Base material for surface protective sheet and surface protective sheet

A technology for protecting sheets and substrates, applied in film/sheet-like adhesives, transportation and packaging, thin material processing, etc., can solve the problems of poor anti-blocking properties of surface protection sheets, and prevent surface roughening and adhesion. Small degree of deterioration in property, effect of suppressing scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

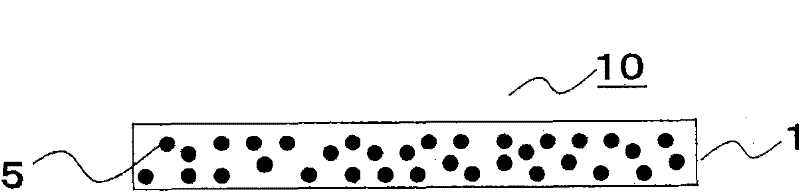

Embodiment 1

[0109] By adding 2 parts by weight of cross-linked polymethyl methacrylate fine particles having an average particle diameter of 10 μm (made by JX Nippon Oil Co., Ltd.) to 100 parts by weight of linear low density polyethylene (Evolue SP2520 manufactured by Prime Polymer Co., Ltd.) & Energy Corporation Uni-Powder NMB-1020) was formed into a sheet by an inflation method at a mold temperature of 200°C. Thus, a base material for a surface protection sheet was prepared. The thickness of the substrate used for the surface protection sheet was 60 μm.

[0110] After that, one surface of the obtained base material for a surface protection sheet was subjected to corona treatment.

[0111] Next, 3 parts by weight of an isocyanate-based crosslinking agent (Coronate L manufactured by Nippon Polyurethane Industry Co., Ltd.) was added to 100 parts by weight of an acrylic pressure-sensitive adhesive (having a weight of 600,000 in terms of polystyrene). average molecular weight) of ethyl ac...

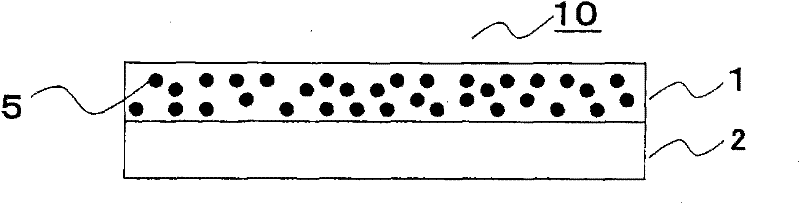

Embodiment 2

[0115] By adding 1 part by weight of crosslinked polystyrene fine particles having an average particle diameter of 8 μm (TECHPOLYMER SBX- 8) The obtained product is prepared as a raw material for the substrate layer (A).

[0116] Polypropylene (WINTECWFX4 manufactured by Japan Polypropylene Corporation) was prepared separately as a raw material for the base material layer (B).

[0117] The base layer (A) and the base layer (B) were co-extruded into two layers at a mold temperature of 220° C. by a T-die method. Thus, a two-layer base material for a surface protection sheet was prepared. The base material layer (A) had a thickness of 10 μm, and the base material layer (B) had a thickness of 50 μm.

[0118] After that, the substrate layer (B) surface side of the resulting two-layer substrate for a surface protection sheet was subjected to corona treatment.

[0119] Next, a styrene-isobutylene-styrene block copolymer (SIBSTAR 072T manufactured by KANEKA CORPORATION) was dissolv...

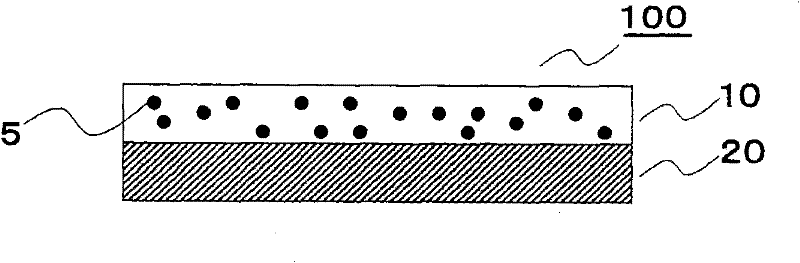

Embodiment 3

[0123] By adding 5 parts by weight of cross-linked polymethyl methacrylate fine particles (TAFTIC manufactured by TOYOBO Co., Ltd.) The product obtained from FHS-005) is prepared as a raw material for the substrate layer (A).

[0124] Polyethylene (Petrocene 204 manufactured by TOSOH CORPORATION) was prepared separately as a raw material of the base material layer (B).

[0125] In addition, by adding 30 parts by weight of petroleum resin (Clearon manufactured by YASUHARA CHEMICAL CO., LTD.) to 100 parts by weight of styrene-ethylene-butylene-styrene block copolymer (Tuftec H1221 manufactured by Asahi Kasei Chemicals Corporation), P-125) obtained product, which is prepared as a raw material for a pressure-sensitive adhesive layer.

[0126] The base material layer (A), the base material layer (B) and the pressure-sensitive adhesive layer were subjected to three-layer coextrusion molding at a mold temperature of 200° C. by a T-die method. Thus a surface protection sheet (3) was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com