Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

134results about How to "Fast heating and cooling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

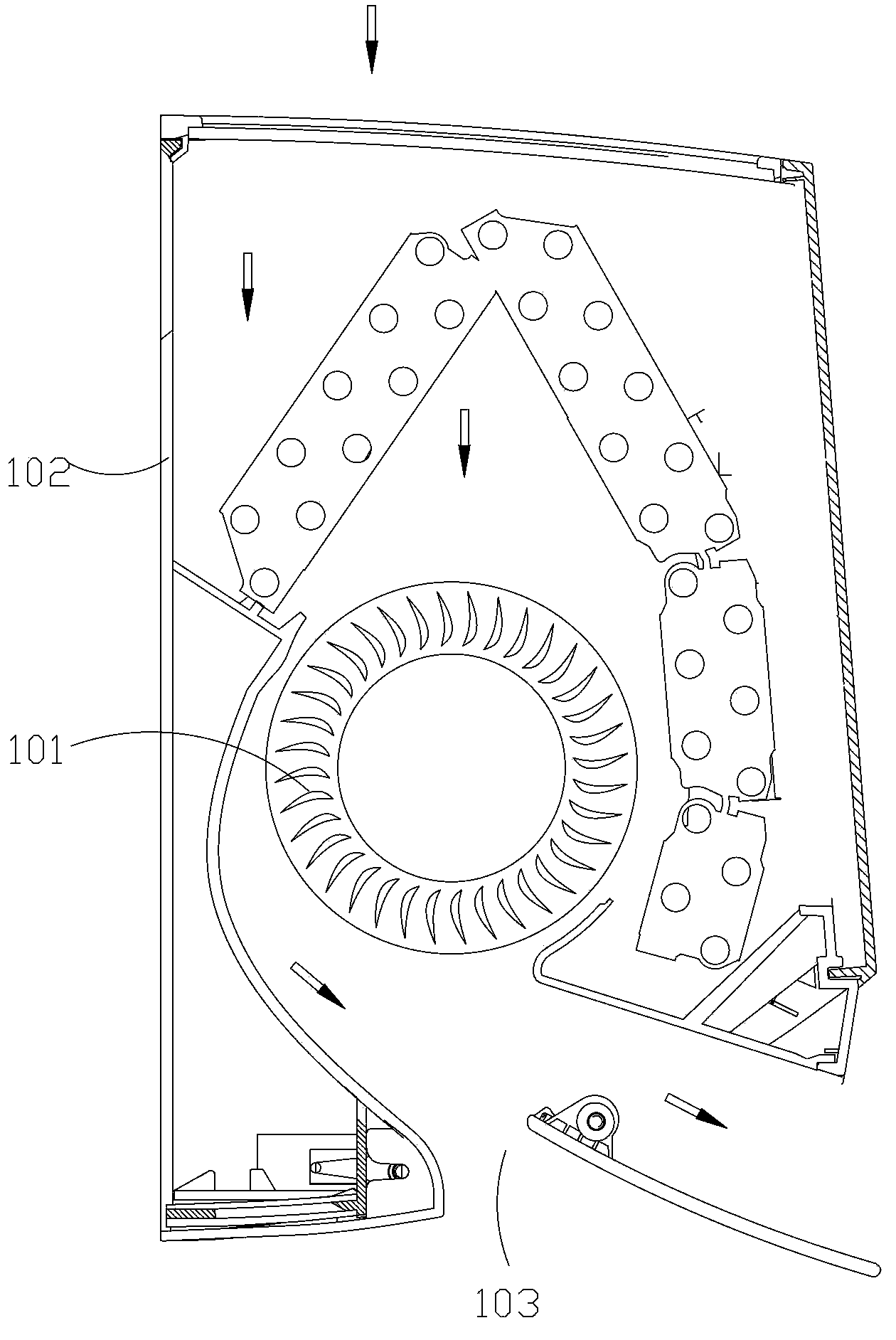

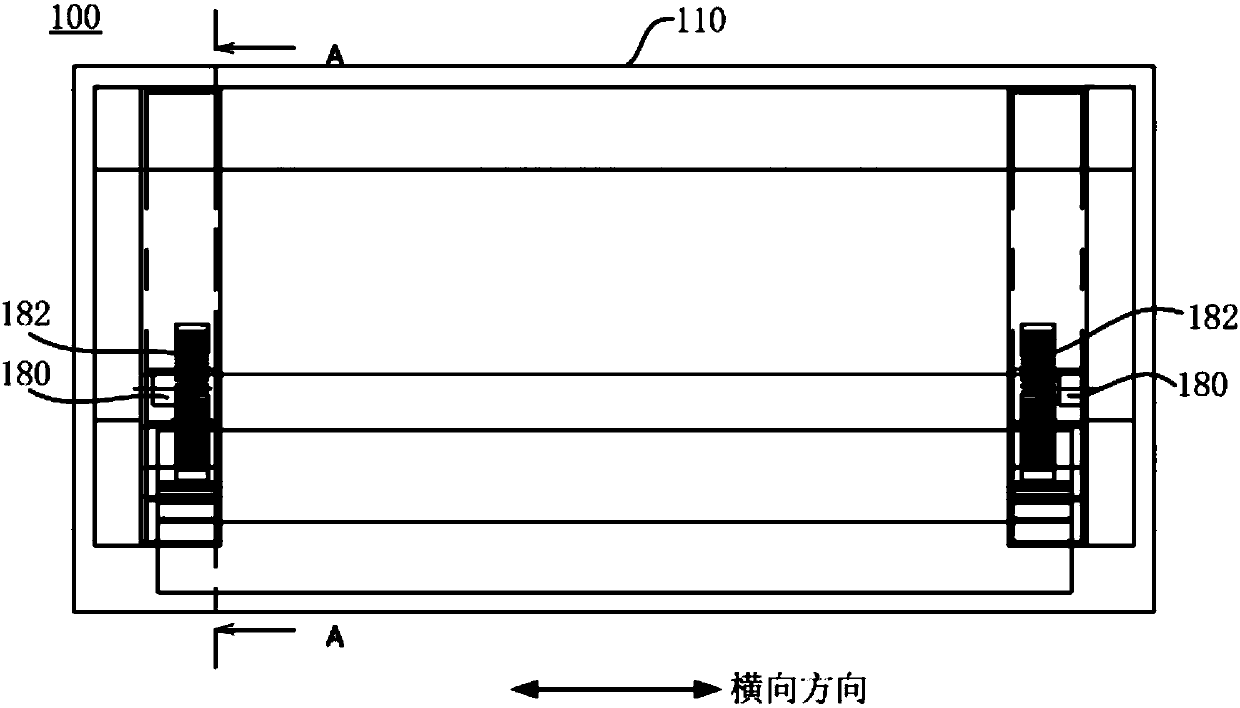

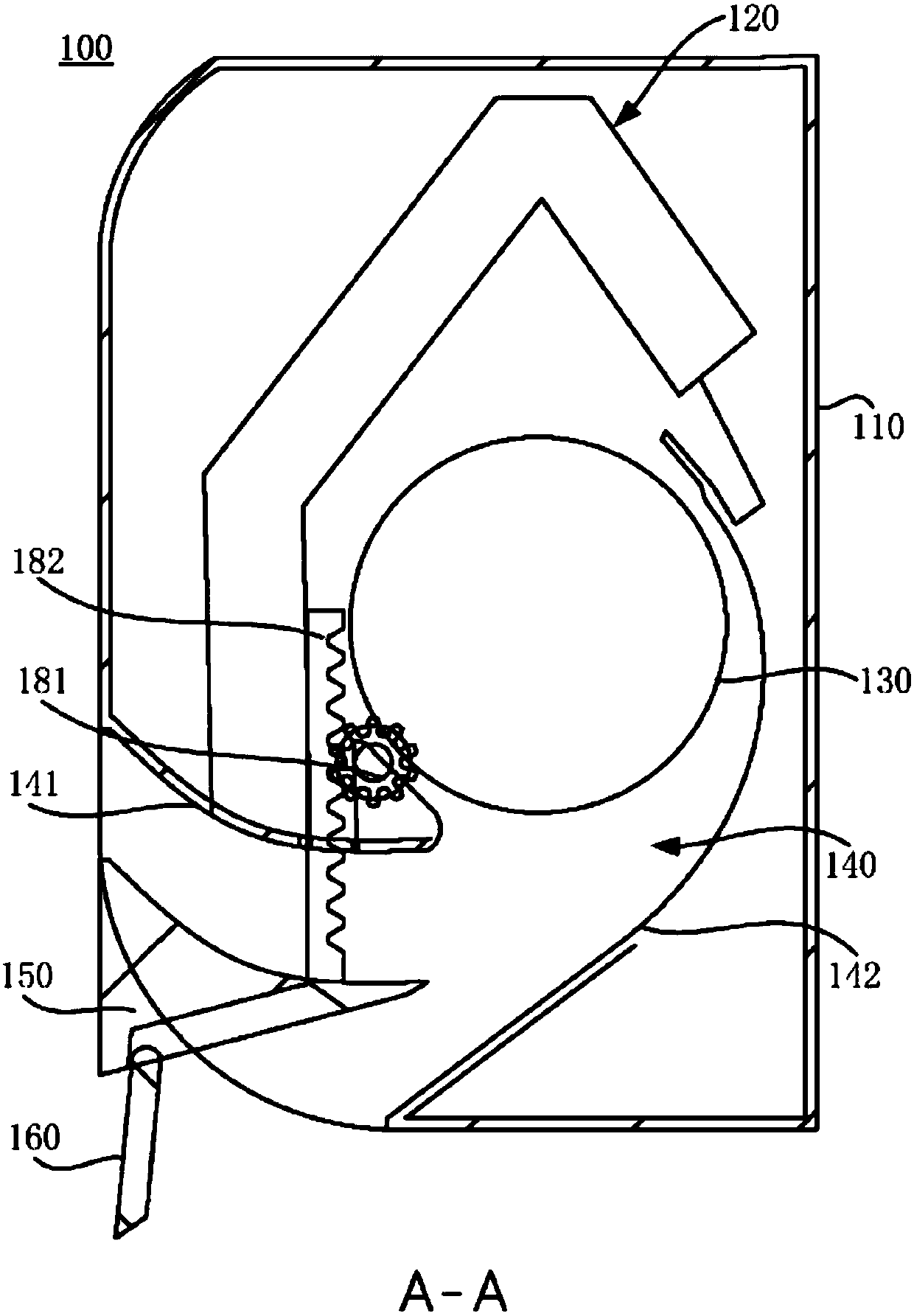

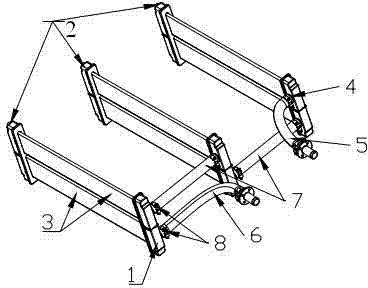

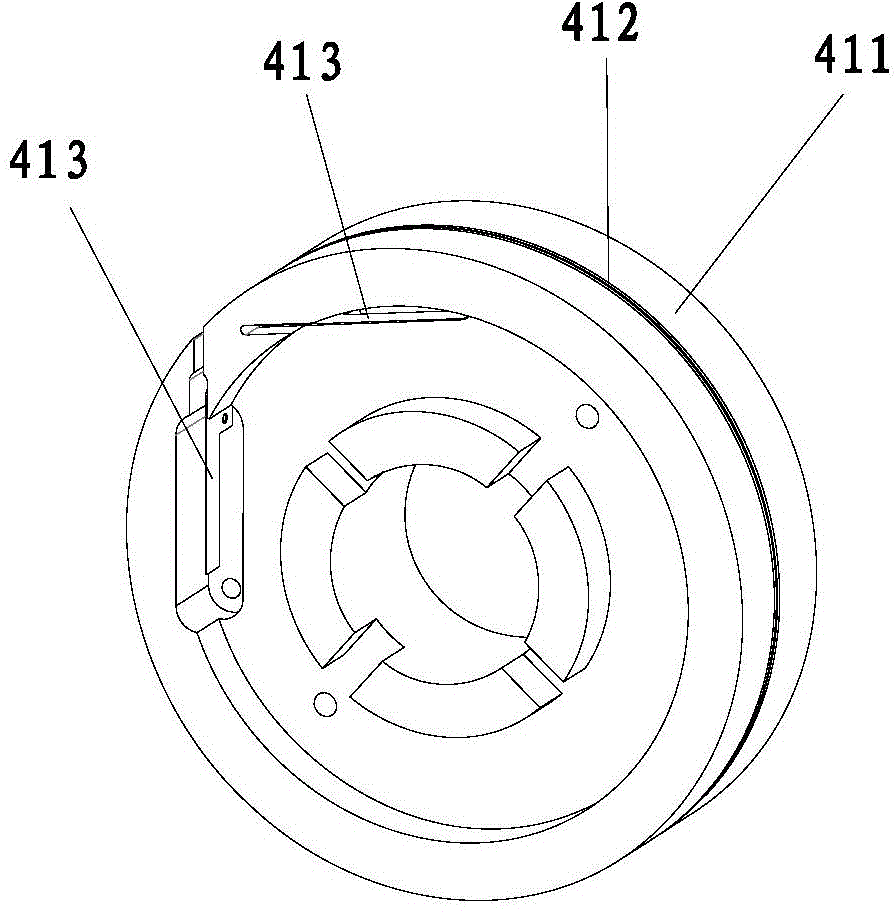

Wall-mounted air conditioner

ActiveCN104110727AExpand the range of air supplyIncrease the air supply distanceSpace heating and ventilation safety systemsCondensate preventionEngineeringCentrifugal fan

The invention provides a wall-mounted air conditioner which comprises a shell. An air intake vent and at least one air outlet are formed in the front portion of the shell. The wall-mounted air condition further comprises a heat exchanger, a front panel, a centrifugal fan, an air duct, independent ventilation parts and a controller. The heat exchanger is arranged at the air intake vent; the front panel is located in front of the heat exchanger and is rotatably mounted at the air intake vent so as to open or close the air intake vent; the centrifugal fan corresponds to the air intake vent and is located at the back of the heat exchanger; the air duct is formed in the shell and is used for communicating the air intake vent and the air outlets; the independent ventilation parts are arranged at the positions of the air outlets and supply air inwardly within 360 degrees; the controller is used for controlling the centrifugal fan, the independent ventilation parts and the front panel to act. The wall-mounted air conditioner has the advantages of little power consumption, convenience and flexibility in use, far air supplying distance, high room cooling and heating speed and good comfortableness, and multidimensional and 360-degree designated air supply can be flexibly realized.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

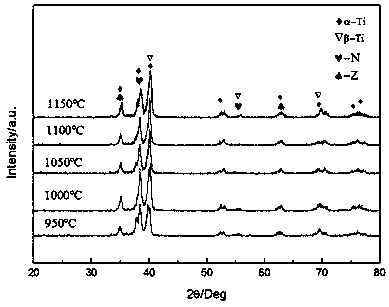

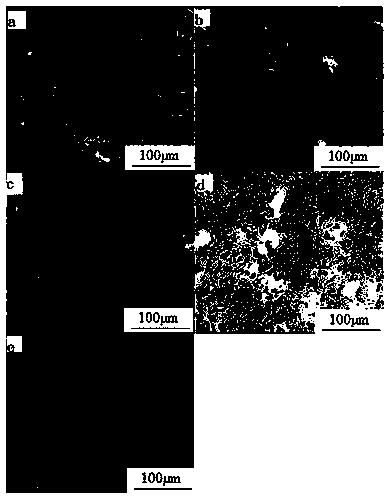

Method for preparing alloy material of high niobium-titanium-aluminum by discharging plasma agglomeration

This invention discloses a method for preparing high-Nb Ti-Al alloy by discharge plasma sintering. The method comprises: loading element mixed powder alloy powder into a graphite mold, placing in a discharge plasma-sintering furnace, applying an axial pressure of 10-80 MPa, heating at a rate of 50-800 deg.C / min in 10-2-6 Pa vacuum or inert atmosphere, sintering at 900-1400 deg.C, keeping the temperature, and cooling to room temperature to obtain high-Nb Ti-Al alloy blocks. The method can prepare highly compact high-Nb Ti-Al alloy blocks with uniform composition and high performance in a short time and at a low sintering temperature. Besides, the method also has such advantages as low energy consumption, little pollution, easy operation and good repeatability.

