Water-based polyurethane modified acrylic ester emulsion and preparation method thereof, and water-based wood coating

A technology of water-based polyurethane and acrylate, which is applied in the field of polymers, can solve the problems of low factory work efficiency, workshop space utilization, wood products that cannot be stacked and stacked, and affect the performance of water-based paints, so as to improve anti-adhesion performance and good film formation Sex, the effect of increasing hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

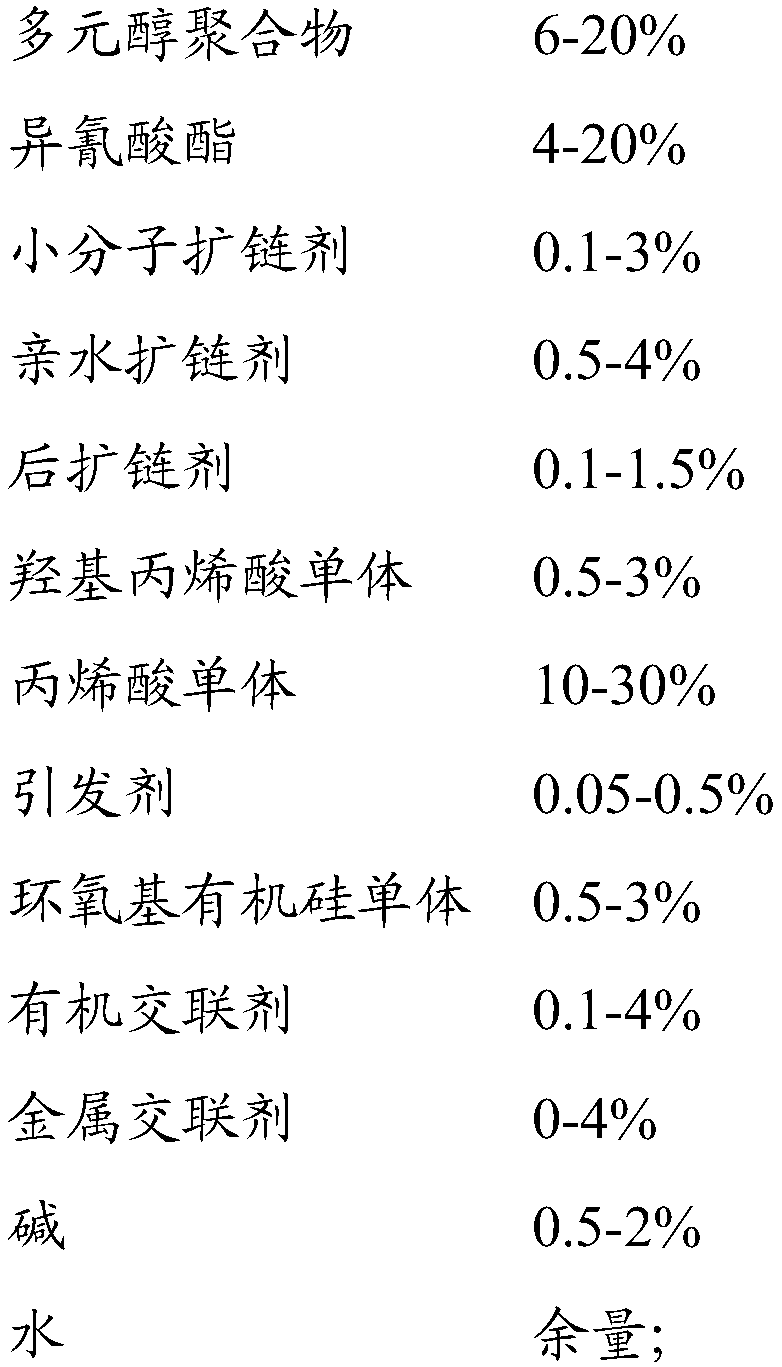

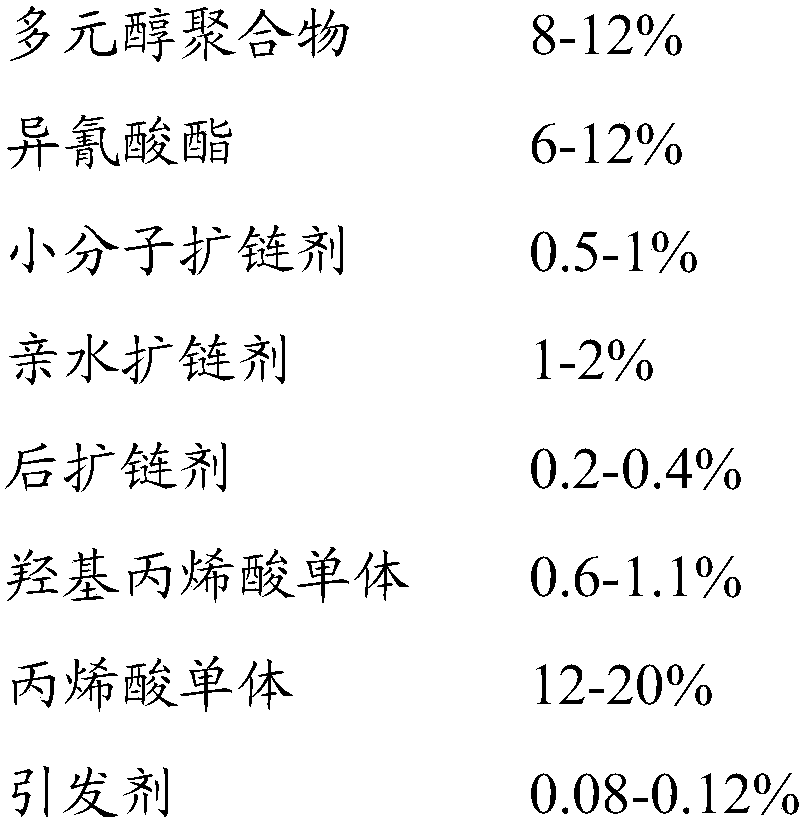

Method used

Image

Examples

Embodiment 1

[0055] The preparation of embodiment 1 waterborne polyurethane modified acrylate emulsion

[0056] (1) dehydrating the polytetrahydrofuran ether diol at a temperature of 120°C and a vacuum of 0.08Mpa, the dehydration time is 1 hour, and the temperature is lowered to obtain the dehydrated polytetrahydrofuran ether diol for later use;

[0057] (2) Add dehydrated polytetrahydrofuran ether glycol 100g, isophorone diisocyanate 100g, 1,4-butanediol 7g, trimethylolpropane 2g and dimethylol propionic acid 17g in the reactor, After reacting at 80°C for 4 hours, cool down to 70°C, add 9g of hydroxyethyl acrylate, react for 2 hours and cool down to 50°C, then add 11g of triethylamine for neutralization, add 600g of water after neutralization for emulsification, emulsify for 20 Minutes later, add ethylenediamine 3g to carry out chain extension to obtain aqueous polyurethane emulsion;

[0058] (3) Add 100 g of methyl methacrylate, 30 g of butyl acrylate and 8 g of diacetone acrylamide to ...

Embodiment 2

[0059] The preparation of embodiment 2 waterborne polyurethane modified acrylate emulsion

