Pre-treatment system and method for nanocrystalline magnetically soft alloy strip

A technology of nanocrystalline soft magnetic and alloy strips, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of inability to achieve prefabricated crystal nuclei, slow heating and cooling speeds, etc., and achieve convenient heat treatment time, small temperature gradient, and fine The effect of grain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

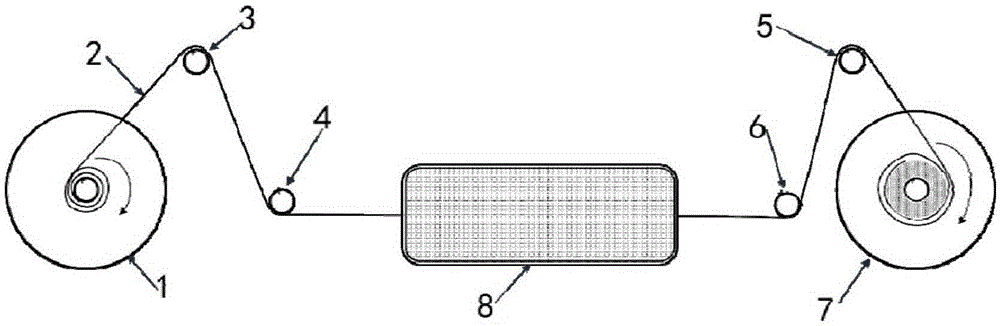

[0052] Such as figure 1 As shown, the pretreatment system of the present embodiment includes: supply pulley 1, constant tension pulley 2, straightening pulley 3, heat treatment device 8, straightening pulley 6, constant tension pulley 5 and take-up pulley 7, realizes nanocrystalline soft Continuous pretreatment of magnetic alloy strips.

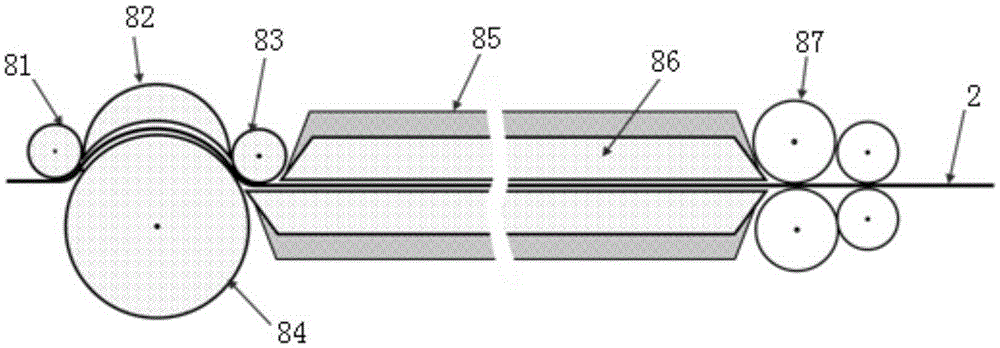

[0053] Such as figure 2 As shown, the heat treatment device 8 of the present embodiment includes: a front heating wheel 81, a heating cover 82, a rear heating wheel 83, a heating roller 84, a heating assembly 85, a heat preservation cover 86 and a cooling roller 87; the front heating wheel 81 and the rear heating wheel 83 compresses the strip on the heating roller 84, the heating mantle 82 heats the other side of the strip heated by the heating roller 84, and the front heating wheel 81, the heating mantle 82, the rear heating wheel 83 and the heating roller 84 work together to realize the strip heating. Both sides of the strip are heated s...

Embodiment 2

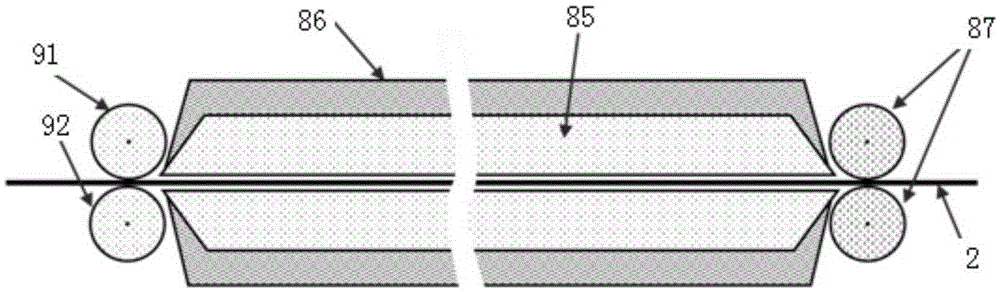

[0058] Such as image 3 As shown, the structure of this embodiment is the same as that of Embodiment 1 except for the heat treatment device 8. In this embodiment, the heat treatment device 8 includes: heating rollers 91 arranged on both sides of the strip 2 and closely attached to the strip; The heating roller 92, the structure of the heat preservation cover and the heating assembly are the same as in Embodiment 1, and a pair of cooling rollers are provided.

[0059] The diameters of the two heating rods range from 15 to 40 cm.

[0060] The flatness of the pretreated strip in this embodiment is better, and the microstructure analysis of the strip shows that α-Fe crystal nuclei with a size of about 2 nm have been prefabricated in the strip. The pretreated strip was subjected to conventional heat treatment, and the magnetic properties were tested, and it was found that the performance of the sample after conventional heat treatment exceeded that reported by Ohta et al.

[0061...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com