Owner:UNIV OF SCI & TECH BEIJING

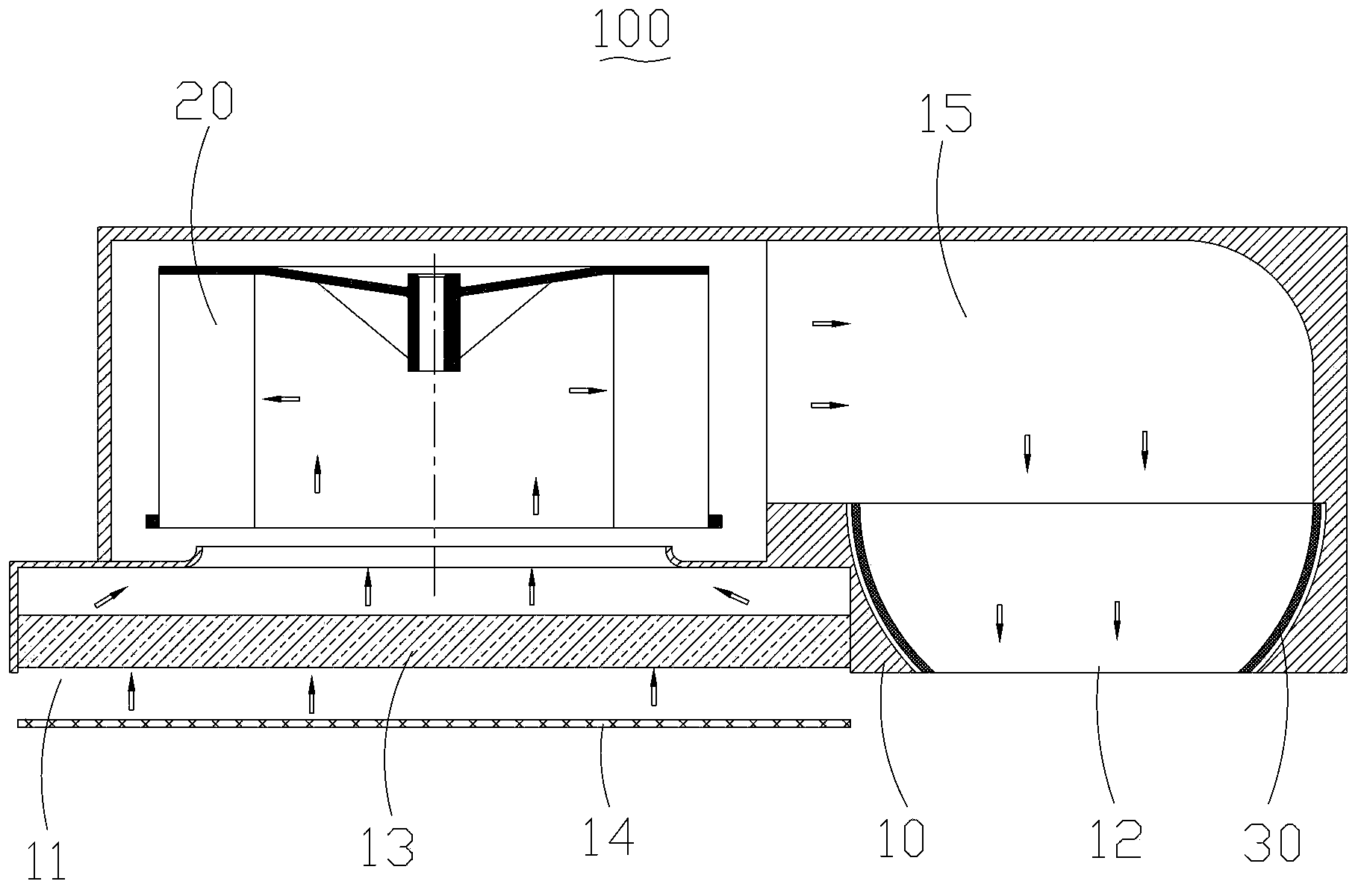

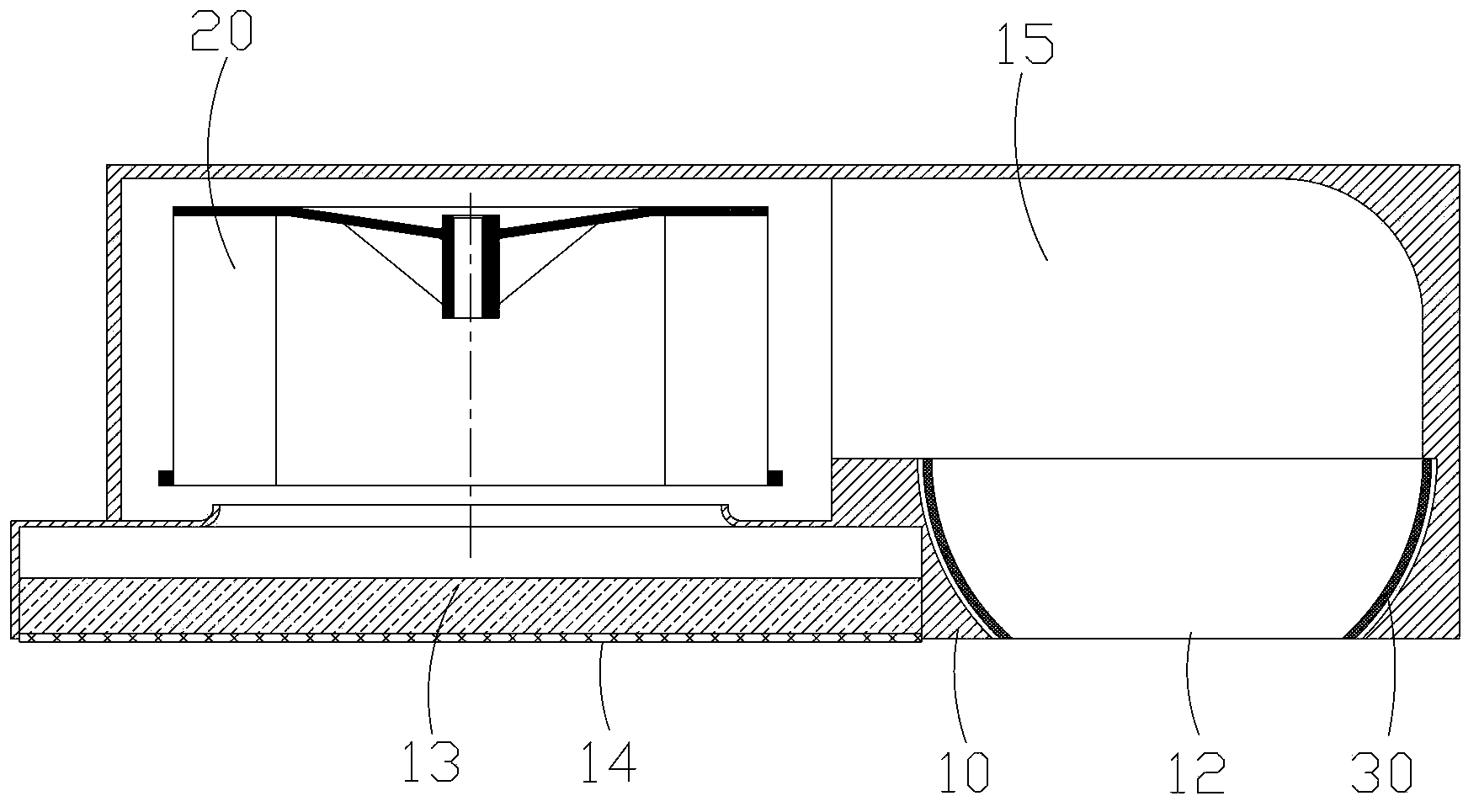

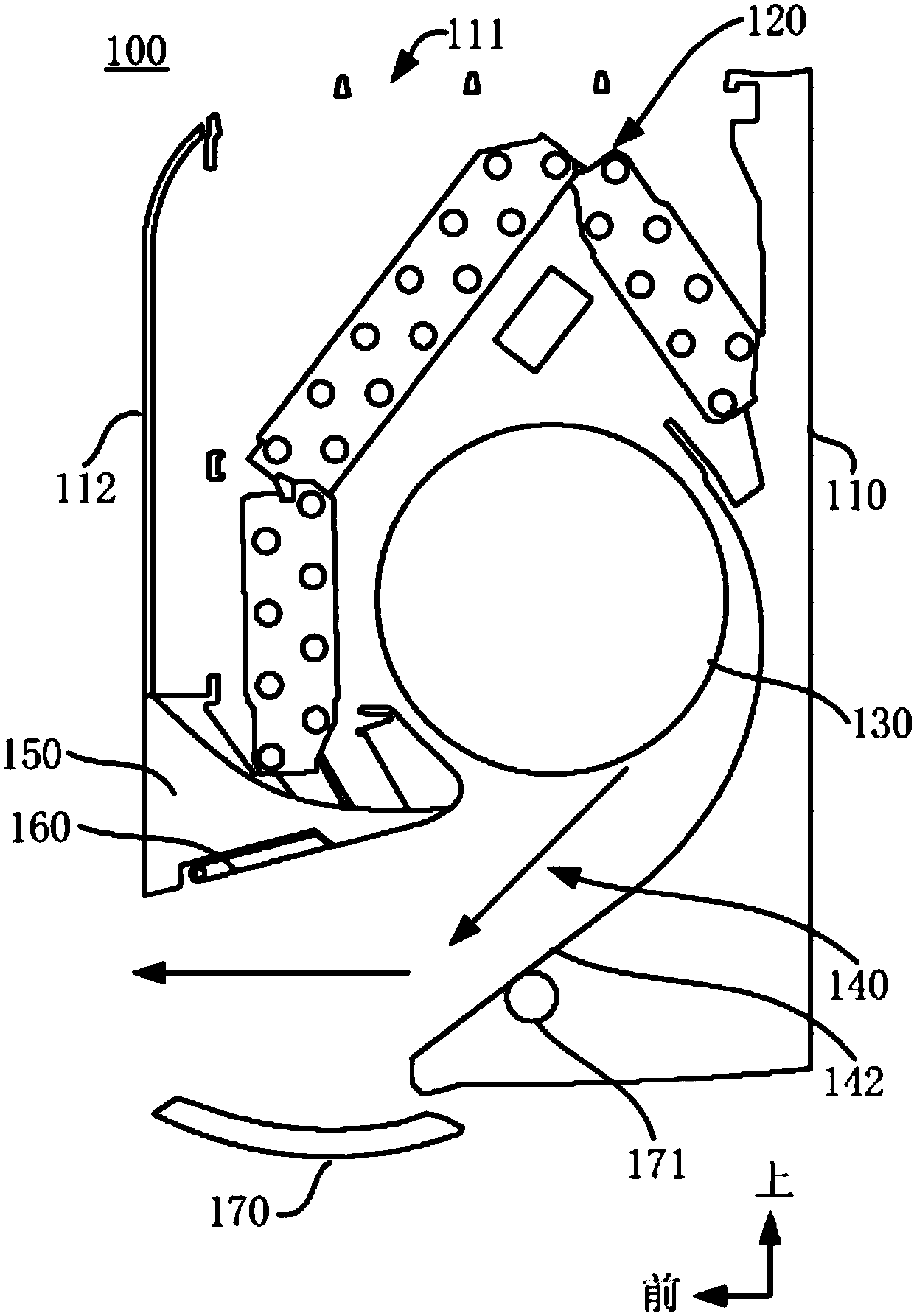

Wall-mounted air conditioner indoor unit

PendingCN107940570ARealize partition air supplyControl cycleLighting and heating apparatusAir conditioning systemsThermodynamicsAir volume

The invention provides a wall-mounted air conditioner indoor unit which comprises a shell, an air outlet channel and a flow guide block. An air outlet is formed in the lower portion of the front sideof the shell. The air outlet channel is arranged in the shell and provided with an upper air channel wall and a lower air channel wall. The outlet end of the air outlet channel communicates with the air outlet. The flow guide block is arranged at the air outlet in the mode that the flow guide block can controllably and horizontally move between the upper air channel wall and the lower air channelwall, and therefore, an air outlet area is adjusted to be a first air outlet area located on the upper portion of the flow guide block and / or a second air outlet area located on the lower portion of the flow guide block. The wall-mounted air conditioner indoor unit is provided with the flow guide block capable of horizontally moving, the air outlet area of the air outlet can be adjusted flexibly,zoned air supply with controllable air volume and air direction is achieved, thus, great air circulation in a room is controlled, and the refrigerating speed and the heating speed are increased.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

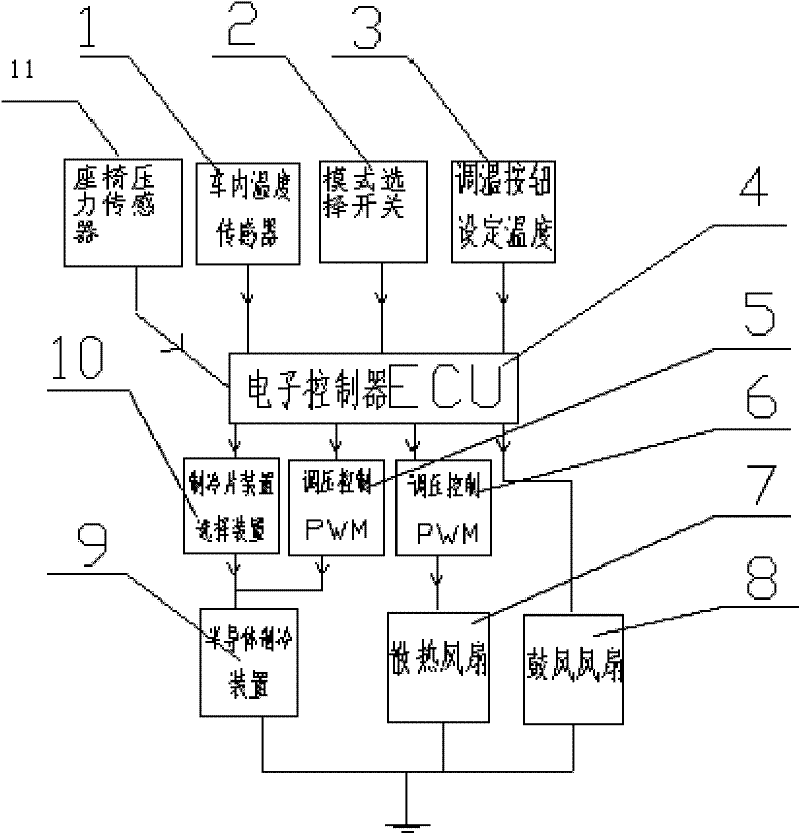

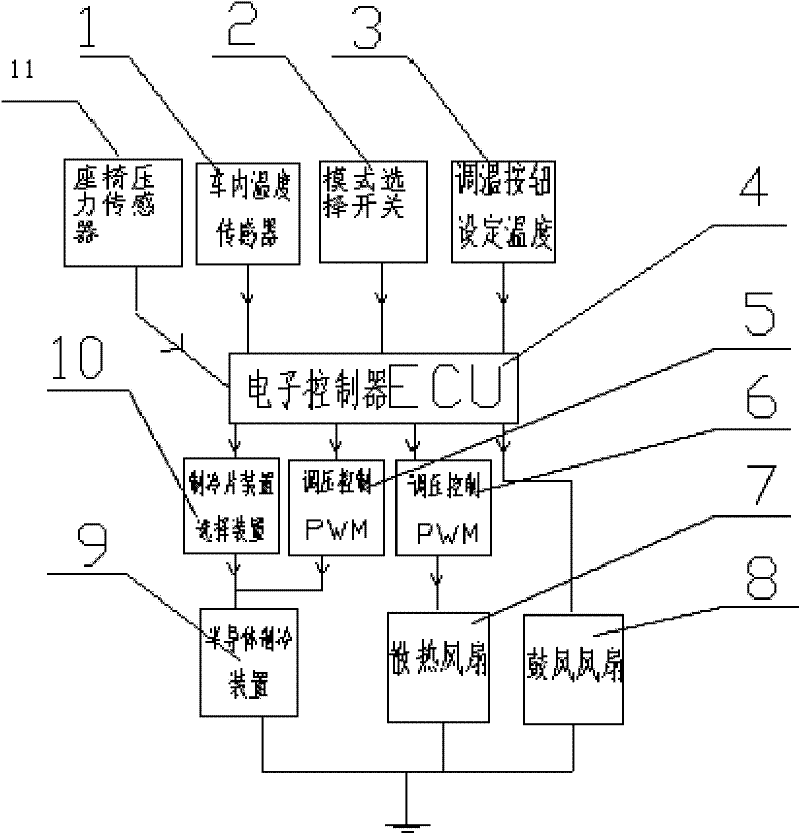

Refrigeration system for automobile air conditioner and control method of refrigeration system

InactiveCN102442177ANo vibrationNo noiseAir-treating devicesVehicle heating/cooling devicesElectronic controllerControl theory

A refrigeration system for an automobile air conditioner comprises a direct-current power supply, an electronic controller, a mode select switch, a plurality of semiconductor refrigeration pieces, a voltage-regulating control PWM (pulse-width modulation) device, a refrigeration piece select device, an in-automobile temperature sensor, a chair pressure sensor, an air-blast fan, a radiator fan and a temperature-regulating button, wherein the input end of the electronic controller is connected with the mode select switch, the in-automobile temperature sensor, the chair pressure sensor and the temperature-regulating button; the output end of the electronic controller is connected with the refrigeration piece select device; and the electronic controller can drive one or more semiconductor refrigeration pieces to work for refrigeration selectively according to temperature values and chair pressure values detected by the in-automobile temperature sensor and the chair pressure sensor as well as the temperature values set by the temperature-regulating button.

Owner:SHANDONG UNIV OF TECH

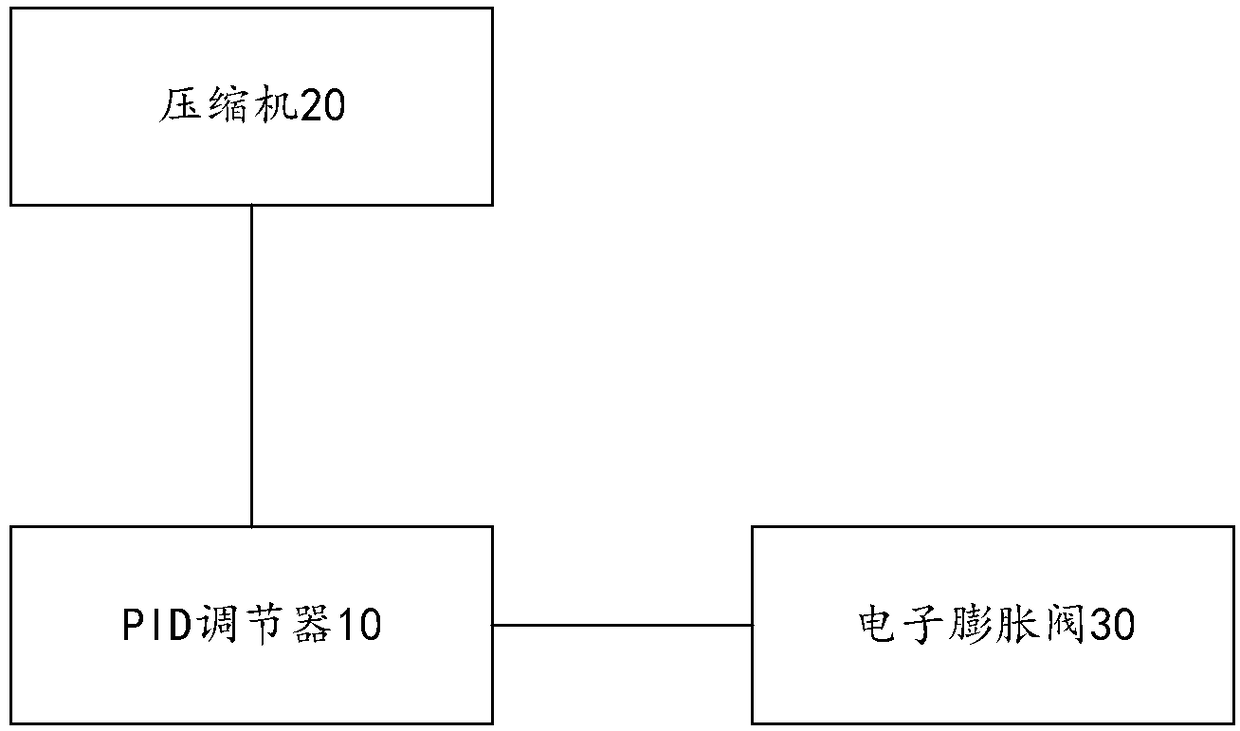

Air conditioner electronic expansion valve adjusting method, computer device and storage medium

InactiveCN108224697ARun energy savingFast heating and coolingMechanical apparatusEfficient regulation technologiesGeneration rateEngineering

The invention discloses an air conditioner electronic expansion valve adjusting method, a computer device and a storage medium. The method comprises the following steps that when a compressor is determined to be in a working state, data of a plurality of actual air exhaust temperature values are acquired within a preset time, the actual air exhaust temperature value newly obtained in the preset time is compared with the target air exhaust temperature value according to the data of the generating data of the plurality of actual air exhaust temperature values, a difference value is generated according to the comparison result, fuzzy reasoning is carried out according to the difference value and the rate, a fuzzy quantity is generated according to the reasoning result, whether a PID output mode is turned into or not is judged, if yes, the fuzzy quantity is converted into a control quantity, and the control quantity is output to control the opening degree of the electronic expansion valve.The invention further provides the computer device and the storage medium for realizing the method. According to the method, the computer device and the storage medium, a variable frequency air conditioning system is capable of being fast and stable, small in air exhaust fluctuation, higher in refrigerating and heating speed, and more energy-saving in operation.

Owner:珠海亚丁科技有限公司

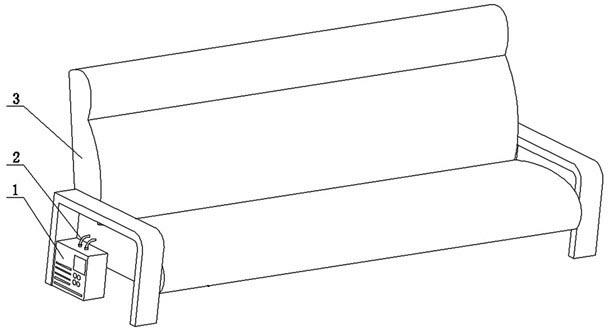

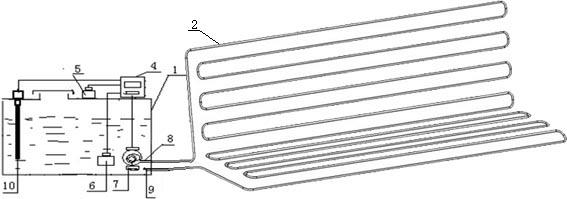

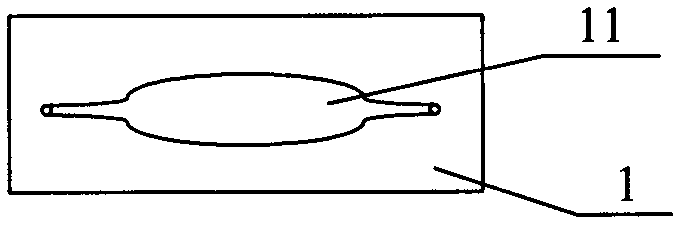

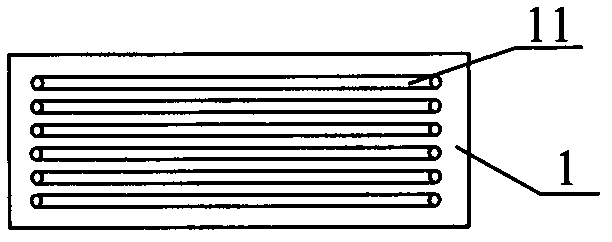

Refrigerating and heating sofa utilizing water medium

InactiveCN102578854AFast heating and coolingIncrease heatSofasCouchesTemperature controlWater storage

The invention relates to a refrigerating and heating sofa utilizing a water medium, wherein the refrigerating and heating sofa comprises a sofa support, a sofa gasket, a water storage device and heat radiation water pipes, wherein the sofa gasket is arranged on the sofa support; the heat radiation water pipes are reciprocating-type bend pipes, and pipe bodies of the heat radiation water pipes are arrayed in the sofa gasket at intervals uniformly; water inlets and water outlets of the heat radiation water pipes are arranged in the water storage device; the surface layer of the sofa gasket is provided with a sofa gasket temperature sensor; the outer part of the water storage device is provided with a temperature control device which is internally provided with a water temperature sensor, a submersible pump and an electric heating element; the temperature control device is respectively connected with the sofa gasket temperature sensor, the water temperature sensor, the submersible pump and the electric heating element through electric wires; the submersible pump and the electric heating element are arranged at the left side and the right side in the water storage pump; the water inlets of the heat radiation water pipes penetrate through the water storage device and are connected with the submersible pump; and the water temperature sensor is arranged beside the submersible pump. The refrigerating and heating sofa utilizing the water medium has the beneficial effects that the refrigerating and heating sofa can realize refrigerating and heating, and can improve temperature and lower the temperature quickly, no matter in severe winter or hot summer, as long as people sit on the sofa, people can be convenient to get warm and enjoy cool.