[0060] (1) Dehydrating the polycarbonate diol at a temperature of 100° C. and a vacuum of 0.07 Mpa, the dehydration time is 2 hours, and cooling down to obtain the dehydrated polycarbonate diol for subsequent use;

[0061] (2) Add 50 g of dehydrated polycarbonate diol, 50 g of polytetrahydrofuran ether diol, 80 g of isophorone diisocyanate, 5 g of 1,4-butanediol, 2 g of trimethylol propane and di 15g of methylolpropionic acid, react at 80°C for 4 hours, then cool down to 70°C, then add 8g of hydroxyethyl acrylate, react for 2 hours, then cool down to 50°C, then add 10g of triethylamine for neutralization, after neutralization Add 600g of water for emulsification, add 3g of ethylenediamine after emulsification for 20 minutes for chain extension, and obtain water-based polyurethane emulsion;

[0062] (3) Add 120g of methyl methacrylate, 40g of butyl acrylate and 10g of diacetone acrylami...

Embodiment 3

[0063] The preparation of embodiment 3 waterborne polyurethane modified acrylate emulsion

[0064] (1) Dehydrating the polytetrahydrofuran ether diol at a temperature of 120°C and a vacuum of 0.09Mpa, the dehydration time is 1 hour, and the temperature is lowered to obtain the dehydrated polytetrahydrofuran ether diol for later use;

[0065] (2) Add dehydrated polytetrahydrofuran ether glycol 100g, isophorone diisocyanate 80g, 1,4-butanediol 5g, trimethylolpropane 2g and dimethylol propionic acid 15g in the reactor, After reacting at 80°C for 4 hours, cool down to 70°C, then add 8g of hydroxyethyl acrylate, react for 2 hours and cool down to 50°C, then add 10g of triethylamine for neutralization, add 600g of water after neutralization for emulsification, and emulsify for 20 Minutes later, add ethylenediamine 3g to carry out chain extension to obtain aqueous polyurethane emulsion;

[0066] (3) Add methyl methacrylate 120g, butyl acrylate 40g and acetoacetoxy ethyl methacrylate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com