Aqueous anti-doodling and anti-affixing paint and its preparation method

An anti-graffiti and coating technology, applied in the field of coatings, can solve the problems of damaging the surface of public facilities coated with small advertisements, not achieving cleaning, beautifying the city environment, time-consuming and labor-intensive problems, etc., achieving convenient and easy construction, improving anti-aging performance, Excellent effect of water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

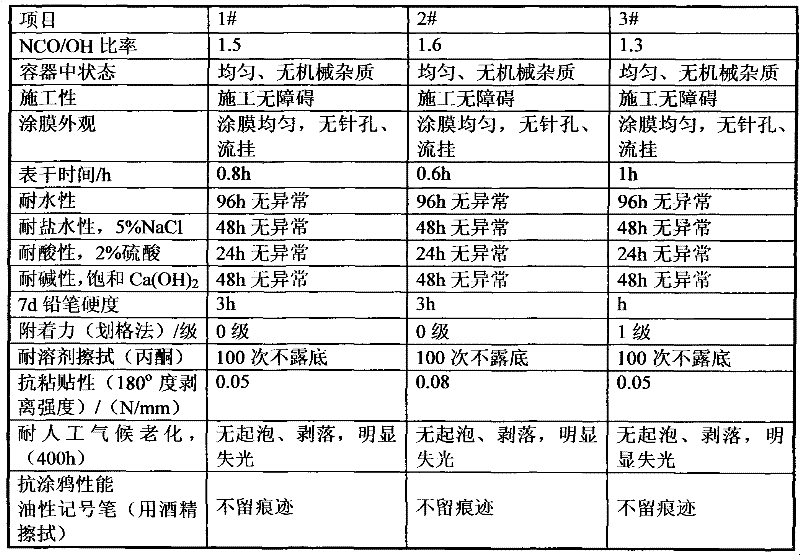

Examples

preparation example Construction

[0058] The preparation method of above-mentioned water-based anti-graffiti anti-sticking coating comprises the steps:

[0059] a): Add anionic polyacrylic acid dispersion and water to the container successively, and stir;

[0060] b): Gradually add pigments and functional fillers, increase the speed while adding, and keep stirring;

[0061] c): After the material is completely dispersed, add anionic polyacrylate dispersion, modified organosilane emulsion, and fumed silica, and stir after reducing the rotation speed;

[0062] d): Increase the rotation speed while adding the thickener, stir evenly, and then filter to form component A;

[0063] e): Mix the obtained component A with the curing agent, stir evenly, and after aging for 5 to 10 minutes, the required coating is obtained, and the construction is carried out within the specified time, wherein, in steps a), c), and e) The corresponding additives are added before stirring, and the ratio of materials in each step is the c...

Embodiment 1

[0068] Production of A component:

[0069] Take 30kg of anionic polyacrylic acid dispersion, 0.3kg of dispersant, 0.1kg of wetting agent, 0.2kg of defoamer, 0.2kg of antifungal agent, 3.0kg of water, 15kg of rutile titanium dioxide, 10kg of filler, and disperse and shear at high speed to make slurry material, then add 20kg of anionic acrylic dispersion, 10kg of modified polysiloxane, 2.0kg of fumed silica, 0.3kg of defoamer, 5.0kg of wax emulsion, and then add appropriate amount of associative thickener and leveling agent to adjust To the required viscosity, disperse for 15 minutes, filter and pack.

[0070] In this example, component A: component B = 100:20. According to this ratio, components A and B are mixed and stirred evenly, aged for 5 minutes to form a coating, and then construction is carried out, and the coating is used up within the construction time limit.

Embodiment 2

[0072] Take 20kg of anionic polyacrylic acid dispersion, 0.3kg of dispersant, 0.1kg of wetting agent, 0.2kg of defoamer, 0.2kg of antifungal agent, 5.0kg of water, 15kg of rutile titanium dioxide, 10kg of filler, and disperse and shear at high speed to make slurry material, then add 40kg of anionic acrylic dispersion, 5kg of modified polysiloxane, 2.0kg of fumed silica, 0.3kg of defoamer, 5.0kg of wax emulsion, and then add appropriate amount of associative thickener and leveling agent to adjust To the required viscosity, disperse for 15 minutes, filter and pack.

[0073] In this example, component A: component B = 100:25. According to this ratio, components A and B are mixed and stirred evenly, aged for 5 minutes to form a coating, and then construction is carried out, and the coating is used up within the construction time limit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com