Owner:SHANGHAI INST OF TECH

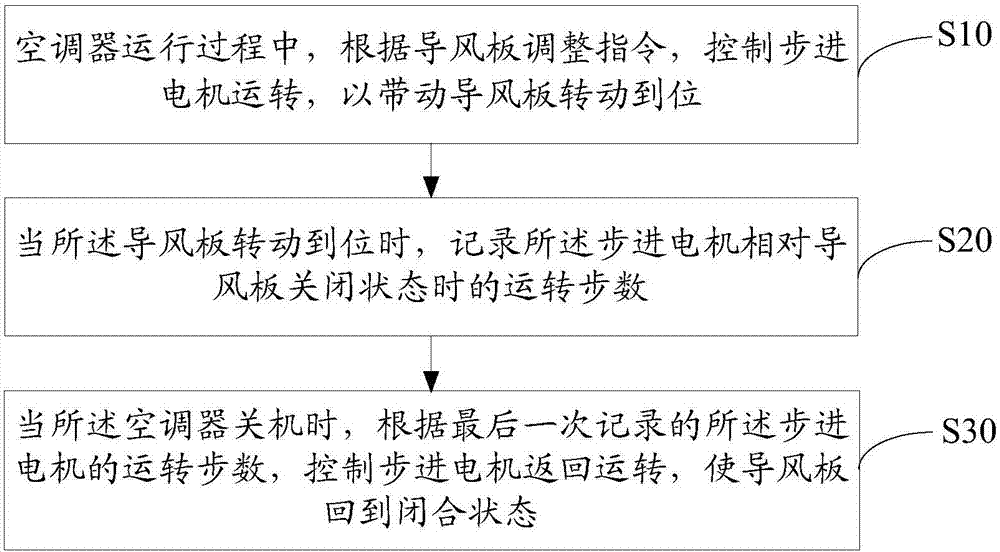

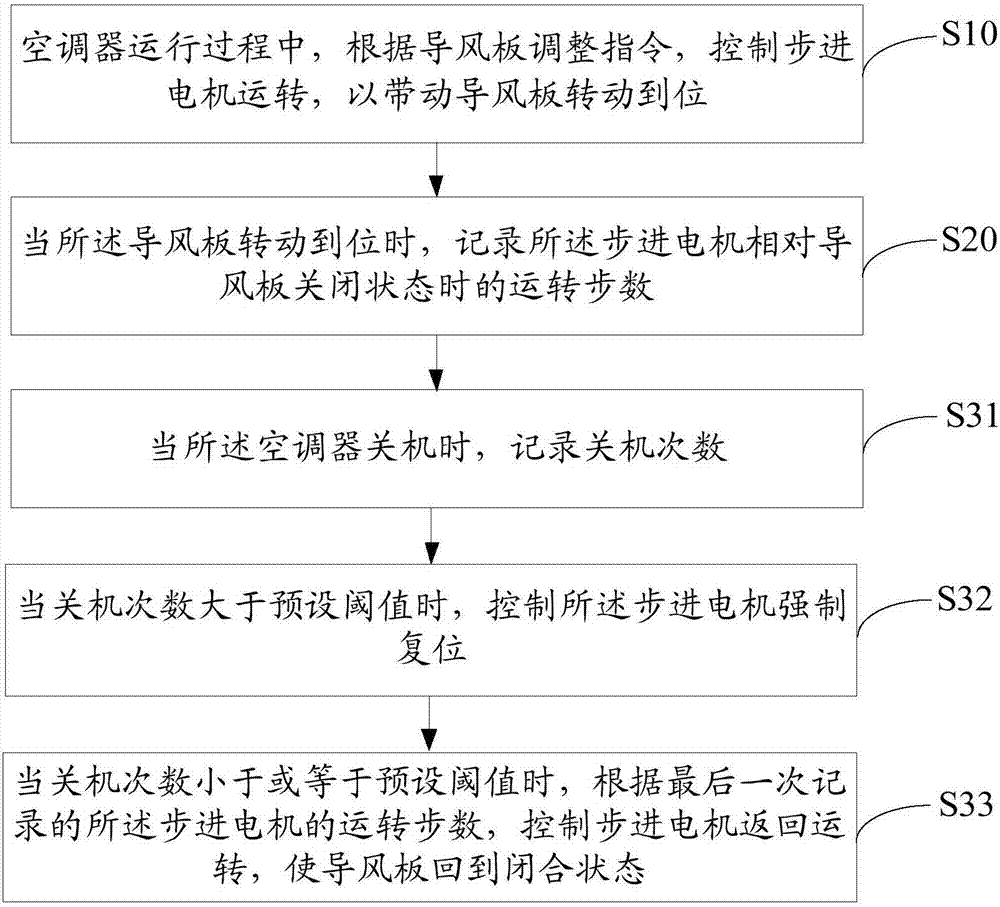

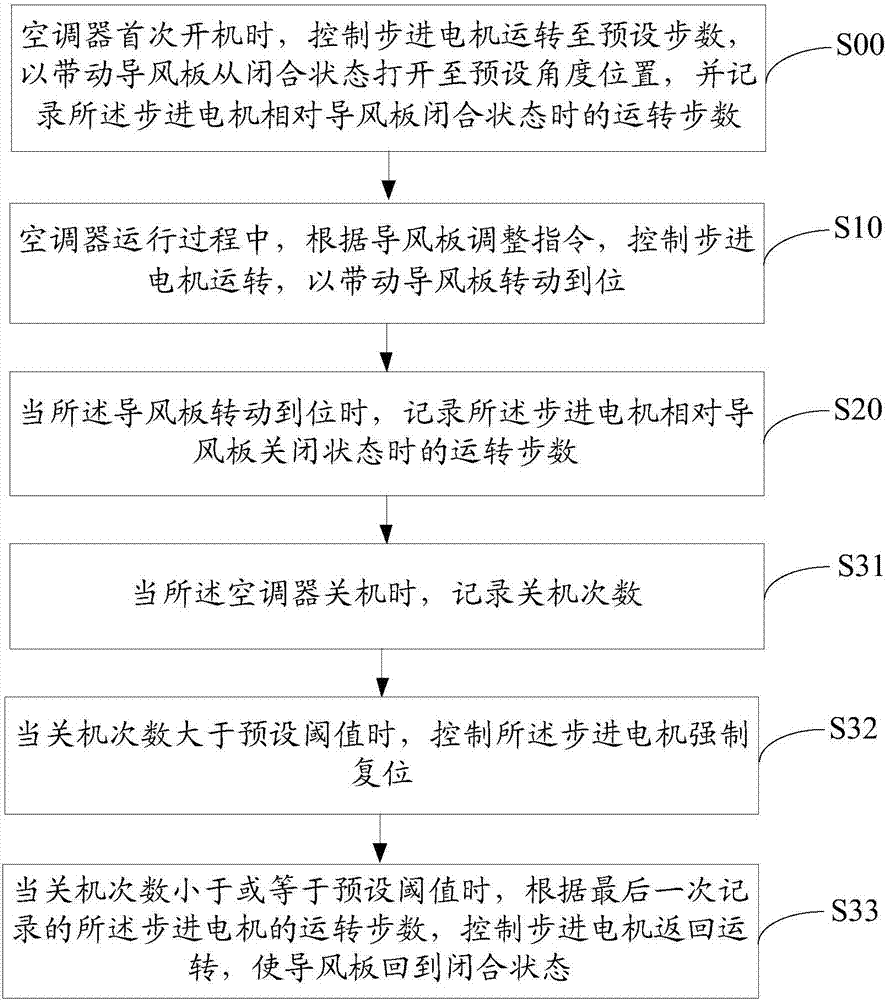

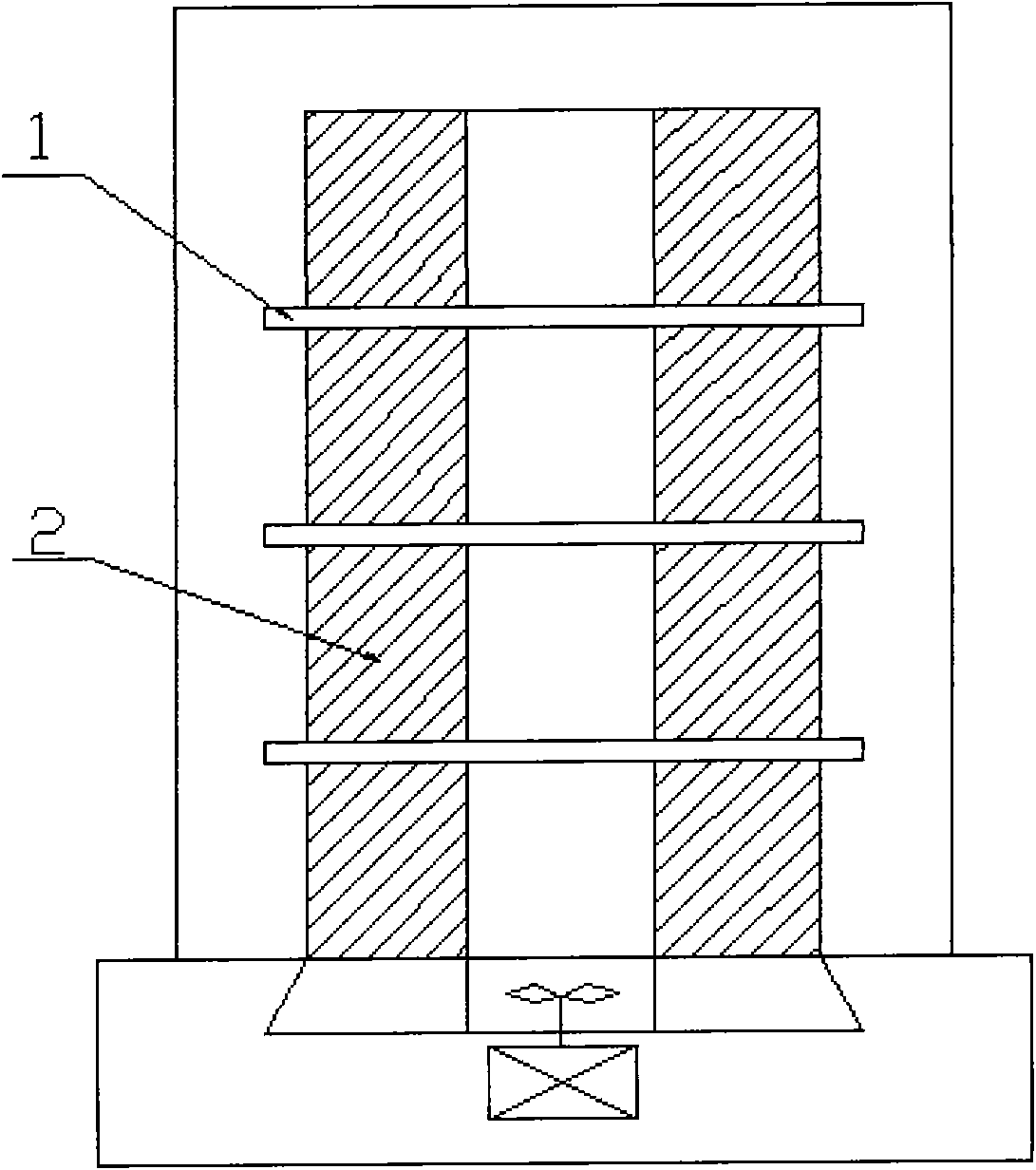

Step motor control method for air conditioner as well as air conditioner

ActiveCN107062513ADelayed resetFast heating and coolingSpace heating and ventilation safety systemsLighting and heating apparatusStep numberEngineering

The invention discloses a step motor control method and device for an air conditioner. The step motor control method for the air conditioner comprises the following steps of regulating an instruction according to an air guide plate to control a step motor to operate in an operation process of the air conditioner, and driving the air guide plate to rotate to the position; when the air guide plate rotates to the position, recording the operation step number, relative to a closed state of the air guide plate, of the step motor; and when the air conditioner is shut down, controlling the step motor to return to operate according to the operation step number, recorded at the last time, of the step motor, and enabling the air guide plate to return to the closed state. The step motor control method for the air conditioner shortens a return process of the step motor of the air conditioner, so that refrigerating / heating speed of the air conditioner is increased, and the service life of the step motor of the air conditioner is prolonged; and meanwhile, the step motor control method for the air conditioner further can reduce noises in a return process of the step motor, so that user experience is improved.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

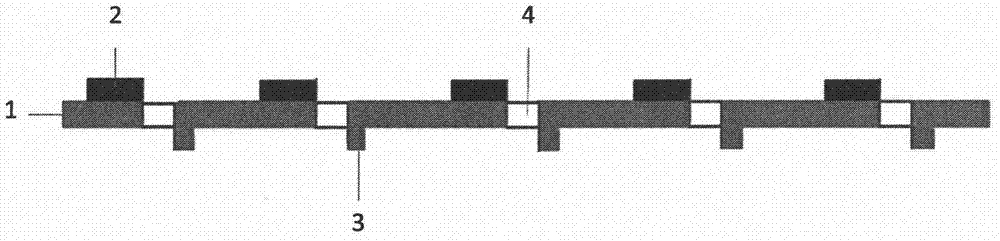

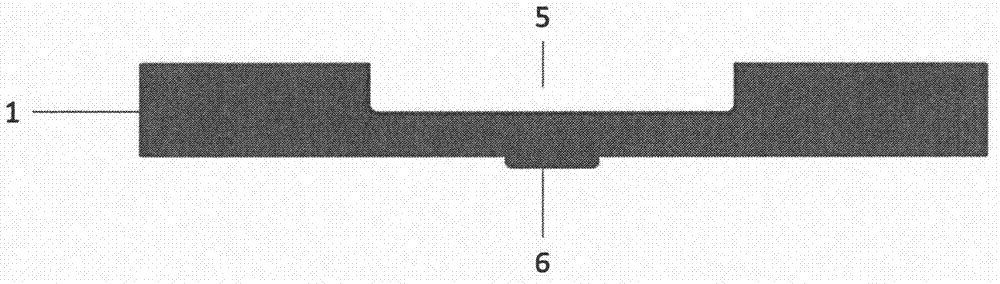

High-efficiency annealing furnace capable of avoiding bonding of cold-rolled strip steel and operating method thereof

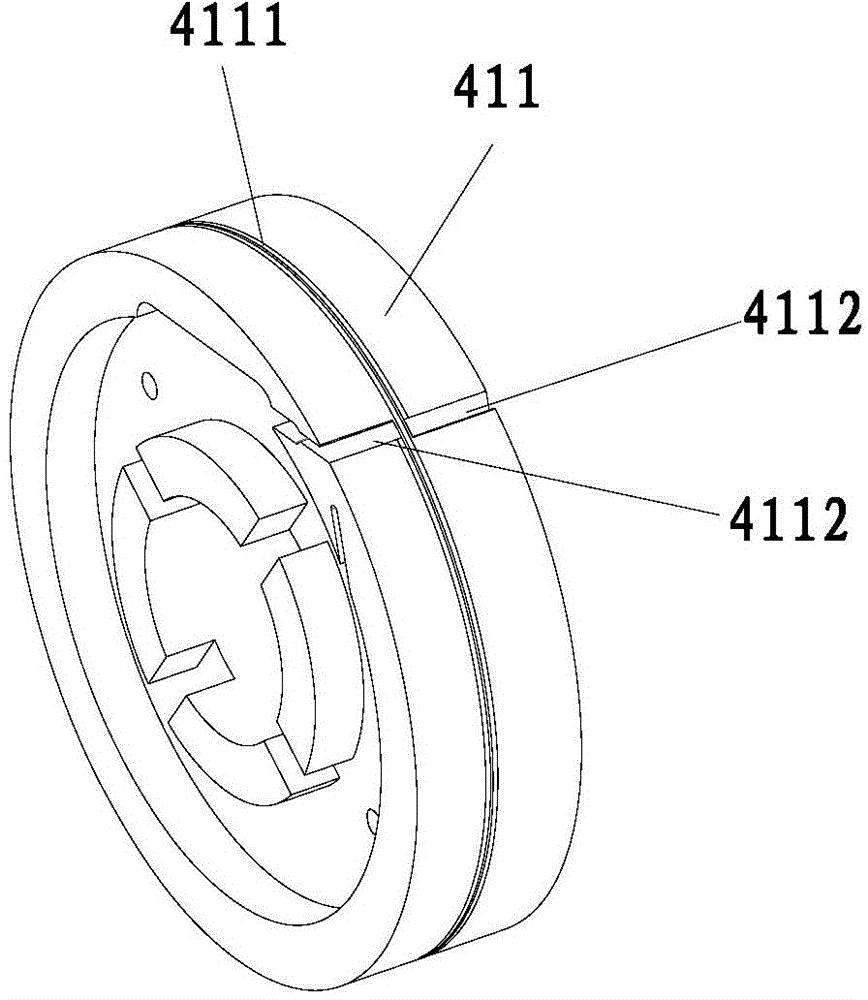

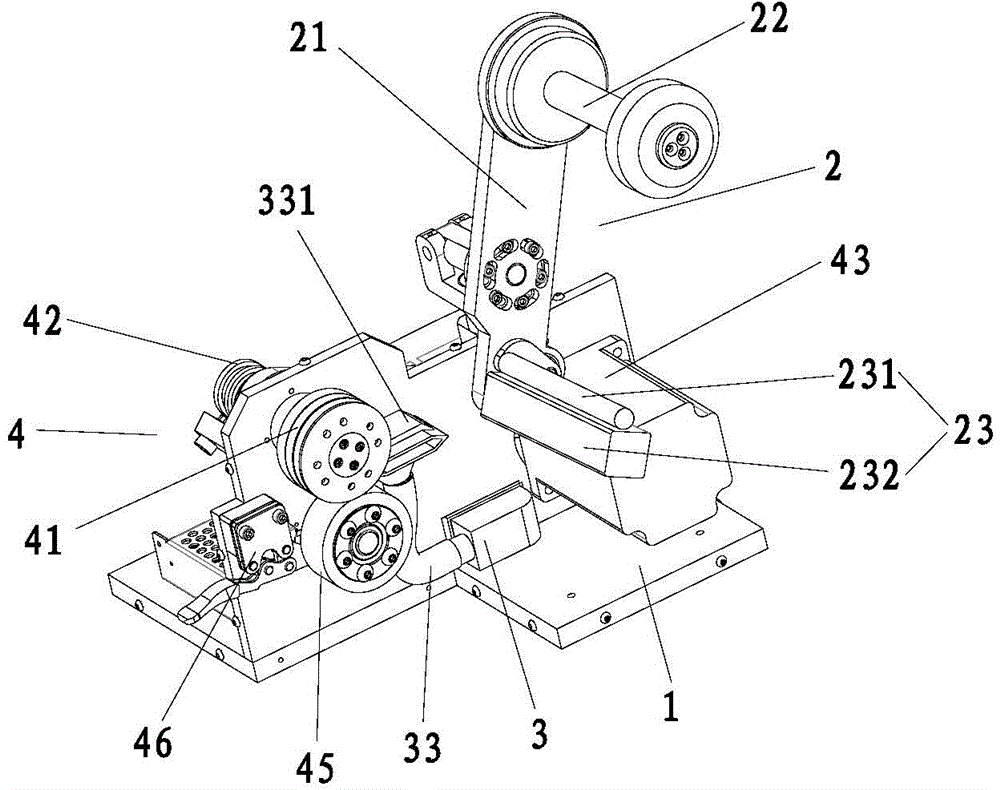

InactiveCN101886166AGood thermal cycle performanceEliminate stickingFurnace typesHeat treatment furnacesShielding gasStrip steel

The invention discloses a high-efficiency annealing furnace capable of avoiding bonding of cold-rolled strip steel and an operating method thereof. The high-efficiency annealing furnace comprises a high power blower, a segment of independent flow guide tube, guide plates provided with upper flow guide tubes and lower flow guide tubes, a guide plate only provided with a lower flow guide tube, and a sealing ring. The annealing furnace is characterized in that the independent flow guide tube (4) is positioned at the core of a first cold-rolled steel coil on a furnace platform and sleeves a reserved air port of the blower on the furnace platform in a ring manner; the upper part of the independent flow guide tube (4) is connected with the lower flow guide tubes (9) of the guide plates (5) provided with the upper flow guide tubes and the lower flow guide tubes through the heat resistant sealing ring (8); the upper flow guide tubes and the lower flow guide tubes of the guide plates (5) provided with the upper flow guide tubes and the lower flow guide tubes are sequentially connected through the heat resistant sealing ring (8); and the guide plate (6) at the upmost end is only provided with the lower guide tube (9) and is arranged between two top steel coils. In the invention, the adopted heat cycle path is as follows: a heating mantle (a cooling mantle), an inner cover, protective gas in the furnace after completing warming (cooling) convection in the middle part, outer rings of the steel coils, and heat radiation of the cores of the steel coils, thus strengthening the convection effect in the middle part and reducing the phenomenon of unbalanced inner temperature and outer temperature.

