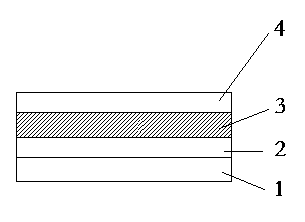

Aluminum plastic film for packaging lithium battery and manufacturing process of aluminum plastic film

An aluminum-plastic film, lithium battery technology, applied in battery pack parts, battery box/jacket, battery box/cover material, etc., can solve the problem of affecting appearance, reduce battery barrier and dielectric coefficient, and only focus on material drawing performance and other issues to achieve the effect of enhancing slipperiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0036] The manufacturing process of the aluminum-plastic film for lithium battery packaging of the present invention is as follows:

[0037] 1) Using aluminum foil, surface treatment is done on both sides of the aluminum foil first, the smooth side is treated with anti-corrosion treatment, and the matte side is treated with increasing surface tension;

[0038] 2) Mix according to the ratio of epoxy resin modified fluororesin coating B: curing agent B = 100:19, and add 80% of the corresponding mass of butanone at the same time, stir and mix evenly;

[0039] 3) Coat the coating of system B on the matte surface of the aluminum foil, with a wet film thickness of 35 μm-50 μm;

[0040] 4) The temperature of the drying tunnel is set to a temperature gradient of 80-100-90°C, and the aluminum foil runs in the drying tunnel at a speed of 5M / min to ensure that the winding is intact;

[0041] 5) The semi-finished product is cured in a curing chamber at 80°C-100°C for 16-24 hours;

[004...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com