrylic emulsion B into a clean container, and then add 26.0% of acrylic emulsion A, 20% of elastic emulsion, 8.0% of wax emulsion and 0.1% of defoamer , stirring at a speed of 800-1000rpm for 20-60 minutes; then slowly dripping 0.5% of wetting agent, 4.0% of propylene glycol monobutyl ether film-forming aid and 3.0% of deionized water at a stirring speed of 400-600rpm, Reduce the rotation speed to 150-300rpm, stir for more than 15 minutes to eliminate foam, and put it in a tank to get the finished varnish.

Embodiment 3

[0043] Pour 46.4% of acrylic emulsion B into a clean container at a stirring speed of 400-600rpm, then add 38.0% of elastic emulsion, 8.0% of wax emulsion and 0.1% of defoamer in turn, at a speed of 800-1000rpm Stir for 20-60 minutes; then slowly add 0.5% wetting agent, 4.0% propylene glycol monobutyl ether film-forming aid and 3.0% deionized water dropwise at a stirring speed of 400-600rpm, reduce the speed to 150-300rpm, Stir for more than 15 minutes to eliminate the foam, then put it in a can to get the finished varnish.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com