Owner:SHANDONG IRON & STEEL CO LTD

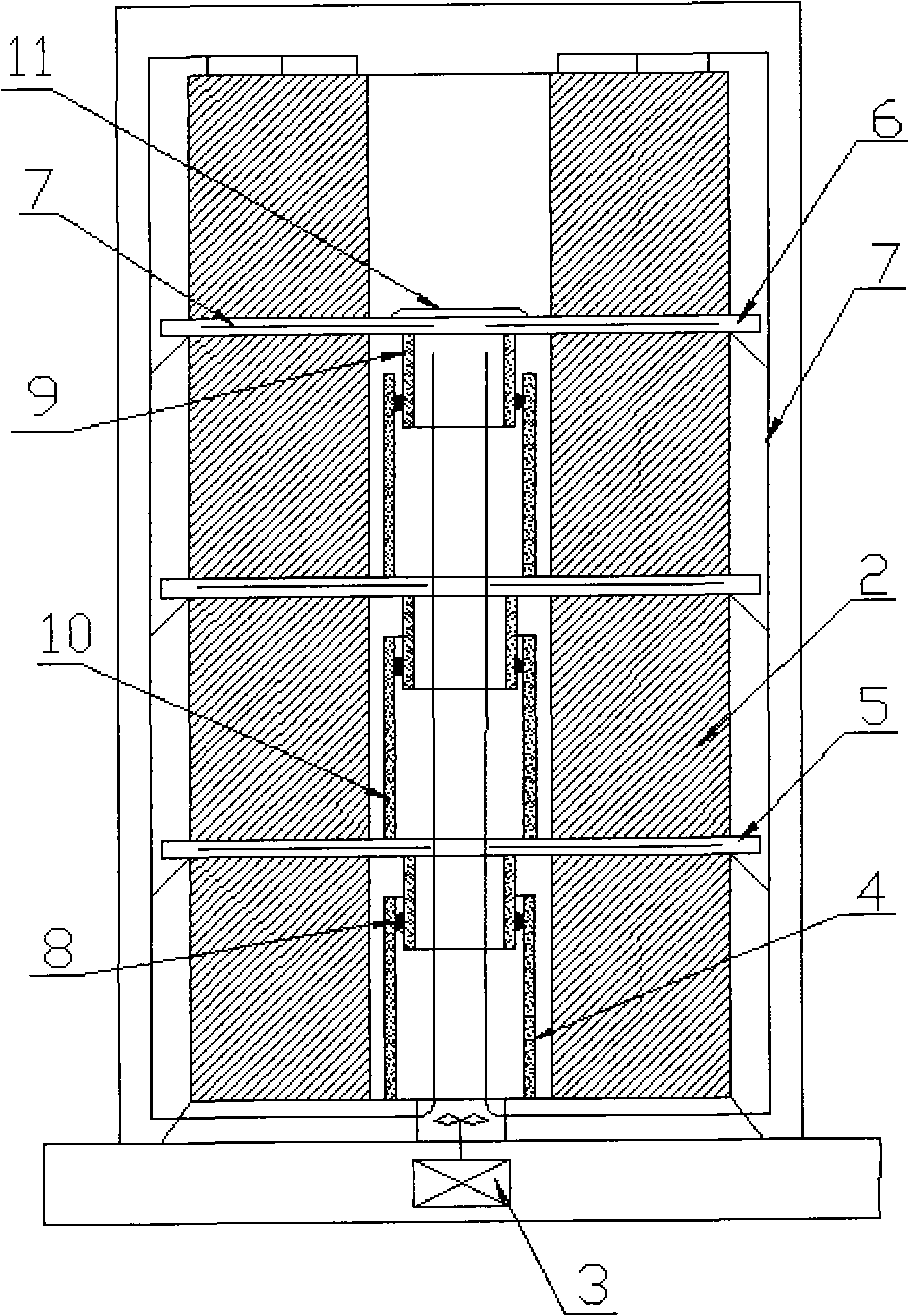

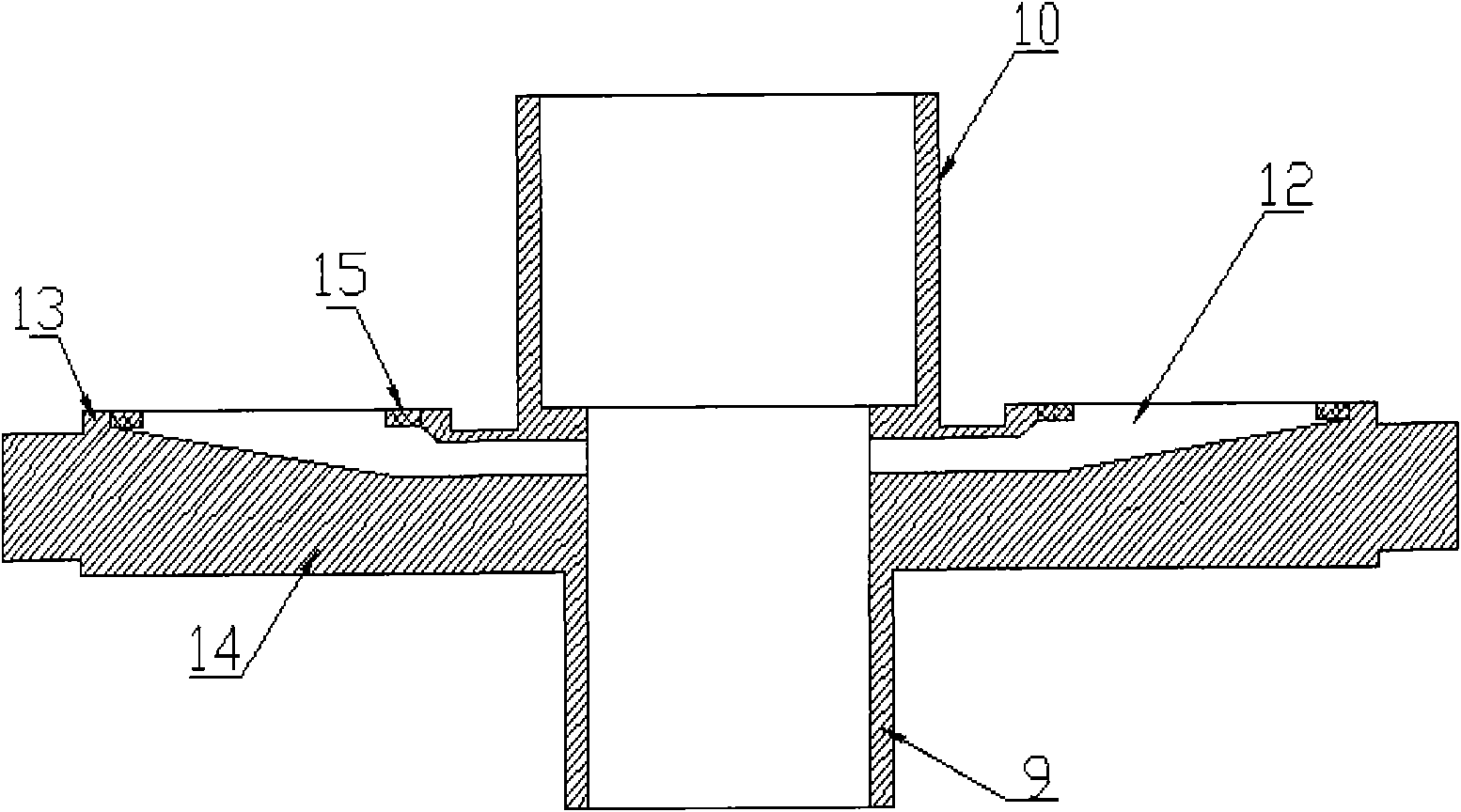

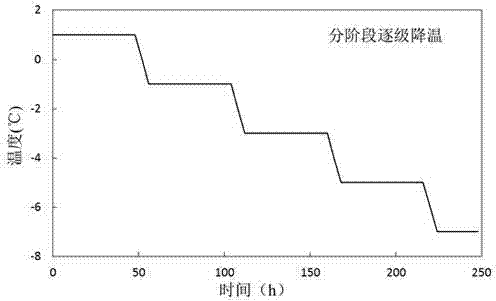

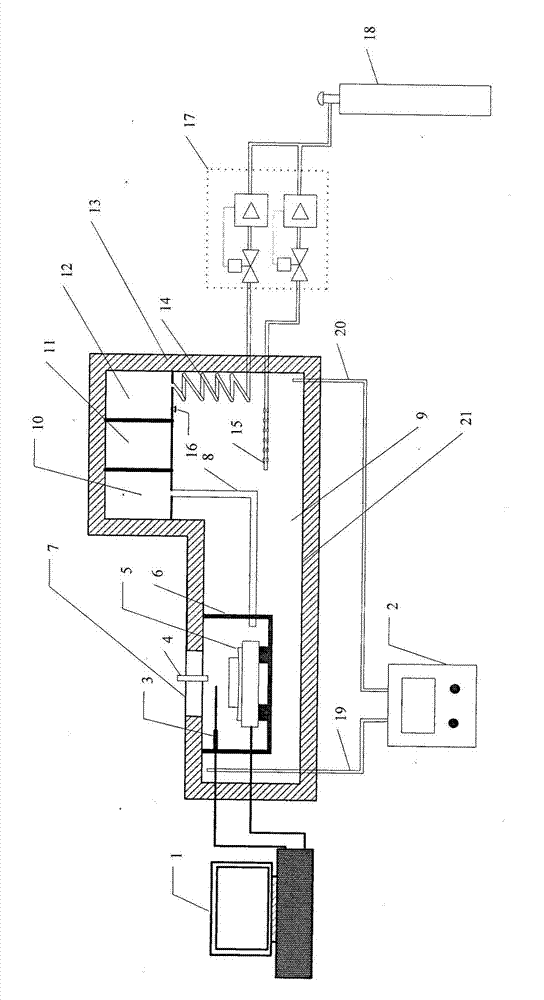

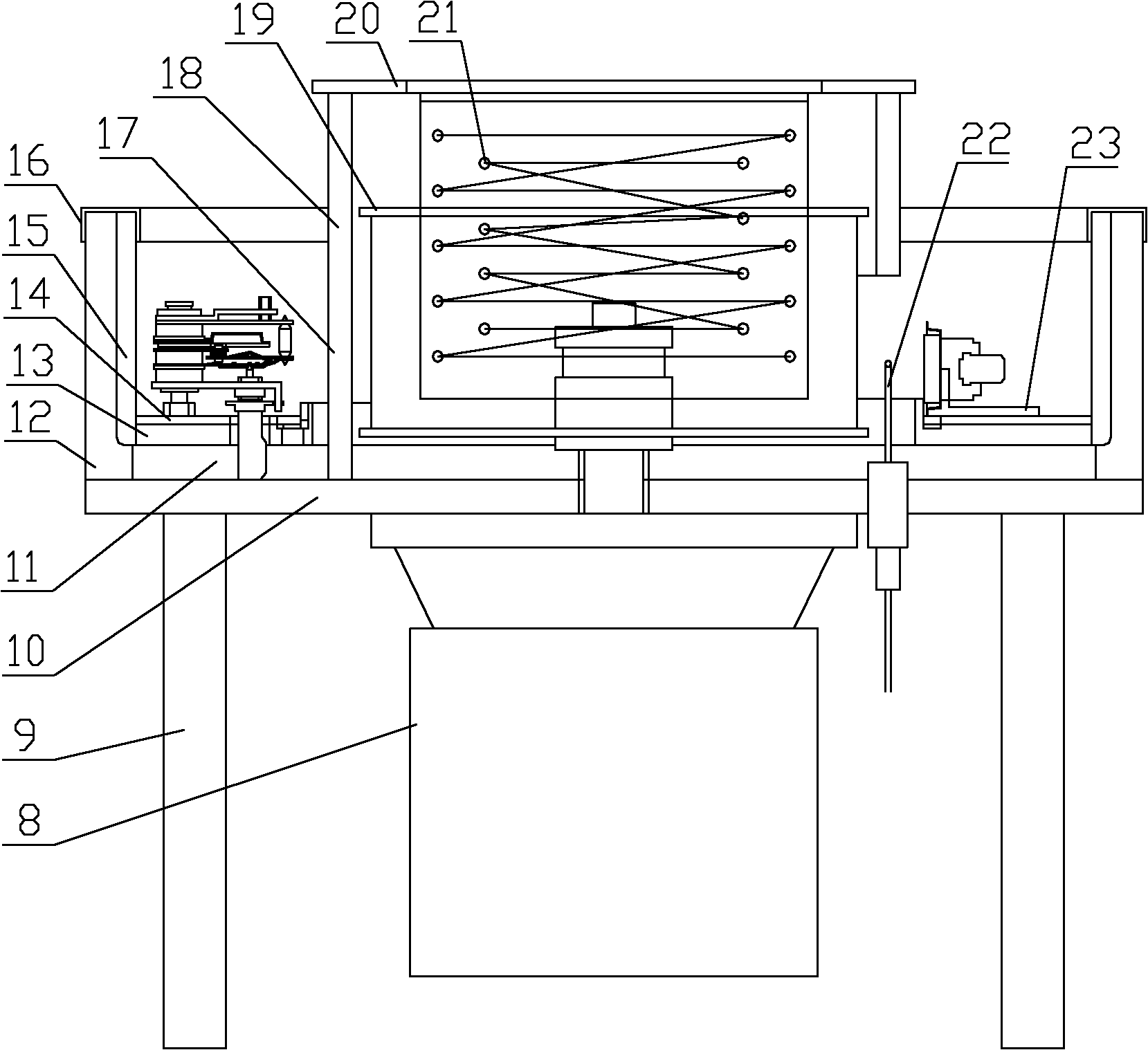

Device for testing hydrothermal variation features of hydrous porous medium in freeze thawing process

The invention relates to a device for testing hydrothermal variation features of a hydrous porous medium in a freeze thawing process. The device is characterized in that a double-layer system of internal and external model boxes is adopted, a test sample and a variety of sensors are arranged in the internal model box, the external model box mainly plays a heat preservation and thermal insulation role, refrigerating coils arranged on the inner side wall and at the bottom of the external model box are communicated with two external cold baths to control the temperature and integrally heat and cool, and such liquid with low freezing points as alcohol, kerosene and ethanediol can be placed in the interlayer space of the internal and external model boxes to improve the temperature control precision and the constant temperature effect. The device provided by the invention is mainly used for testing the hydrothermal variation feature parameters of the hydrous porous medium in the freeze thawing process, comprising temperature, volume unfrozen water content, matric suction and the like, so that a water feature curve of the hydrous porous medium in the freeze thawing process is drawn. The device provided by the invention has the advantages of simplicity in operation, stable work, high temperature control precision, high overall heating and cooling speed and the like, data are automatically collected by a data collector, and then the hydrothermal variation feature parameters of the hydrous porous medium in the freeze thawing process are effectively tested and the water feature curve is accurately obtained.

Owner:NORTHWEST INST OF ECO ENVIRONMENT & RESOURCES CAS

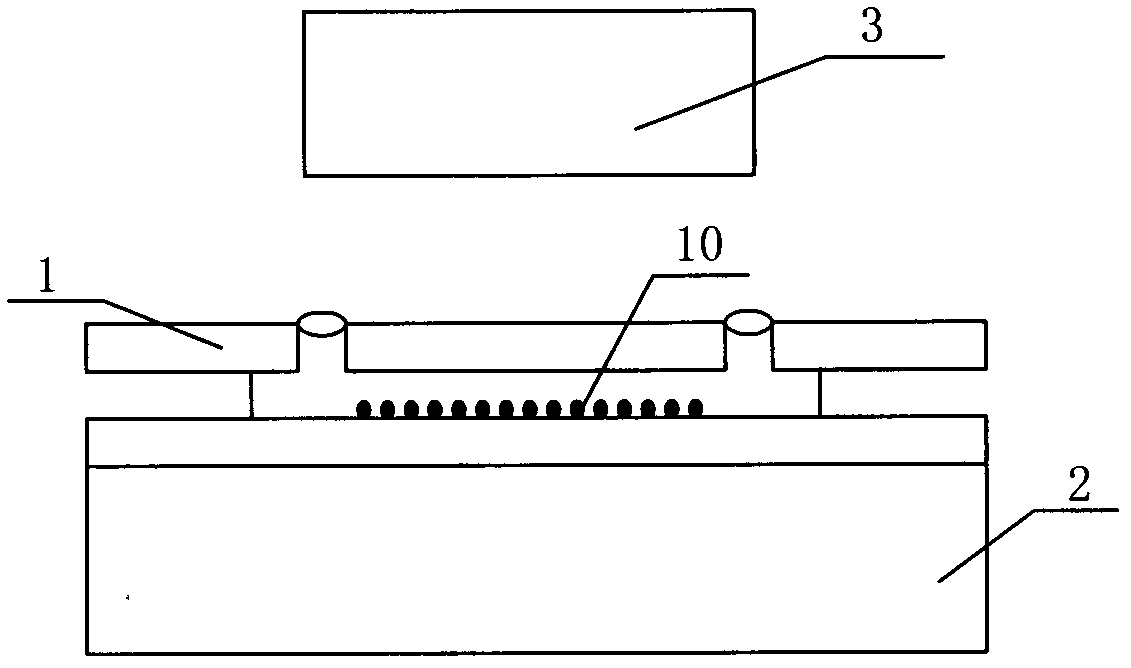

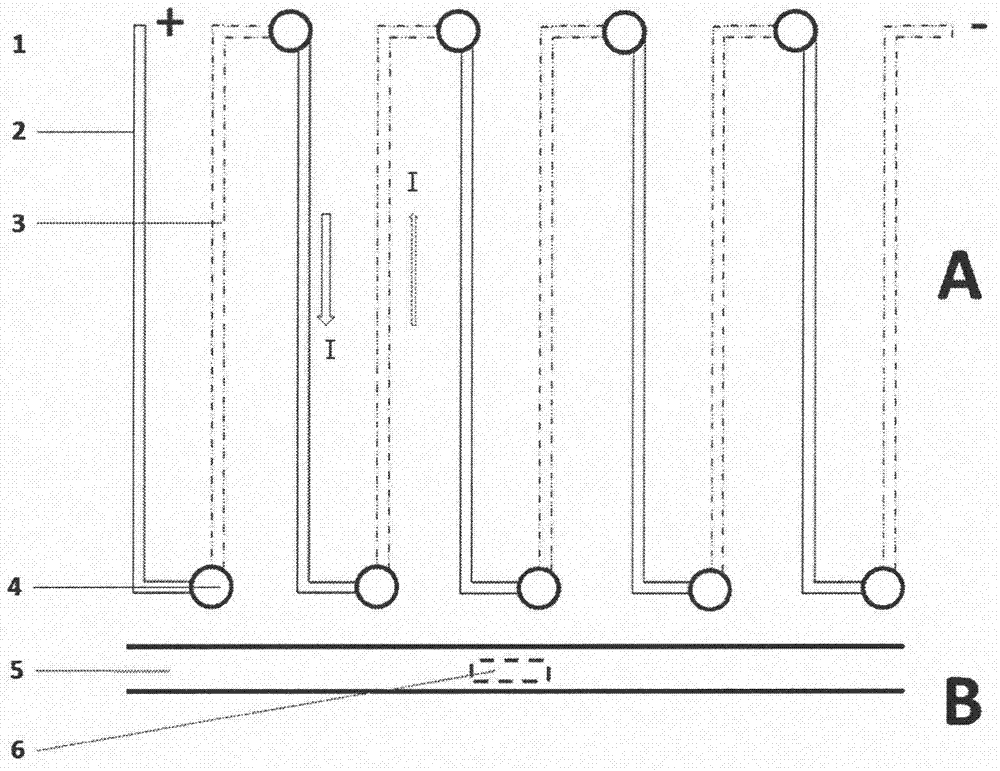

Gene sequencing equipment

ActiveCN102604826ASimple structurePrevent malfunctionBioreactor/fermenter combinationsBiological substance pretreatmentsTemperature controlGene

The invention relates to the field of biochemical equipment and provides gene sequencing equipment, which comprises a sequencing reaction chamber and a temperature control component. The sequencing reaction chamber is used for fixing samples and performing sequencing reaction; the temperature control component is fixed in an area of the sequencing reaction chamber when the samples are fixed and used for controlling temperature of the sequencing reaction chamber. The temperature of the sequencing reaction chamber rises and decreases quickly by the temperature control component, and sequencing reaction efficiency is improved.

Owner:盛司潼

Preparation method of titanium base biomedical gradient composite material

ActiveCN108380891AGood surface porosityImprove mechanical propertiesMaterials preparationCompressive resistance

The invention discloses a preparation method of a titanium base biomedical gradient composite material, and belongs to the technical field of biomedical material preparation. The method comprises thefollowing main process steps: Ti-NH4HCO3 mixed powder and TiNbZr alloy mixed powder are respectively filled in an outer layer and an inner layer of a sleeve with an annular separation plate, and are molded by pressing after taking out of the separation plate to obtain a cylinder blank with different materials of a core part and an outer layer after removal of the sleeve; after the cylinder blank is sintered by SPS, a pore forming agent is volatilized; and a block is taken out from a mold after cooling to obtain a TiNbZr / porous Ti gradient composite material with two layers of classification structures (a core part is compact TiNbZr alloys and the surface is porous titanium). The composite material prepared by the method has excellent biocompatibility and low elastic modulus matched with skeletons, is excellent in compressive resistance, can serve as an artificial bone tissue repair or replacement material, and has the characteristics of short preparation flow and simple and environment-friendly process.

Owner:KUNMING UNIV OF SCI & TECH

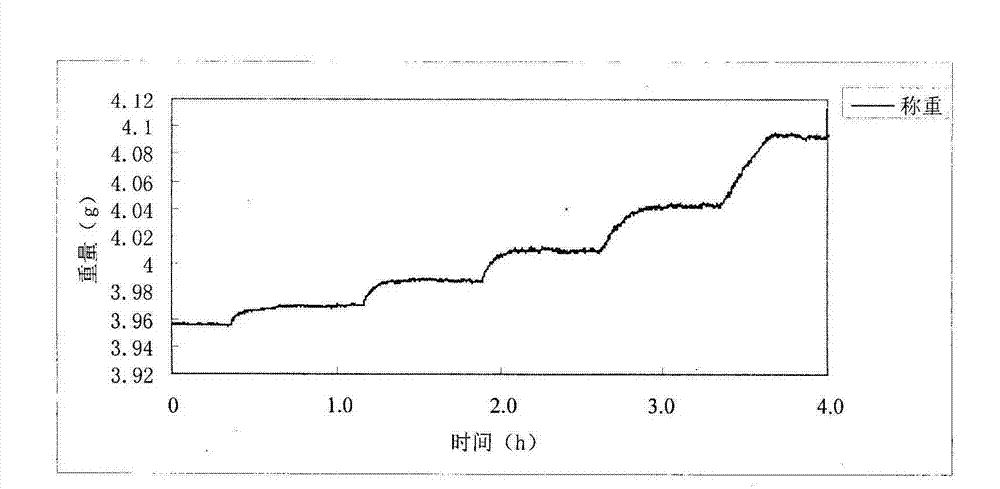

Device for detecting moisture isothermal adsorption and desorption of biomass

ActiveCN102768162AGuaranteed reliabilityGuaranteed stabilityWeighing by absorbing componentDesorptionData acquisition

A device for detecting moisture isothermal adsorption and desorption of biomass comprises a gas premixing system, a constant temperature control system, a humidity control system, a weighing system, a data collecting and recording system, and the like. The device has the advantages that (1) working temperature and humidity intervals are wide, wherein the adjustment ranges of the temperature and humidity are as follows: the temperature ranges from 5 DEG C to 50 DEG C, the control accuracy is 0.3 DEG C, the relative humidity ranges from 5% to 95%, and the control accuracy is 3%; a constant temperature tank inner container is made of high heat conduction metal so that the temperature stability is good; and the device is provided with an external heating and refrigerating circulation device so that heating and refrigerating are fast, and reliability and stability of a test are ensured; (2) the weighing system is arranged in the device with the quality measurement range of 100g and accuracy of 0.0001g; weight information of a test sample can be continuously collected through a computer so that inconvenience of frequent sampling is avoided, influences on test conditions during sampling are removed, and the test is ensured to be performed under stable conditions; and (3) test parameters are conveniently set and can achieve automatic adjusting and real-time monitoring.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

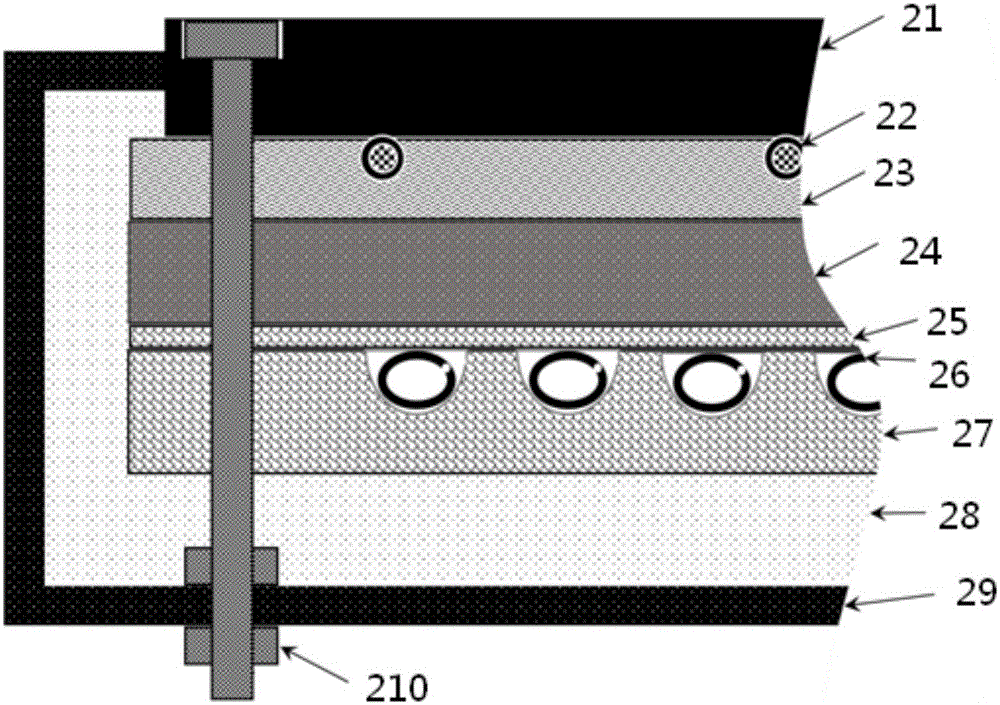

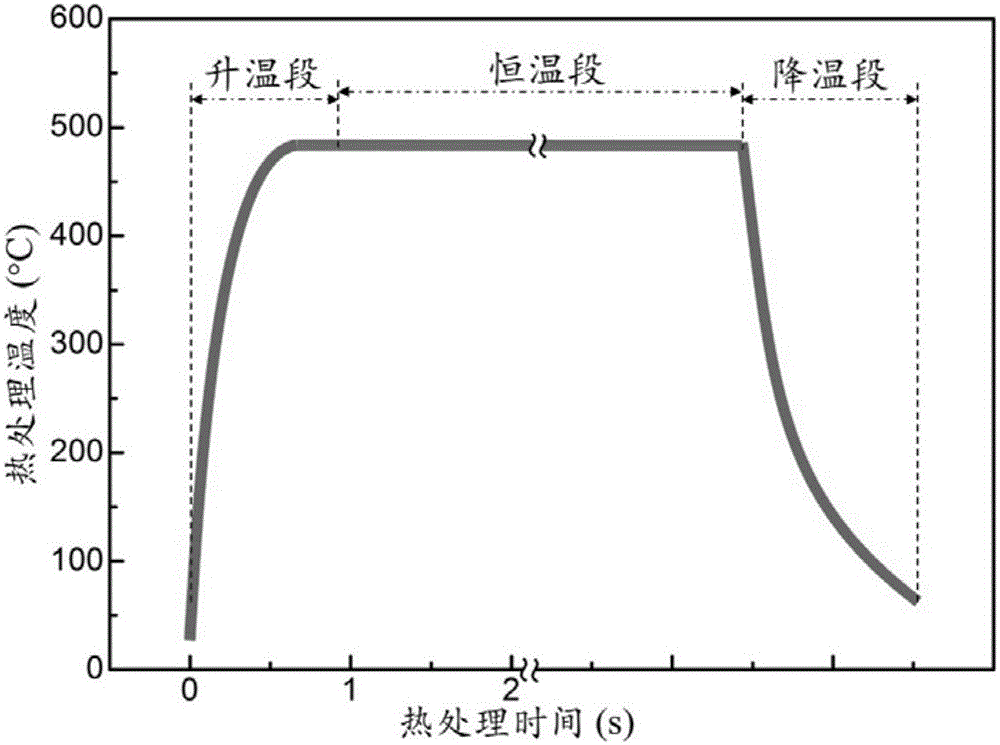

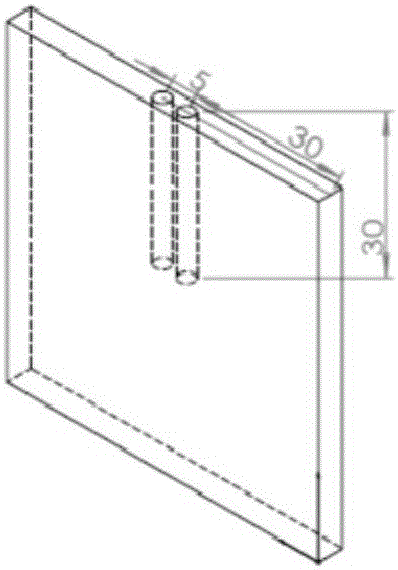

Rapid-heating heat treatment furnace

ActiveCN105157436AIncrease temperatureHigh precisionCeramic layered productsNatural mineral layered productsTime controlHeat capacity

The invention discloses a rapid-heating heat treatment furnace which comprises a furnace cavity, a positioning piece and a heat source. The positioning piece is used for fixing a sample in the furnace cavity, and the heat source is used for heating the sample. The rapid-heating heat treatment furnace further comprises a heat source driving component and a positioning piece driving component. The heat source comprises two heating plates with opposite heating faces. The heat source driving component is used for driving the two heating plates to clamp the sample or be away from each other. A radiation area is formed between the two heating plates. The positioning piece driving component is used for driving the positioning piece to enable the sample to enter or exit from the radiation area. The two heating plates are adopted to carry out two-face synchronous contact heating on the sample, so that accurate control over the ultrahigh heating and cooling speed and heat treatment time is achieved by means of the low heat capacity and high heat conductivity of the thin-belt sample in a direct-contact manner, and meanwhile the cooling speed can be adjusted as needed. The rapid-heating heat treatment furnace has the beneficial effects of being high in heating and cooling speed, convenient to operate, high in temperature and time control precision and applicable to heat treatment of low-heat-capacity and high-heat-conductivity thin belt, thin film and powder samples.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

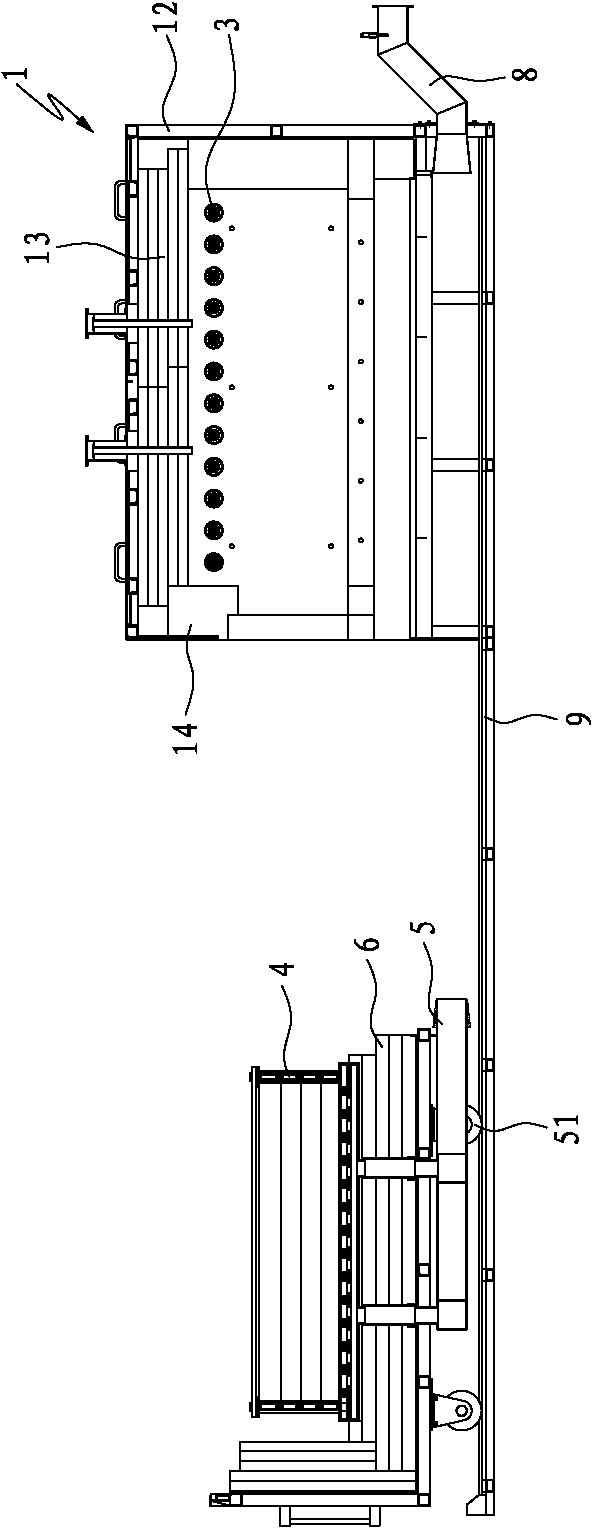

Solar polycrystalline silicon purification equipment employing directional solidification metallurgical method

InactiveCN102701213AAchieve warm-upPrecise temperature gradient controlPolycrystalline material growthFrom frozen solutionsElectricityInsulation layer

The invention discloses solar polycrystalline silicon purification equipment employing the directional solidification metallurgical method. The solar polycrystalline silicon solidification equipment comprises a furnace body and a trolley, wherein a movable door is arranged on one side surface of the furnace body; the trolley can move in and out of the furnace body; a heat preservation and insulation layer is arranged on the trolley, an ingot mold is supported on trolley, and movable wheels are arranged at the lower part of the trolley; a heat preservation and insulation layer is arranged on the inner wall of the furnace body, and a heat dissipation ventilation pipe is arranged on the furnace body; a thermoelectric couple is arranged on the furnace body; a heating silicon carbide rod is arranged on the top of a hearth of the furnace body; and the thermoelectric couple and the heating silicon carbide rod are electrically connected with a control system outside the furnace body. With the adoption of the solar polycrystalline silicon purification equipment, the efficacies of low manufacturing cost, high capacity and low power consumption are realized, the metallurgical method that silicon material is directly subjected to atmospheric high-capacity directional solidification purification after the smelting procedure is finished is also realized, the yield and the purification effect of cast ingot are improved, and furthermore, the production cost is reduced, and the large-scale production is realized.

Owner:JACO SOLAR SILICON LONGYAN CO LTD

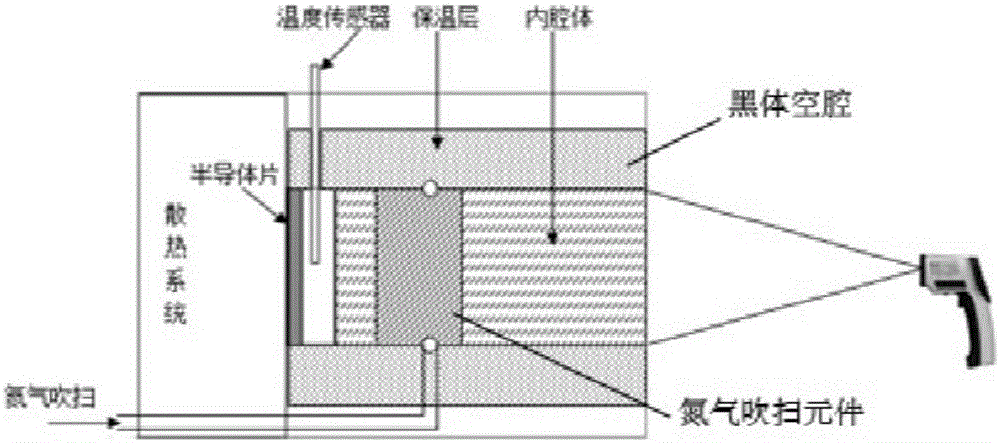

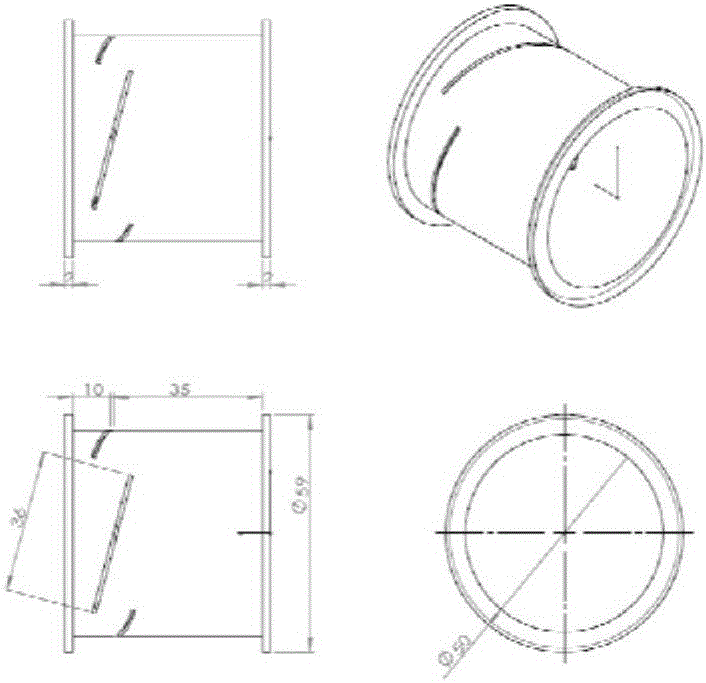

Portable blackbody metering furnace based on semiconductor and mini-sized water cooling and heat radiation technology

InactiveCN105865632AFast heating and coolingHigh emissivityRadiation pyrometryTemperature controlRough surface

The invention discloses a portable blackbody metering furnace based on a semiconductor and a mini-sized water cooling and heat radiation technology. The furnace includes a blackbody cavity of which one end is provided with a uniform temperature block. The uniform temperature block is provided with a temperature sensor at the center position inside the uniform temperature block. Outside the blackbody cavity, a surface of the uniform temperature block is closely adhered to a semiconductor sheet. A surface of the semiconductor sheet is closed adhered to a heat radiation system. Inside the blackbody cavity, a surface of the uniform temperature block is subject to rough treatment and assumes a rough surface, and is also subject to blackening treatment. The blackbody cavity is provided with a nitrogen purging element therein. An external circumference of the blackbody cavity is wrapped with a heat-insulation layer. The furnace also includes a PCB temperature control circuit which is intended for regulating heating or cooling of the semiconductor sheet based on an output of a temperature control instrument. The furnace provides a comparatively stable calibration source for a medium and low temperature infrared thermometric indicator on an industrial site to conduct accurate calibration. The furnace is easy to carry out and fast in temperature increasing and decreasing rate, and can greatly increase calibration efficiency of a radiation thermometer.

Owner:ZHEJIANG MEASUREMENT SCI RES INST

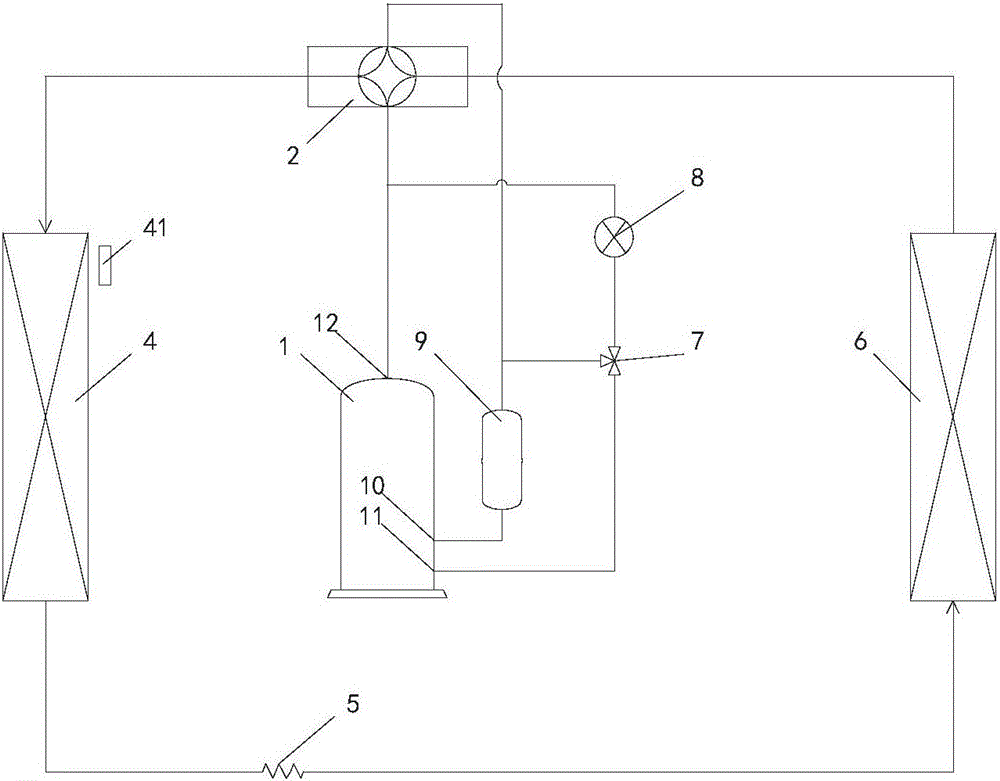

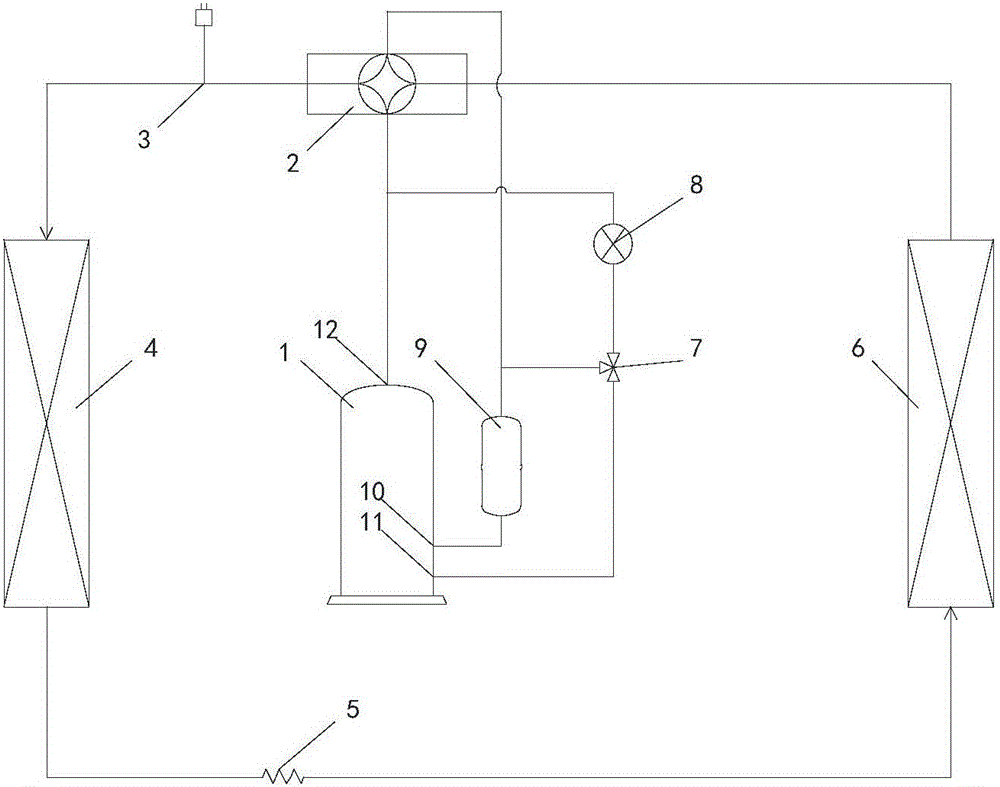

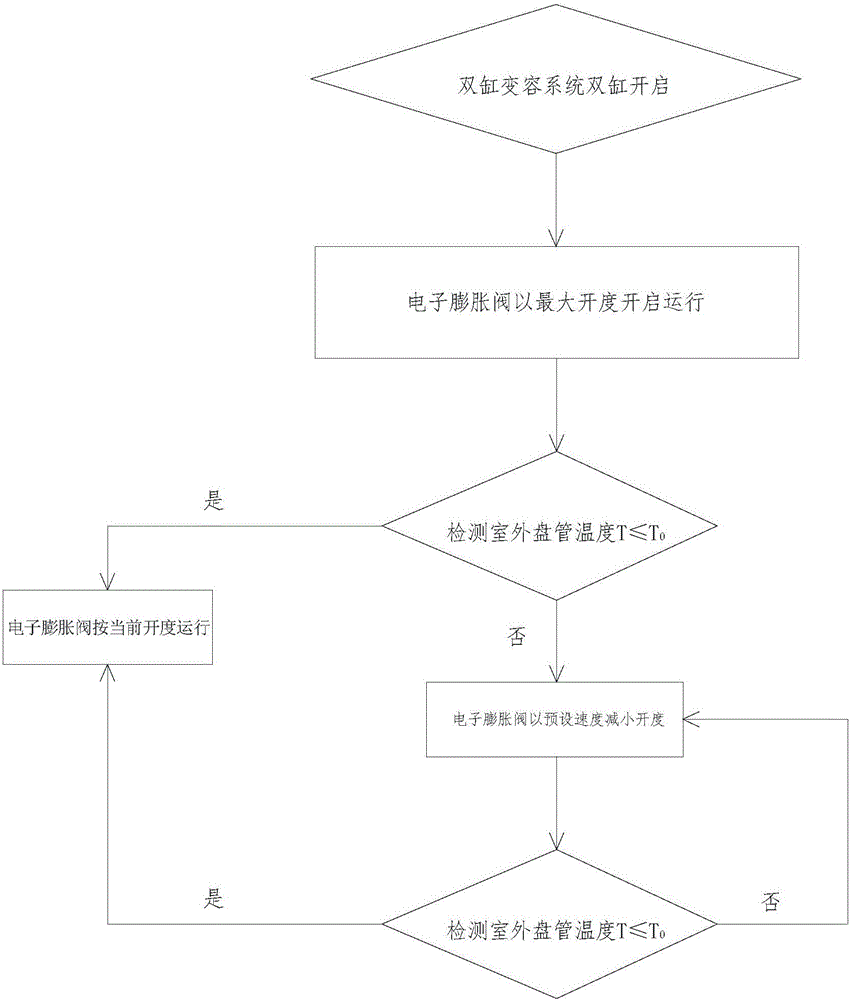

Double-cylinder variable-capacity air conditioning system and control method

ActiveCN106403349AFast cooling and heatingRegulation stabilityMechanical apparatusSpace heating and ventilation safety systemsSystem pressureEngineering

The invention relates to a double-cylinder variable-capacity air conditioning system and a control method thereof. The double-cylinder variable-capacity air conditioning system comprises a double-cylinder variable-capacity compressor, a four-way valve, an outdoor heat exchanger, a throttling assembly and an indoor heat exchanger which are connected to be a loop, and further comprises an electronic expansion valve, wherein the outdoor heat exchanger is equipped with a temperature sensor for detecting the temperature of an outdoor heat exchanger coil pipe; and a pressure sensor for detecting pressure of the air conditioning system is arranged on a pipeline between a gas outlet of the double-cylinder variable-capacity compressor and the outdoor heat exchanger. According to the double-cylinder variable-capacity air conditioning system and the control method thereof, stable regulation can be carried out according to practical parameters to keep temperature stability, so that temperature difference fluctuation is small; and the double-cylinder variable-capacity air conditioning system saves energy and is comfortable, and reliability of the system is improved.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

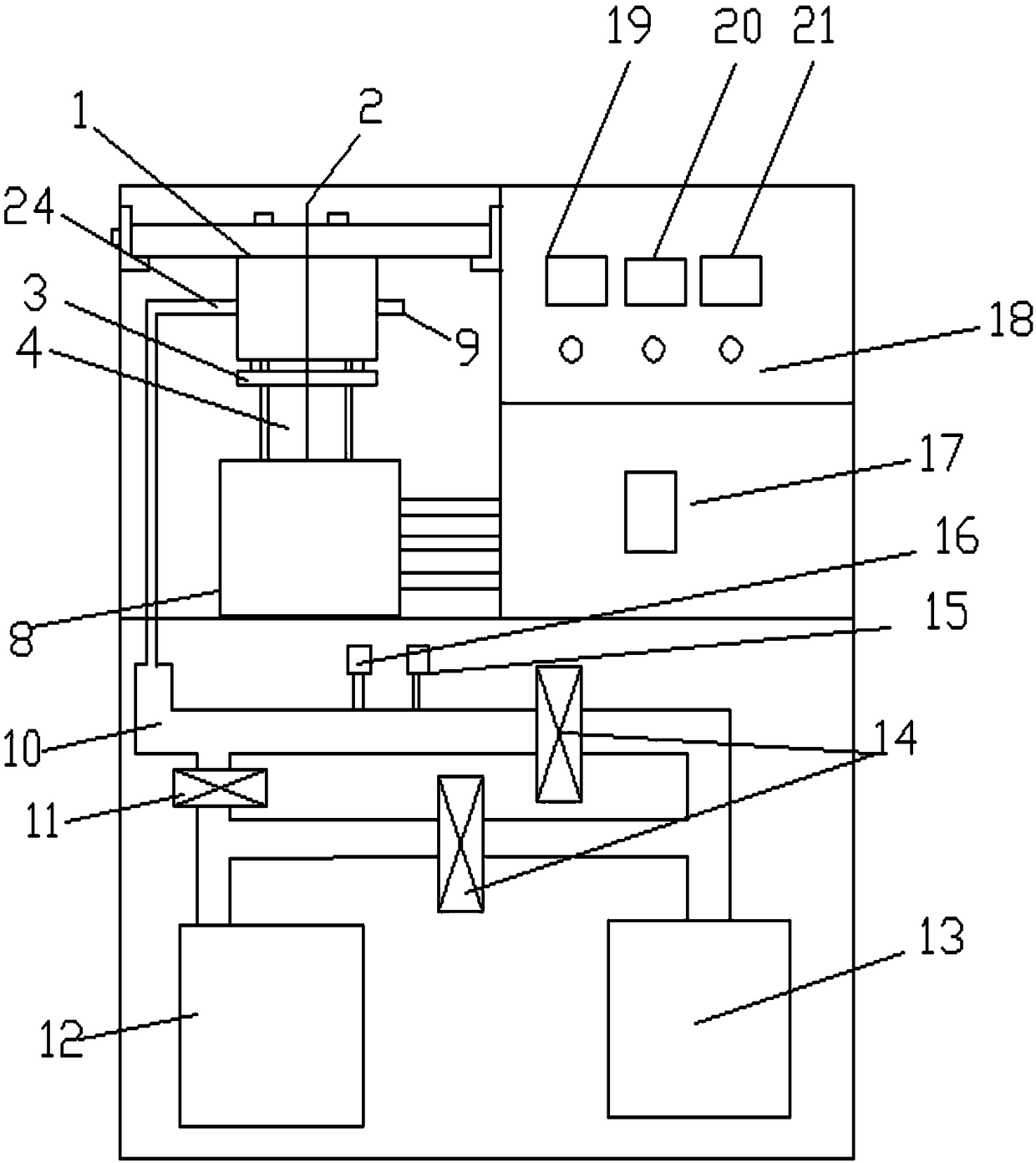

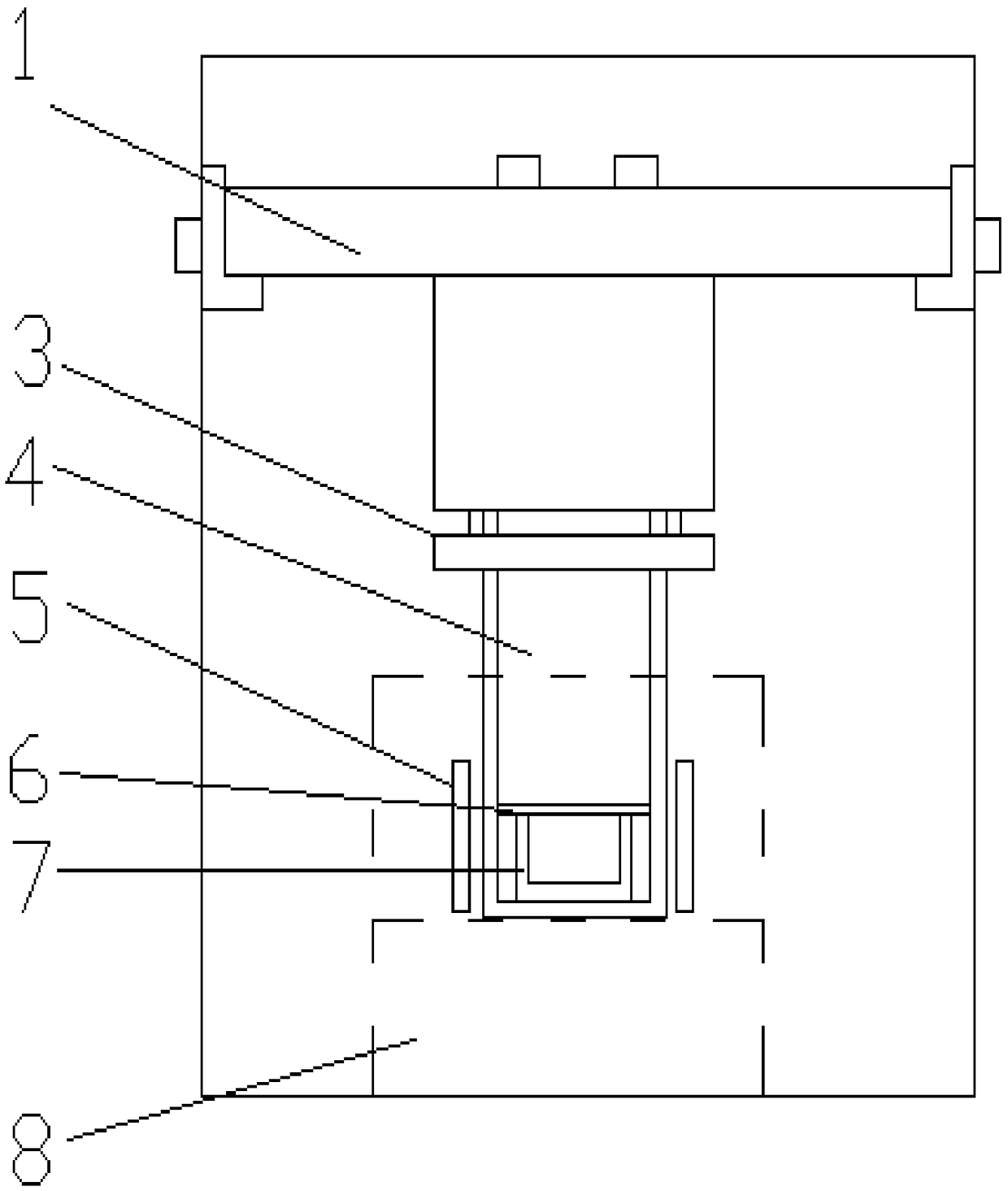

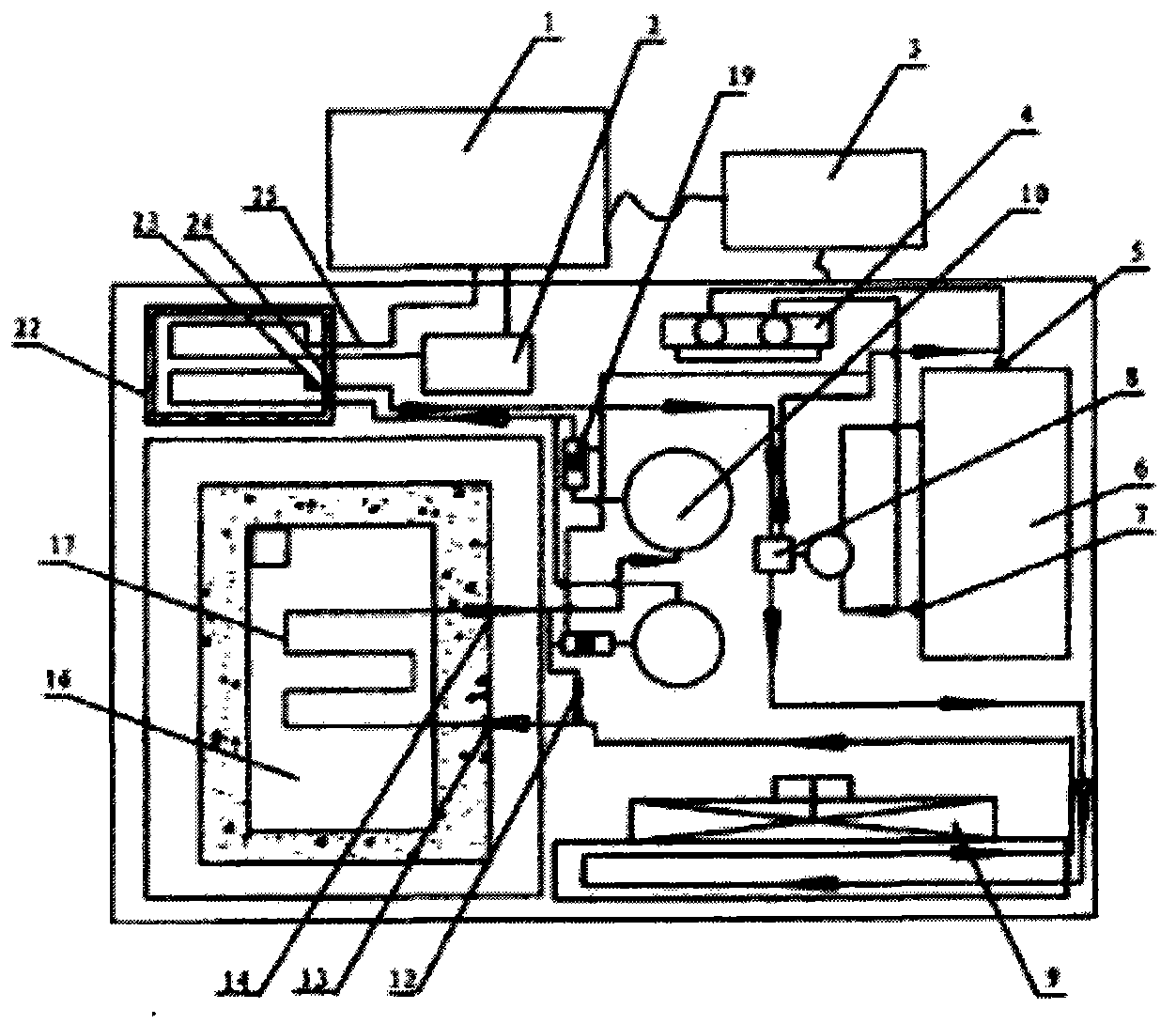

Vacuum thermal shock cycle testing machine

InactiveCN108645739AFast heating and coolingSmall footprintStrength propertiesThermal shockSmall footprint

The invention belongs to the technical field of test apparatuses, and particularly relates to a vacuum thermal shock testing machine. The machine comprises a support, a controller, an induction powersupply, a temperature measuring device and a vacuum chamber. The support is provided with a vacuum chamber frame body, the vacuum chamber and a cooling device. The vacuum chamber frame body is provided with an air inlet hole and an air suction hole in order to realize thermal shock test in a vacuum environment or a protection gas environment. A crucible is arranged in the vacuum chamber, a test sample is placed in the crucible, the crucible is heated according to an induction heating principle, and a fiber cover sheet is placed on the crucible to achieve heat insulation. The temperature is measured by the temperature measuring device and is displayed in a temperature display, and the controller can automatically start or stop heating for achieving an assigned temperature and set the numberof shocks. Compared with test machines in the prior art, the vacuum thermal shock testing machine in the invention can carry out vacuum high-temperature thermal shock test, can control the vacuum degree and the thermal shock during experiments, and has the advantages of fast temperature rising speed, three-dimensional integral and compact structure, small occupied area, simple structure and wideapplication range.

Owner:DALIAN UNIV OF TECH

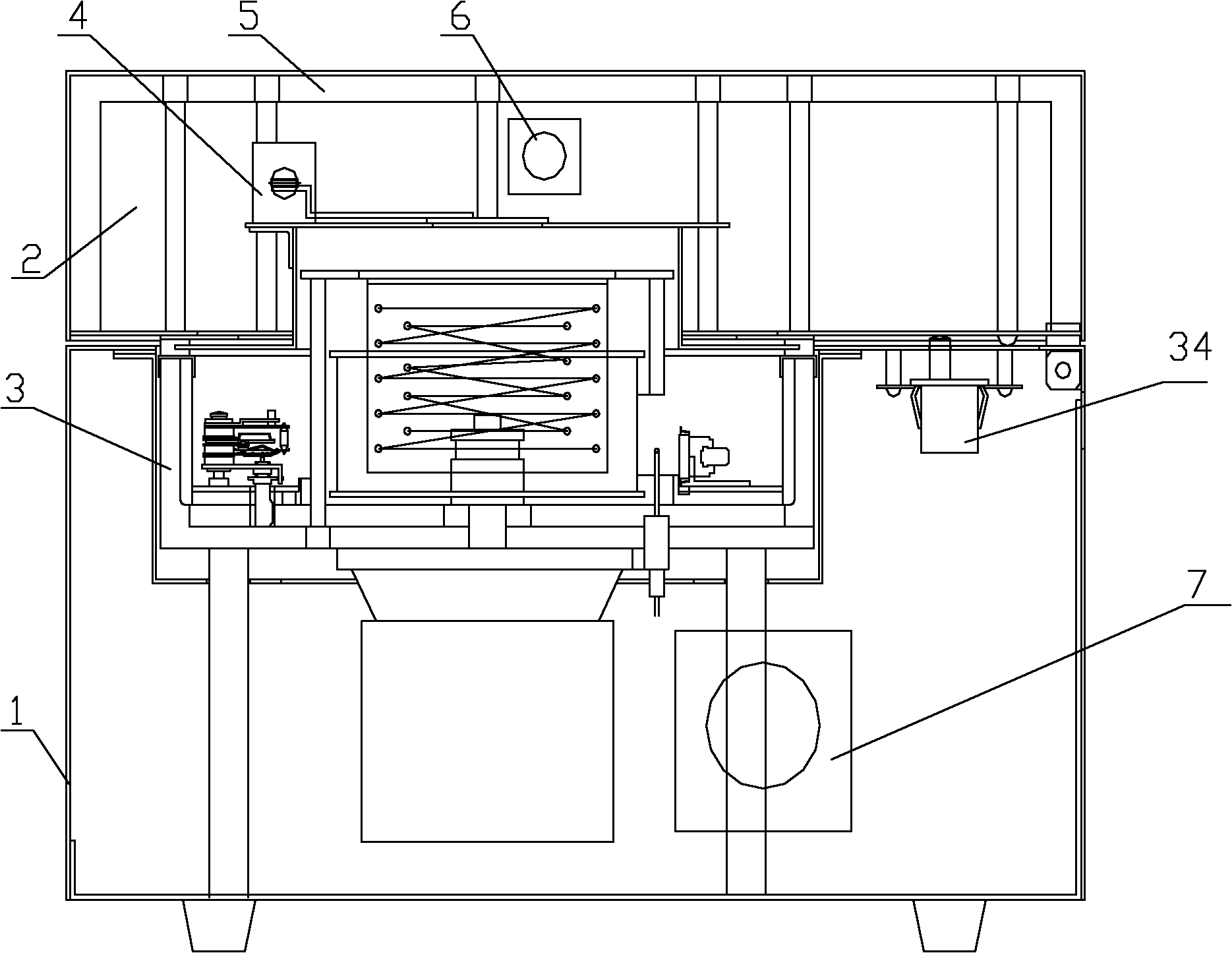

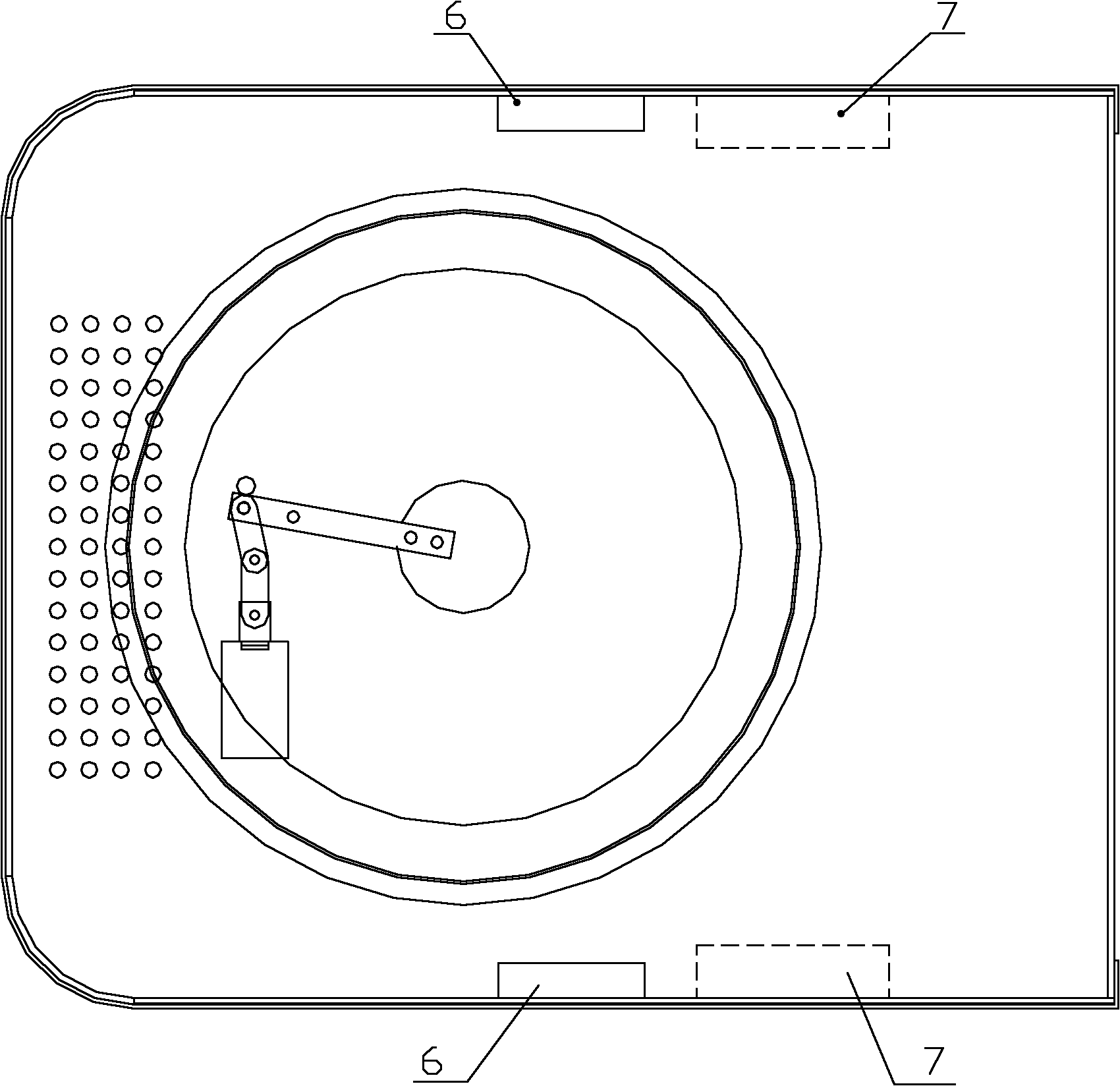

Constant-temperature air bath device and method for detecting temperature controller thereof and testing aging of temperature controller

ActiveCN102436251AUniform temperature distributionFast heating and coolingLighting and heating apparatusTesting/monitoring control systemsAging testAirflow

The invention discloses a constant-temperature air bath device and a method for detecting a temperature controller thereof and testing the aging of the temperature controller. The device comprises an outer box body, an upper cover, a heating cavity and an air feed and discharge mechanism, wherein the outer box body is internally provided with the heating cavity, the side of the outer box body is provided with an air feed and discharge fan, the top part of the outer box body is provided with a control switch, the air feed and discharge mechanism is arranged below the upper cover, the side of the upper cover is provided with an air discharge fan, the side and the upper of the upper cover are respectively provided with a heat-preservation layer, the heating cavity is connected with the outer box body through a supporting column, and the air feed and the discharge mechanism is clung to a protective cover in the heating cavity through a sealing ring. Compared with the prior art, in the invention, the heating cavity is circular, air flow ring-shaped circulation and sample circumferential positioning are combined, and the accurate temperature control is realized by an air heat-conduction mode. Simultaneously, in the invention, the temperature in the heating cavity is uniformly distributed, and can be quickly raised and reduced, and the heat-preservation and heat-dissipation effects are good.

Owner:光机电(广州)科技研究院有限公司

Carbon paper laminated composite thermal insulating lining

ActiveCN103663407ALow thermal conductivityGood heat insulationNon-macromolecular adhesive additivesBy pulling from meltThermal insulationBarrier effect

The invention provides a carbon paper laminated composite thermal insulating lining of a Czochralski silicon furnace. The carbon paper laminated composite thermal insulating lining comprises a substrate formed by curling flexible graphite paper, wherein an adhesive is applied between the curled contact surfaces of the substrate to form an adhesive layer. Consequently, a composite thermal insulating material composed of the flexible graphite paper and the adhesive material is formed. The carbon paper laminated composite thermal insulating lining provided by the invention is small in thermal conductivity coefficient, good in thermal barrier effect, high in temperature rise and fall rate, and low in thermal inertia. Furthermore, the carbon paper laminated composite thermal insulating lining is stable in thermal field system and excellent in thermal insulation properties. Besides, the carbon paper laminated composite thermal insulating lining is convenient to operate and advantageous for environmental protection.

Owner:嘉兴市航龙塑料制品股份有限公司

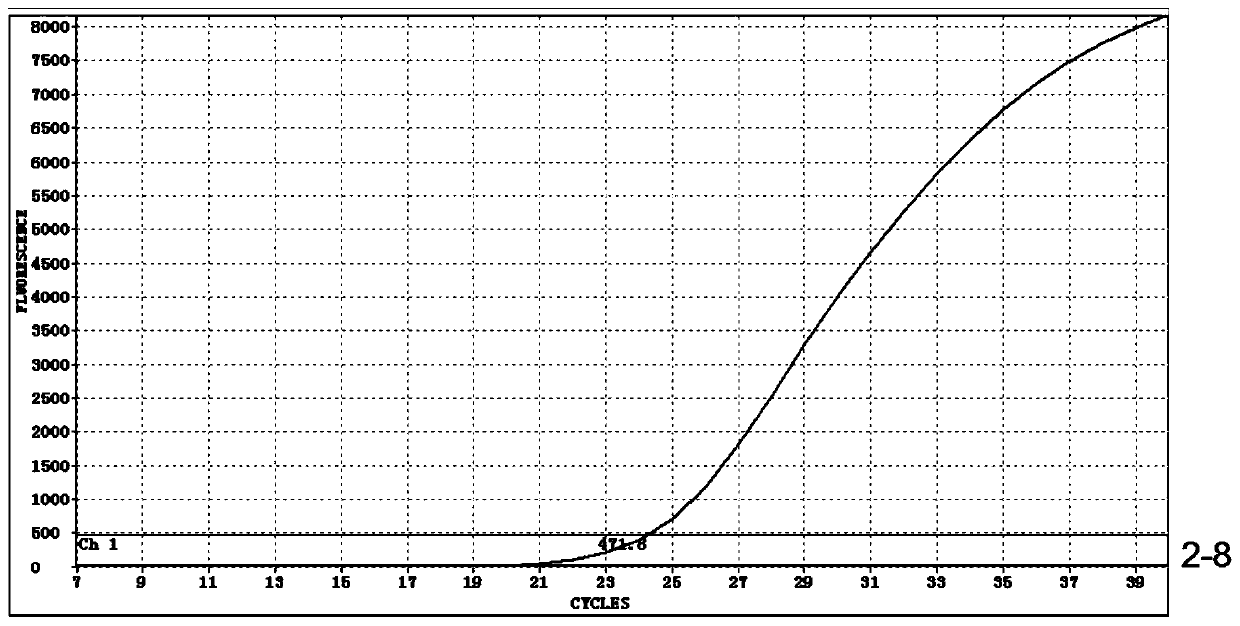

Double fluorescent lyophilized microchip, kit and method for detecting novel coronavirus 2019-nCoV

ActiveCN111334608ASensitive detectionImprove accuracyMicrobiological testing/measurementAgainst vector-borne diseasesReverse transcriptaseFreeze-drying

The invention discloses a double fluorescent lyophilized microchip, a kit and a method for the novel coronavirus (2019-nCoV). The kit comprises the lyophilized microchip, a tube of mineral oil, a tubeof positive control, a tube of negative control, a tube of diluent and a tube of nuclease-free water, wherein the lyophilized microchip is coated with a primer, a probe, Taq enzyme, reverse transcriptase, trehalose, Tris-Cl, dNTP, Mg<2+>. According to the lyophilizing condition, the temperature of an insulator is reduced to negative 55 DEG C at a pre-freezing stage; pre-freezing is kept for 1 hour, and equipment is used for vacuumizing, and freeze-drying is kept for 1 hour; in an analytic drying stage, the temperature of the insulator is increased to negative 25 DEG C and kept for 1 hour, isincreased to 37 DEG C and kept for 2 hours and is reduced to 25 DEG C and kept for 1 hour to obtain the lyophilized microchip, and the diluent and sample nucleic acid are added during use. The doublefluorescent lyophilized microchip can be used for simultaneously detecting an ORF 1a / b gene and an N gene. The detection kit and detection method have high accuracy, high specificity, high sensitivityand short detection time.

Owner:BEIJING YISEN BIOTECH

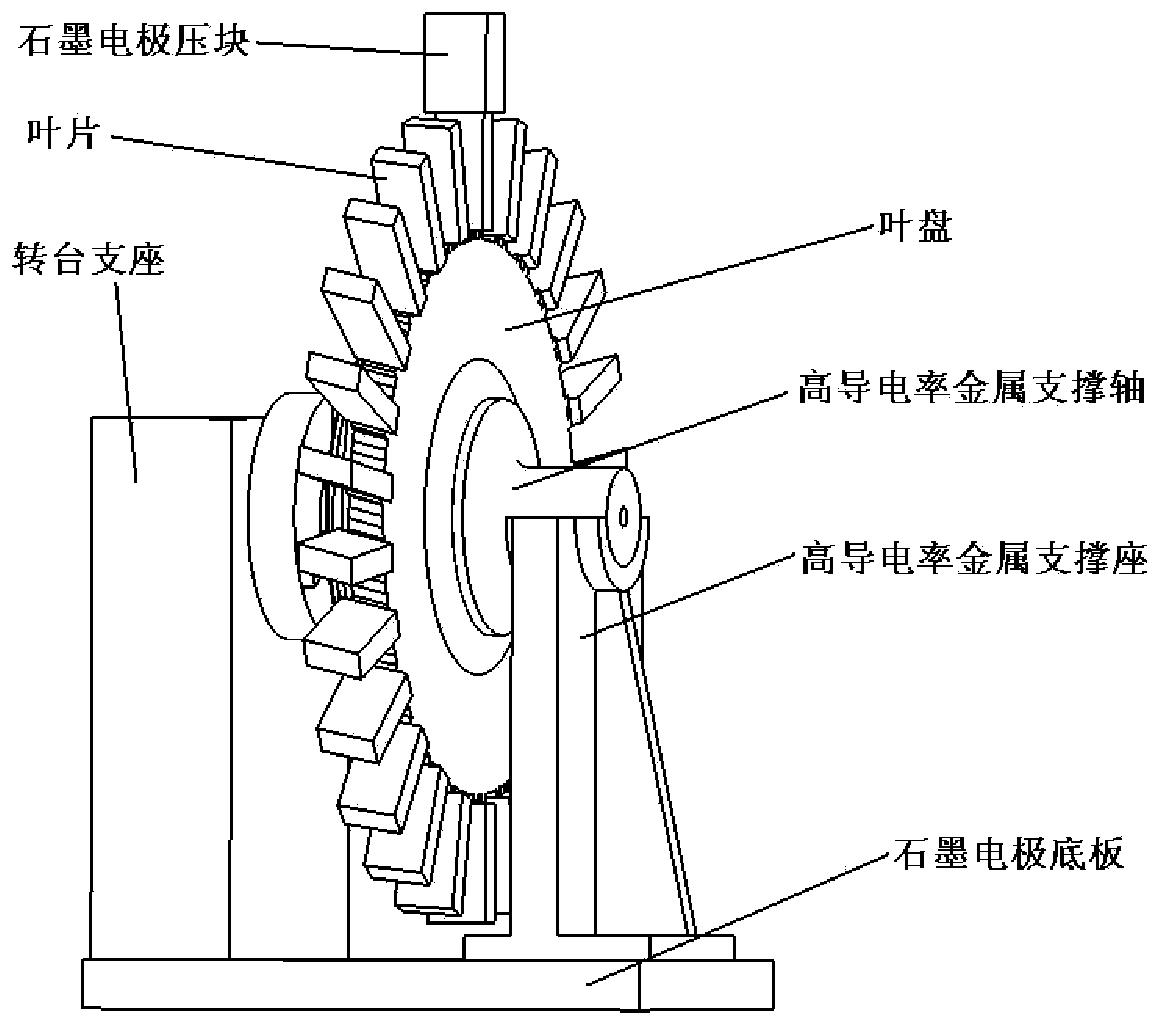

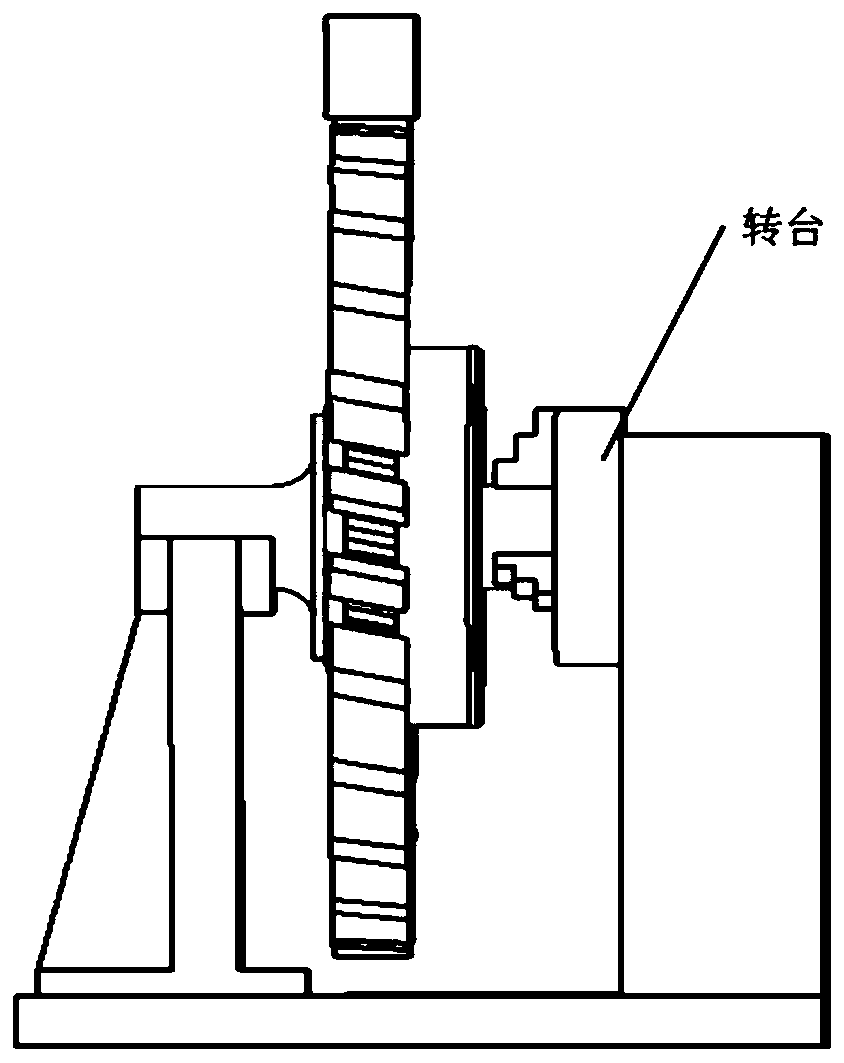

Manufacturing method for dissimilar alloy integral blade disc structure

ActiveCN110303259ASolve difficultyMeet the needs of high-performance blisksWelding apparatusPlasma diffusionAlloy

The invention relates to a manufacturing method for a dissimilar alloy integral blade disc structure. The method comprises the steps that a blade disc is rotationally and axially mounted on a high-conductivity metal support base through a high-conductivity metal support shaft, and the support base is mounted on a graphite electrode bottom plate; and after blades and the blade disc are assembled, discharge plasma diffusion welding is adopted for welding, during welding, the upper portions of the blades are pressed through a graphite electrode pressing block, direct current pulse current is connected between the graphite electrode pressing block and the graphite electrode bottom plate, discharge plasma is generated, diffusion welding of the blades and the blade disc is rapidly achieved underthe action of impact pressure, joule heat and an electric field, all the blades are welded to the blade disc, and the integral blade disc is obtained, wherein the blades and the blade disc are prepared from different alloys. Through the discharge plasma diffusion welding method, the problems of high manufacturing difficulty and high scrap rate of integral blade discs are solved, the performance and economic complementarity advantages of the dissimilar alloys are fully achieved, and the demand for the high performance integral blade disc of aeroengines is met.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

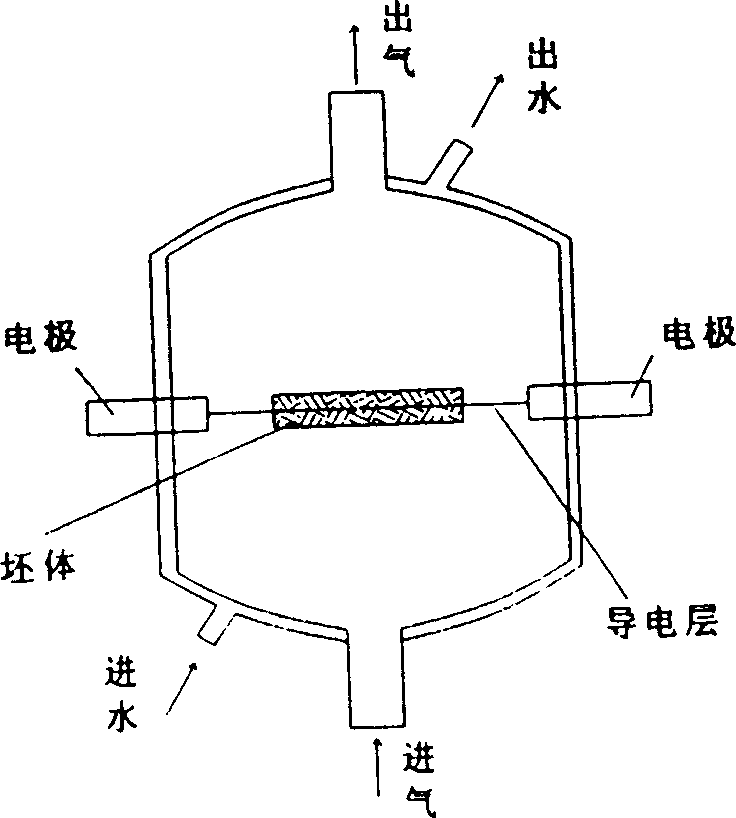

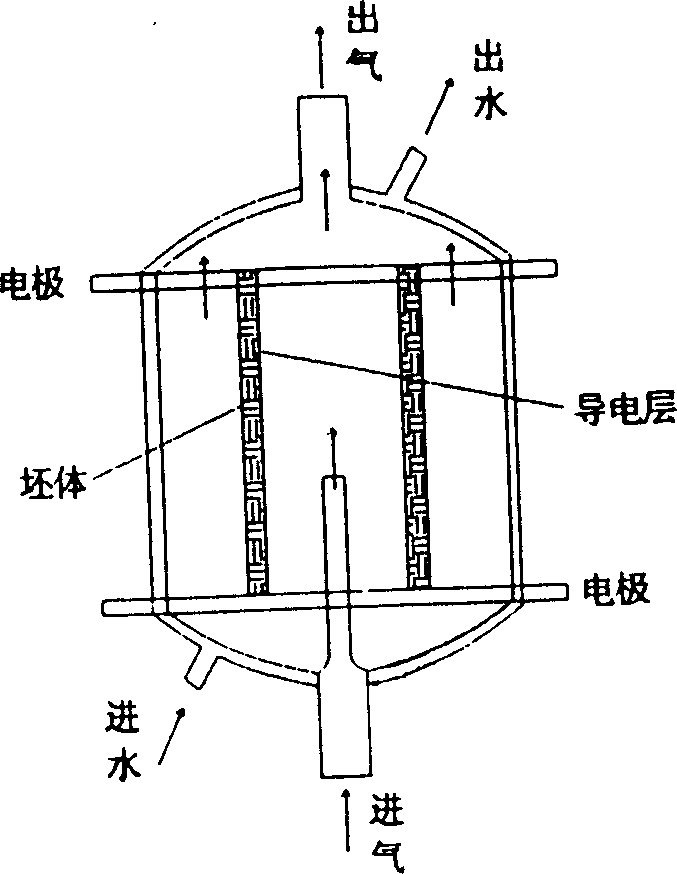

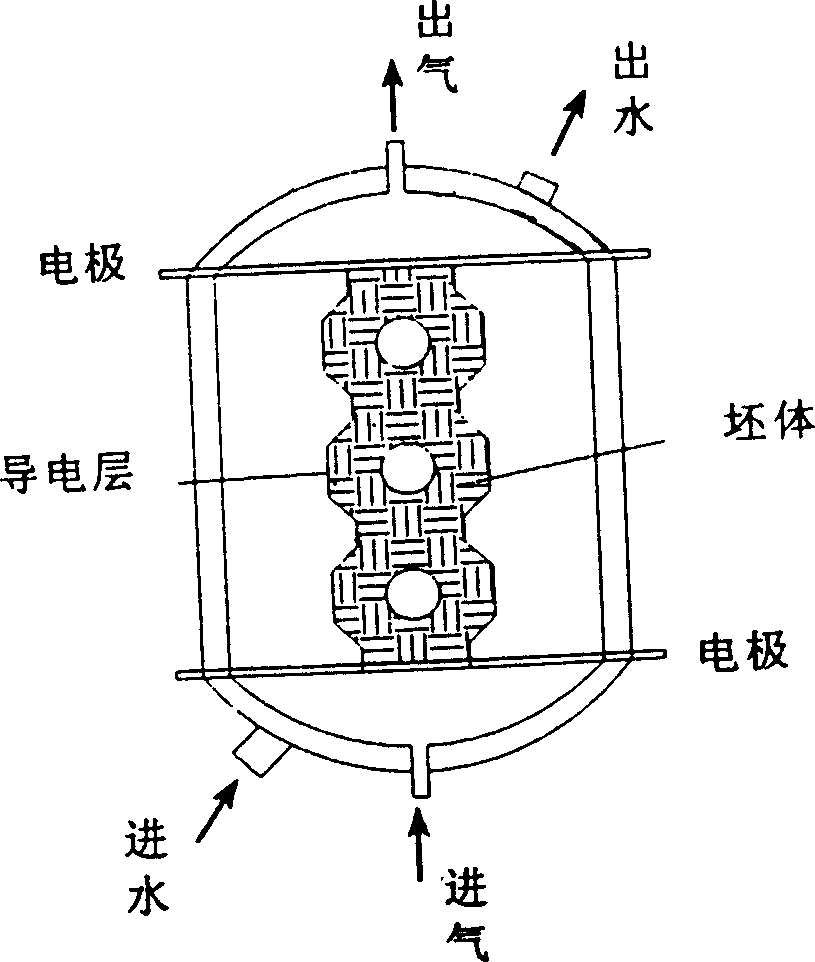

Method for rapidly preparing carbon/carbon composite material under physics field by CVD

InactiveCN1676664AImprove utilization efficiencyThe heat transfer path is reasonably shortenedChemical vapor deposition coatingCarbon compositesGas phase

This invention is about the decomposition method of compound, especial about the method for depositing charcoal and carbide. The conducting layer is made up of tungsten filament, molybdenum filament and graphite layer; through the conducting layer the physical field is adjusted and controlled. We put charcoal / charcoal combined material body into the chemical gas phase depositing furnace, where the depositing temperature is controlled between 600deg.C and 1100deg.C. The carbon hydrogen gas is filled as reaction gas, while Ar or N2 is used as dilution gas. The concentration of the carbon hydrogen gas is from 5% to 100%, and the flow of the reaction gas should be between 0.2 and 1.2 square meters per hour.square meters. If you choose this invention, the densification speed of the carbon / carbon combined material can be increased, and the producing time can be reduced. You can adjust and control the structure of the thermal decomposition charcoal, and the density and uniform is good. Also, you can reduce the producing cost.

Owner:CENT SOUTH UNIV

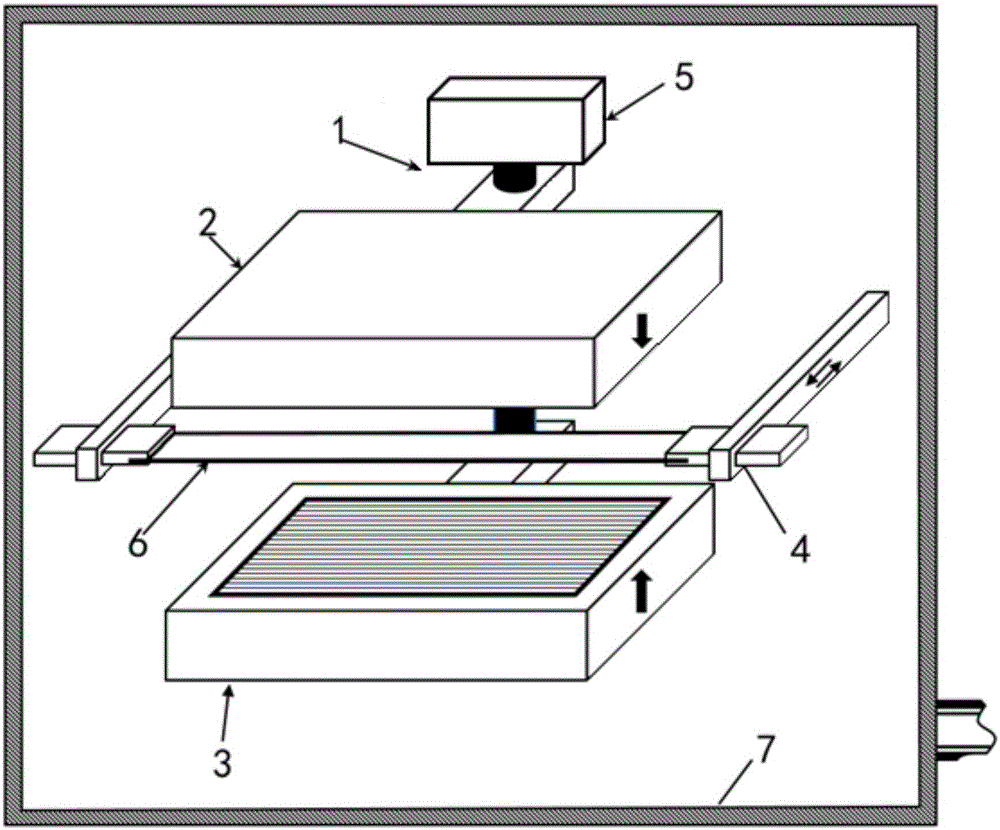

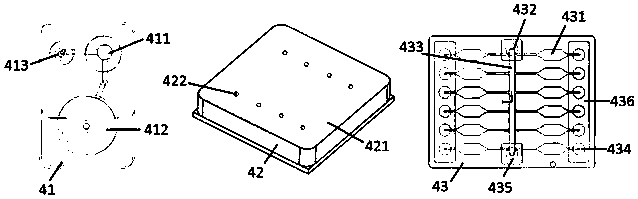

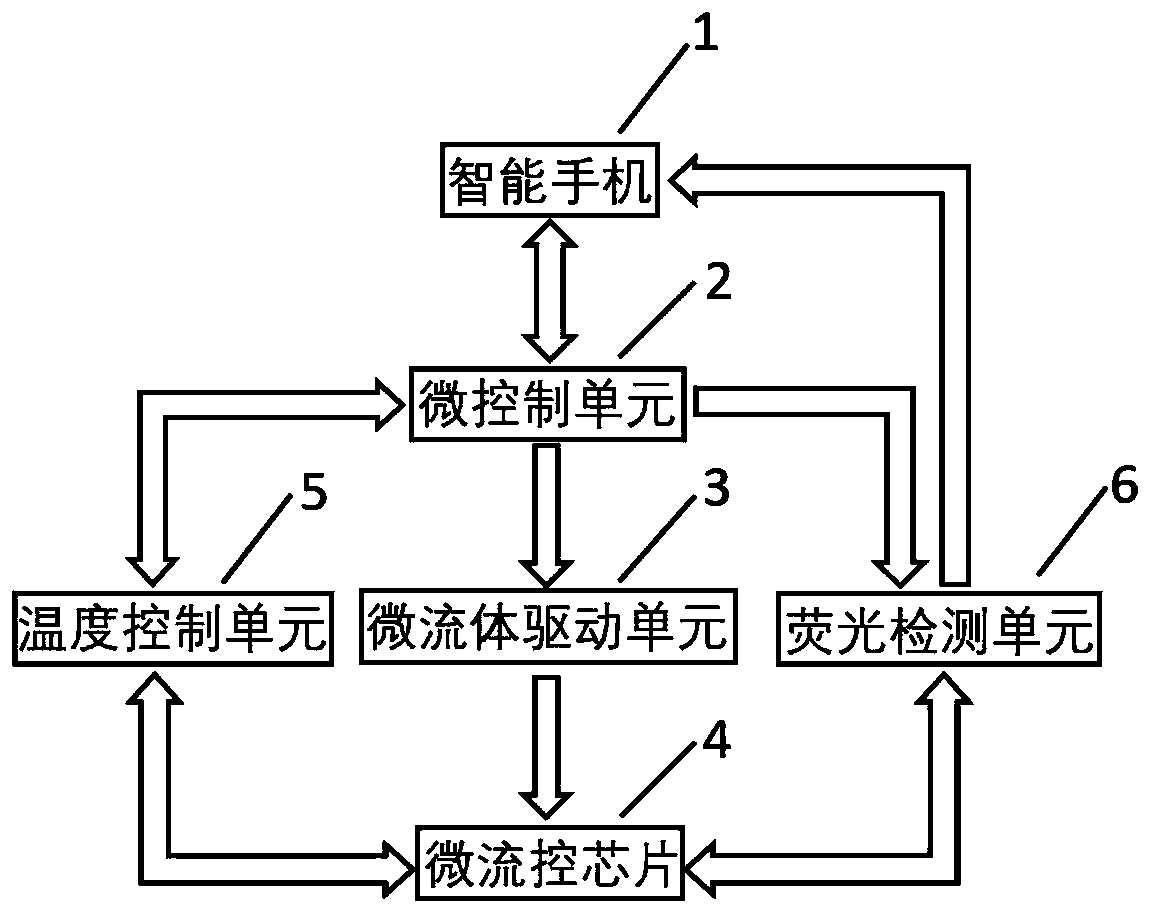

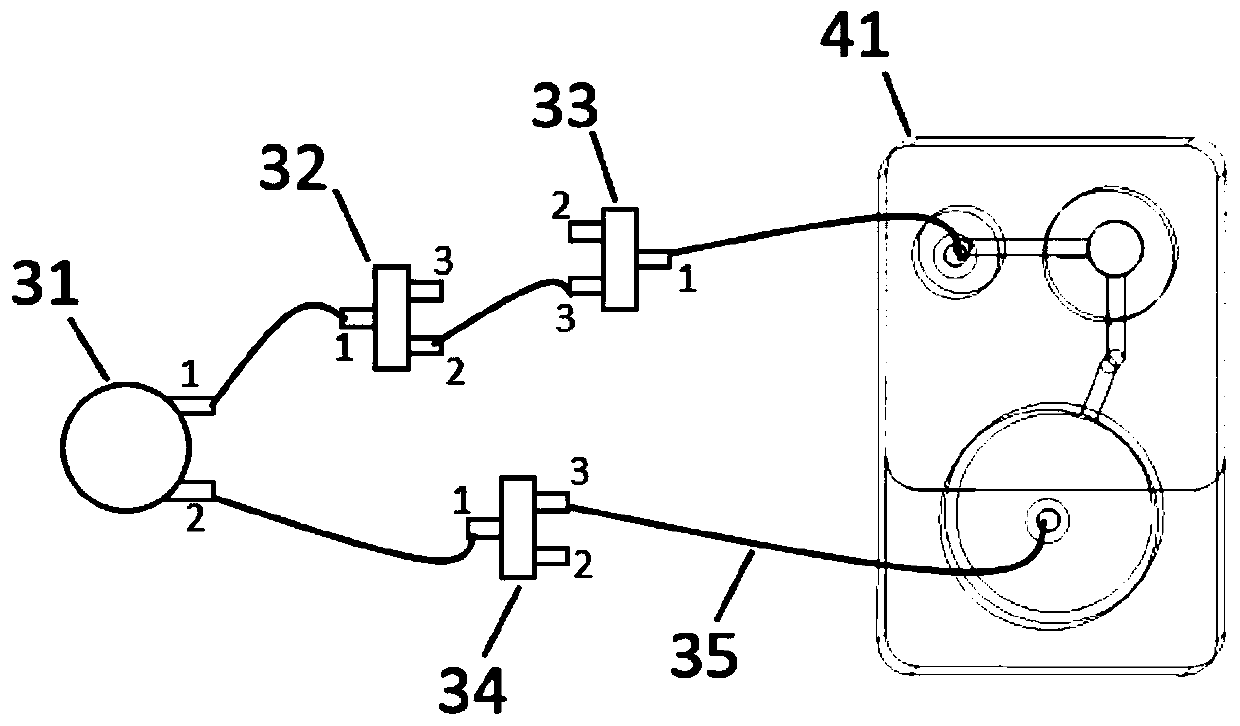

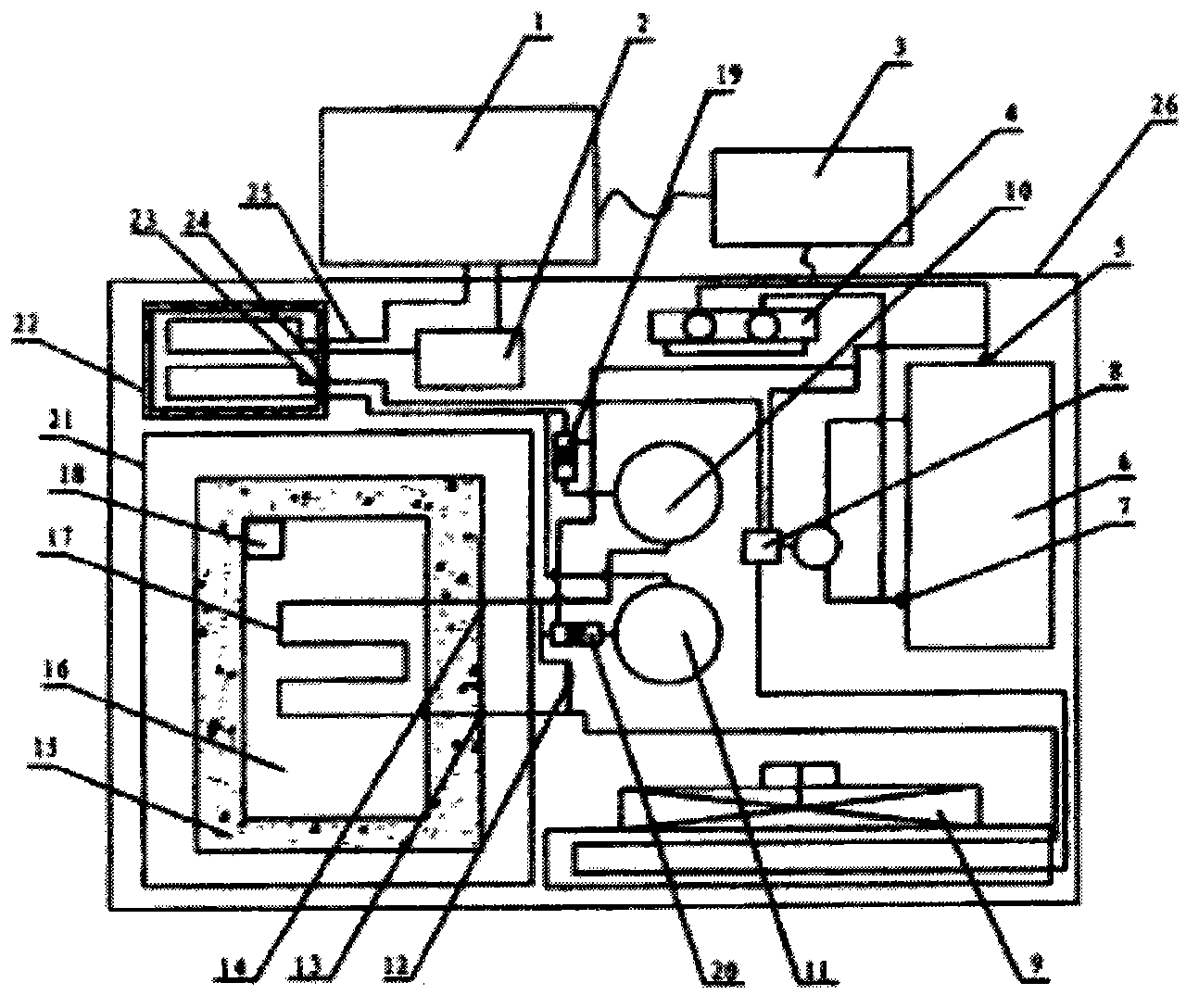

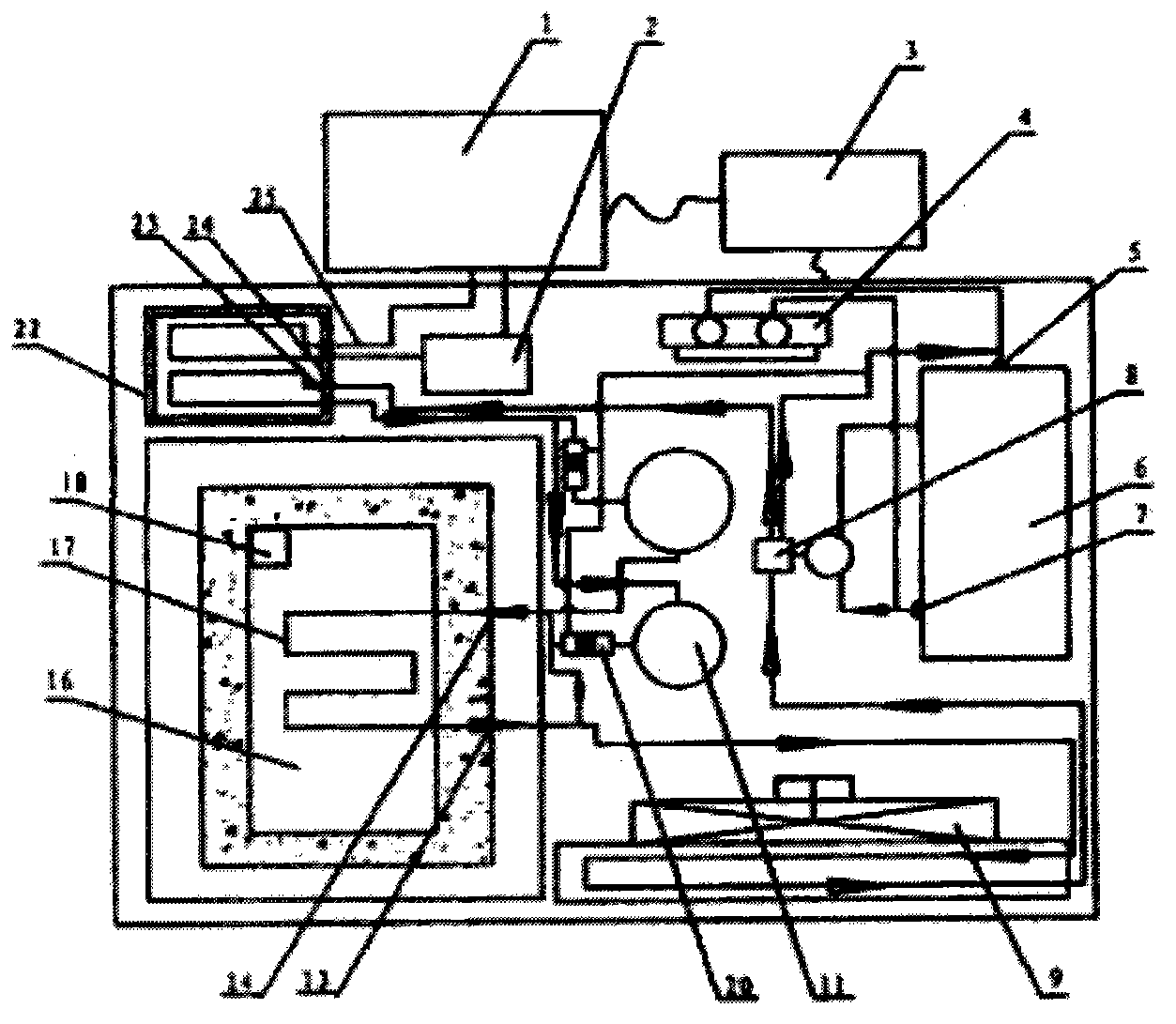

Analysis device for integrated nucleic acid extraction and amplification detection based on smart phone and method thereof

ActiveCN111197003AFast heating and coolingHigh temperature control accuracyBioreactor/fermenter combinationsBiological substance pretreatmentsMultiplexImaging processing

The invention discloses an analysis device for integrated nucleic acid extraction and amplification detection based on a smart phone and a method thereof, which relates to the key technical field of intelligent medical instruments. According to the analysis device, the smart phone is used as a main component, the smart phone is integrated with microfluid driving, temperature control and multicolorfluorescence detection, a portable multifunctional universalization device integrating nucleic acid extraction, amplification and detection is formed, the device is combined with a micro-fluidic chip; on-chip nucleic acid extraction, isothermal amplification qualitative detection and detection of real-time fluorescent quantitative PCR (Quantitative Real-time PCR,qPCR) and multiple fluorescent PCR(Multiplex PCR) are realized, and analysis and detection of pathogen nucleic acid are realized. The analysis method comprises the steps of nucleic acid extraction, system configuration, system loading, temperature setting, image acquisition, image processing and result storage and sharing. The smart phone is used as a main component, the size is small, the cost is low, the functions are complete,the applicability is high, and the detection method is diversified.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI +1

Freeze-thaw cycle testing machine

InactiveCN103575758AReduce consumptionHigh speedMaterial thermal analysisStored energyFreeze thawing

The invention provides a freeze-thaw cycle testing machine, comprising a cold and heat exchange set, a test piece box and a control device, wherein the control device is respectively connected with the cold and heat exchange set and the test piece box and controls the cold and heat exchange set and the test piece box to operate; and the cold and heat exchange set further comprises an energy storage device which is connected between a plate-type heat exchanger and a fan-type heat exchanger in the cold and heat exchange set. The energy storage device is used for storing one part of energy which needs to be given up in a previous refrigeration or heating process of the test piece box and releasing the stored energy in a next corresponding refrigeration or heating process, so that the speed of the refrigeration or heating process is improved, a large quantity of waste gas energy is recycled, the energy consumption is reduced, the working efficiency is improved, the speed of heating and refrigeration is guaranteed, and noises are small. The freeze-thaw cycle testing machine is well-adapted to working environments and is applicable to various test sites and natural environments.

Owner:李健

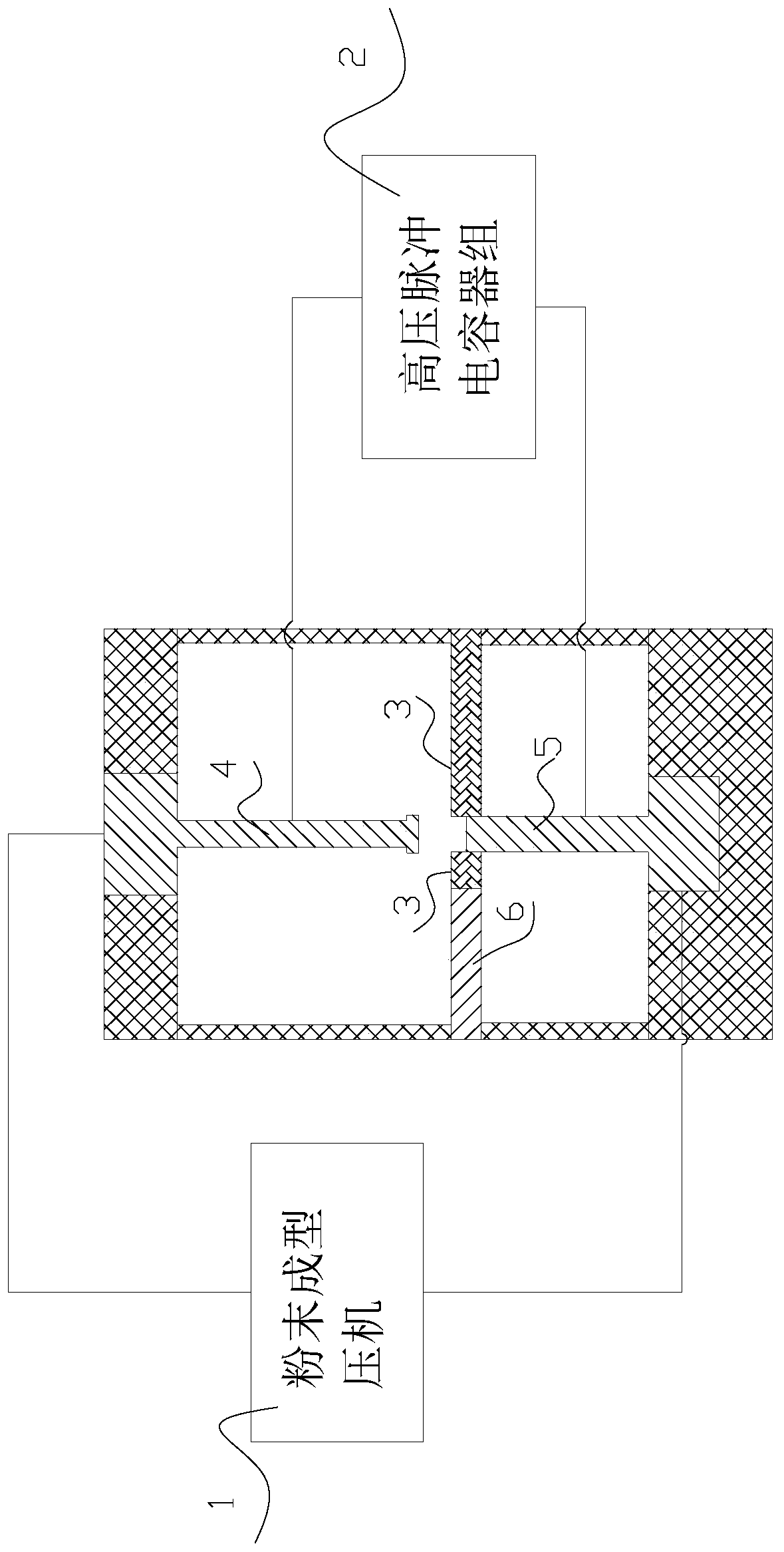

Pulse discharge flash sintering metal-based part near-net forming technology method

InactiveCN109894615ASimple processHigh energy consumptionAdditive manufacturing apparatusPorosityMetal powder

The invention discloses a pulse discharge flash sintering metal-based part near-net forming technology method, and belongs to the technical field of powder metallurgy. The problems that a traditionalpowder metallurgy part production process is high in power consumption, tedious and complex in process flow and low in production efficiency are solved. The method mainly comprises the steps of pushing metal powder into a mold, and forming the metal powder through stamping; enabling the inner wall, making contact with the metal powder, of the mold to have the insulation property; and enabling stamping to serve as an electrode of a pulse discharge body, and enabling stamping to synchronously carry out pulse discharge in the metal powder forming process. According to the method, the process flowis greatly simplified, large-scale industrialized application is easily achieved, the near-net forming advantage is achieved, the product quality is high, porosity adjusting control is convenient, practicality is high, and the method has the important significance in the powder metallurgy industry manufacturing field.

Owner:YANGZHOUSSHINE POWDER METALLURGY

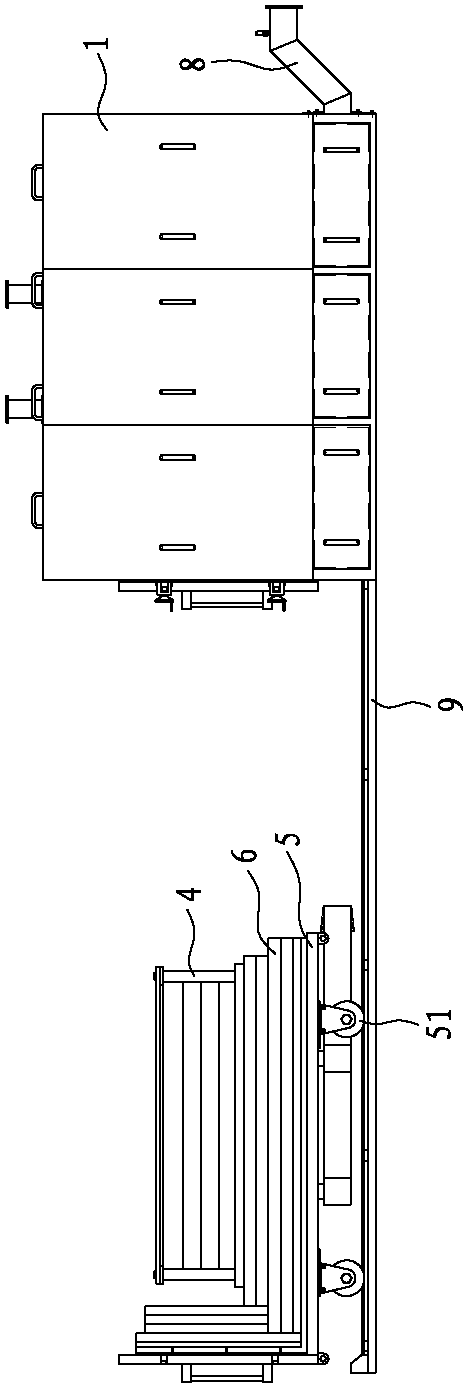

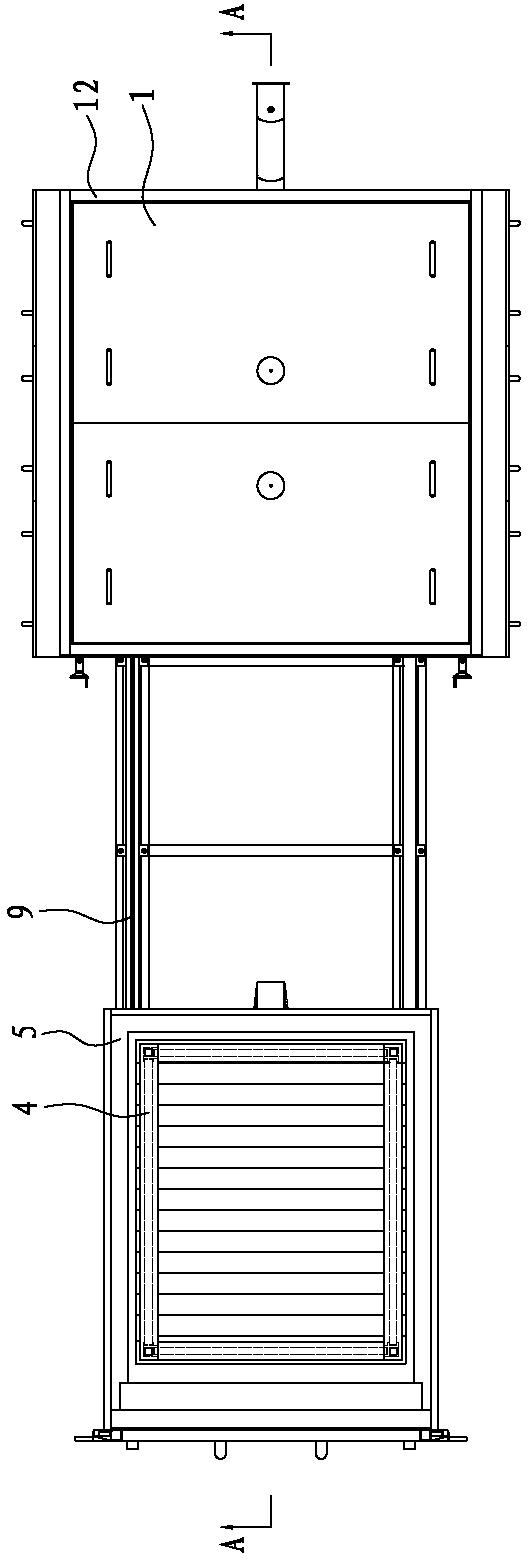

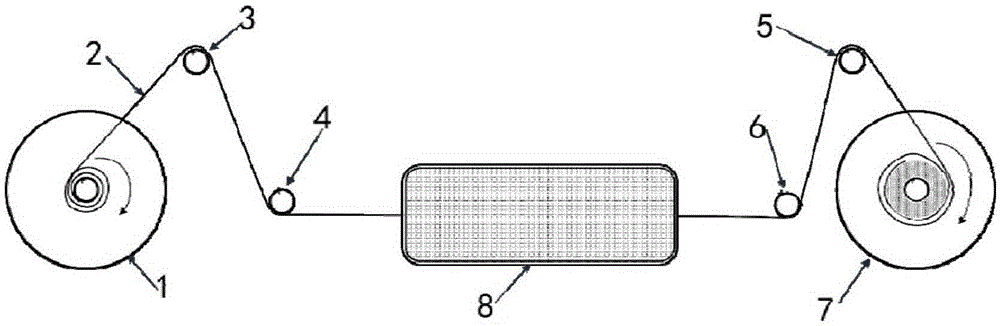

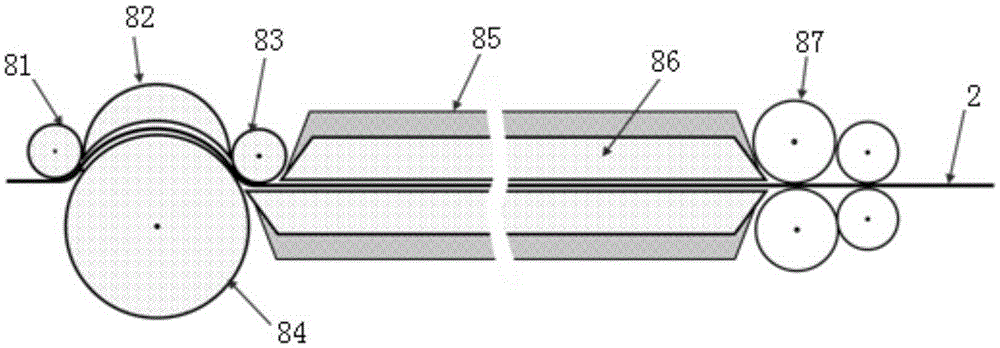

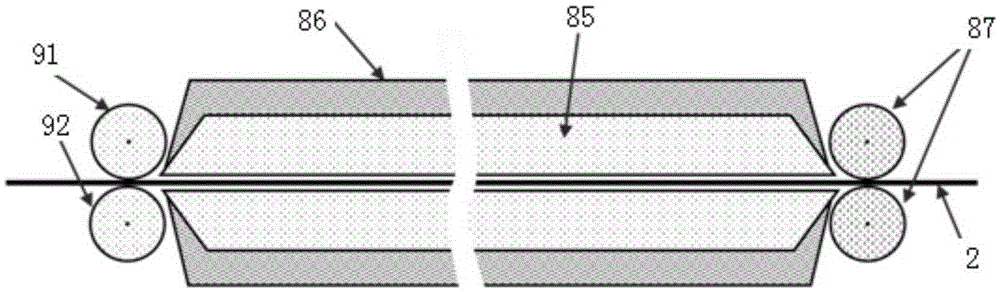

Pre-treatment system and method for nanocrystalline magnetically soft alloy strip

ActiveCN105420484AReduce temperature gradientHigh densityFurnace typesHeat treatment furnacesPretreatment methodTemperature Unit

The invention discloses a pre-treatment system for a nanocrystalline magnetically soft alloy strip. The system comprises a feeding device and a thermal treatment device, wherein the feeding device is used for feeding, tightening, guiding and collecting the nanocrystalline magnetically soft alloy strip along a route at the preset feeding speed; the thermal treatment device comprises a first heating roller, a heating unit, a constant-temperature unit and a cooling unit; the heating surface of the first heating roller is tightly attached to one side face of the nanocrystalline magnetically soft alloy strip; the heating unit is used for heating the other side face of the nanocrystalline magnetically soft alloy strip and the heating unit and the first heating roller heat the same region of the nanocrystalline magnetically soft alloy strip; the nanocrystalline magnetically soft alloy strip heated through the first heating roller and the heating unit is heated and heat is preserved through the constant-temperature unit; and the nanocrystalline magnetically soft alloy strip which is heated at the constant temperature is cooled through the cooling unit. The invention further discloses a pre-treatment method for the nanocrystalline magnetically soft alloy strip. The system and method have the beneficial effects that the heating roller tightly-attaching heating manner and the double-face synchronous heating manner are adopted, the temperature increase and decrease speed is high, operation is convenient, temperature and time control accuracy is high, and the treated strip is flat and straight.

Owner:NINGBO INNOVATION CENT FOR APPLIED MAGNETICS CO LTD

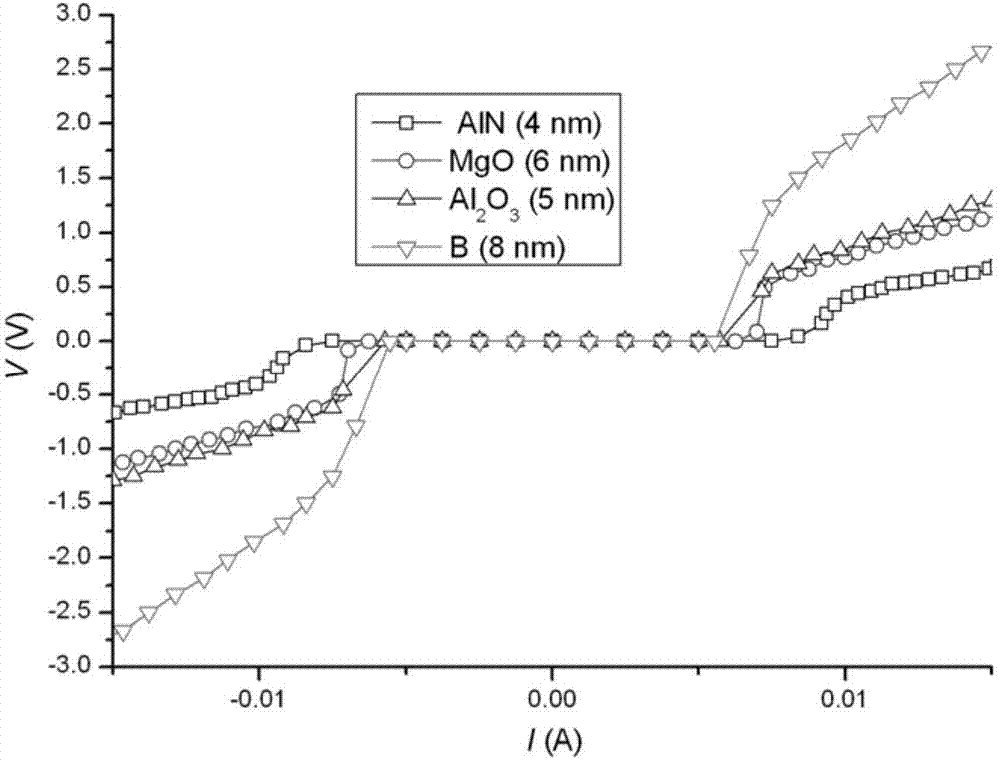

Method for preparing magnesium diboride superconductive Josephson junction through secondary mask method

ActiveCN103904210AReduce component diffusionShort annealing timeSuperconductor device manufacture/treatmentChemical reactionInsulation layer

Disclosed is a method for preparing a magnesium diboride superconductive Josephson junction through a secondary mask method. According to the method, an electron beam is adopted to carry out annealing on an interlayer type (sandwich type) magnesium diboride Josephson junction precursor film. The interlayer type magnesium diboride Josephson junction precursor film is a (Mg / B)-X-(Mg-B) structure precursor film prepared through the secondary mask method, X represents a standard conductor layer N or an insulation layer I, magnesium elementary substance and boron elementary substance in the precursor film are made to generate a chemical reaction within the annealing time of a second magnitude order, finally the SNS type or SIS type magnesium diboride superconductive Josephson junction of a MgB2-X-MgB2 structure is generated, and S represents a superconductive layer.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Manufacturing method of controllable-temperature microfluidic chip

ActiveCN107377023AHigh cooling and temperature control efficiencyHigh temperature control accuracyLaboratory glasswaresTemperature controlThermoelectric materials

The invention discloses a manufacturing method of a controllable-temperature microfluidic chip. The method is characterized by comprising the following steps: printing a thermoelectric semiconductor temperature control circuit on the upper plane of the microfluidic chip, wherein the chip comprises at least one reaction groove area and at least one temperature control circuit area; processing a reaction groove one surface of the reaction groove area, and printing a temperature sensing probe on the rear surface of the other surface of the reaction groove; correspondingly printing circuit layers which are correspondingly manufactured through an N type thermoelectric material and a P type thermoelectric material on two surfaces of the chip at the temperature control circuit area; forming an N-P-N-P...alternative series-connection circuit structure through copper plating through holes; and connecting a power supply to refrigerate and heat the reaction groove area. The method has the advantages that the temperature of the groove reactor area of the microfluidic chip can be accurately controlled; the temperature control accuracy is high; the temperature is rapidly increased; and the method is applicable to high-flux biological detection and multi-temperature-section complex micro-reaction process study.

Owner:上海萃励电子科技有限公司

Harmonica channel type heat exchanger

InactiveCN104733799AAchieve water cooling effectCompact structureSecondary cellsElectrical batteryEngineering

The invention provides a harmonica channel type heat exchanger, aiming at solving the problems that for a pure electric vehicle and a serial hybrid electric vehicle, an air heat exchanger difficultly meets a battery heat management effect. The harmonica channel type heat exchanger is characterized by comprising a plurality of groups of heat radiation assemblies which are arrayed in parallel at intervals, wherein each heat radiation assembly comprises a first current collector, a second current collector, and a water cooling plate for communicating the first current collector and the second current collector; the first current collector is provided with two water pipe connectors; the first current collector of the heat radiation assembly at one side is connected with a water inlet pipe, and the first current collector of the heat radiation assembly at the other side is connected with a water outlet pipe; the first current collectors of all the heat radiation assemblies are communicated with each other by a middle water pipe; batteries are arranged at the two sides of the water cooling plates of each heat radiation assembly; and the batteries and the water cooling plates are clamped and firmly fitted. The harmonica channel type heat exchanger has the advantages that the heat radiation assemblies are arrayed in parallel at intervals, and are clamped and firmly fitted with the batteries, so that the water cooling effect is realized; the structure is relatively simple and compact and the cost is low, the heat-exchanging coefficients are relatively high, the cooling and heating speed is rapid, the safety performance is high and the effect is relatively good.

Owner:纳百川控股有限公司 +1

Thermal packaging used-heating head and packaging device with same

InactiveCN104159336AFit tightlyGuaranteed uptimePaper-makingBox making operationsControl systemEngineering

The invention provides a thermal packaging used-heating head. The heating head is a cylindrical substrate; the side face of the substrate is provided with an annular groove; a heating wire is arranged inside the groove; the heating wire is tightly matched in the groove; and the surface of the heating wire is flush with the cylindrical surface of the substrate. Power consumption of the thermal packaging used-heating head is extremely low and is far lower than the work power consumption of the prior packaging device, and the temperature is stable and can be maintained within a proper range. The invention also provides an inflatable bag inflatable packaging device which is quick in thermal packaging speed and high in the qualified rate of finished products. The packaging device comprises a body, a discharge assembly arranged in a rotating mode on the body, an inflatable assembly fixedly arranged on the body, a thermal packaging assembly arranged on the body and a control system arranged on the body. As the cylindrical heating head is used and rolling friction exists between the heating head and the inflatable bag, joining is tight, operation is stable, the packaging speed is quicker, and the speed is more than two times of the packaging speed of the prior inflatable bag inflatable packaging device.

Owner:SUZHOU IND PARK XINHE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com